Clear Water SC27P User manual

Ozone Systems

Installation & Operation Manual

SC27P

Corona Discharge Ozone Generator

Tested and certified by

WQA to NSF/ANSI 50 as a

component only.

Testedand certified by

WQAto NSF/ANSI 50 as a

componentonly.

ClearWater Tech, LLC.

Integrated Ozone Systems

850-E Capitolio Way, San Luis Obispo, Ca 93401 • 805-549-9724 • Fax: 805-549-0306 • E-mail: service@cwtozone.com • www.cwtozone.com

Copyright © 2005 -ClearWater Tech, LLC • Reproduction of any kind is prohibited • LIT135 • REV093010

1

THEORY OF OPERATION/PRODUCT DESCRIPTION CHAPTER 1

ClearWater Tech ozone systems are designed for safe, effective use in a variety of water treatment applications. The

SC27P ozone generator have been tested and certified by the Water Quality Association according to NSF/ANSI 50. Each

complete, integrated system may include the following components required for reliable, efficient ozone production and

can be divided into four general segments:

• Air preparation system • Ozone generator • Ozone injection/contacting • Ozone destruct

Air Preparation System

The ClearWater Tech SC27P ozone generator requires a source of clean, dry, oil-free, oxygen-enriched air for effective

ozone production. To meet that need, the built-in air preparation system employs pressure swing adsorption (PSA)

technology with an oil-less compressor to increase the concentration of oxygen and reduce the moisture content in the

feed gas (the air supplied to the ozone generator). This substantially improves the output capability of the ozone generator

and prevents premature failure of key internal components. These air preparation systems deliver 90%+/-3% oxygen

purity at -100°F dew point and at very low pneumatic pressures, minimizing noise and reducing compressor wear.

The air preparation system affects ozone production in grams per hour and more importantly ozone concentration, also

known as “percent by weight.” Since ozone is produced with oxygen, the greater the percent of oxygen that enters the

ozone generator will produce more grams per hour and concentration of ozone. Since the SC27P ozone generation system

incorporates PSA oxygen concentrator it will yield the highest grams per hour at the highest concentrations. Greater ozone

concentration equates to higher solubility of the ozone gas in solution, which will yield a greater oxidation potential.

Ozone Generator

The ClearWater Tech SC27P self-contained pressurized ozone generator is designed to supply high concentrations of

ozone gas (up to 10%) at 10 PSI. The oxygen feed gas produced by the air preparation system is supplied to the ozone

generator, which flows through the built-in flow meter. A stainless steel needle valve (located under the SC27P), is used

to maintain optimum pneumatic parameters inside the ozone reaction chambers. After this point the vacuum created at the

ozone injector draws the ozone gas into the water line. The ozone generator is equipped with a pressure switch, which

prevents operation if pressure within the reaction chambers drops below 9 PSI.

As the feed gas enters the fused, thermally protected reaction chambers inside the ozone generator, some of the oxygen

molecules are split while passing through the high voltage electrical field (the “corona”), forming single oxygen atoms

(O1). These oxygen atoms then recombine with other oxygen molecules in the air stream, forming ozone. The modular,

multiple reaction chamber design allows the ozone generator to keep working even if one of the chambers requires

service. Depending on the application, the ClearWater Tech ozone generator may be interlocked with an ORP controller,

PPM controller, pressure switch, timer or circulation pump.

Booster Pump Ozone Injector

Water Flow Off Gas

Vent Optional Destruct System

Ozone Generator Ozone

Destruct

Unit

Water Trap

Shown: ClearWater Tech SC27P Ozone System Contact Vessel

Theory of Operation/Product Description (continued)

2

Ozone Injection/Contacting

The ozone injector serves two purposes: One, it creates the vacuum

required to safely draw the ozone gas from the ozone generator and

two, it provides a means by which the ozone gas can become

dissolved in water. A very dynamic injection process is required to

effectively dissolve ozone in water.

ClearWater Tech injection systems use only Mazzei® injectors for

maximum mass transfer efficiency. The injector produces a

cavitation effect, enabling the ozone gas to join the water stream in

the form of extremely tiny bubbles. These bubbles must be as small

as possible in order to increase the ratio of bubble surface area to

the amount of ozone entering the water.

Depending on the application and the water treatment goals, a ClearWater Tech contacting system may also be required.

Some oxidation reactions take place so quickly that they are limited only by the rate at which the ozone is dissolved in the

water. Other reactions, such as disinfection, may require that proper ozone residual be maintained for a specific amount of

time. A correctly-sized contact vessel is used for this purpose.

Ozone Destruct

The ClearWater Tech off-gas destruct systems, consists of two components -the ozone destruct unit (a heated chamber

filled with manganese dioxide and copper oxide) and a water trap. Used in conjunction with a ClearWater Tech off gas

vent, the ozone destruct system is an effective way to vent the contact vessel(s) when it is impractical to send the off gas

to atmosphere or reintroduce it to the water.

3

SAFETY INFORMATION CHAPTER 2

SAFETY WARNINGS

Two aspects of ClearWater Tech ozone generators represent potential dangers –ozone gas and high voltage electricity.

OZONE GAS -WARNING: HIGH CONCENTRATIONS OF OZONE GAS ARE DANGEROUS

TO HUMANS. LOW CONCENTRATIONS CAN CAUSE IRRITATION TO THE

EYES, THROAT AND RESPIRATORY SYSTEM.

This ClearWater Tech corona discharge ozone

generator is designed to operate under a pressure

condition. While safety precautions have been taken,

entering the equipment area should be avoided if ozone

gas is detected. Ozone has a very distinctive odor and is

detectable at very low concentrations (0.02 ppm), which

is far below OSHA’s maximum permissible exposure

level of 0.1 ppm.

HIGH VOLTAGE -WARNING: CLEARWATER TECH OZONE GENERATORS OPERATE

AT HIGH VOLTAGE. DO NOT TAMPER WITH OR DELIBERATELY

BYPASS THE COVER OR SAFETY SWITCHES BUILT INTO THE

OZONE GENERATOR UNLESS INSTRUCTED TO DO SO BY THIS

MANUAL. IF CONTACT IS MADE WITH OPERATING HIGH VOLTAGE

COMPONENTS, ELECTRIC SHOCK WILL OCCUR.

