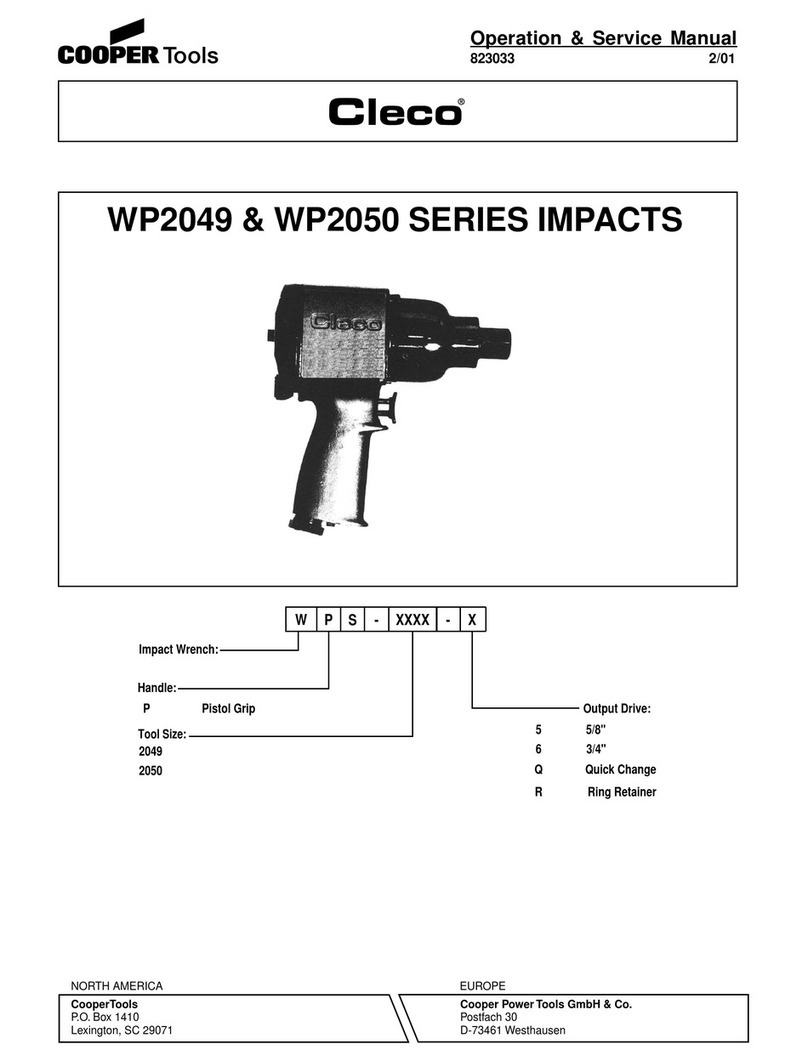

Cleco WP-2060B SERIES IMPACTS Installation and operating instructions

1

Operation & Service Manual

823034 2/01

WP-2059 & 2060B SERIES IMPACTS

-

Concept

Second

B

Tool Generation:

2059 & 2060

Tool Size:

W

Pistol Grip

Impact Wrench:

P

Handle:

-- XXXXXPXX

Spline Drive (No. 5 Spline)

Quick Change

S

Q

*8 1"

Optional Equipment:

6" Extended Spindle

*6E 3" Extended Spindle

*3E

Output Drive:

*6 3/4"

XX

NORTH AMERICA EUROPE

CooperTools

P.O. Box 1410

Lexington, SC 29071

Cooper PowerTools GmbH & Co.

Postfach 30

D-73461 Westhausen

2

SafetyRecommendations

hoseofaccumulateddustandmoisture.Beforeremovingatoolfrom

service or changing sockets, make sure the air line is shut off and

drained of air. This will prevent the tool from operating if the throttle

is accidently engaged.

Neverusetheairhoseforsupporting,lifting,orloweringthetool.Use

a safety line or cable on the tool when working in elevated areas.

