viii 750-437

Q Series Full Modulation

Q Series Spare Parts List Continued

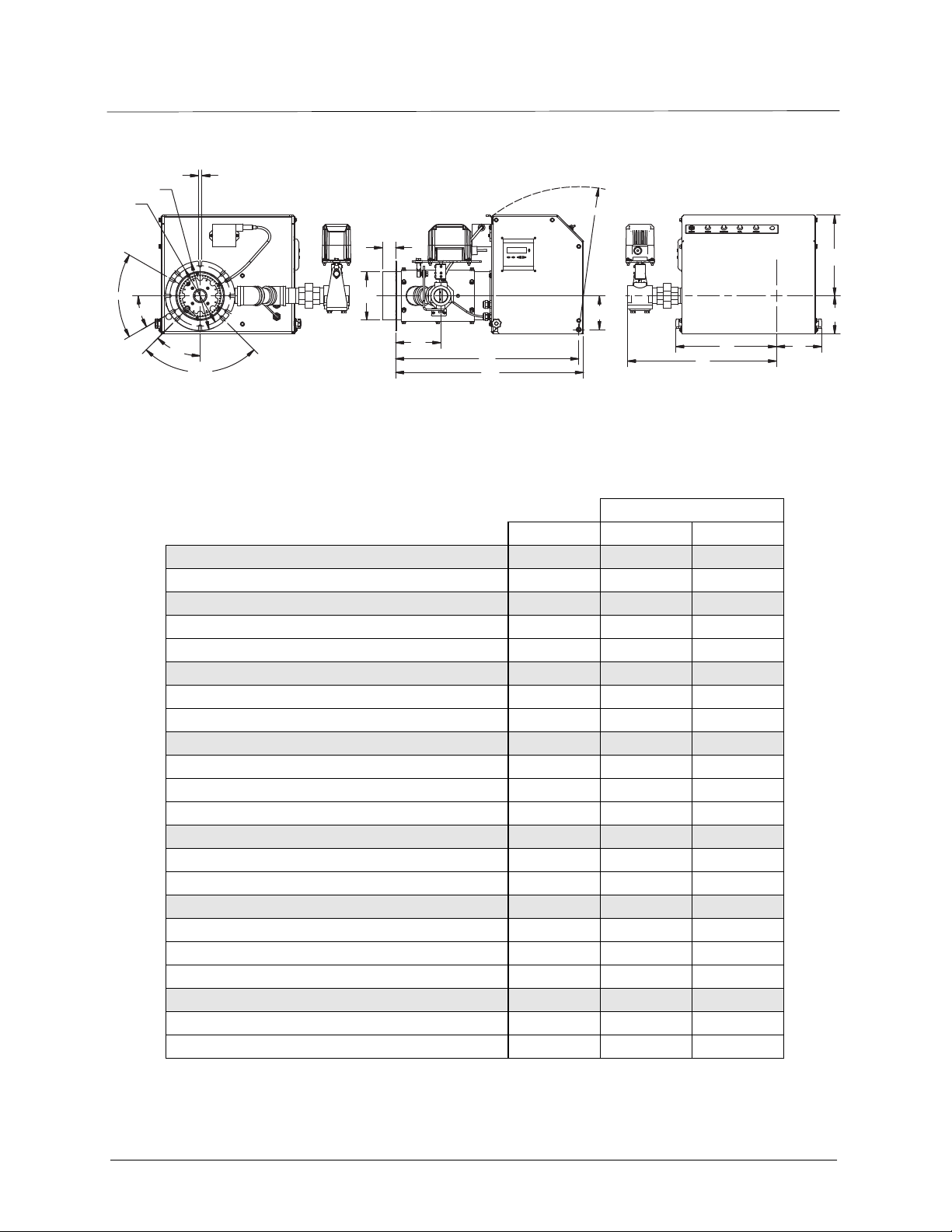

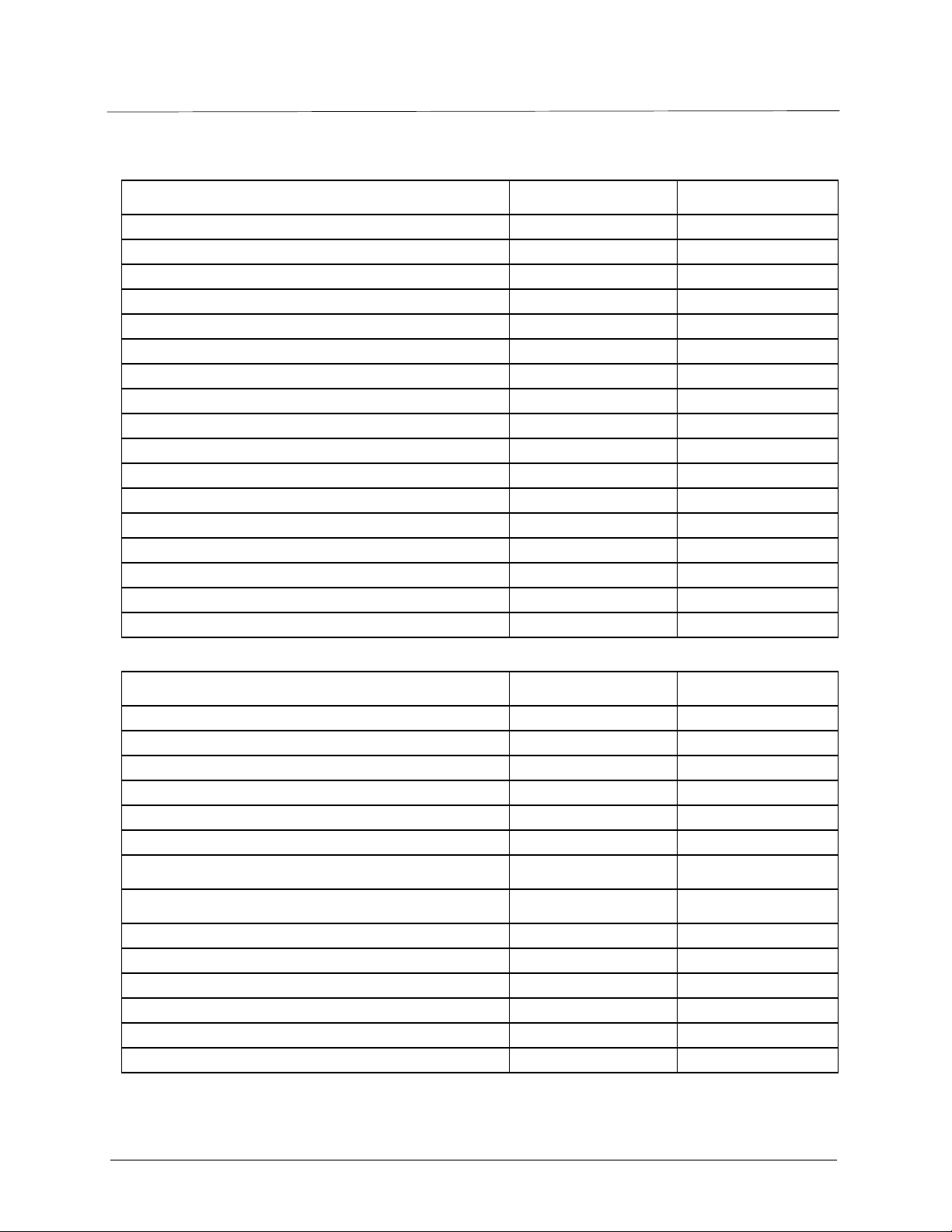

PART DESCRIPTION - GAS TRAIN COMPONENTS GAS TRAIN OPTION PART NUMBER

Regulator, Maxitrol RV 1 1/2” All Standard Pressure 817-00622

Valve, Gas Diaphragm 1 1/2” All Standard Pressure 940-01090

Bleed, Used with Gas Diaphragm Standard on All 940-01373

Valve, Gas Solenoid 1 1/2” All Standard Pressure 235-00368-000

Ball Valves 1 1/2” All Standard Pressure 941-00127

Regulator, Maxitrol RV 2” All Low Pressure 817-00617

Valve, Gas Diaphragm 2” All Low Pressure 940-01108

Bleed, Used with Gas Diaphragm Standard on All 940-01373

Valve, Gas Solenoid 2” All Low Pressure 235-00369-000

Ball Valves 2” All Low Pressure 941-00128

Regulator, Maxitrol 210 1” All High Pressure 817-00674

Valve, Gas Diaphragm 1” All High Pressure 940-01103

Bleed, Used with Gas Diaphragm Standard on All 940-01373