ClearWater Tech corona discharge ozone generators take line voltage and convert it to 48 VDC. A high voltage

transformer then boosts the voltage. While each ozone generator has a door switch and other safety interlocks, proper care

must be used by a qualified electrician when making any internal adjustments or performing any maintenance procedures.

4

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed, including the

following:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. SAVE THESE INSTRUCTIONS.

3. All electrical connections should be made by a licensed, qualified electrician.

4. Before attempting any electrical connections, be sure all power is off at the main circuit breaker.

5. Install all electrical equipment at least five feet from any open body of water using non-metallic plumbing.

6. Install check valves and a vacuum break to prevent water from contacting the electrical equipment.

7. The electrical supply for this product must include a suitably rated switch or circuit breaker to open all

ungrounded supply conductors to comply with Section 422-20 of the National Electrical Code, ANSI/NFPA

70-1987. The disconnecting means must be readily accessible to the operator(s) but installed at least five

feet from any open body of water.

8. Be sure to bond (ground) the system using the copper-bonding lug on the bottom of the ozone generator.

The system should be bonded with solid copper wire conforming to all local, state and national electrical

codes.

9. The system should be sized appropriately for its intended use by a qualified professional familiar with the

application. This equipment must be validated by the manufacturer for its intended use; failure to do so

may void the warranty.

5

INSTALLATION PROCEDURES - Getting Started CHAPTER 3

Unpacking

Compare the ozone system equipment received to the packing list provided. Before beginning any

installation procedures, thoroughly inspect all components for damage. If damage is noticed,

promptly notify the freight carrier and request an on-site inspection. Inspect all packing materials

for small parts before discarding. Inspect all plumbing, fittings and tubing for packing material

that may have become lodged in openings.

Equipment Placement

• When placing the ozone system components in the equipment room, make sure to consider safety, maintenance

requirements, local building and fire codes, etc. The components should be easily accessible by the operators,

including equipment access doors and electrical hook-up boxes. All meters, gauges, indicator lights, and switches

should be visible and accessible. Dimensional drawings of each air preparation system and ozone generator are

included in Section A of the Appendix.

• The SC27P should be located as close as possible to the point of ozone injection. Ozone is an unstable gas and

will begin reverting back to oxygen very quickly. To determine the most favorable ozone injection point, the

following items should be considered:

• Located downstream of all other existing water system components.

• Located upstream of the residual sanitizer injection point (if so equipped).

• In a Sidestream plumbing configuration (see Figure 4-1) with recirculation, the pH adjustment

chemical injection point must be located downstream of the residual sanitizer injection point (if so

equipped).

• In a Full Flow plumbing configuration (see Figure 4-2) without recirculation, locate downstream of the

pH adjustment chemical injection point.

• Adequate protection from weather, dust and excessive heat.

• Like any electronic component, performance and longevity is enhanced by favorable operating conditions. Also,

since ozone generator is air-cooled, a relatively dust-free, well-ventilated area is required. No caustic chemicals

should be stored in the area surrounding the equipment. A minimum clearance of six inches from the vents on

either side of the ozone generator is required.

• The equipment is heavy and requires proper support. Therefore, a clean, dry, level vertical surface should be

provided for the SC27P. The system mounting bar should be securely fastened to the surface using the mounting

holes provided. Hang the SC27P from the wall mounting bar and level system on the wall with the leveling feet

provided on the backside of the system.

• The SC27P system is designed for specific voltage requirements, withstand typical outdoor elements and frequent

(though not constant) wash down, though should not be subjected to outdoor extremes including contact internally

with water and/or temperature extremes. Therefore, the equipment must be installed in an environment consistent

with the following operating parameters:

• Ambient temperature range: 20°F to 95°F continuous. If the temperature around the equipment

consistently exceeds 95°F, additional air-cooling must be provided.

• Humidity: 0 –90% relative humidity, non-condensing environment

• Line voltage: +/-10% of rated input

Note: Equipment installed in extreme environmental conditions will void manufacturer's warranty.

• Allow room for the peripheral equipment (booster pump, injector manifold, contact vessel, etc.).

6

INSTALLATION PROCEDURES – Plumbing CHAPTER 4

The ozone system should be plumbed using either a sidestream or full flow configuration. The sidestream

loop method takes a portion of the water from the main flow (see Figure 4-1) and diverts it into a

sidestream downstream of the filter (if so equipped). Ozone is introduced into the sidestream water and is

allowed contact time with the water before it is returned to the main flow at a point downstream of all other

equipment (heaters, solar panels, etc., if so equipped) in the circulation system. A booster pump is usually employed to

compensate for the flow restriction caused by the sidestream loop and the injector manifold. If a halogen-type residual

sanitizer is utilized, its injection point should be as far downstream as possible from the point at which the sidestream

water returns to the main flow. In a full flow configuration, the same system components are usually involved and appear

in the same order with respect to the direction of flow. However, all the water in the main flow is allowed contact time

with the ozone (see Figure 4-2). A booster pump may be necessary to maintain proper flow requirements. If employed, the

booster pump is located upstream of the point at which the ozone injector manifold is installed.

NOTES:

• Adequate use of unions and isolation valves is

strongly recommended to facilitate maintenance

and repairs.

• Use Schedule 80 PVC for all plumbing connections

wherever possible. Plumbing size requirements

are dictated by the water flow characteristics of

the system.

• Make sure to use proper plumbing practices and

secure all plumbing and system equipment

according to local codes.

• Ozone is a powerful oxidizer and will degrade certain

materials. Use ozone-compatible plumbing materials

for section(s) of the system that will come in contact

with ozone dissolved in water. The following is a list of

materials that are compatible with ozone:

• PVC • Stainless Steel (300 series)

• CPVC • Viton

• Kynar • EPDM

• Teflon • Concrete

• Depending on the application, other components (psi

gauge, flow meter, etc.) may be installed to assist in

monitoring system parameters.