Tools with exposed throttles should not be used where obstructions

canhold thethrottle inthe “on”position. Animpact wrenchoperating

in reverse will move backwards as a nut is removed and can trap an

operator's hand, making it difficult to release an outside trigger.

Inside trigger or pistol grip tools are advised for close quarter

operation.

Onlyusesocketsdesignedforusewithimpactwrenches.Never use

a hand tool socket on an impact wrench. Hand tool sockets can

break, resulting in a hazard from flying pieces. Inspect sockets,

retainers, and drives regularly for wear or damage, and replace as

necessary. Worn sockets reduce power, cause drive wear, and

increase the chance for breakage and should not be used.

Some individuals may be susceptible to disorders of the hands and

arms when performing tasks consisting of highly repetitive motions

and/orexposuretoextendedvibration.Cumulativetraumadisorders

such as carpal tunnel syndrome and tendonitis may be caused or

aggravated by repetitious, forceful exertions of the hands and arms.

Vibrationmay contributeto acondition calledRaynaud'sSyndrome.

These disorders develop gradually over periods of weeks, months,

and years. It is presently unknown to what extent exposure to

vibrations or repetitive motions may contribute to the disorders.

Hereditary factors, vascular or circulatory problems, exposure to

coldanddampness,diet,smoking andwork practicesarethoughtto

contribute to the conditions.

For your safety and the safety of others, read and understand the

safety recommendations before operating an impact wrench.

Always wear protective equipment and clothing.

For additional infor-

mation on eye pro-

tection,refer toFed-

eral OSHA Regula-

tions, 29 CFR, Sec-

tion 1910.133, Eye

andFaceProtection,

and ANSI Z87.1, Occupational and Educational Eye and Face

Protection. This standard is available from the American National

StandardsInstitute,Inc.,11West42ndStreet,NewYork,NY10036.

Hearingprotectionis

recommended in

high noise areas

(above 85 dBA).

Close proximity of

additional tools, re-

flective surfaces,

process noises, and resonant structures can substantially contrib-

ute to the sound level experienced by the operator. Proper hearing

conservation measures, including annual audiograms and training

in the use and fit of hearing protection devices may be necessary.

For additional information on hearing protection, refer to Federal

OSHA Regulations, 29 CFR, Section 1910.95, Occupational Noise

Exposure, and American National Standards Institute, ANSI S12.6,

Hearing Protectors.

• Gloves and other protective clothing should be worn as

required, unless they create a greater hazard.

• Do not wear loose fitting clothing, or clothing that may

restrict movement, become entangled or in any way

interfere with the safe operation of the impact.

Clecoimpactwrenches are designedtooperate on 90 psig(6.2 bar)

maximum air pressure. If the tool is properly sized and applied,

higher air pressure is unnecessary. Excessive air pressure in-

creases the loads and stresses on the tool parts, sockets, and

fasteners and may result in breakage. Installation of a filter-regula-

tor-lubricator in the air supply line ahead of the tool is highly

recommended.

Before the tool is connected to the air supply, check the throttle for

proper operation (i.e., throttle moves freely and returns to closed

position). Being careful not endanger adjacent personnel, clear air

Repetitive work motions and/or vibration

may cause injury to hands and arms.

Use minimum hand grip force consistent

with proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

WARNING

!

Avoid repeated bending of wrists and hands.

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

3

SafetyRecommendations

widely in design, material, vibration reduction, and wrist support

qualities, it is recommended that the glove manufacturer be con-

sulted for gloves designed for your specific application. WARNING!

Proper fit of gloves is important. Improperly fitted gloves may

restrict blood flow to the fingers and can substantially reduce

grip strength.

Also note that various tool wraps are available from a number of

different manufacturers. Like gloves, these wraps are also intended

to reduce and moderate the effects of extended vibration exposure.

They vary widely in design, material, thickness, vibration reduction,

effectiveness, and durability, so consideration must be given to

choosing the proper wrap for the specific application.

