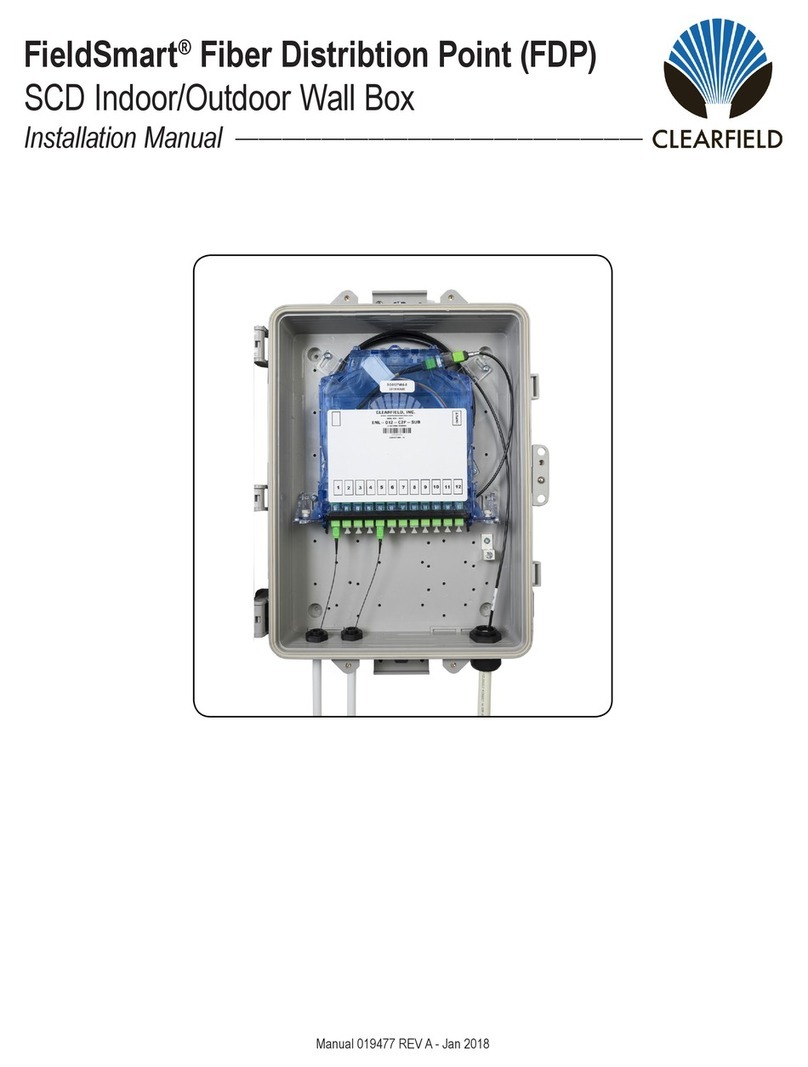

Clearfield FieldShield YOURx-TAP User manual

FieldShield YOURx-TAP

Installation Manual ______________________________________________________

Manual 018446 REV A - AUG 2017

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

2

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

Table of Contents

Product Packaging 3

Parts List 3

Required Tools 4

Box Mounting 4

Preparing Ports 5

Bottom Deploy Reel Installation 5

Congurations 8

TopDeployReelInstallation 8

Installing Bulkheads 9

EnteringandExitingFiberCongurations 10

StoringSlackFiberontheTAPSlackReel 11

YOURx-TAPAccessories 12

ConnectorCleaningProcedure 13

StandardWarranty 16

ProprietaryNotice 17

TechnicalSupport 17

3

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

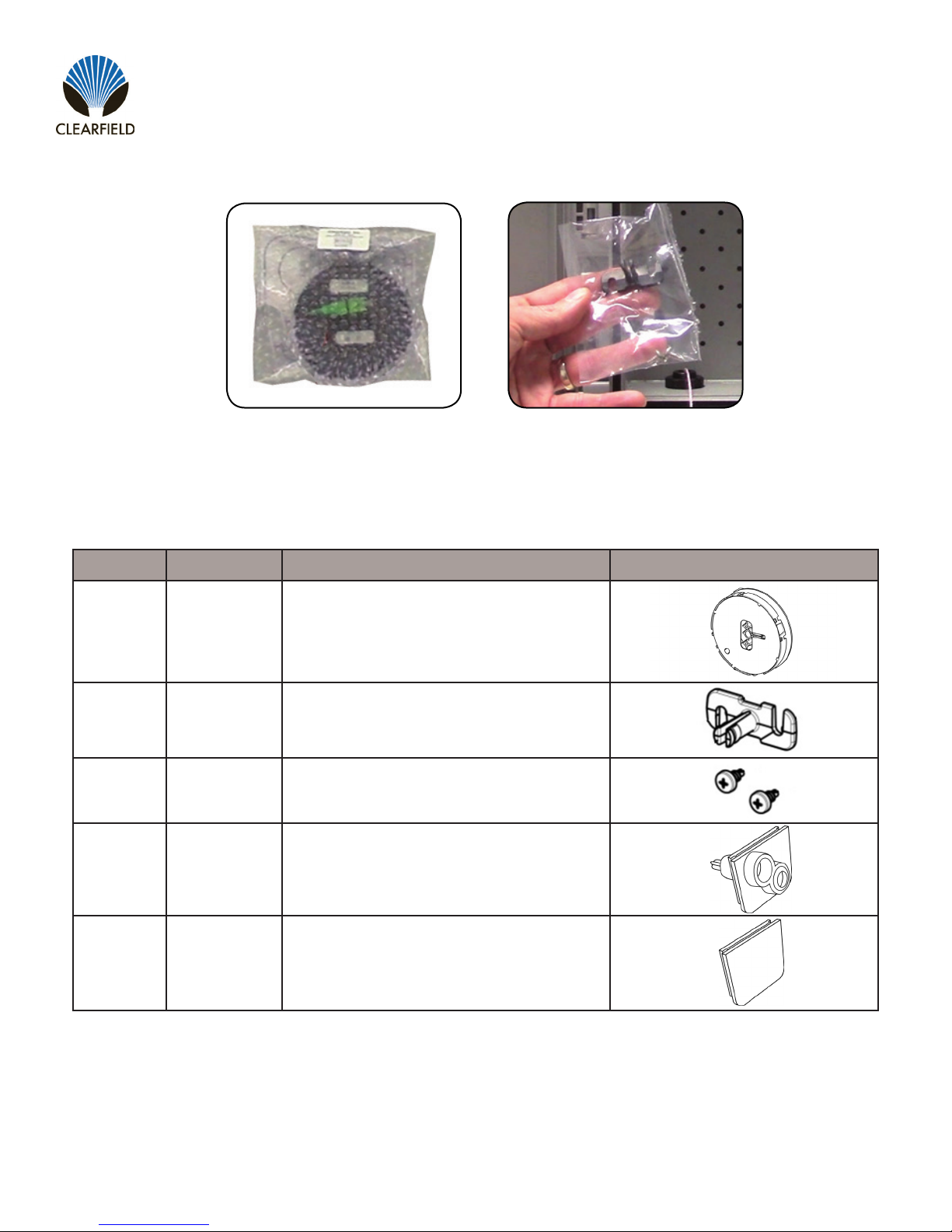

Product Packaging

StrongFiber Deploy Reels are shipped in a bubble wrap packaging (Figure1)with mounting

hardware included in a plastic pouch (Figure2).

Figure1 Figure2

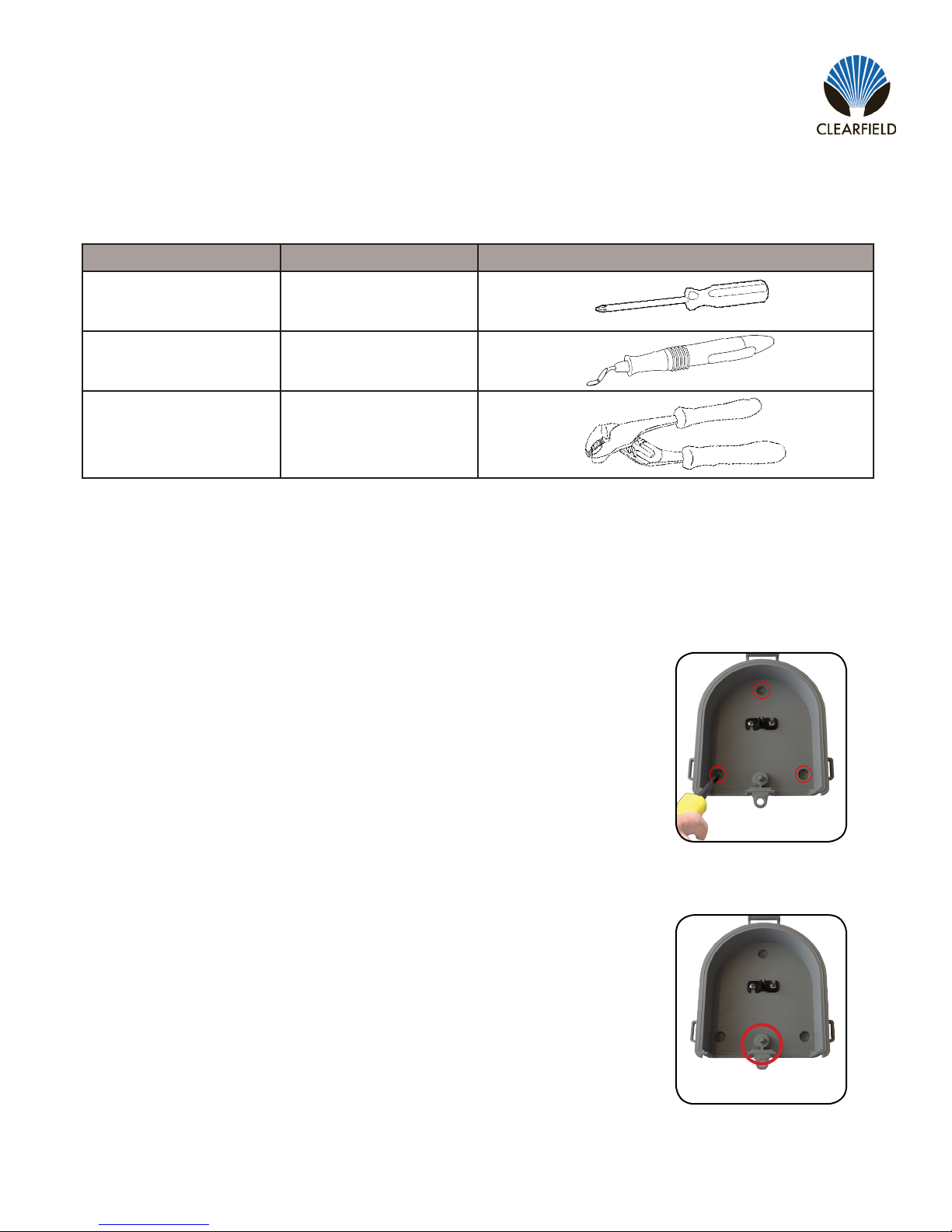

Find No. Quantity Description Image

001 1 SmartFiber Deploy Reel

002 1 Back post

003 5 Self Taping Screws

004 1 Cable Entrance Bulkhead

005 1 Blank Bulkhead

Parts List

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

4

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

Figure1

Step1:MountTAPBox

Use a Philips Screwdriver to attach the back post to wall box or mounting surface

using the provided self taping screws (Figure1).

Box Mounting

Figure2

Note: A pass through hole is provided on the back of the wall box as an option to

directly penetrate into the customer premise. (Figure2).

If this option is used a 1/4 inch hole must be drilled into the home prior to mount-

ing the TAP box. It is also recommended that the hole be sleeved with a piece of

10/6 microduct for unobstructed access into the customer premise.

Find No. Tool Image

006 Phillips Scewdriver

007 Deburring Tool

008 Pliers

Required Tools

5

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

Step1:Install Back Post

Use a Philips Screwdriver to attach the back post to wall box

or mounting surface using the provided self taping screws

(Figure 1).

Figure1

Bottom Deploy Reel Installation

Step2:Mount Deploy Reel

Align center hole on Deploy Reel with Back Post (Figure 2). The surrounding holes will be used to lock the

Reel down after installation. Press Deploy Reel onto Back Post (Figure 3).

