Clements SUC89851 User manual

INSTRUCTION

MANUAL

INSTRUCTION MANUAL

VENTURI NOZZLE

FOR HIGH FLOW / HIGH VACUUM

PUBLICATION CODE: MO093

EDITION: n° 1

DATE: February 2021

Sponsor:

ICU Medical Australia Pty Ltd

Unit U, 10 – 16 South St, Rydalmere

NSW 2116, Australia

Tel: +61 2 9466 5300 -www.clements.net.au

FLOW METER S.p.A.

Via del Lino, 6 – 24040 LEVATE (Bergamo) – Italy

Tel. +39/035/594047 – Fax +39/035/594821

e-mail: info@flowmeter.it - www.flowmeter.it

0546

Contents

Important ................................................. 2

Application............................................... 3

Controls and connections ........................ 3

Installation and use..................................3

Cleaning and disposal .............................4

Technical features ...................................4

Important

CAUTION: INDICATION OF DANGER

Attention: Important indication

General information

•

Read this manual carefully before using

the venturi nozzle

for high flow/ high

vacuum.

•

AFTER UNPACKING, CONNECT THE DEVICE

AS DESCRIBED IN THE SECTION

“INSTALLATION AND USE”.

•

BEFORE EACH USE CARR

Y OUT THE

OPERATIONS DESCRIBED

IN THE SECTION

“INSTALLATION AND USE”.

•

INSTALLATIONS THAT ARE NOT ENVISAGED

BY THIS MANUAL MAY REDUCE THE SAFETY

LEVEL OF THE APPLIANCE.

•

BEFORE EACH USE, ENS

URE THAT THE

DIRECT SUCTION NOZZLE FOR HIGH FLOW /

HIGH VACUUM, IS DIRECTLY OR INDIRECTLY

CONNECTED TO A COLLE

CTION VESSEL

FITTED WITH AN OVERF

LOW VALVE AND

ANTIBACTERIAL FILTER

, AND THAT THE

CONNECTOR HOSES USED CONFORM WITH

THE STANDARD EN ISO 10079-3.

•

The company will not

accept any

responsibility if the instructions in this

manual are not observed, if original spare

parts and/or authorized technicians are

not used.

Connections

•

CONNECT THE UNIT AND CHECK THE SEALS

BETWEEN THE COMPONENTS AS DESCRIBED

IN “START-UP PROCEDURE” SECTION.

FAILURE TO MAKE THES

E CONTROLS MAY

COMPROMISE THE SAFET

Y AND

FUNCTIONING OF THE DEVICE.

•

OILS AND GREASES MUS

T NOT COME IN

CONTACT WITH THE EQUIPMENT.

•

The vacuum supply connector is positioned

on the back

part of the device and may be

identified by referring to the drawing on page

3 of this manual (pos. 4).

Operation

•

THE VENTURI NOZZLE FOR HIGH FLOW / HIGH

VACUUM, MUST BE USED CAREFULLY AND ONLY

BY PERSONNEL WHO ARE

FAMILIAR WITH THE

CONSEQUENCES OF THIS THERAPY.

•

Disconnect the vacuum supply when the

unit is not in use.

Service

•

All the modifications and repairs must only

be performed by personnel authorized by

the Manufacturer

or by hospital technicians

approved by the same company.

•

Original spare

parts must always be used

for the maintenance operations.

•

Check the direct suction nozzle every day

or in accordance with hospital routine.

•

For periodical updating reasons, the device

configuration can be subjected to changes.

Therefore, the Manufacturer

guarantees

spare parts to be available for at least 5

years from the manufacturing date.

•

Any modifications to the device must be

approved by the Manufacturer

, and carried

out in accordance with the procedures

prescribed.

The device has been

designed and

manufactured to satisfy the safety

requirements of the following standards:

EN ISO 10079-3

Page 2

Application

Venturi nozzles for high flow / high vacuum are used where simple On-Off suction control is required.

The Nozzles have a simple and robust

construction and are designed for applications where direct

suction is instantly required. The dual-scale vacuum gauge for controlling the line depression is accurate

and easy to read. The non-return valve protects the suction system from blowbacks. Venturi nozzles for

high flow / high vacuum are suitable for connection to most of terminal units available on the market.

