4

Safety Recommendations

•Tasks should be performed in such a manner that the

wrists are maintained in a neutral position, which is

not flexed, hyperextended, or turned side to side

•Stressful postures should be avoided —select a tool

appropriate for the job and work location

•Avoid highly repetitive movements of hands and

wrists, and continuous vibration exposure (after each

period of operation, exercise to increase blood circu-

lation)

•Use quality abrasive wheels

•Keep tool well maintained and replace worn parts

Work gloves with vibration reducing liners and wrist supports are

available from some manufacturers of industrial work gloves.

Tool wraps and grips are also available from a number of

different manufacturers. These gloves, wraps, and wrist sup-

ports are designed to reduce and moderate the effects of

extended vibration exposure and repetitive wrist trauma. Since

they vary widely in design, material, thickness, vibration reduc-

tion, and wrist support qualities, it is recommended that the

glove, tool wrap, or wrist support manufacturer be consulted for

items designed for your specific application. WARNING! Proper

fit of gloves is important. Improperly fitted gloves may

restrict blood flow to the fingers and can substantially

reduce grip strength.

USE QUALITY ABRASIVE WHEELS

The primary source of vibration when using a portable grinder is

an abrasive wheel that is out of balance, out of round, untrue, or

possibly any combination of all three.

The use of quality abrasive wheels which are well balanced,

round, and true is highly recommended as they have been found

to significantly reduce vibration. Some abrasive wheels lose

their balance, roundness, and trueness as they wear from use.

Because of the abusive nature of the vibration caused by out of

balance, out of round, and untrue condition of some abrasive

wheels, it is felt that these wheels are more susceptible to failure.

Excessive vibration may signal eminent wheel failure. Flat

spotting of the abrasive wheel, caused by grinding the wheel to

a stop after the power has been shut off can result in changes to

the balance and shape of the wheel. Be sure the grinding wheel

has stopped before setting the tool down. Set the tool in a tool

rest or tool holder when not in use.

Some individuals may be susceptible to disorders of the hands

and arms when performing tasks consisting of highly repetitive

motions and/or exposure to extended vibration. Cumulative

trauma disorders such as carpal tunnel syndrome and tendoni-

tis may be caused or aggravated by repetitious, forceful exer-

tions of the hands and arms. Vibration may contribute to a

condition called Raynaud's Syndrome. These disorders de-

velop gradually over periods of weeks, months, and years. It is

presently unknown to what extent exposure to vibrations or

repetitive motions may contribute to the disorders. Hereditary

factors, vasculatory or circulatory problems, exposure to cold

and dampness, diet, smoking and work practices are thought

to contribute to the conditions. Any tool operator should be aware

of the following warning signs and symptoms so that a problem

can be addressed before it becomes a debilitating injury. Any

user suffering prolonged symptoms of tingling, numbness,

blanching of fingers, clumsiness or weakened grip, nocturnal

pain in the hand, or any other disorder of the shoulders, arms,

wrists, or fingers is advised to consult a physician. If it is

determined that the symptoms are job related or aggravated by

movements and postures dictated by the job design, it may be

necessary for the employer to take steps to prevent further

occurrences. These steps might include, but are not limited to,

repositioning the workpiece or redesigning the workstation,

reassigning workers to other jobs, rotating jobs, changing work

pace, and/or changing the type of tool used so as to minimize

stress on the operator. Some tasks may require more than one

type of tool to obtain the optimum operator/tool/task relation-

ship.

The following suggestions will help reduce or moderate the

effects of repetitive work motions and/or extended vibration

exposure:

•Use a minimum hand grip force consistent with proper

control and safe operation

•Keep body and hands warm and dry (cold weather is

reported to be a major factor contributing to Raynaud's

Syndrome)

•Avoid anything that inhibits blood circulation

—Smoking Tobacco (another contributing

factor)

—Cold Temperatures

—Certain Drugs

WARNING!

Repetitive work motions and/or vibration

can cause injury to hands and arms.

Use minimum hand grip force.

Keep body and hands warm and dry.

Avoid anything that inhibits blood curculation.

Avoid continuous vibration exposure.

Keep wrists straight.

Avoid repeated bending of wrists and hands.

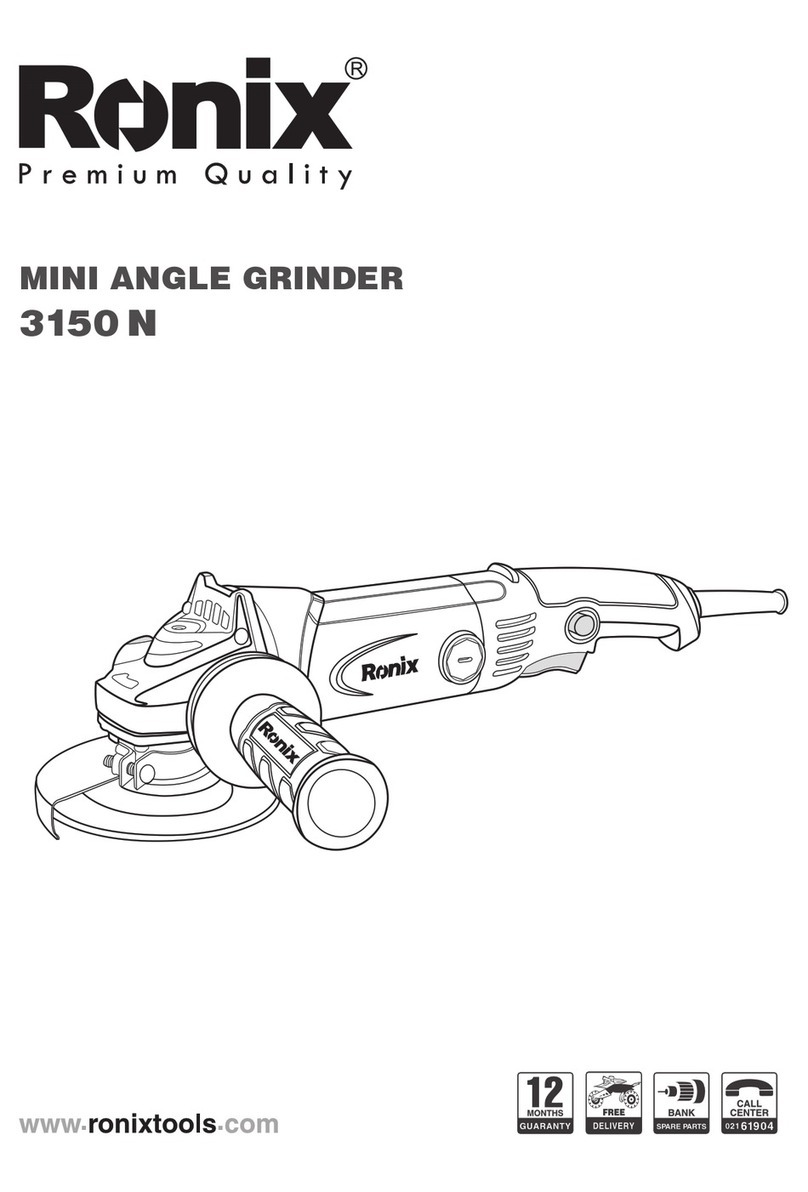

Extension Neutral Flexion Radial Deviation Neutral Ulnar Deviation

Avoid Avoid Avoid

OK Avoid OK