Step 1: Arrange the ozone system equipment (booster pump, injector and contact vessel) according to mechanical print

or as dictated by equipment layout and serviceability considerations. Do not secure booster pump and contact

vessel to housekeeping pads at this point. Dry fit plumbing as appropriate to insure proper fit and location

before making permanent connections.

Step 2: Install a tee or plumbing saddle into the main water line after the filter (if so equipped) and before the flow

diversion mechanism. The purpose of the mechanism is to restrict water flow so water is diverted into the

sidestream (see Figure 4-1). If such a mechanism is not present in the system (such as a heater bypass valve,

etc.), it will require installation of a valve (butterfly, gate or ball) or a flow controller.

Step 3: Plumb a line from the tee or plumbing saddle to the booster pump. For serviceability of the equipment in the

sidestream loop, be sure to install an isolation valve between the tee or saddle and the booster pump.

Step 4: Plumb from the booster pump to the injector manifold. Make sure to note the correct direction of flow, indicated

by a blue arrow on the inlet side of the manifold body. The check valve assembly is strapped to the manifold

using wire ties. Remove the assembly; using Teflon® tape; install it onto the top opening of the injector.

Step 5: Plumb from the injector manifold to the inlet side of the contact vessel. To reduce possible backpressure to the

injector, minimize the number of elbows between the injector manifold and contact vessel. The contact vessel is

a specified size, determined by water flow requirements. ClearWater Tech contact columns and the 30, 40, 80,

and 120-gallon contact tanks have inlet and outlet fittings on the bottom of the vessel and are designated with

arrows showing the direction of flow. Note: The inlet and outlet arrows on the contact tanks are under the

base of the tank. The inlet on the 264, 463 and 850-gallon tanks is located at the top with the outlet at the

bottom.

Step 6: Using a tee or plumbing saddle, plumb from the outlet of the contact vessel back into the main water line. For

serviceability of the equipment in the side stream loop, be sure to install an isolation valve between the outlet

fitting on the contact vessel and before returning to the main water line.

Step 7: Secure the booster pump and contact vessel to solid mounting surfaces using appropriate hardware and

according to local codes. If installing a ClearWater Tech contact column, use a ClearWater Tech contact

Plumbing (continued)

7

column mounting kit and install according to the instructions below. If installing a contact tank, secure to a solid

horizontal surface using mounting flange or feet.

Step 8: Install the contact vessel venting system into the top of the vessel. If using the ClearWater Tech contact column,

the vent kit supplied includes fittings, a control valve and Teflon® tubing. The contact tank venting system

includes an air relief valve, fittings and a length of Teflon® tubing. Depending on conditions, the vented gas

may be directed to an ozone destruct system, to atmosphere or to the low-pressure side of the water system.

Note: Do not direct the tubing to the suction side of any pump in the system.

Contact Column Installation (if so equipped)

Step 1: Make sure the following hardware items are included in the contact column mounting kit:

• 'L' bracket

• 1/2” concrete anchors

• 6” clamp assembly

• Unistrut bar

• Protective end cap

• Mounting hardware

Step 2: Referring to Figure 4-3, mark the two holes for mounting the 'L' bracket to the wall. The bracket should be

located so that the 6” clamp assembly will be approximately 12” from the top of the contact column. Drill a

1/2” hole at each of the marks, about 3 1/2” deep. Insert a concrete anchor into each hole with the threaded end

facing outward. Slip the 'L' bracket over the threaded ends of the anchors, followed by a washer for each

anchor. Secure the bracket to the wall by threading a nut onto each anchor and tightening.

Step 3: Cut the unistrut bar to the desired length and attach it to the 'L' bracket using hardware provided.

Step 4: Slip the two sides of the 6” clamp into the unistrut bar and then around the contact column. Tighten the retaining

bolt, securing the contact column to the unistrut bar.

Step 5: Slip the protective end cap over the exposed end of the unistrut bar.

Sidestream Plumbing Installation Diagram

Figure 4-1

Flow Diversion

Mechanism

Filter Isolation Isolation

Valve Valve

Booster Ozone Injector

Pump

Bypass Valve

Contact

Vessel

Isolation

Service Loop Valve

Isolation Isolation

Valve Ozone Injector Valve

Booster Bypass

Pump Valve

Contact

Vessel

Full Flow Plumbing Installation Diagram

Figure 4-2

Plumbing (continued)

8

Column

Column Flange Bolts &

Flange Washers(8 ea.)

Diffuser

Riser Tube

Base Flange Gasket

Base Flange Nuts &

Washers (8ea.)

Contact Column Exploded View

Figure 4-4

Contact Column Installation Diagram

Figure 4-3

6” Clamp Assembly Bolts, nuts &

with bolt & Nut washers (2ea.)

Unistrut

(cut to length)

Unistrut “L” Bracket

Protective

End cap Concrete Anchors

with nuts &

washers (2ea.)

9

INSTALLATION PROCEDURES – Electrical CHAPTER 5

The SC27P ozone generation system is designed to

hard wire to the main power source with specific input

voltage requirements. All possible pre-wiring has been

completed at the factory. Logic Schematics have been

provided in the Appendix-Section C.

• All electrical connections should be made by a

licensed, qualified electrician. All local, state and

national codes must be observed.

• Make sure all power is off at the main circuit

breaker before making any electrical connections.

Step 1: Conforming to all local, state and national electrical codes, ground the ozone generator to a true earth ground.

Use solid copper bonding wire (usually #8 AWG) from the copper-bonding lug located on the bottom of the

ozone generator to the grounding point.

Step 2: Main Power: Wire main power to the Electrical Hook-up Box located on

the left side of the SC27P with specified input voltage, either 120VAC

60Hz (L1-Black and Neutral-White) or 220VAC 50Hz (L1-Red and

L2/Neutral-Black), single phase (1ø). Using #12 AWG, wire L1 main

power to terminal #1. Using #12 AWG, wire a system neutral to terminal #4. Using #12 AWG, wire a system

ground to terminal #6. See Figure 5-1 for Electrical Hook-up Box Terminal Strip Diagram. See Appendix-

Section A for Electrical Terminal Strip location.

