PipingPiping

PipingPiping

Piping

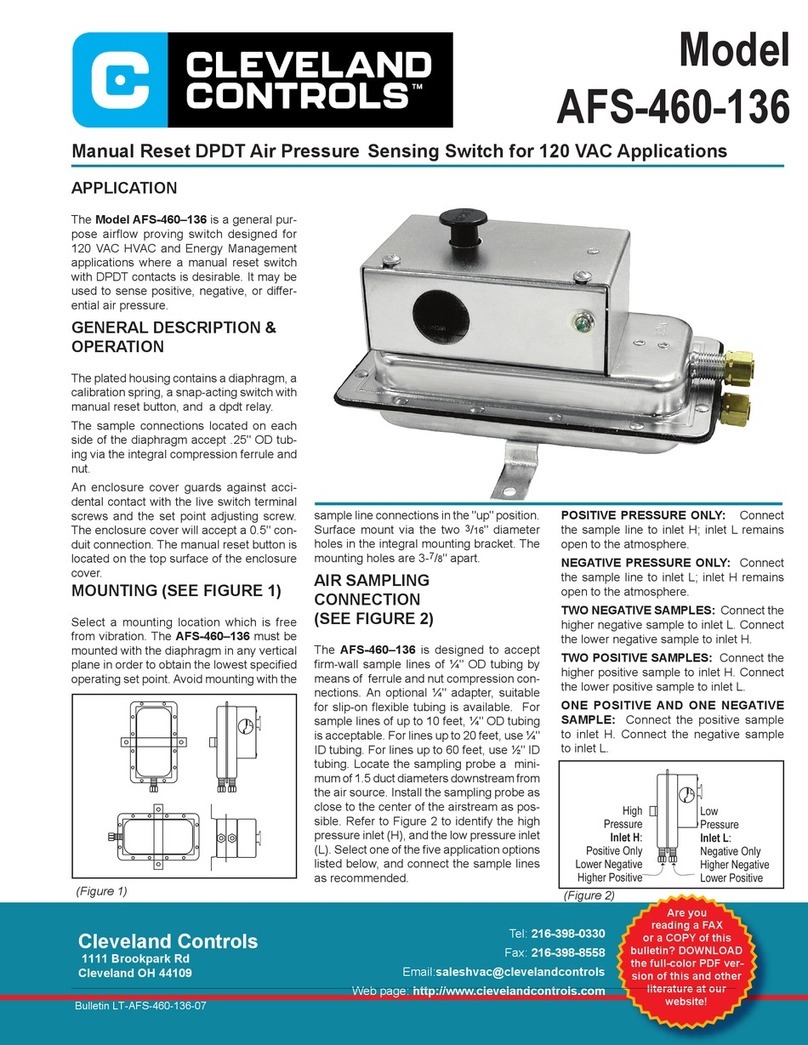

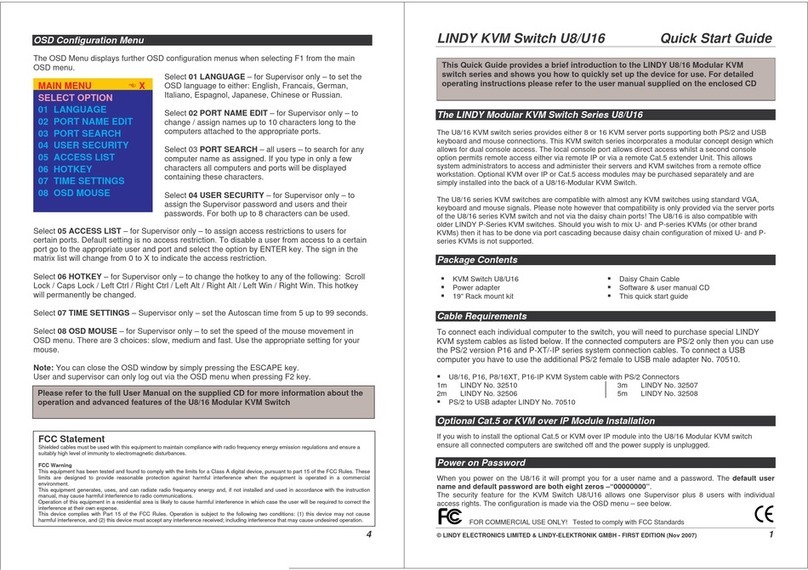

The field sample line connectors, two

1/4" - 18 NPT female fittings, labeled

H (high) and L (low), are located on

the side of the enclosure as shown in

Figure 1.