Figure2 Figure 3

Step1:Remove Port Tab

Use a pair of pliers to snap off port tab.

(Figure 1 & Figure 2).

Step2:Ream Port

Use appropriate tool (we reccomend deburring tool)

to ream and chamfer edges of port.

(Figure 3)

Preparing Ports

Figure1 Figure2 Figure 3

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

6

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

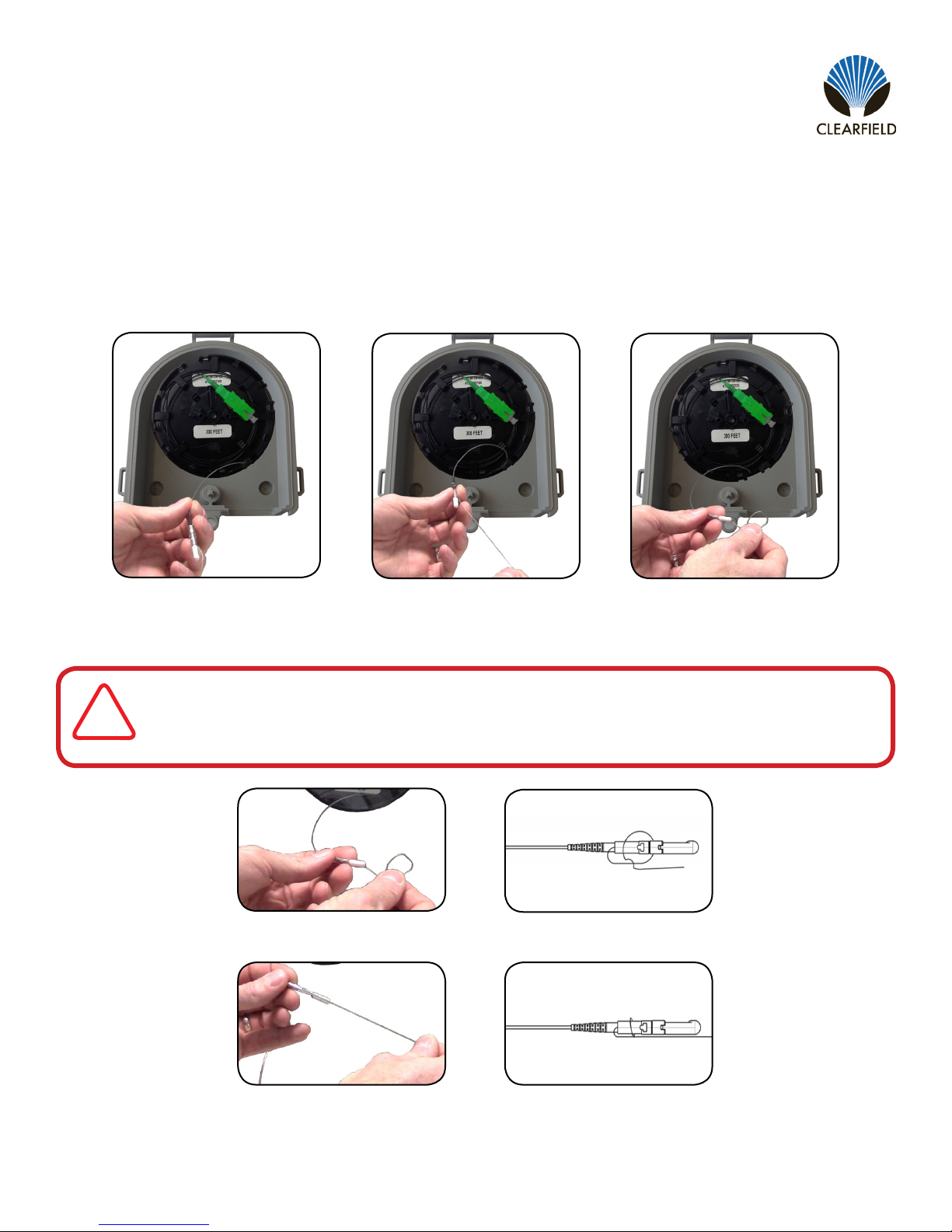

Step 3:Prepare Pullable SC Connector

Remove the Pullable SC Connector from the reel and remove protective tape (Figure 7). Find the

integrated pull string on the connector (Figure 8) and make a simple loop/half hitch in the pull string (Figure

Figure7 Figure8

Step 4:Tie Pull String to SC Connector

Loop the pull string around the rst notch on the metal crimp tube. (Figure 10 & Figure 11).

Thread the end of the pull string under itself using a half hitch knot and pull to tighten (Figure 12 & Figure 13).

Figure 9

Figure13

Figure10

Figure12

Figure11

!