Step 3: MCI (Motor Control Interlock) Power: The MCI is a fused factory-wired interlock, which may be used to

energize or de-energize the SC27P with other electrical component(s) via an input signal. If the MCI is used,

remove the factory-wired jumper between L1, terminal #1 and the MCI, terminal #2, of the Electrical Hook-up

Box Terminal Strip. Using #18 AWG, wire a 120VAC power signal (1 amp max) for a 120VAC 60Hz system

or a 220VAC power signal (1amp max) for a 220VAC 50Hz system to the top of the MCI, terminal #2. If so

required, a MCI Neutral may also be wired, using a #18 AWG wire to terminal #5. See Figure 5-1 for

Electrical Hook-up Box Terminal Strip Diagram. See Appendix-Section A for Electrical Terminal Strip

location. Note: The SC27P will not function without an input signal to the MCI, terminal #2.

Step 4: External Contactor Signal: The SC27P is equipped with an external contactor output signal. The output

voltage will be 120VAC (2 amp max) for a 120VAC 60Hz system or 220VAC (2 amp max) for a 220VAC

50Hz system. Using a #18 AWG, wire from the External Contactor, terminal #3 of the Electrical Hook-up Box

Terminal Strip, to the coil side of a contactor. If so required, an External Contactor Neutral may also be wired,

using a #18 AWG wire from the Auxiliary Neutral, terminal #5 to the coil side of the contactor. See Figure 5-1

for Electrical Hook-up Box Terminal Strip Diagram. See Appendix-Section A for Electrical Terminal Strip

location.

Step 5: External Loop: The external loop is a true dry contact interface. Note: The term ‘dry contact’ means that

this loop does not supply output nor accept input voltages. Warning: Supplying voltage to the external

loop will cause damage to the ozone generator and void warranty. Under normal operation, the external

loop will effectively interrupt the ozone output when the loop has lost continuity; this will also illuminate

“External Loop” LED and turn off the “Ozone Output” LED(s) located on the control panel of the system (see

Appendix-Section A). Note: When the external loop has lost continuity main power to the ozone

generator will remain “ON” giving power to the rest of the systems components. When continuity is

present through the external loop, ozone output will continue. This continuity will effectively turn “OFF” the

“External Loop” LED and will again illuminate the “Ozone Output” LED(s).

The external loop is located on the left side of the system, positions #9 and #10 on the terminal block (see

Appendix -Section A), and can be interfaced to any control device, i.e., pressure switch, vacuum switch, flow

switch, float switch, ORP controller, PPM controller, or timer. If the control device used supplies an output

voltage a single pole single throw (SPST) normally-open relay may be used to create a dry contact interface

(see Figure 5-2, “External Loop Electrical Interface”).

Step 6: Ozone Output Control: The SC27P ozone generator is equipped with two options for controlling the ozone

output. The first option is a Manual 0-100% Ozone Output Control and the second is a Remote 4-20mA

Control signal. See Appendix-Section A for the location of the manual ozone output control knob and remote

4-20mA control leads (orange and purple). An LED located on the systems control panel indicates the ozone

Power Consumption

Input

Voltage

120VAC

60Hz

220VAC

50Hz

SC27P

9 amps

4.5 amps

10

output control selected, see, Start-Up and Calibration Procedures, Figure 7-1A for LED function and

Appendix-Section A for LED location.

1. Manual Ozone Output Control: Turning the control knob counterclockwise will decrease the ozone output down to

0% while turning the knob clockwise will increase the ozone output up to 100%. The ozone output level is indicated

by the “Ozone Output” LED(s) on the control panel of the ozone generator, see Start-Up and Calibration Procedures,

Figure 7-1A for LED function and Appendix-Section A for LED location.

2. Remote 4-20mA Control: The ozone generator will automatically sense the 4-20mA input signal and override the

setting of the manual ozone output control. Based on the 4-20mA signal, ozone output will increase or decrease,

4mA = 0% ozone output, 20mA = 100% ozone output. The “Ozone Output” is indicated by the LED(s) on the

control panel of the ozone generator, see Start-Up and Calibration Procedures, Figure 7-1A for LED function and

Appendix-Section A for LED location. Note: If the remote 4-20mA signal fails or is missing, the system will

default to the manual ozone output setting. Check and adjust the manual ozone output control knob to avoid

over-ozonation. Following the directions in the manual of the 4-20mA control device, wire the negative (-) input

signal to the Purple wire of the ozone generator and the positive (+) input signal to the Orange wire of the ozone

generator.

Electrical Hook-Up Box Diagram

Figure 5-1

11

External Loop Electrical Interface

Figure 5-2

120V

COIL

N

Power from ORP, PPM,

pump or timer

L1

Interface Relay

External Loop

120VAC Signal

240VAC Signal

L1

L2

240V

COIL

Interface Relay

Power from ORP, PPM,

pump or timer

External Loop

12

Vacuum Break Detail

Figure 6-2

INSTALLATION PROCEDURES – Pneumatic CHAPTER 6

This section outlines the steps required to complete the

ozone system pneumatic hook-ups. The system

components include the air preparation system, ozone

generator, vacuum break, and ozone injector manifold

(see Figure 6-1). The air preparation system provides the

ozone generator with a source of dry, oil-free oxygen-

enriched air (90% +/-3% oxygen purity at -100˚F dew

point). The air is drawn from the ozone generator (where

ozone is produced from the oxygen in the air stream) and

through the vacuum break by the suction created at the

ozone injector manifold.

Figure 6-1

Vacuum break-to-injector manifold

The SC27P ozone generator incorporates a ClearWater Tech vacuum break, which provides a positive atmospheric

“break” between the ozone injector manifold and the SC27P system, preventing water from flowing back into the ozone

generator should the venturi check valve fail. If the check valve at the venturi begins to leak or fails completely, vacuum

is interrupted and water will flow toward the ozone generator. With the incorporated vacuum break the water will flow

down the riser tube (away from the ozone generator) and out to drain, protecting

the SC27P from potential water damage. All pneumatic connections have been

made between the ozone generation components of the SC27P and the vacuum

break. The only pneumatic field connections required are between the vacuum

break ozone outlet fitting and the injector manifold. Follow the steps outlined

below for this procedure, see Figure 6-2.