For sample lines up to 10 ft., use ¼"

OD tubing or 1/8" pipe.

For sample lines up to 20 ft., use ¼"

ID tubing or 1/4" pipe.

For sample lines up to 60 ft., use ½"

ID tubing or 1/2" pipe.

For sample lines up to 90 ft., use 3/4"

ID tubing or 3/4" pipe.

For sample lines up to 120 ft., use

1" ID tubing or 1" pipe.For each right

angle bend, add four feet to the computed

line length in order to determine correct

pipe or tubing size.

If either sample line connector is

vented to the atmosphere, attach an el-

bow to it so that the open end of the con-

nector points downward. This will help

protect the switch from contamination.

Sample Line ConnectionsSample Line Connections

Sample Line ConnectionsSample Line Connections

Sample Line Connections

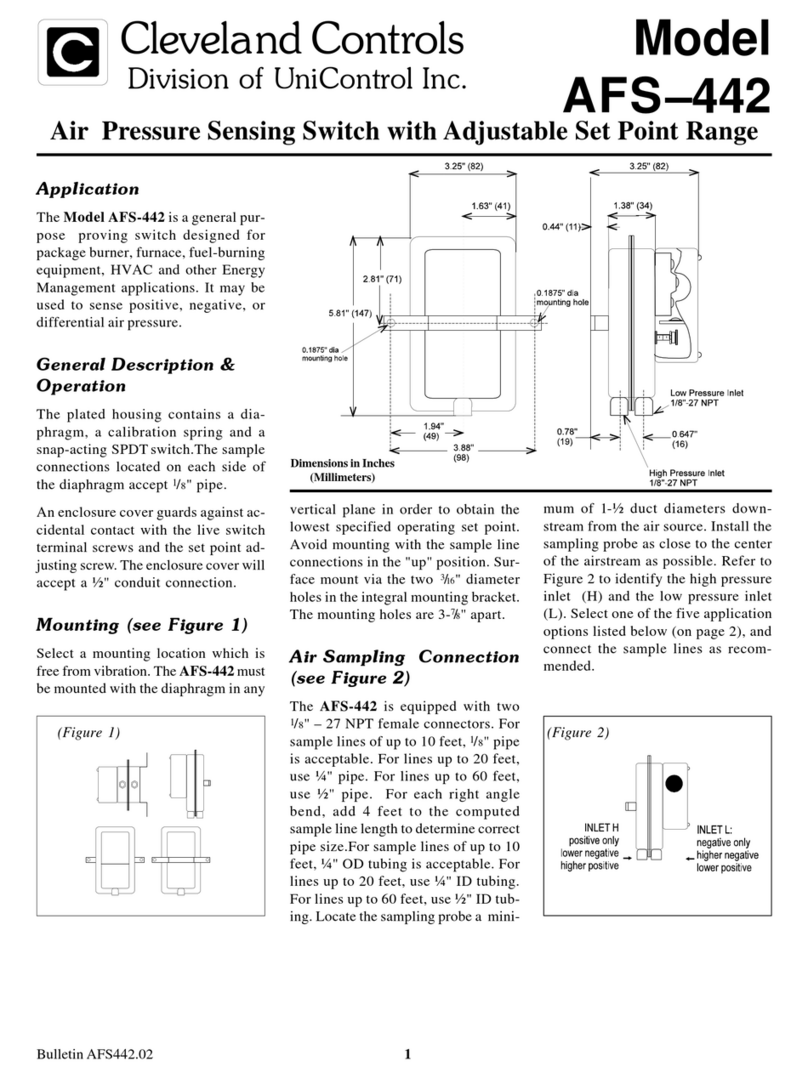

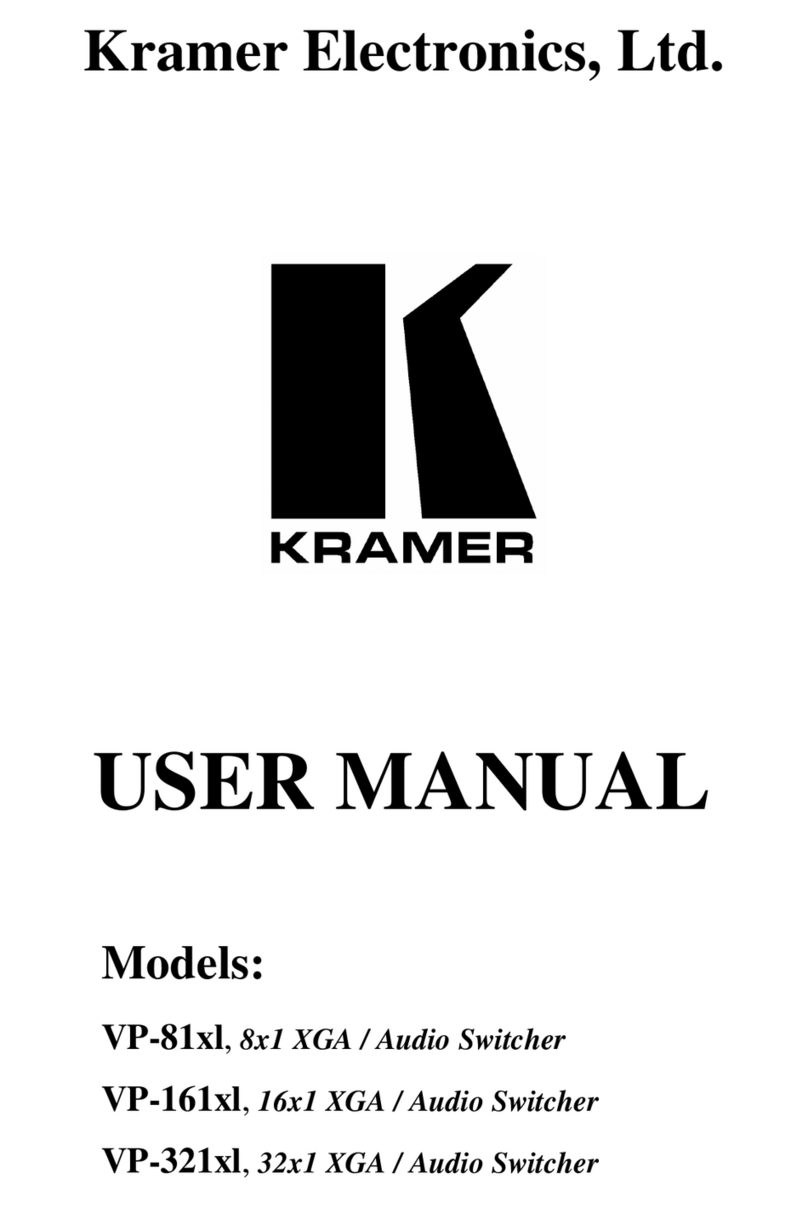

Positive Pressure only:

Connect sample line to H;

Lremains open to the atmosphere.

Negative Pressure only:

Connect sample line to L:

Hremains open to the atmosphere.

Two Negative Samples:

Connect higher negative sample to L:

Connect lower negative sample to H.

Two Positive Samples:

Connect higher positive sample to H:

Connect lower positive sample to L.

One Negative and One Positive

Sample:

Connect positive sample line to H:

Connect negative sample line to L.