IMPORTANT

7

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

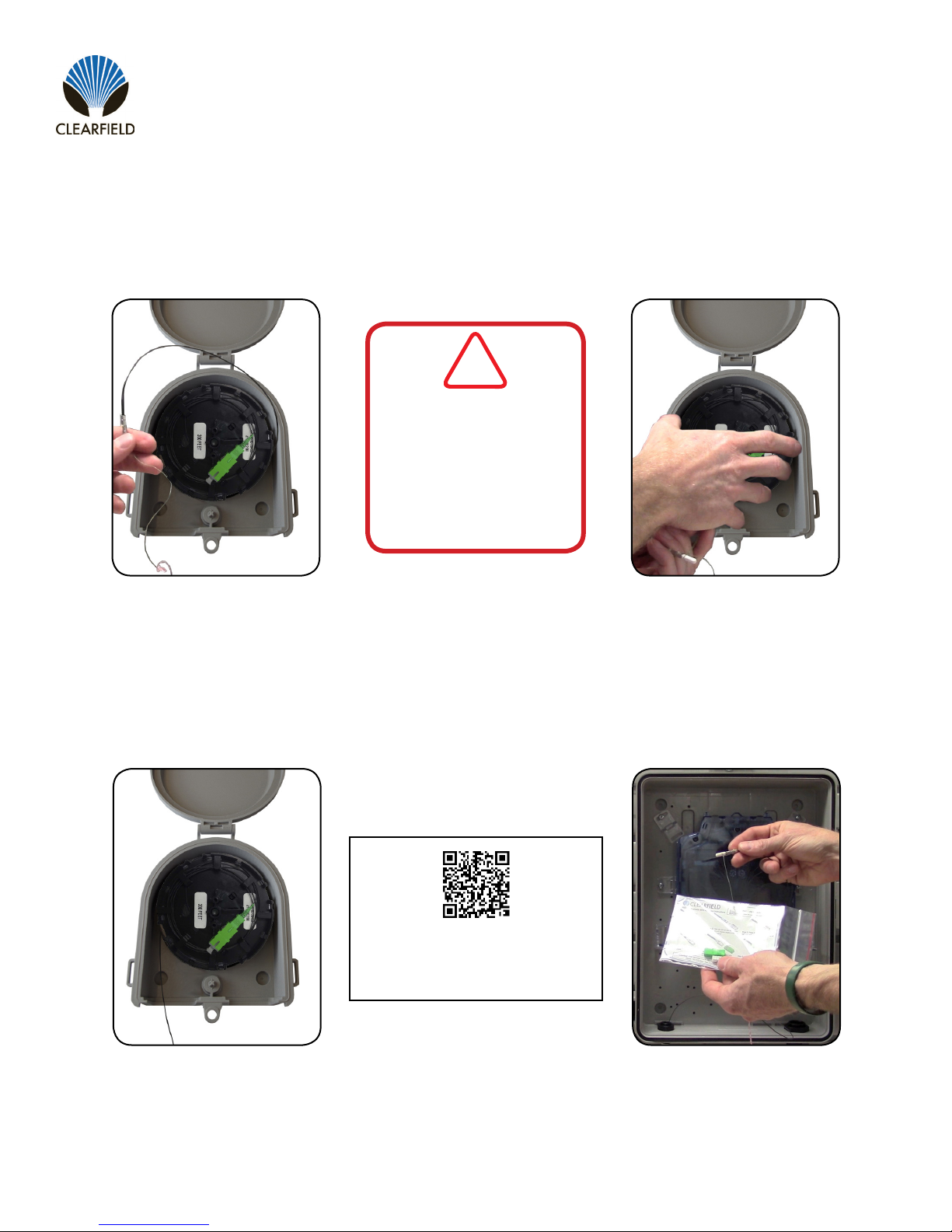

Step 5:Connect Pull Strings

Tie Connector Pull String to Duct Pull String

(Figure 14).

Figure14 Figure15

Step6:Unlock Deploy Reel

Pull out gently on Deploy Reel to unlock it from

the backpost (Figure 15).

Step7:Insert Connector

Insert Connector fully into duct before

pulling ber through. (Figure 16).

Figure16

Step8:PullFiberthroughDuct

Use the Duct Pull String to pull the

required length of ber through the

duct to the network access point.

Step 9:Assemble Connector End

Once pulled throught the duct,

assemble the FieldShield Connecter

following instructions provided with

the FieldShield Reel. (Figure 17).

Figure17

Watch the Installation Video

FieldShield SC Connector

www.clfd.net/media/deployreel.php

DO NOT use any type of

tape when tying the pull

string to the microduct pull

string. This will cause friction

and will result in blockage of

the microduct.

!

IMPORTANT

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

8

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

Conguration1:

Bottom: Empty Deploy Reel

Top: StrongFiber Delpoy Reel

(Figure 1).

Figure1

Congurations

The FieldShield YOURx-TAP can be used in the following congurations.

Figure2 Figure 3

Conguration2:

Bottom: StrongFiber Deploy Reel

Top: StrongFiber Delpoy Reel

(Figure 2).

Conguration3:

Bottom: StrongFiber Deploy Reel

Top: FLEXdrop Slack Reel

(Figure 3).

Top Deploy Reel Installation

Figure2

Step2:Mount Deploy Reel

Align center hole on Deploy Reel with Back Post.

Press Deploy Reel onto Back Post (Figure 2).

Figure2

Step1:Install Back Post

Use a Philips Screwdriver to attach the back post

to bottom Deploy Reel using the provided self

taping screws (Figure 1).

Note: Back post cannot be secured to FLEXdrop

slack reel.