Step 1: Remove the vacuum break’s stainless steel cover located on the right

hand side of the SC27P.

Step 2: Remove the Fill Port Cap and fill the Riser Tube with clean water (no

particulate matter) to the fill level line of the overflow tube.

Step 3: Re-install the Fill Port Cap, hand tight. Note: Do not over tighten as

damage to PVC fittings may occur.

Step 4: Connect one end of a suitable length of Teflon® delivery line to the

vacuum breaks’ ozone outlet. The other end of the Teflon® delivery

line will be attached to the fitting threaded into the top of the check

valve assembly located on the injector manifold, do not attach this line

until directed in Chapter 7 of the “Start-up and Calibration Procedures”.

Booster Pump Ozone Injector

Water Flow

Ozone Generator

Ozone Delivery Line

Vacuum Break

Shown: ClearWater Tech SC27P Ozone System. Vacuum

break stainless steel cover removed for clarity.

Fill Port Cap

Ozone Inlet

Drain Holes

Ozone Outlet

Overflow Tube

Fill Level

Riser Tube

Flapper Check

Valve

13

START-UP & CALIBRATION CHAPTER 7

The previous sections of this manual have involved comparatively static procedures –making

electrical and pneumatic connections, fitting pipe, etc. This section involves the dynamic process of

starting up and balancing the components of the ozone system, including initiating water flow, making

air and water flow adjustments, etc.

Maximum performance and reliability is achieved when the prescribed air flow is maintained at the ozone generator while

the system is operating under pressure. Air from the air preparation system is flowing through the ozone reaction

chambers under pressure, and from the ozone generator under a slight vacuum (created by the ozone injector manifold).

The change from pressure to vacuum occurs after the stainless steel ozone outlet needle valve on the ozone generator.

SC27P Ozone Generation System and Injection Manifold

Warning: Disconnect the External Loop dry contact from the ozone generator while performing all start-up

procedures. Failure to do so may result in ozone escaping to atmosphere.

Step 1: Make sure all isolation valves in the ozone water system are open (Figures 4-1 or 4-2 show recommended

isolation valve locations).

Step 2: Apply main power to the SC27P. Switch the main power switch to the “ON” position. At this time the SC27P

will be powered up, the air preparation system and cooling fans should be “ON” and power should be present

to the External Contactor output signal. If the External Contactor output signal is interlocked to a booster

pump, the booster pump should be “ON”. Note: Ozone will not be produced until the “External Loop” is

in place and at least 9 PSI present at the PSI gauge located on the control panel.

Step 3: Start-up hydraulics. Allow the water in the system to reach hydraulic equilibrium (contact vessel full, off-gas

vent operating, etc.) and observe for plumbing leaks. Note: Water flow must be established through the

main water pump and the ozone system booster pump (if so equipped).

Step 4: Close the ball valve on the injector manifold about half way.

Step 5: Using your thumb, check for the presence of vacuum (suction) at the

ozone injection manifold check valve assembly or use a ClearWater

Tech vacuum test assembly to check vacuum at the injector port. If no

suction is present, continue to close the ball valve on the injector

manifold until vacuum is detected. If using the vacuum test assembly,

check the VAC/PSI gauge for vacuum. If the needle is in the red zone

on the pressure (PSI) side of the gauge, gradually close the ball valve on

the injector manifold until the needle moves into the green zone. If the

needle is in the red zone on the vacuum (in.Hg) side of the gauge,

gradually open the ball valve on the injector manifold until the needle

moves into the green zone. While vacuum is in the green zone you must

be able to achieve proper SCFH (Standard Cubic Feet per Hour) of air flow (see the “Pneumatic Operating

Parameters” chart for venturi SCFH required, Figure 7-2).

Step 6: The air preparation system air flow must be set to “atmospheric pressure” prior to final start-up of the SC27P.

Step 1: Check to make sure the compressor of the air preparation system is operating.

Step 2: Check the system PSI gauge for pressure, located on the control panel. If pressure is registered on

the PSI gauge open the stainless steel needle valve by turn it counter clockwise so that no pressure is

registered on the gauge. See Appendix-Section A for PSI gauge and stainless steel needle valve locations.

Step 3: Using the air flow gauge adjustment valve on the control panel, adjust the SCFH air flow according

to the “Air prep system air flow” specifications outlined in Figure 7-2.

Step 7: Connect the Teflonozone delivery line from the vacuum break to the ozone inlet fitting located at the ozone

injection manifold check valve assembly.

Step 8: Adjust the stainless steel needle valve located at the bottom the ozone generator (see Appendix-Section A)

clock-wise, adjusting the system backpressure to 10 PSI. Check the PSI gauge on the control panel, which

measures this backpressure. If there is insufficient backpressure the needle valve may be closed slightly;

similarly, if there is too much backpressure the valve may be opened slightly. Due to the pressure switch

installed, the PSI gauge must achieve 9 PSI before ozone will begin production.

Step 9: By setting the air preparation SCFH (step 6) and system backpressure PSI (step 8), the air flow gauge on the

control panel will read in CFH rather than SCFH. At this point the air flow meter becomes passive and should

Start-Up and Calibration (continued)

14

read in the range indicated on the “Ozone Generator Air Flow” line of the “Pneumatic Operating Parameters”

chart, Figure 7-2. Note: When the system is under normal operation, the “Air Prep System Air Flow” set

point will drop from the initial setting due to the system being under backpressure. DO NOT RE-

ADJUST THE AIR FLOW GAUGE ADJUSTMENT VALVE.

Step 10: Perform a final check of all air connections from the SC27P to the ozone injector manifold. Repair leaks as

required. Check all system water connections, including the ozone injector manifold, vacuum break and

contact vessel. Repair leaks as required. Note: The check valve at the ozone injector manifold may make a

humming noise. This is normal.

Step 11: Reconnect the External Loop connector to the ozone generator. Note: The Ozone LED(s) will not illuminate

and ozone will not be produced until the External Loop has been replaced.