Electrical ConnectionsElectrical Connections

Electrical ConnectionsElectrical Connections

Electrical Connections

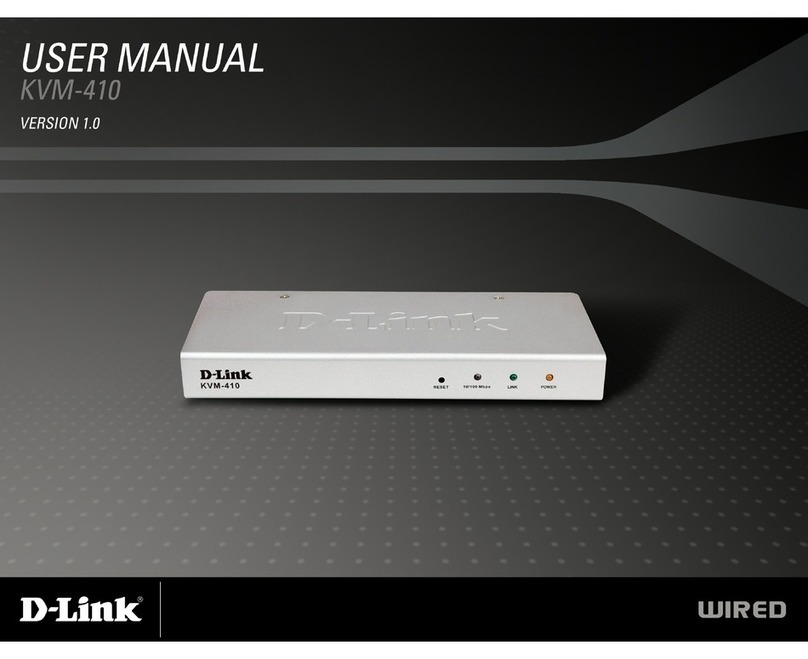

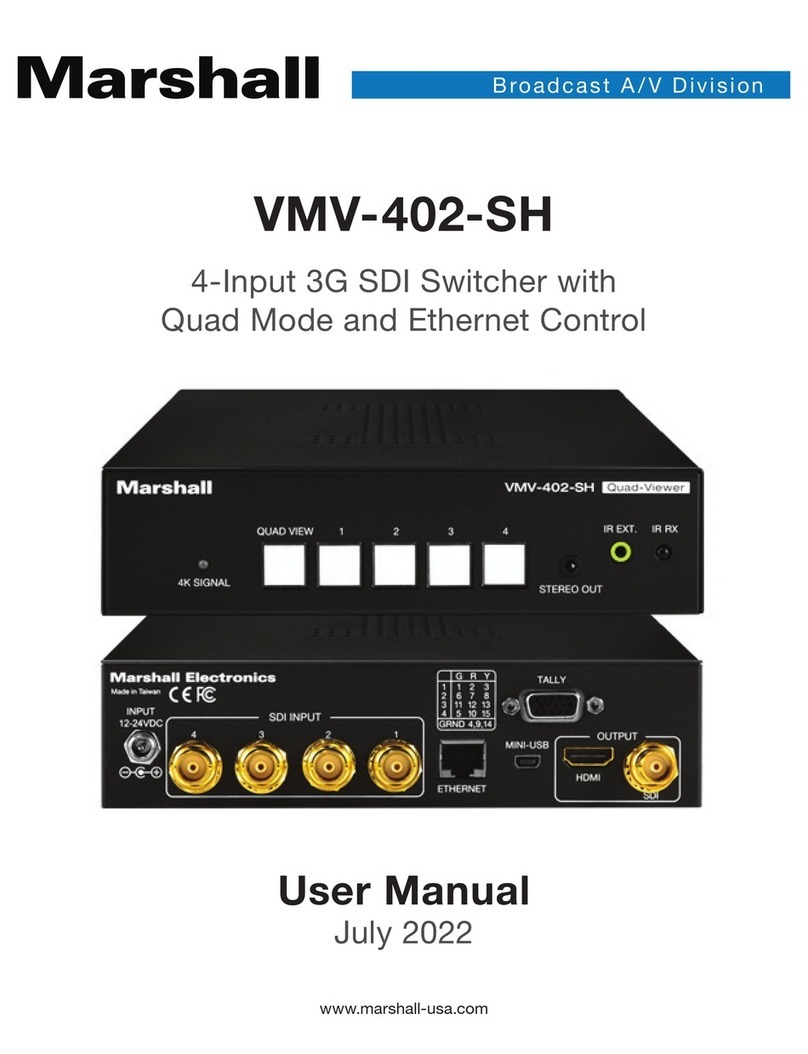

Three (3) terminals are provided for field

wiring. Before pressure is applied to the

diaphragm, the switch contacts will be in

the normally closed position as shown in

Figure 2.

