Bulletin AFS 460137.03 2

Specifications

Model AFS–460–137 Air

Pressure Sensing Switch with

manual reset feature, DPDT

contact arrangement , for 24 VAC

applications.

Sample Media: Air or

combustion products that do not

degrade silicone.

Mounting Position (in order to

meet lowest operating

specifications): Diaphragm in any

vertical plane.

Field Adjustable Range:

0.40 ± .06"w.c. to 12.0"w.c.

Switch Differential: Progressive,

increasing from approximately

.06± .01"w.c. at minimum set

point, to approximately .8"w.c. at

maximum set point.

Maximum Pressure:

0.5 psi (0.03 bar)

Operating Temperature Range:

-40 to 180F (-40 to 82C)

Electrical Rating:

0.5 VA @ 24 V AC, 50/60 Hz.

Contacts:

DPDT, 2 form-C

rated 8 amp @ 250 V AC.

Electrical Connections:

Screw terminals.

Sample Line Connections:

Ferrule and nut compression type

connectors will accept .25" OD

rigid tubing.

Shipping Weight: 1.2 lbs.

Agency Approvals: pending

Accessories

•P/N 18311 Slip-on ¼" OD Tubing Adapter,

suitable for slipping on flexible plastic

tubing. • Sample line probes. • Orifice

plugs (pulsation dampers).