Thisinformationisacompilationofgeneralsafetypracticesobtained

from various sources available at the date of production. However,

our company does not represent that every acceptable safety

practice is offered herein, or that abnormal or unusual circum-

stancesmaynotwarrantorrequireadditionalprocedures.Yourwork

may require additional specific safety procedures. Follow these

procedures as required by your company.

Warnings

The warnings found on these tools are an essential part of the

product. Warnings should be checked periodically for legibility.

Replace warnings when missing or when the information can no

longer be read. Replacements can be ordered as any spare part.

869976

For more information, see the latest edition of ANSI B186.1,

SafetyCodefor Portable AirTools,availablefrom the American

National Standards Institute, Inc., 11 West 42nd Street, New

York, NY 10036.

These operating instructions and service manual should ac-

companytoolifitissubsequentlysoldorownershipischanged.

Tool operators should be aware of the following warning signs and

symptoms so that a problem can be addressed before it becomes a

debilitating injury. Any user suffering prolonged symptoms of tin-

gling, numbness, blanching of fingers, clumsiness or weakened

grip, nocturnal pain in the hand, or any other disorder of the

shoulders, arms, wrists, or fingers is advised to consult a physician.

If it is determined that the symptoms are job related or aggravated

by movements and postures dictated by the job design, it may be

necessary for the employer to take steps to prevent further occur-

rences.Thesestepsmight include, but are not limited to,reposition-

ing the workpiece or redesigning the workstation, reassigning work-

erstootherjobs,rotatingjobs,changingworkpace,and/orchanging

the type of tool used so as to minimize stress on the operator. Some

tasks may require more than one type of tool to obtain the optimum

operator/tool/task relationship.

• Tasks should be performed in such a manner that the

wrists are maintained in a neutral position, which is not

flexed, hyperextended, or turned side to side.

• Stressful postures should be avoided. Select a tool appropri-

ate for the job and work location.

The following suggestions will help reduce or moderate the effects

of repetitive work motions and/or extended vibration exposure.

•Use a minimum hand grip force consistent with proper

control and safe operation

•Keep body and hands warm and dry

•Avoid anything that inhibits blood circulation

—Smoking Tobacco

—Cold Temperatures

—Certain Drugs

•Keep wrists as straight as possible

•Avoid highly repetitive movements of hands and wrists,

and continuous vibration exposure

Work gloves with vibration reducing liners and wrist supports are

availablefromsome manufacturers of industrial workgloves.These

glovesaredesigned toreduceandmoderatetheeffectsofextended

vibration exposure and repetitive wrist trauma. Since they vary

OVER

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

Read Operating Instructions carefully. Follow

the Safety Recommendations for your safety

and the safety of others.

Hearing protection is recommended in high noise

areas (above 85 dBA). Close proximity of other

tools, reflective surfaces, process noises, and

resonant structures can substantially contribute

to the sound level experienced by the user.

WARNING

!

Repetitive work motions and/or vibration

can cause injury to hands and arms.

Use minimum hand grip force consistent with

proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

Avoid repeated bending of wrists and hands.

Do not remove this tag until

the operator of this tool has

read these safety precautions.

BAD POSTURE

GOOD POSTURE

4

OPERATION

This tool is designed to operate on 90 psig (6.2 bar) air pressure,

measured at the tool's air inlet with the tool running, using a 3/8"

(10 mm) hose up to 8' (2.5m) in length. Installation of an auto-

matic in-line filter-regulator- lubricator is highly recommended to

supply the tool with clean lubricated air. This will keep the tool in

sustained operation and increase its service life.

The air hose should be cleared of accumulated dirt and moisture,

then 1 teaspoon (5ml) of 10W machine oil should be poured into

the tool's air inlet before connecting the hose to the tool.

IMPORTANT: If a quick-disconnect coupling is used with the tool.

it should be separated from the tool by a whip hose.

All tools and hoses should be installed by trained competent per-

sonnel. Hoses and fittings should be inspected regularly for wear

or damage and replaced if necessary.

