Clear Water CD-2000 Manual

Annual Maintenance Procedure

FOR USE WITH M1500, CD1500, P2000 & CD2000

ClearWater Tech, LLC. Page 1

1.800.262.0203 • 805.549-9724

850-E Capitolio Way, San Luis Obispo, CA 93401 • email: service@cwtozone.com • www.cwtozone.com LIT234 Rev.

072412

Included in this maintenance kit:

Pictured are overview images of the CD2000 and the contents of a CD2000

maintenance kit.

Numbered items correspond to descriptions below and their installed locations within

the ozone generator.

M1500, CD1500 & P2000 systems will have similar maintenance kits and generator

layouts. They will have differences in quantity of parts and type of circuit boards

however the steps will be the same.

The M1500 & CD1500 models will have a single set of o-rings (#5), as the units have

one reaction chamber.

Maintenance Will Involve the Following:

1. Cooling Filter: Clean or replace the cooling fan filter elements as required.

2. Inline Particulate Filter: Remove colored protective caps before installing the

new filter. Re-tape threads with Teflon tape. Orientation is universal.

3. Check Valves: Replace both check valves (one at the ozone generator and one at

the injector). Make note of check valve direction before removing old check valve

and reinstall new valve in same direction. Re-tape threads with Teflon tape.

4. Fuses: Save the replacement fuses for use as needed.

5. Reaction Chamber O-Ring Replacement: See page 2 for reaction chamber

maintenance instructions.

Maintenance of the ozone system is critical to its longevity and operating efficiency. Follow the steps below to perform the

preventative annual maintenance. If you have additional questions regarding the maintenance of your ozone installation, please consult

the operation manual or contact your dealer.

Before you start:

System Shutdown Procedures

Step 1: Turn off power to any peripheral

system hydraulic components and

air prep system.

Step 2: Turn the Main Power switch on

the ozone generator to the “OFF”

position.

Step 3: Disconnect the power to the ozone

system at the service disconnect

box (if so equipped), main circuit

breaker or by disconnecting the

power cord.

Recommended Tools

Nut Driver: 11/32”, 3/8”

Screwdrivers: Phillips and flat-

head

O-Ring Removal Pick

Hex Key: 7/64”, 9/64” (for

CD1500)

Wrench: 5/8” or adjustable

2” Ball hone (optional)

Cloth Shop Towel

Denatured Alcohol

Scissors

Teflon Sealing Tape

Video Walkthroughs

Visit our video channel at:

http://www.youtube.com/ClearWaterTech

These, and other procedures are shown.

Annual Maintenance Procedure

FOR USE WITH M1500, CD1500, P2000 & CD2000

ClearWater Tech, LLC. Page 2

1.800.262.0203 • 805.549-9724

850-E Capitolio Way, San Luis Obispo, CA 93401 • email: service@cwtozone.com • www.cwtozone.com LIT234 Rev.

072412

Reaction Chamber Removal and

Disassembly:

Note: Read through all the steps before disassembling the reaction

chamber.

Step 1: Make sure all power to the ozone generator has been

disconnected according to the “System Shutdown Procedures”

outlined above.

Step 2: Disconnect the white high voltage lead from the black

transformer, the black insulation boot will have to be drawn

back to expose the connection.

Step 3: Disconnect the tubing connections on both ends of the reaction

chamber.

Step 4: Remove the 4 nuts securing each chamber and remove the

reaction chamber from ozone generator.

Step 5: Remove retaining screws and washers from the end caps (4 each).

Step 6: Using a gentle back-and-forth twisting motion, remove the non-high voltage end cap (the one without the high voltage attachment screw) from the heat

sink/cathode assembly. A flat-head screwdriver may be used to gently pry the end cap off, as long as equal pressure is applied to each side of the end cap.

Step 7: Remove the high voltage end cap and dielectric from the heat sink/cathode assembly.

Step 8: Draw back the white cap along the white high voltage lead at the end cap, this will expose a screw to be removed. Pull/twist the end cap off the glass. Push the

contact brush out of the dielectric glass. Also remove the anode (foil-like material) from within the glass, it may come out with the brush.

Step 9: Inspect the dielectric, foil, end caps and cathode for breakage, corrosion or debris; then follow the assembly and re-installation steps below.

Reaction Chamber Assembly and Re-installation:

Step 1: Remove o-rings from end caps, then clean the dielectric glass, end caps and interior of the stainless steel cathode cylinder. Use denatured alcohol and shop

towels to clean the above components and be sure to remove all old o-ring debris. A 2” ball hone can be used to clean the major debris out of the cathode if

there is heavy buildup. Note: If the brush’s core is intact, but discolored, it is likely fine. The anode foil may also have been discolored from residual oil and

heat, it will not require replacement. If there are ragged ends on the foil, trim them off (1/8”-1/4”) with a pair of scissors.

Step 2: Prepare the end caps for re-assembly by replacing the o-rings. Attach the high voltage lead to the screw and install it onto the high voltage end cap. Thread the

hex brush adapter nut, with contact brush attached, onto the interior of the high voltage end cap. Re-tape the threads of the elbow fittings if needed.