9

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

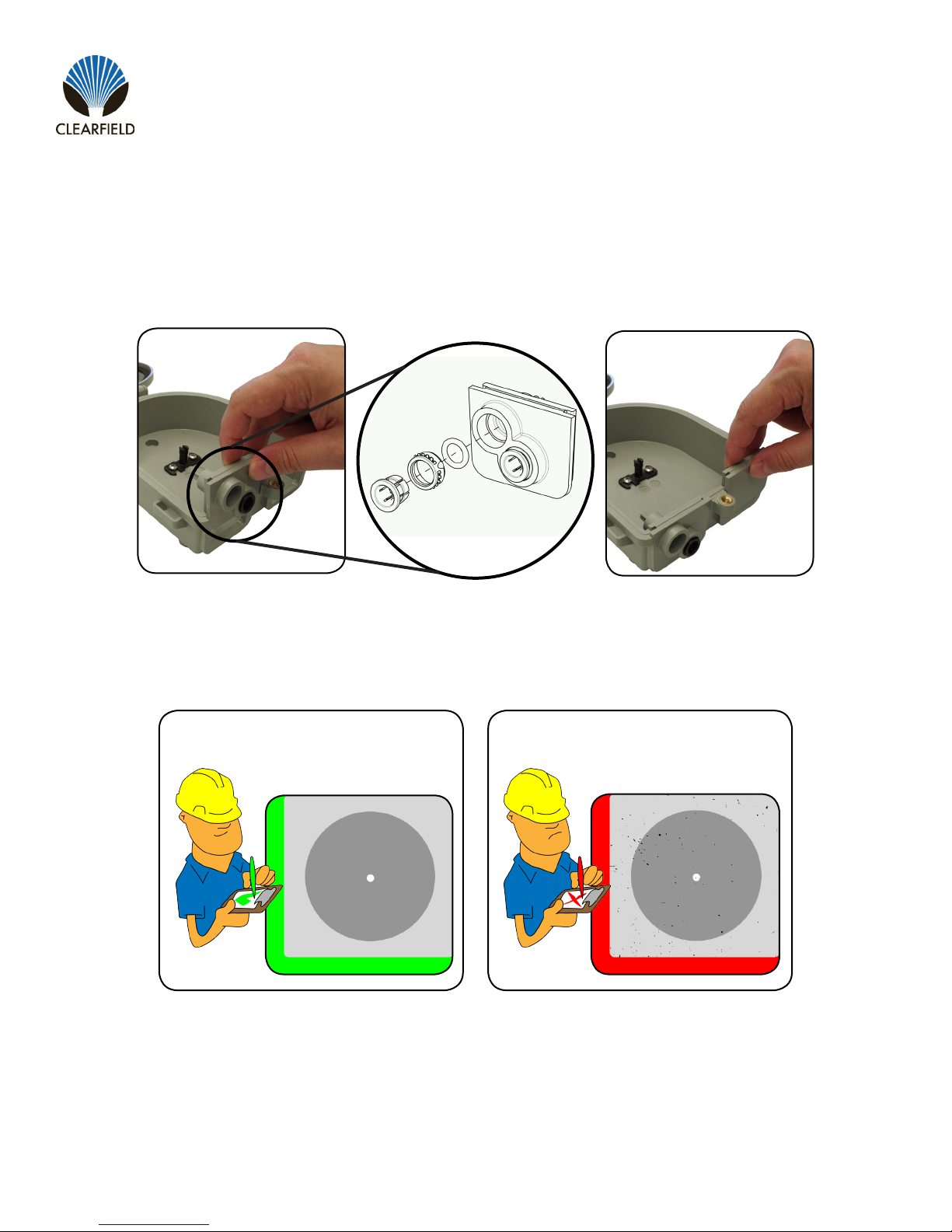

Figure1

Installing Bulkheads

The YOURx-TAP is shipped with Qty (1) Cable Entrance Bulkhead (Figure 1) Qty (1) Blank Bulkhead (Figure 2). Additional

Bulkheads are available for custom congurations.

Figure2

INSPECT BEFORE YOU CONNECT!

CLEAN CONNECTOR DIRTY CONNECTOR

SEE PAGE 13 FOR RECOMMENDED CLEANING PROCEDURES

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

10

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

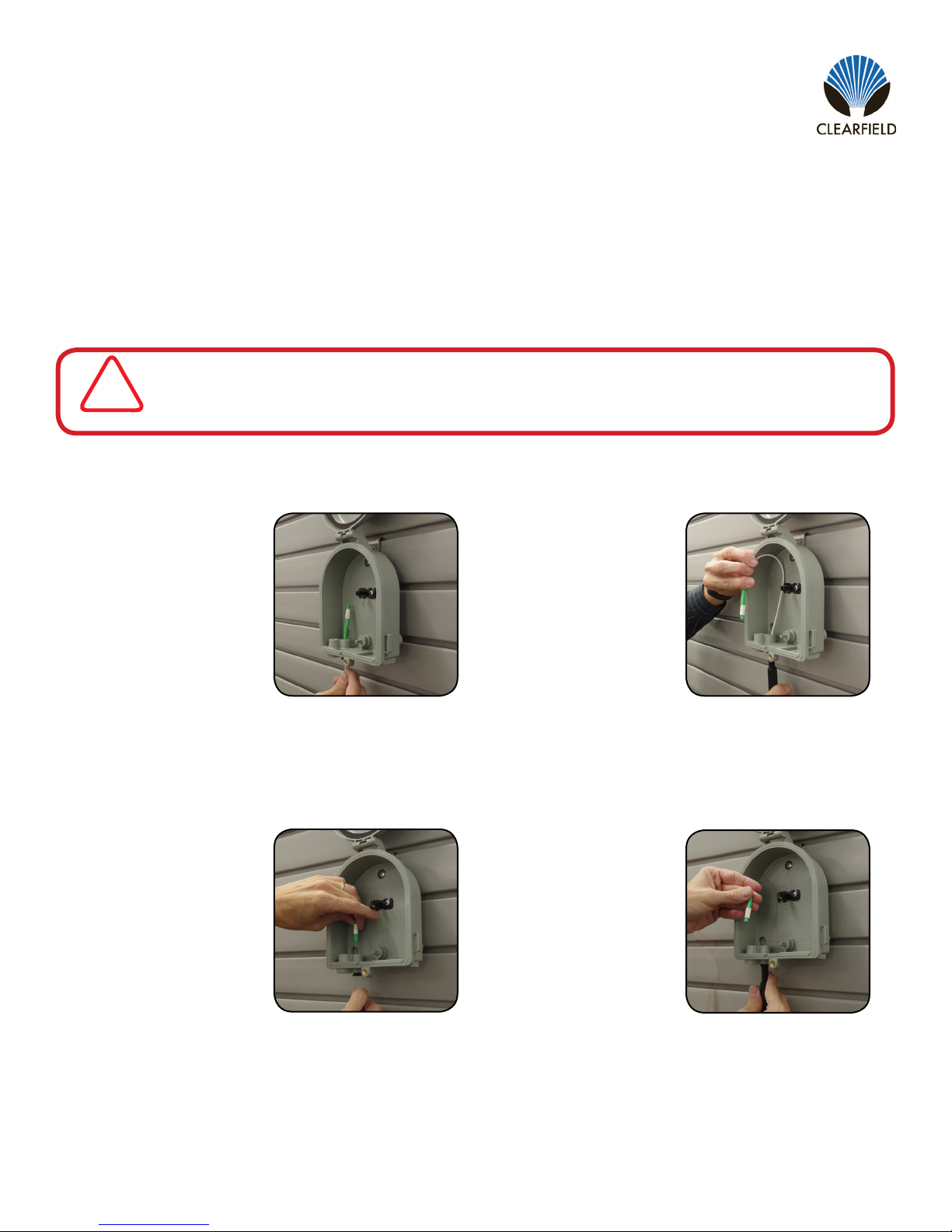

Figure1

Step1:Feed through

Port

Guide preconnectorized

ber (unassembled) into

YOURx-TAP port and pull

until hardened connector

reaches port. (Figure1).

Step2:Seat Connector

Once ber is through,

seat connector into port.

(Figure2).

Figure2

EnteringandExitingFiberCongurations

Fiber can enter or exit the YOURx-TAP through the removable bulkheads at the bottom of the unit, or through the pass

through port at the back ot the unit.