The correct socket retainer should always be used on your tool.

Tools equipped with a square drive commonly use an "O"-ring

and pin for a socket retention. Tools equipped with a spline drive

have an integral socket retainer pin, and a screwdriver or similar

tool is used to depress the socket retainer plunger to either install

or remove the socket. Always use the socket retainer compo-

nents recommended by the socket manufacturer. Never substi-

tute wire, nails, or welding rods for retaining pins. Always use

sockets designed for impact wrench service.

The air supply to the tool should always be off when changing

sockets.

Sockets, retainers, and drives should be inspected regularly for

wear or damaged parts and the parts should be replaced if nec-

essary.

LUBRICATION

An automatic in-line filter-lubricator is recommended as it in-

creases tool life and keeps the tool in sustained operation. The

inlinelubricatorshould be regularlycheckedand filled with agood

grade of 10W machine oil. Proper adjustment of the in-line lubri-

cator is performed by placing a sheet of paper next to the ex-

haust ports and holding the throttle open approximately 30 sec-

onds. The lubricator is properly set when a light stain of oil col-

lects on the paper. Excessive amounts of oil should be avoided.

In the event an in-line lubricator is not used, the oil reservoir in

the handle should be utilized.

The oil reservoir marked "30W oil" should be checked periodi-

cally. The tool should be held with the rear of the tool up and the

two oil plugs should be removed. Fill the reservoir with 30W oil

until it comes out the other oil plug hole.

STORAGE

In the event that it becomes necessary to store the tool for an

extended period of time (overnight, weekend, etc.), it should re-

ceive a generous amount of lubrication at that time and again

when returned to service. The tool should be stored in a clean

and dry environment.

DISASSEMBLY

Loosen and remove the four (4) housing bolts. This will allow the

anvil housing and impact mechanism to be removed from the

front of the motor housing. The motor unit may now be slipped

out the rear of the motor housing.

Remove the anvil and anvil timing pin from the front of the cam

shaft. Clamp the hammer in a soft-jawed vise with the spring cap

up. Depress the spring cap and remove the two (2) spring keep-

ers. This will allow the cam shaft and related components to be

removed from the rear of the hammer.

Slip the two (2) bearing plates off the rotor and remove the cylin-

der and six (6) rotor blades.

Unscrewing the air inlet bushing will allow the throttle valve to be

removed for inspection of the throttle valve seal. Remove the air

inlet screen for cleaning and inspection. The throttle valve bush-

ing may be removed by drilling and tapping a 1/4-20 N.C. thread

and using a 1/4-20 bolt to remove the bushing.

REASSEMBLY

All parts should be cleaned in a solvent and inspected for wear or

damage. If rotor blades measure less than 11/32" (8.7mm) on

either end they should be replaced. Replace blade if less than

11/32" (8.7mm) on either end.

Rotor bearings should be replaced if they feel rough or show ex-

cessive looseness. Rotor shaft seals and the anvil seal should

be replaced if they are badly worn or are no longer flexible .

IMPORTANT NOTE: During reassembly of the WP-2059 motor,

the blue coded bearing plate, No. 869745, is assembled to the

rear of the motor. During reassembly of the WP-2060B motor,

the blue coded bearing plate, No. 869745, is assembled to the

front of the motor.

Clean the bearing plates and anvil housing with a solvent and

coat the seal bores with " PERMATEX "Aviation Form-a-gasket

#3H. Allow to air dry at least four (4) minutes before pressing in

the seals. Press the rotor shaft seals into the bearing plates with

their "lips" facing outward (visible after assembly). Press the an-

vil seal into the anvil housing with its "lip" toward the rear of the

housing ("lip" not visible after assembly).