Step 12: Observe indicating LED(s), on the control panel of the SC27P and adjust the manual ozone output control

knob to desired level setting. See Figure 7-1 A-C for proper LED function and Appendix-Section A for

location of the LED’s.

SC27P –Control Panel LED Function Figure 7-1A

LED

Function

SC27P LED Display

System Power

Main Power is “ON” to the SC27P, when LED is Illuminated

Pressure

The SC27P has sufficient pressure, when LED is Illuminated

Motor Control

Interlock (MCI)

The MCI is energized, when LED is illuminated

External Loop

The External Loop has continuity through it when the LED is not

illuminated, which indicates ozone is being produced. The External

Loop does not have continuity, when the LED is illuminated, which

indicates no ozone production.

Manual Control

Ozone output is being controlled by the Manual Ozone Output Control,

when LED is illuminated

Remote 4-20mA

Control

Ozone output is being controlled by an External 4-20mA Control signal,

when LED is illuminated

Ozone Output

Level

The ten LED’s represent 0-100%, minimum to maximum ozone output.

Each LED is equal to 10% output. These LED’s can be adjusted with

the manual ozone output control knob located on the control panel of

the SC27P or automatically with a remote 4-20mA control signal.

Drive 1 and Drive

2 -Power

Power is being sent to the high voltage Drive board, when the LED is

illuminated

Drive 1 and Drive

2 -Fault

When illuminated, this LED indicates that there is a fault with the drive

module or the Ozone Reaction Chamber. If this LED is illuminated, refer

to the Troubleshooting Guide. Notes: Upon startup, the fault LED

will remain illuminated for 30 seconds before ozone is produced

and the ozone output LED’s will not be illuminated. If the drive

module goes to a fault condition, the drive board will restart every

30 seconds. If the fault is not remedied the drive module will

continue to go into a fault mode. When the drive module is in fault

mode ozone will not be generated.

OZONE GENERATOR STATUS

SYSTEM POWER

PRESSURE

MOTOR CONTROLLED

INTERLOCK (MCI)

EXTERNAL LOOP

OZONE OUTPUT CONTROL

MANUAL CONTROL

REMOTE 4-20mA CONTROL

MAXIMUM OUTPUT

OZONE

OUTPUT

LEVEL

MINIMUM OUTPUT

GENERATOR DRIVE STATUS

GENERATOR DRIVE 1

POWER

FAULT

POWER

FAULT

GENERATOR DRIVE 2

Start-Up and Calibration (continued)

15

SC27P -Ozone Generator Drive Board LED Function Figure 7-1B

LED

Function

12V MAIN

POWER

When illuminated, this “Green” LED indicates that main power is supplied to the drive module up to the “on board”

fuse of the drive board.

XFMR

POWER

When illuminated, this “Green” LED indicates that 48V Buss power is available to the drive module transformer

(XFMR) from the “on board” fuse to the drive transformer.

OZONE

OUTPUT

The “Amber” ozone output LED will illuminate when ozone is being generated. The LED will also pulse as the

output increases or decreases with either the Manual Ozone Output Control or from a Remote 4-20mA signal.

FAULT

When illuminated, this “Red” LED indicates that there is a fault with the drive module or the Ozone Reaction

Chamber. If this LED is illuminated, refer to the Troubleshooting Guide. Notes: Upon startup, the fault LED will

remain illuminated for 30 seconds before ozone is produced. If the drive module goes to a fault condition,

the drive board will restart every 30 seconds. If the fault is not remedied the drive module will continue to

go into a fault mode. When the drive module is in fault mode ozone will not be generated.

SC27P Drive Board

Figure 7-1C

Vacuum Break

Check the water level in the vacuum break, making sure it is above the flapper valve (see Figure 6-2). If water is not

pressing downward on the flapper valve it will open, causing a loss of vacuum. A loss of vacuum means ozone cannot

flow from the vacuum break, which in turn can cause an ozone leak. Note: If the vacuum break must be refilled with

water disconnect the External Loop from the SC27P and shut down the system and follow the steps outline in

Chapter 6 “Installation Procedures –Pneumatic.” Then re-start the system by following the steps outlined in

Chapter 7 “Start-up and Calibration Procedures.”

Pneumatic Operating Parameters Figure 7-2

SC27P Operating Range Optimum

Air prep System air flow *

Ozone generator air flow (gauge –front control panel)

PSI gauge (gauge –front control panel)

Injector manifold air flow

Injector manifold injector

8 to 10 scfh

4 to 6 cfh

9 to 12 psi

8 to 12 scfh

-3 to -8 in. Hg.

10 scfh

6 cfh

10 psi

10 scfh

-5 in. Hg.

* Be sure that the SCFH flow rate is regulated to no more than 10 SCFH with the air flow gauge

adjustment valve.

Drive Board

Fuse

Variable Input Connector

DC Power Input Connector

Fault LED

Drive Board Main Power LED

Transformer –XFMR LED

Ozone Output LED

24VDC Output Connector

16

MAINTENANCE CHAPTER 8

Maintenance of the ozone system is critical to its longevity and operating efficiency. While all system

components are built to provide years of reliable service with minimum maintenance, following the

procedures outlined below is strongly recommended.

All maintenance procedures have been segmented by interval: daily, monthly, semi-annual and annual.

Daily procedures involve quick, visual checks for changes in normal operating conditions. Monthly,

semi-annual and annual procedures include cleaning and/or replacement of certain critical parts.

NOTES:

• The ozone generator warranty states that it “does

not extend to any product or part which has been

damaged or rendered defective as a result of use of

parts not sold by ClearWater Tech, or service or

unit modification not authorized by ClearWater

Tech” Please contact your ClearWater Tech dealer

if you have any questions about any maintenance

procedure before you begin that procedure.

• CAUTION: Observe all common safety practices

and review the “Safety Warnings and Instructions”

in Chapter 2 before attempting any maintenance

procedure that requires the use of tools and/or

shutting down the ozone system.

Daily Procedures

Ozone Generator

• Indicator Lights: Check all indicating LED’s on the control panel of the SC27P. See Appendix-Section A for

location and See Figure 7-1A for Control Panel LED function. See Troubleshooting Guide as required.