To Prove Excessive Air Flow or Pres-

sure:

Connect Terminal 1 to a hot line, Ter-

minal 2 to an alarm circuit (if desired),

and Terminal 3 to the control circuit.

To Prove Insufficient Air Flow or

Pressure:

Connect Terminal 1 to a hot line, Termi-

nal 2 to the control circuit, and Terminal

3 to an alarm circuit (if desired).

NOTE: When the switch is wired in

this manner, an alarm circuit will

be energized at start up, and will

stay energized until the set point of

the air switch is satisfied. To avoid

nuisance alarm, a time delay, equal to

the amount of time required for pres-

sure to activate the air switch, should

be wired in series between Terminal 3

and the alarm device.

Field AdjustmentsField Adjustments

Field AdjustmentsField Adjustments

Field Adjustments

Field adjustments to the operating set

point are made by removing the protec-

tive plug button on the side of the con-

trol enclosure and inserting a standard

blade-type screwdriver, at least 3 inches

long*.

The adjustment range is 0.05 ± .02"

w.c. to 12.0" w.c. To adjust the set point,

turn the adjusting screw counterclockwise

until motion has stopped. Next, turn the

adjusting screw 4 complete turns in a

clockwise direction to engage the spring.

For the next 10 turns, each full turn

represents approximately 1.2" w.c.

At higher operating pressures, there is a

slight increase in the switching differ-

ential. Please note: To properly cali-

brate an air pressure sensing switch, a

digital manometer or other measuring

device should be used to confirm the ac-

tual set point.

SPECIFICASPECIFICA

SPECIFICASPECIFICA

SPECIFICATIONSTIONS

TIONSTIONS

TIONS

MODELS: AFS-951,MODELS: AFS-951,

MODELS: AFS-951,MODELS: AFS-951,

MODELS: AFS-951,

AFS-951-1, AFS-951-2AFS-951-1, AFS-951-2

AFS-951-1, AFS-951-2AFS-951-1, AFS-951-2

AFS-951-1, AFS-951-2

Air Pressure Sensing SwitchAir Pressure Sensing Switch

Air Pressure Sensing SwitchAir Pressure Sensing Switch

Air Pressure Sensing Switch

ELECTRICAL RATING:

300 VA pilot duty at 277 v AC

260 VA pilot duty at 240 v AC

130 VA pilot duty at 120 v AC

15 amp noninductive to 277 vAC.

CONDUIT OPENING:

7/8" diameter opening accepts 1/2" conduit

fitting.

ELECTRICAL SWITCH

(Contact Arrangement): SPDT NC

Single pole, double throw snap-action switch.

Contacts in a normally closed position before

pressure is applied.

CONTROL SET POINT /ADJUSTABLE OP-

ERATING RANGE:

Field-adjustable, 0.05 ±0.02 to 12.0" w.c.;

(1.3 to 305 mm w.c.; 0 to 0.43 psi)

SWITCH DIFFERENTIAL:

0.02 ± 0.01" w.c. at minimum set point, to ap-

proximately 0.8" w.c. at maximum set point

(0.5 ±.25 mm to approximately 20.3 mm).

MAXIMUM PRESSURE:

1/2 PSI (0.03 bar)

ELECTRICAL CONNECTIONS:

Numbered terminal panel

RECOMMENDED OPERATING POSITION:

Mount with the diaphragm vertical to obtain

the lowest operating set point.

OPERATING TEMPERATURE RANGE:

- 40 TO 180F (- 40 to 82C)

SAMPLE LINE CONNECTORS:

Two 1/4"—18 NPT female fittings.

APPROVALS: UL listed. CSA and FM

approved.

*Standard enclosure only.

Figure 2: Electrical Connections

PP

PP

Pressure Conversion Tressure Conversion T

ressure Conversion Tressure Conversion T

ressure Conversion Tableable

ableable

able

1"wc = 0.0361psi

or 0.0736"Hg

1"Hg = 0.491psi

or 13.6" wc

1psi = 27.7"wc

or 2.036"Hg

NC NO

3

2

1

NUMBERED TERMINALS

L

H

H

L

H: L:

HIGH POSITIVE LOW POSITIVE

POSITIVE NEGATIVE

LOW NEGATIVE HIGH NEGATIVE

Figure 1