All impact mechanism parts should receive a thin coating of 30W

oil before reassembly. Insert the cam timing pin into the recess

located on the small O.D. of the cam and then install the cam and

pin into the rear of the hammer. Slip the cam shaft through the

cam and assemble the hammer spring and spring cap to the front

of the cam shaft. Depress the spring cap and insert the two (2)

spring keepers into the groove on the cam shaft. After assembly

of the complete tool, the tool should be held with the rear of the

tool up and 1-1/4 fluid ounces (40ml) of 30W oil should be added

to 30W oil fill hole. A few drops of 10W machine oil should be

poured into the air inlet of the tool to ensure lubrication of the

motor parts as soon as air is applied.

All tools should be tested after repair or replacement of parts to

ensure that they are functioning properly.

5

The complete spline drive anvil can be purchased as a subassembly using part no 861024

PART NO.

842394

861739

863589

863591

865779

867949

867950

867957

869361

869362

869363

869364

869365

869366

869367

869368

869369

869370

PART NO.

869371

869375

869376

869381

869382

869384

869385

869386

869387

869388

869389

869392

869393

869398

869399

869400

869402

869403

869412

NAME OF PART

Retainer Ring

Anvil Housing (incl. 869376, 869392, 869393)

15/32" Steel Ball

Collar Spring

Anvil Timing Pin

Socket Retainer Spring

Socket Retainer Plunger

Socket Retainer Pin

Hammer

3/4" Sq. Dr. Anvil

3/4" Sq. Dr. Anvil - 3" Extended

3/4" Sq. Dr. Anvil - 6" Extended

1" Sq. Dr. Anvil

1" Sq. Dr. Anvil - 3" Extended

1" Sq. Dr. Anvil - 6" Extended

Cam Shaft

Cam

Cam Roller

NAME OF PART

Cam Timing Pin

Spring Cap

Anvil Bushing

Gasket

Hammer Spring

Cam Roller Shaft

Retainer Sleeve

Butt Plate

Insulator

Shock Absorber

Spring Keeper

Retainer Ring

Anvil Seal

Suspension Bail

Quick Change Anvil

Spline Drive Anvil

Release Collar

Spring Retainer

Housing Bolt

QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

QTY.

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

4

PARTS LIST —IMPACT MECHANISM

6

PART NO.

844287

844383

863399

844892

869311

869359

869360

869374

PART NO.

869378

869381

869394

869395

869396

869397

869738

869745

NAME OF PART

Lockwasher

Nut

O-ring

Oil Plug

Oil Plug

Cylinder

Rotor

Backcap

NAME OF PART

Rotor Blade

Gasket

Rotor Shaft Seal

O-ring 2-11/16" X 2-7/8"

Rotor Bearing

Alignment Pin

Bearing Plate (Silver)

Bearing Plate (Blue)

QTY.

1

4

4

1

1

1

1

1

QTY.

6

1

2

2

2

1

1

1

PARTS LIST —MOTOR

7

The complete Motor Housing can be purchased as a subassembly using Part No 861740

PART NO.

202470

202471

412775

842550

843590

844309

844799

845090

846170

863072

863074

PART NO.

863093

863520

863600

869372

869373

869379

869380

869390

869998

NAME OF PART

Muffler Element (Not Shown)

Muffler

Air Inlet Screen

Oil Plug

Oiler Valve

"O"-Ring 7/16" x 518"

Trigger Pin

Trigger Stop Pin

Reversing Valve Bushing

Throttle Valve Spring

Air Inlet Bushing

NAME OF PART

"O"-Ring 1" x 1-1/8"

Trigger

Throttle Valve Seal

Motor Housing (incl. 843590,

869379,844170)

Reversing Valve

Throttle Valve Bushing

Throttle Valve

Exhaust Deflector

Exhaust Deflector Screw

QTY.

1

1

1

1

1

1

1

1

1

1

1

QTY.

1

1

1

1

1

1

1

1

2

PARTS LIST —MOTOR HOUSING

8

CooperTools

670 Industrial Drive

Lexington, SC 29072

Phone: (803) 359-1200

Fax: (803) 359-2013

www.cooperindustries.com

This manual suits for next models

1

Table of contents

Other Cleco Impact Driver manuals