• Air Flow: Check the air flow meter on the SC27P control panel. Make sure air flow is within the CFH (cubic feet

per hour) range shown on the “Ozone generator air flow” line of the “Pneumatic Operating Parameters” (see

Figure 7-2). Adjust if necessary by following steps outlined in the “Start-Up & Calibration” section.

• Pressure: Check the PSI gauge located on the ozone generator cabinet door. Make sure pressure is within the

range shown on the “PSI Gauge” line of the “Pneumatic Operating Parameters” chart (see Figure 7-2). Adjust if

necessary by following steps outlined in the “Start-Up & Calibration” section.

Vacuum Break

• Water Level: Check the water level in the vacuum break. Make sure it is above the flapper valve in the overflow

tube. If the vacuum break must be refilled with water disconnect the External Loop from the SC27P and shut

down the system and follow the steps outline in Chapter 6 “ Installation Procedures –Pneumatic.” Then re-start

the system by following the steps outlined in Chapter 7 “Start-up and Calibration Procedures.”

Injection Manifold

• Check Valve: Inspect the Teflonozone delivery line that runs between the vacuum break and the check valve

assembly on the suction port of the ozone injector manifold. If water is observed in the delivery line near the

check valve assembly, the check valve has failed. See Troubleshooting Guide.

Monthly Procedures

Ozone Generator

• Cooling Fan Operation: Check to make sure the two cooling fans (mounted on the bottom panel of the SC27P.)

and the two exhaust fans (located behind the air preparation compressor) are operating. If not, refer to the

Troubleshooting Guide.

• Cooling Fan Filters: Check the cooling fan filter elements (mounted on the bottom of the SC27P) and clean as

required. Operating conditions in the equipment area will dictate the frequency required for this procedure.

Remove the filter element and clean with soap and water, drying them completely before re-installing (see Figure

8-1). Note: Fan filter stainless steel cover must be removed to access fan filters.

Booster Pump(s)

• Strainer Baskets: Check and clean the strainer basket in the booster pump(s) as required (if so equipped).

Maintenance (continued)

17

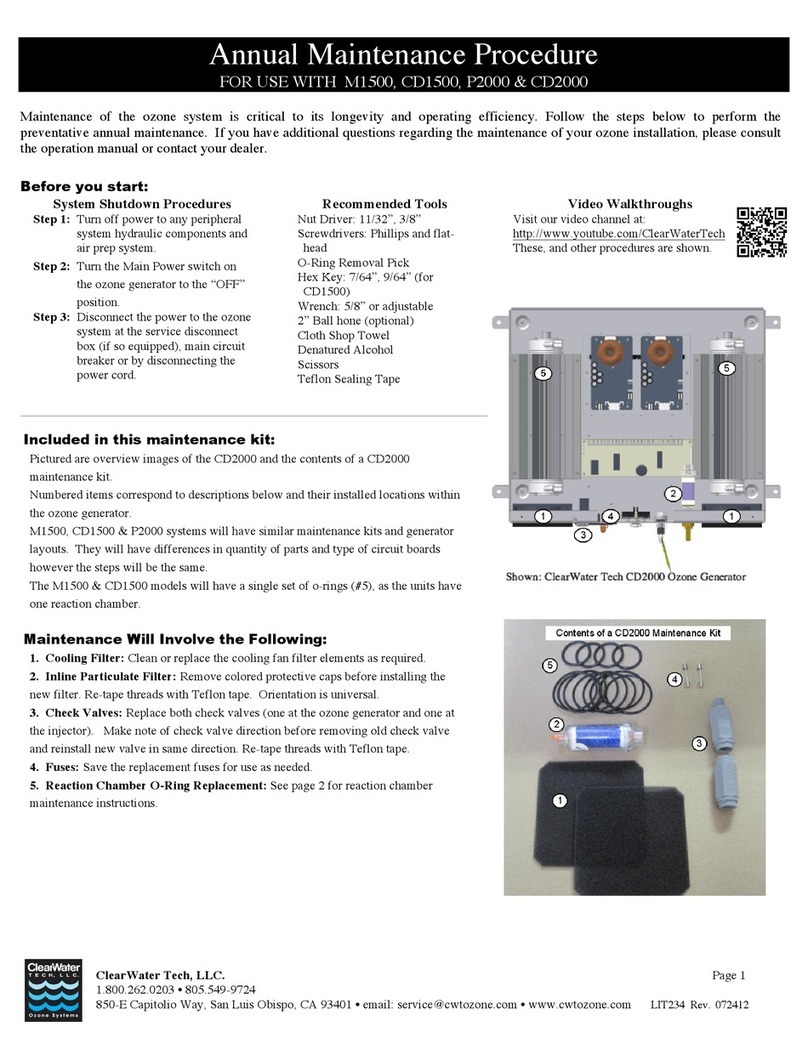

Ozone Generator Cooling Fan Assembly

Figure 8-1

System Shutdown Procedures

CAUTION: The ozone generator operates at high voltage. Follow these steps carefully before performing any

semi-annual or annual maintenance procedures.

Step 1: Turn off power to any peripheral system hydraulic components.

Step 2: Turn the Main Power switch on the SC27P to the “OFF” position. The Main Power LED’s on the control panel

should not be illuminated.

Step 3: Disconnect the power to the ozone system either at the service disconnect box (if so equipped) or main circuit

breaker.

Semi-Annual Procedures

CAUTION: Follow system shutdown procedures (outlined above) before performing any of the following steps.

Air Preparation System

• Air Inlet Filter: Replace the air compressor inlet filter. See Appendix-Section A for location. Note:

Manufacturers' recommended replacement interval is 4,000 hours of operation. Operating conditions in

the equipment area will dictate the required frequency of this procedure.

Annual Procedures

CAUTION:Follow system shutdown procedures before performing any of the following steps.

Air Preparation System

• Compressor: Following the procedures outlined in the compressor rebuild kit, rebuild the two compressor heads.

See Appendix-Section A for location. Note: Manufacturers' recommended interval is 5,000 to 12,000 hours of

operation. Compressor performance and/or operating conditions in the equipment area will dictate the

required frequency of this procedure.