When entering the YOURx-TAP DO NOT assemble SC Connector Outer Housing until ber has been

passed through the port. Fully connectorized ber will not pass through port.

!

IMPORTANT

Figure1 Figure2

FieldShield Flat-SC

FieldShield D-ROP

Step1:Feed through

Port

Guide preconnectorized

ber (unassembled) into

YOURx-TAP port and pull

until hardened connector

reaches port. (Figure1).

Step2:Seat Connector

Once ber is through,

seat connector into port.

(Figure2).

11

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

Figure1 Figure2

Figure1 Figure2

FieldShield FLEXdrop or FieldShield

FieldShield StrongFiber

Step1:Install Duct

Seat microduct into

YOURx-TAP port.

(Figure1).

Step2:Feed through

Duct

Push or pull ber

(unassembled) through

the duct and into the

YOURx TAP. (Figure2).

Step1:Install Duct

Seat microduct into

YOURx-TAP port and tie

StrongFiber pull string to

duct pullstring with double

knot. (Figure1).

Step2:Feed through

Duct

Release deploy reel and

pull ber (unassembled)

out through the duct and

into the YOURx TAP.

(Figure2).

Storing Slack Fiber on the TAP Slack Reel

Up to 50 feet of FieldShield or FieldShield FLEXdrop can be stored on the TAP Slack Reel.

Figure1 Figure2

Step1:Coil Fiber

Once ber has been

terminated in the Strong-

Fiber Deploy Reel, wrap

excess ber around the

the TAP Slack Reel in a

counter-clockwise motion,

making sure not to intro-

duce a twist to the ber.

(Figure1).

Step2:Mount Reel

Mount TAP Slack Reel

onto back post attached

to StrongFiber Deploy

Reel. (Figure2).

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

12

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

Part Number Description

018664 FlexPort Plug, ller for 10mm Cartridges

Part Number Description

FSX-10MM EXPANSION KIT Bag of four 10mm FlexPorts and 10mm Plugs

Part Number Description

016280 FlexPort, Push to Connect, 10mm

Part Number Description

016280 FlexPort, Push to Connect, 10mm

FS-GBLOCK-10MM-04

Description

Fits around ber onto duct, providing gas-tight protection. The FS-GBLOCK-10MM-04

includes 4 - 10mm gas blockers and 4 - 3” of 10mm FieldShield Microduct.

Pre-ConguredPartNumbers

FSX-10mmExpansionKit

Description

Bag of 4 individual FlexPorts (016280) and 4 - 10mm FlexPorts plugs (018664) for securing

10mm microduct into the YOURx-TAP.

Pre-ConguredPartNumbers

10MMPlug

Description

FieldShield FlexPort ller plug for 10mm into the YOURx-TAP.

Application: Used for sealing FlexPort holes if plug on the inside is removed.

Pre-ConguredPartNumbers

FieldShield FlexPort

Description

Individual FieldShield FlexPort for securing 10mm or 14mm microduct into the FieldShield

YOURx-Terminal or YOURx-TAP. Includes the outer coupler, inner housing and O-ring.