Valve, Gas Solenoid 1” All High Pressure 940-01191

Ball Valves 1” All High Pressure 941-00594

Gas Pressure Switch, High Ventless Standard on All 817-00977

Gas Pressure Switch, Low Ventless Standard on All 817-00876

PART DESCRIPTION - AIR INLET ORIFICE PLATE BURNER SIZE PART NUMBER

550 MBTU Burner (1.5” diameter) Q6 059-11448-000

750 MBTU Burner (1.8” diameter) Q6 059-11449-000

1000 MBTU Burner (2.25” diameter) Q6 059-11450-000

1300 MBTU Burner (2.95” diameter) Q6 059-11452-000

1750 MBTU Burner (3.45” diameter) Q8 059-11457-000

2000 MBTU Burner (3.8” diameter) Q8 059-11458-000

PART DESCRIPTION - DUCTED AIR INLET PARTS BURNER SIZE PART NUMBER

Instruction Drawing Q6 880-06261-000

Ducted-Air Adapter, 4" ID Q6 001-01680-000

Panel Side Plate With Ducted-Air Adapter Cutout Q6 136-04096-000

Instruction Drawing Q8 880-06262-000

Ducted-Air Adapter, 6" ID Q8 001-01681-000

Panel Side Plate With Ducted-Air Adapter Cutout Q8 136-04097-000