Ozone Generator

• Cooling Fan Filters: Clean or replace the cooling fan filter elements as required. Note: Fan filter stainless steel

cover must be removed to access fan filters.

• Depressurization Valve: Rebuild the depressurization valve, see Appendix-Section A for location.

• Check Valve: Replace check valve located behind the system control panel, see Appendix-Section A for location.

• Reaction Chambers: Remove and disassemble one reaction chamber according to the steps outlined below (see

Figure 8-2). Check the chamber interior and dielectric tube for oil, dirt or moisture. Note: CWT pressurized

reaction chambers are anodized blue.

Removal and Disassembly

Note: Disassembly and service of the reaction chamber is a technical, delicate and critical procedure. Please

consult your ClearWater Tech dealer before attempting this procedure.

Step 1: Make sure all power to the ozone generator has been disconnected according to the “System Shutdown

Procedures” outlined above.

Step 2: Unplug the electrical connections from the drive module.

Step 3: Disconnect tubing connections from the fittings on both ends of the reaction chamber.

Step 4: Remove reaction chamber from ozone generator.

Step 5: Disconnect the high voltage lead from the drive module.

Step 6: Remove retaining screws from the two end caps (4 each).

Step 7: Using a gentle back-and-forth twisting motion, remove the non-high voltage end cap (the one without the white

power lead attached) from the heat sink/cathode assembly. Note: The stainless steel clamp must not be

removed.

Step 8: Remove the high voltage end cap and dielectric from the heat sink/cathode assembly. Note: The stainless steel

clamp must not be removed.

Step 9: With contact brush attached, remove the brush adapter nut from the high voltage end cap.

Fan

Finger Guard

Ozone Generator Bottom Panel

Fan Filter Element

Fan Filter Grill

18

High Voltage End Cap

Brush Adapter Nut

High Voltage

Lead

Stainless Steel

Washer

Viton Washer

Oxygen Inlet Fitting

Contact Brush

High Voltage Anode

Glass Dielectric

Heat Sink and Cathode

Stainless Steel Clamp

Bottom End Cap

Ozone Outlet Fitting

End Cap Retaining

Screw and Washer

Step 10: Inspect the dielectric, end caps and cathode for breakage, corrosion or debris. Clean and/or replace parts as

necessary. If cleaning and/or parts replacement is not required, re-assemble the reaction chamber per the

instructions below.

Assembly and Re-installation

Step 1: Make sure the glass dielectric is clean (free of dust, dirt, grease, oils, etc.).

Step 2: Prepare the end caps for re-assembly by replacing the O-rings. Thread the hex brush adapter nut, with contact

brush attached, onto the end of the high voltage end cap (cap with the white power lead attached) center screw.

Step 3: Using a gentle twisting motion, press the non-high voltage end cap onto the heat sink/cathode assembly until

flush with the heat sink cooling fins. Note: See Figure 8-2 for correct orientation of end cap.

Step 4: Slide the four end cap retaining screws through the holes in the non-high voltage end cap, aligning them with

the heat sink screw bosses. Thread screws into screw bosses until heads are snug against the end cap.

Step 5: Roll the high voltage anode (foil-like material) lengthwise, preserving the longer dimension. Insert the rolled

anode into the dielectric. Center the anode in the dielectric (approximately 1/2” from either end of the glass),

making sure it is rolled squarely.

Step 6: Slide the dielectric into the heat sink/cathode assembly. Seat the dielectric into the O-rings of the non-high

voltage end cap by applying pressure with a gentle twisting motion. (There must not be any dirt, debris, oils or

fingerprints on the dielectric upon re-installation).

Step 7: Slowly insert the high voltage end cap assembly into the dielectric. Note: Do not bend center wire of the

brush during this procedure. It is normal for the bristles to bend. Using a gentle twisting motion, press the

high voltage end cap onto the heat sink/cathode assembly until flush with the heat sink cooling fins.

Step 8: Slide the four end cap retaining screws through the holes in the end cap, aligning them with the heat sink screw

bosses. Thread screws into screw bosses until heads are snug against the end cap.

Step 9:Re-install complete reaction chamber assembly into the ozone generator by following the “Removal and

Disassembly” instructions in reverse order, from Step 6 to Step 2. Follow steps outlined in Chapter 7, “Start-

Up and Calibration,” to re-start the ozone system.

2” Pressurized Reaction Chamber - Exploded View

Figure 8-2

19

Vacuum Break

• Cleaning: Disconnect ozone delivery lines. Remove the vacuum break from mounting clamps. Disconnect the

overflow tube from flapper valve, open flapper and clean the seat with a soft clothe. Remove riser tube threaded

fitting and flush riser tube with water. Re-assemble and re-install vacuum break, making sure to add water to

correct level (see Figure 6-2).

Injector Manifold

• Check Valve: Replace the check valve located at the ozone injection manifold. Note: Because the system is in

the shutdown mode, no vacuum is present at the injector. Therefore, it is normal for some water to be

flowing from the injector during this procedure.

Contact Vessel

• Cleaning: Contact Column only. Inspect the diffuser slots at the top of the contact column riser tube. If they are

clear, no further maintenance is required. If the slots are fouled, disassemble the column and clean as required,

following the steps outlined below (see Figure 4-4).

Step 1: Make sure the isolation valves before and after the contact column are closed.

Step 2: Disconnect the vent line from the top of the contact column.

Step 3: Remove the bolts in the 6” base flange.

Step 4: Remove the column, lifting it over the interior riser tube.

Step 5: Remove and clean the diffuser.

Step 6: Inspect the flange gasket and replace if necessary.

Step 7: Reassemble the contact column and attach vent lines.

Table of contents

Other Clear Water Portable Generator manuals

Popular Portable Generator manuals by other brands

Scheppach

Scheppach DSE5500 Translation of original instruction manual

Generac Power Systems

Generac Power Systems 005724-0 owner's manual

Briggs & Stratton

Briggs & Stratton 3500 Watt Portable Generator Operator's manual

Xantrex

Xantrex xPower1500 owner's guide

Husky

Husky HU40181 Series Operator's manual

PANDROL

PANDROL 03700A Operation and maintenance manual