Pressure Conversion Table

1" H2O = .0361 lbs./sq. in. or .0735 in. mercury

1" Hg. = .491 lbs./sq. in. or 13.6 in. water

1 psi = 27.7 in. water or 2.036 in. mercury

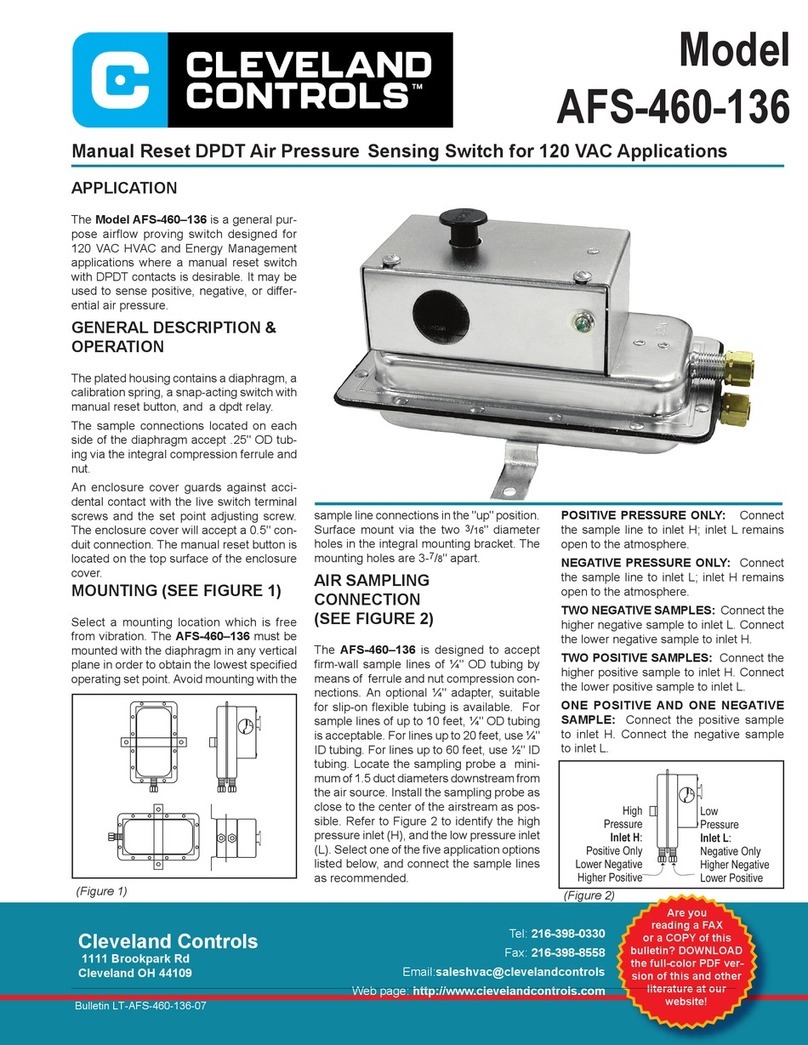

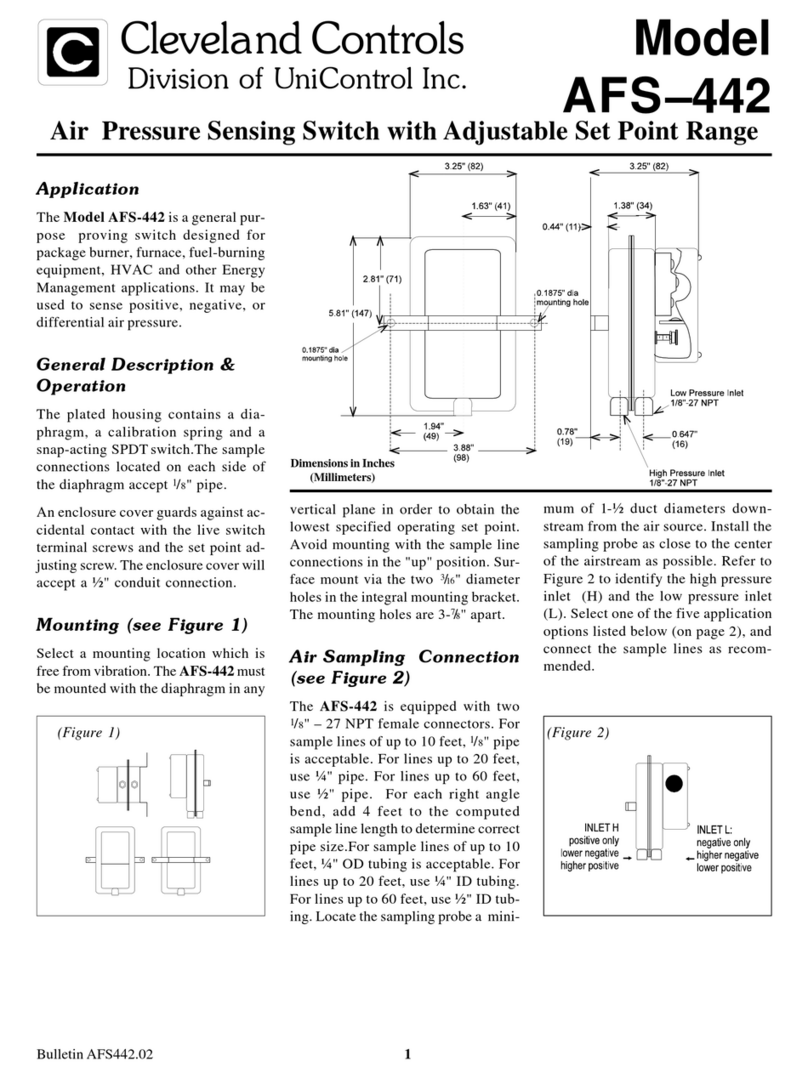

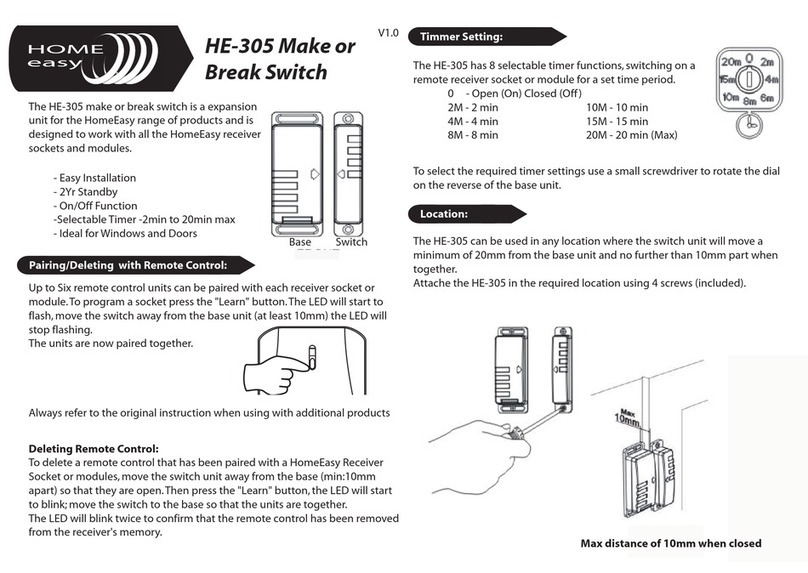

POSITIVE PRESSURE ONLY: Con-

nect the sample line to inlet H; inlet L

remains open to the atmosphere.

NEGATIVE PRESSURE ONLY: Con-

nect the sample line to inlet L; inlet H

remains open to the atmosphere.

TWO NEGATIVE SAMPLES: Con-

nect the higher negative sample to inlet

L. Connect the lower negative sample

to inlet H.

TWO POSITIVE SAMPLES: Con-

nect the higher positive sample to inlet

H. Connect the lower positive sample

to inlet L.

ONE POSITIVE AND ONE NEGA-

TIVE SAMPLE: Connect the positive

sample to inlet H. Connect the negative

sample to inlet L.

Electrical Connections

(see Figure 3)

Before pressure is applied to the dia-

phragm, the snap switch contacts will be

in the normally closed (NC) position.

As differential pressure rises above the

field adjustable set point, the snap

switch opens, de-energizing the coil on

the slave relay, which activates the

DPDT contacts. An LED indicates that

the snap switch exceeds differential set

point. It remains lit until the manual re-

set push button is depressed.

Field Adjustment

The AFS-460–137 Manual Reset Air

Switch has an adjustment range of 0.40

to 12.0" w.c., ±.06" w.c. To adjust the

set point:

Turn the adjusting screw counterclock-

wise until motion has stopped. Next,

turn the adjusting screw 4 complete

turns in a clockwise direction to engage

the spring. From this point, the next ten

turns will be used for the actual cali-

bration. Each full turn represents ap-

proximately 1.16" w.c.

Please note: To properly calibrate an

air switch, a digital manometer or other

measuring device should be used to

confirm the actual set point.

C

NC MANUAL

RESET

HIGH

PRESS

LOW

PRESS

H

K1

CONVERTER

NC1

NO 1 C1

NC2NO 2 C2

Shown in "on shelf " condition:

no power and no differential

pressure applied.

Note that when power is applied across

H and N :

1) Relay K1 is energized

2) Contacts change state (i.e., NO contact

closes and NC contact opens)

3) LED is illuminated when differential

pressure exceeds set point.

TB2 #1

24 V AC

TB2 #2

COMMON