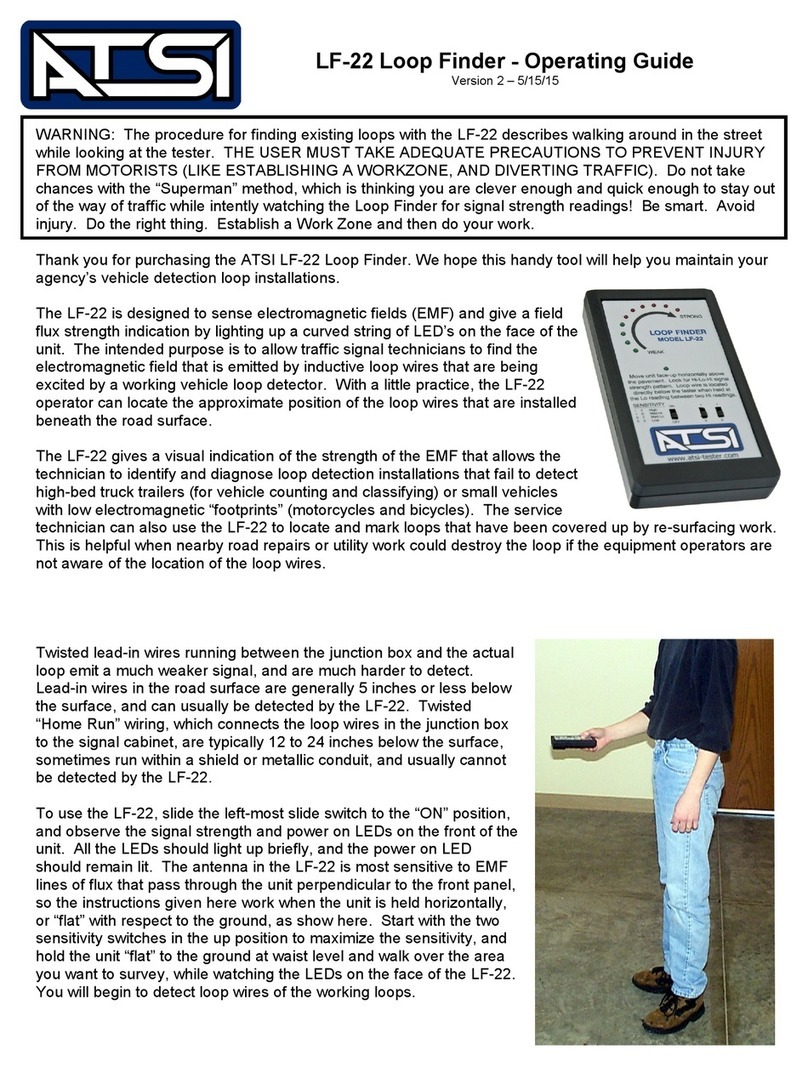

Controls and connections

LEGEND

1 - Silicone protection sleeve (optional)

2 – Controlling vacuum gauge (optional)

3 – Non-return ball valve

4 – Specific gas quick coupling for suction supply

(VAC-IN)

5 – Chrome-plated metal body

6 – Sintered bronze filter

7 – Vacuum supply hose connector (VAC-OUT)

Installation and use

Check the functioning of the unit every day or in accordance

with the hospital routine. The connection procedures for the

venturi nozzle is described below.

•Connect the specific gas quick coupling for suction

supply VAC IN (4), to the rapid supply outlet of the

centralised hospital plant;

•Connect a suitable flexible hose to the vacuum supply

hose connector VAC OUT (7)

(e.g. silicone hose

autoclavable at 134 °C for 18 minutes), pressing onto

the end;

•Connect a suitable type of collection

container for

aspirated fluid to the other end of the hose.

The procedure below must be followed to make the appliance

operational:

•Check the suction on the control vacuum gauge (2), after

the block of the hose connector used for the suction. The

system is then ready for use.

After use, the procedure below must be followed:

•Disconnect the vacuum supply (4) from the main supply

outlet of the centralised hospital plant;

•Remove the collection container by disconnecting it from

the suction nozzle and detaching the PATIENT circuit.

Page 3

Installation and use

WARNING

FOR THE CORRECT USE OF THE COLLECTION CONTAINER, READ THE INSTRUCTIONS IN THE USER

MANUAL SUPPLIED WITH THE DEVICE.

THE LIQUIDS COLLECTED MUST ONLY BE DRAINED OUT IN AREAS ASSIGNED TO THE DISPOSAL OF

HOSPITAL WASTE AND/OR STRICTLY FOLLOWING THE INSTRUCTIONS OF THE AUTHORITIES FOR THE

TREATMENT OF THESE PRODUCTS.

Cleaning and disposal

•

Clean the device every day or in accordance with the hospital routine

•

Clean or replace the sintered bronze filter (6) if necessary.

•

Carefully clean all the external surfaces of the device using a soft damp cotton cloth rinsed in neutral detergent

diluted 10% in water.

CAUTION

DO NOT USE SOLVENTS OR ABRASIVE PRODUCTS FOR CLEANING: THESE CAN SERIOUSLY DAMAGE

THE SURFACES OF THE EQUIPMENT AND THE PLASTIC PARTS.

•

DO NOT IMMERSE THE UNIT IN DISINFECTANT;

•

DO NOT PLACE THE UNIT IN AN AUTOCLAVE;

•

DO NOT USE INFLAMMABLE PRODUCTS.

IF THE EQUIPMENT IS ACCIDENTALLY CONTAMINATED BY SUCTIONED LIQUIDS, IT MUST BE ISOLATED

AND THE NECESSARY CLEANING AND DISINFECTION OPERATIONS MUST BE

CARRIED OUT BY

QUALIFIED PERSONNEL.

IF NECESSARY, STERILISE THE VENTURI NOZZLE WITH A VALIDATED

ETHYLENE OXIDE

STERILIZATION CYCLE (E.G. 14% EO 12 H. / 50 KPA / 37 °C).

CAUTION FOR DISPOSAL

IF THE DEVICE IS DAMAGED AND CANNOT BE REPAIRED, DISPOSE AND DISCARD IT ACCORDING TO

THE INTERNAL PROCEDURES OF THE HOSPITAL. DO NOT RECYCLE OR REUSE ANY COMPONENT.

Technical features

Sales description ..................................................

Dimensions (mm)..................................................

Weight (g) .............................................................

Scale of the vacuum gauge...................................

Maximum suction flow...........................................

Maximum supply depression.................................

Vacuum supply connection ...................................

Vacuum connector................................................

Storage conditions ................................................

Operating conditions .............................................

Direct suction nozzle

Height:

195

Width:

68

Depth: 48

400

From 0 to -100 kPa graduated at 5 kPa

From 0 to -760 mm Hg graduated at 20 mm Hg

60 L/min ± 5 L/min at -98 kPa

-98 kPa

Thread M8x1 F

Hose connector Ø 10÷12mm

-40 °C ± 2 °C / +60 °C ± 5 °C and 40% to 70% RH

+5 °C ± 2 °C / +35 °C ± 5 °C

Page 4