Pre-ConguredPartNumbers

YOURx-TAP Accessories

13

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

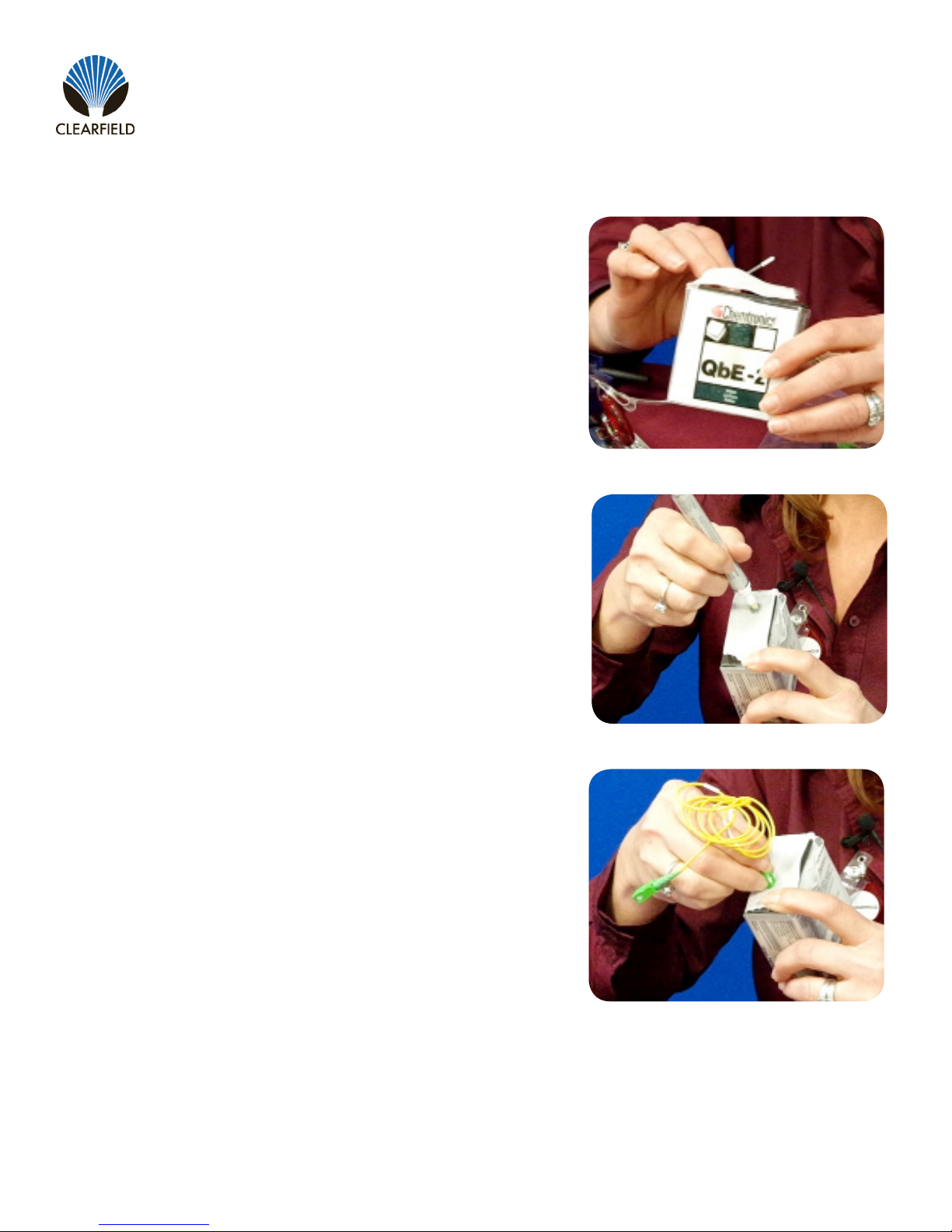

Whether factory terminated or eld spliced, clean connectors are essential

for proper system operation. Even the smallest dust particle can cause

transmission problems, so for optimal network performance, inspect and if

necessary, clean all connectors and adapters prior to mating.

I.B.Y.C…InspectBeforeYouConnect!

ALWAYS inspect the connector rst thing with a clean ber scope inspect

the pair. Three types of contamination require different cleaning techniques.

The use of Chemtronics end face and bulkhead cleaning products and

techniques ensures a clean end face, no matter the type of contamination.

These are Cleareld recommended products/application. Use the product

you feel will complete your cleaning procedures. Create a “best practice” for

your company and follow those procedures.

**NOTE: It is NOT recommended to use IPA to clean the end-face.

Cleaningtheend-face…butnotjusttheend-face

• Place one wiping paper on QbE-2 FiberSafe™ Cleaning Platen. Figure1

• Apply small amount of precision cleaner (about 1” in diameter) with Elec-

tro-Wash MX pen on to one end of the wipe. Figure2

• Hold end face 90 degree. Adjust for APC connection by slightly tilting the

container or end face. Angle is correct when no drag is left on the end face.

Figure 3

• Draw end face from wet to dry part of the wipe 3 times. Use just enough

pressure to ensure complete contact between end face and the wipe.

DO NOT retrace previous step.

Figure 1

Figure 2

Figure 3

Connector Cleaning Procedure

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

14

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

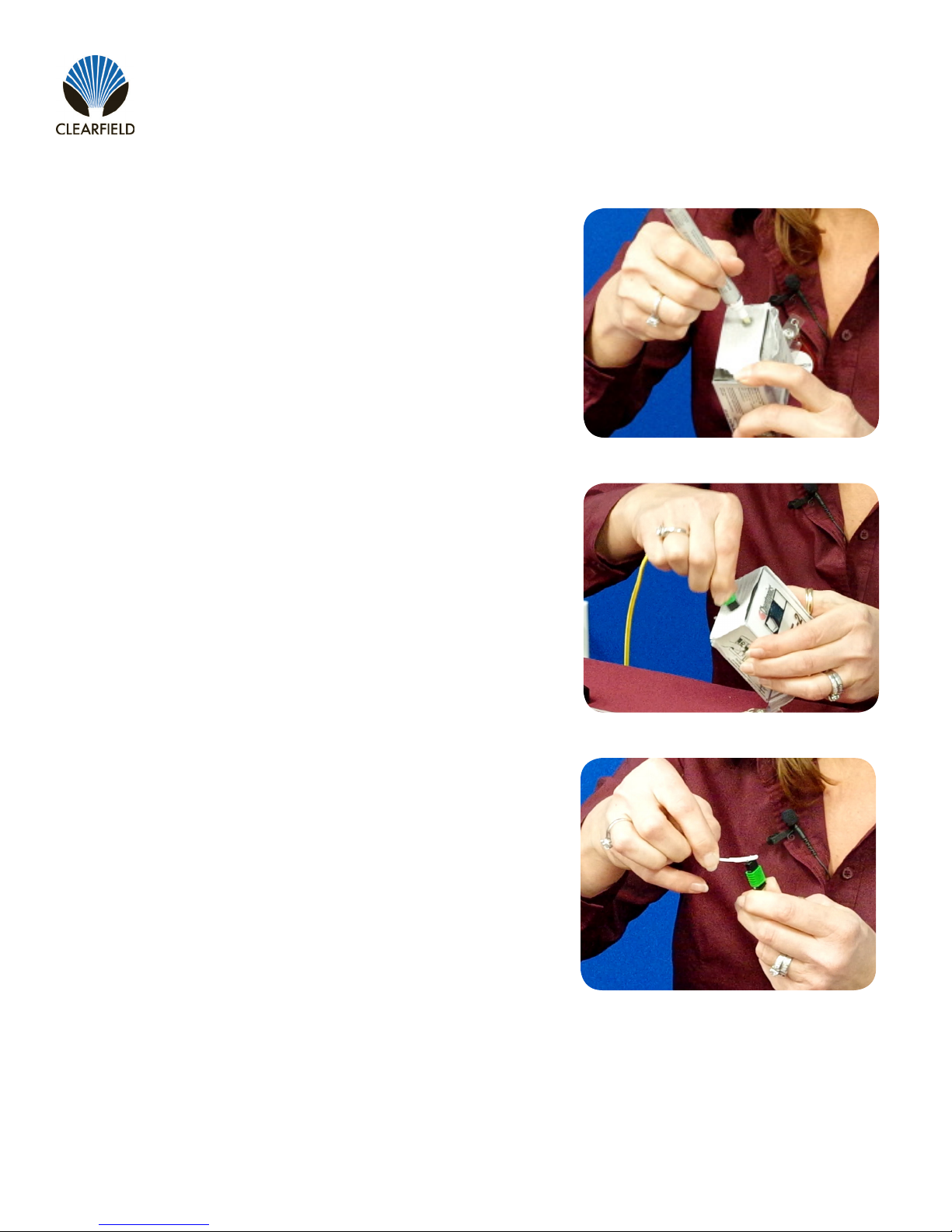

• CLEAN THE FERRULE…Lightly moisten the ber optic swab

(2.5mm/38542F or 1.25mm/38040) by spotting a small amount (about

1”) of Electro-Wash PX or Electro-Wash MX pen onto the Qbe. Hold the

swab, 1 side down to the wetted area and hold for a count of 1-2-3-4-5.