Step 3: Using a gentle twisting motion, press the non-high voltage end cap onto the heat sink/cathode assembly until flush with the heat sink cooling fins. Turn the end

cap to the correct orientation.

Step 4: Slide the four end cap retaining screws with washers through the holes in the non-high voltage end cap, aligning them with the heat sink screw bosses. Thread

screws into screw bosses until heads are snug against the end cap.

Step 5: Next we focus on assembling the rest of the subcomponents before installing them into the reaction chamber. Roll and insert the anode foil into the glass

dielectric, center the anode foil in the glass. Secure the foil with a finger against the inside of the glass to keep it centered and insert the contact brush into the

dielectric. Insure the foil is centered before fully seating the glass into the high voltage end cap. Clean the glass with denatured alcohol once more, and do not

retouch the glass without re-cleaning.

Step 6: Hold the reaction chamber upright on a flat surface, empty side up. Grasp the high voltage end cap and lower the glass into the reaction chamber. Press

directly downwards on the high voltage end cap to fully seat the dielectric assembly; the end caps should be flush with the heat sink cooling fins. Turn the end

cap to the correct orientation.

Step 8: Slide the four end cap retaining screws with washers through the holes in the end cap, aligning them with the heat sink screw bosses. Thread screws into screw

bosses until heads are snug against the end cap.

Step 9: Re-install the complete reaction chamber assembly into the ozone generator by securing the reaction chamber to its mounts, securing delivery line and

connecting the high voltage insulated wire.

Other manuals for CD-2000

1

This manual suits for next models

3

Table of contents

Other Clear Water Portable Generator manuals

Popular Portable Generator manuals by other brands

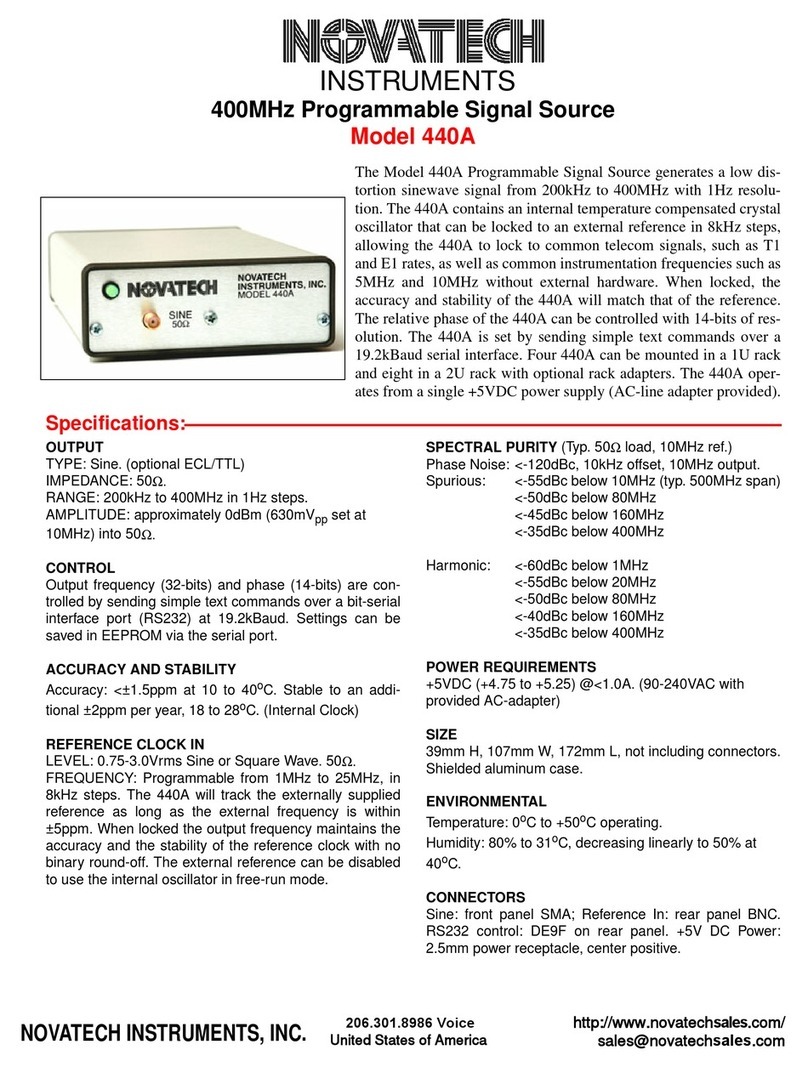

Novatech Instruments

Novatech Instruments 440A manual

MQ Power

MQ Power WhisperWatt DCA800SSK Operation manual and parts list

Power Stroke

Power Stroke PS903500 Series Operator's manual

Briggs & Stratton

Briggs & Stratton 01532-2 owner's manual

FXA

FXA 502313382 instruction manual

MULTIQUIP

MULTIQUIP GDP-5HA manual