Figure 4

• Insert swab into side of ferrule, wet side to the ceramic ferrule and

circle around 2-3 times and remove. Turn swab to dry side and repeat.

Figure 5

Cleaning the mate through a bulkhead adapter AND the

adapteritself!

• Lightly moisten the ber optic swab(2.5mm/38542F or 1.25mm/38040)

by spotting a small amount (about 1”) of Electro-Wash PX or Elec-

tro-Wash MX pen onto the Qbe. Hold the tip of the swab onto the wetted

area and hold for a count of 1-2-3-4-5.

• Insert the swab into the adapter to the connector, press lightly against

the connector, twist 2-3 times, remove and discard.

• Dry with a second dry swab.

• Inspect (re-clean if necessary) and test for signal strength.

• Use additional swabs to clean inside the actual adapter. Moisten swab,

like above, insert through hole and remove while twisting. Figure6

Figure 4

Figure 5

Figure 6

15

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

Cleaning an MPO/MTP Connector

Female Connector

• Place one wiping paper on QbE-2 FiberSafe™ Cleaning Platen and

apply small amount of precision cleaner (about 1” in diameter) with Elec-

tro-Wash MX pen on to one end of the wipe. Figure1

• Hold end face 90 degree. Adjust for APC connection by slightly tilting

the container or end face. Angle is correct when no drag is left on the end

face. Figure2

Male Connector

• Lightly moisten the ber optic swab (CC505F) like above, moistening 1

side.

• Place swab, wet side down at one end of connector end-face and draw

across in a diagonal sweep (ie: from ber 1 up and across to ber 12).

Turn swab over to dry and draw back from ber 12 to ber 1. Figure 3

BEFORE cleaning any connector…be sure you know what type of con-

taminate you are cleaning…dry? Fluidic?...All the available products are

good, it’s the process that you need to be aware of. Using a dry cleaning

method to clean “dirt” can lead to scratching of the end-face. Learn the

process of cleaning properly!

Figure 1

Figure 2

Figure 3

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

16

FieldShield YOURx-TAP

Installation Manual _________________________________________________________

Manual 018446 REV A - AUG 2017

Standard Warranty

Cleareld warrants to the original purchaser of the Product sold hereunder is free from defects in material and workmanship under normal use and

service, subject to exceptions stated herein. Product purchased is warranted as follows: Cleareld designed and branded Products are warranted for

ve (5) years: Products manufactured by Cleareld to customer prints and/or specications are warranted for one (1) year; and any Product Clear-

eld acquires from or through a third-party manufacturer or distributor and resells to Customer as the original customer will carry the manufacturer’s

pass-through warranty, if any. In all cases, the warranty period commences on the date of shipment to the original purchaser.

Warranty Claim Procedure

If any Product purchased from Cleareld is found defective under the above warranty, the following basic procedure must be followed:

1. Customer must contact Cleareld and obtain a Return Materials Authorization

2. Following authorization, the Customer ships the product-freight collect-to Cleareld’s manufacturing facility

3. Cleareld shall repair or replace the defective Product at its sole option and discretion, and return the repaired or replacement Product to Cus-

tomer’s site, freight prepaid

Note: If the Product is not found to be defective at Cleareld, the product will be returned to the Customer and the customer billed for freight in both

directions.

Limitations of Warranty

Correction of defects by repair or replacement, at the option of Cleareld Inc, shall constitute the exclusive sole remedy for a breach of this limited

warranty. Cleareld shall not be liable under any circumstances for any special, consequential, incidental, punitive, or exemplary damages arising

out of or in any way connected with the product or with agreement to sell product to buyer, including, but not limited to damages for lost prots, loss

of use, or for any damages or sums paid by buyer to third parties. The foregoing limitation of liability shall apply whether the claim is based upon

principles of contract, warranty, negligence or other tort, breach of statutory duty, principles of indemnity or contribution, the failure of any limited or

exclusive remedy to achieve its essential purpose, or otherwise.

Cleareld will not be responsible for any labor or materials costs associated with installation or incorporation of Cleareld products at customer sites,

including any costs of alteration, replacement or defective product, or any eld repairs.

Other Limitations

1. Cleareld assumes no warranty liability regarding defects caused by:

2. Customer’s modication of Product, excepting installation activities described in Cleareld documentation

3. Customer re-packaging of Product for shipment to third parties or destinations other than those originally shipped to by Cleareld, or any de-

fects suffered during shipping where the Product has been re-packaged

4. Customer’s installation or maintenance, excepting activities described in and performed in accordance with Cleareld documentation

5. Customer’s improper or negligent use or application of Product

6. Other causes external to the Product, including but not limited to accidents, catastrophe, acts of God, government action, war, riot, strikes, civil

commotion, sovereign conduct, or the acts or conduct of any person or persons not party to or associated with Cleareld

17

FieldShield YOURx-TAP

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018446 REV A - AUG 2017

Proprietary Notice

About FieldShield Product Line Application

Information contained in this document is copyrighted by Cleareld, Inc. and may not be duplicated in full or part by any person without prior written

approval of Cleareld, Inc.

Its purpose is to provide the user with adequately detailed documentation to efciently install the equipment supplied. Every effort has been made to

keep the information contained in this document current and accurate as of the date of publication or revision.

However, no guarantee is given or implied that the document is error free or that it is accurate with regard to any specication.

Technical Support

Cleareld, Inc. can be contacted for any issues that arise with the supplied product.

If you need to return the supplied product, you must contact the Cleareld, Inc. Customer Service Department to request a Returned Materials

Authorization (RMA) number.

Cleareld, Inc.

7050 Winnetka Ave N

Minneapolis, MN 55428

Toll Free: 800.422.2537

Phone: 763.476.6866

Fax: 763.475.8457

Table of contents

Other Clearfield Cable Box manuals

Popular Cable Box manuals by other brands

VISSEM Electronics

VISSEM Electronics Opticube VSOF-OTB-E manual

KS Tools

KS Tools efuturo Wallbox operating instructions

Sanus

Sanus SA808 instruction manual

Minebea Intec

Minebea Intec PR 6130/68S installation manual

Pentair

Pentair Raychem JBS-100-E manual

Sanus Systems

Sanus Systems ELM301 quick start guide