Cleveland Controls RSS-495-011 Series User manual

Cleveland Controls

DIVISION OF UNICONTROL INC.

1111 Brookpark Rd

Cleveland OH 44109

Tel: 216-398-0330

Fax: 216-398-8558

Email:[email protected]

Web page: http://www.clevelandcontrols.com

Are you

reading a FAX

or a COPY of this

bulletin? DOWNLOAD

the full-color PDF ver-

sion of this and other

literature at our

website!

Cleveland Controls

Division of UniControl Inc.

LTRSS495011.09

APPLICATION

The Series RSS-495-011 Sensing Switch

Kit provides an economical and convenient

solution for many residential and light com-

mercial HVAC applications. The kit contains

a compact Series RSS-495 switch with an

adjustable set point range of 0.20" w.c. to

1.0" w.c. The switch has been factory set to

actuate on a pressure rise of 0.20" w.c. The

individually boxed kit includes a P/N 28419

hex wrench (1⁄16") for eld calibration, a P/N

28429 tube-to-tube reduction adapter, and

two (2) P/N 27577-037 slotted hex head

mounting screws (#6 x ⅜").

GENERAL DESCRIPTION &

OPERATION

The RSS-495 switch has a thermoplastic

housing containing a diaphragm and snap-

acting switch. Duo-barbed sample line

connectors on each side of the diaphragm

accept ¼" ID or ⅜" ID slip-on exible tubing.

The electrical connection consists of three

(3) male 90º quick-connect terminals. The

snap action switch can be actuated by a

positive or negative pressure, or by a pres-

sure differential.

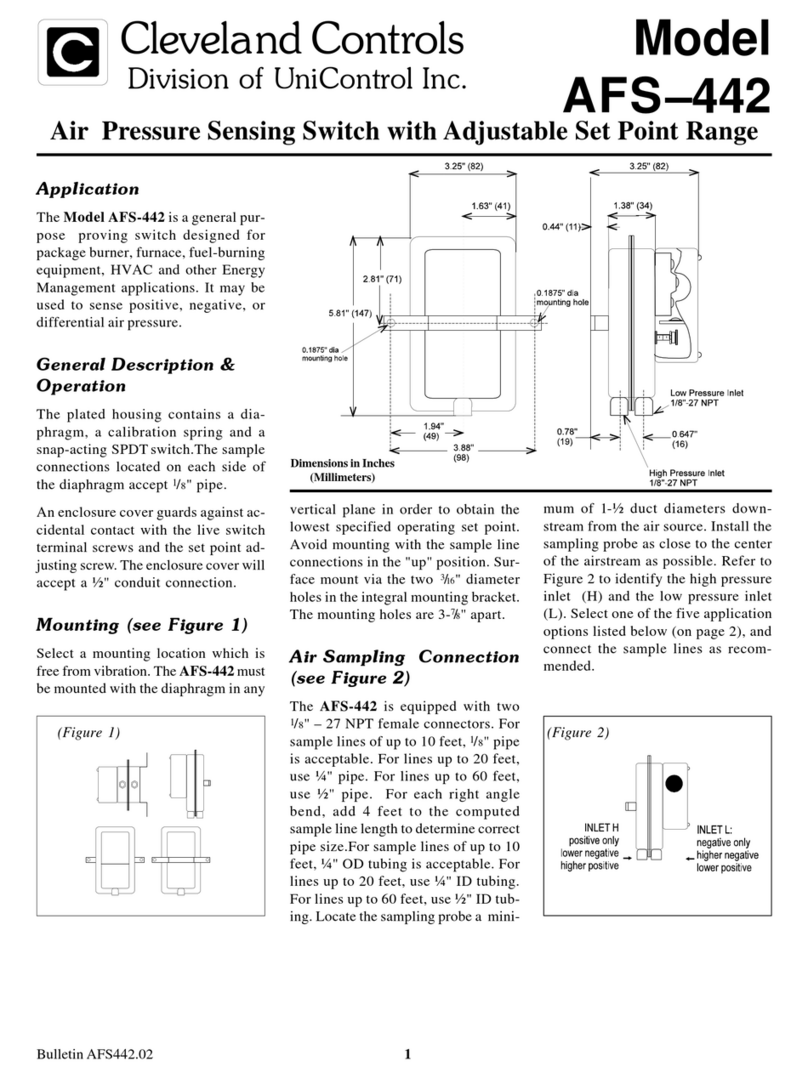

MOUNTING (FIGURE 1)

Select a mounting location that is free from

vibration. Mount with the diaphragm in

any vertical plane in order to maintain the

specied operating set point. Do not mount

with the sample line connections directed

upward. Surface mount via the two 0.14"

slots in the integral foot bracket, using the

two (2) slotted hex head mounting screws

(#6 x ⅜") provided in the kit.

AIR SAMPLING CONNECTION

(FIGURE 2)

Refer to Figure 2 to identify the High inlet

(H) and the Low inlet (L). Connect the

sample lines as follows:

Positive Pressure Only: Connect the

sample line to H; Lremains open to the

atmosphere.

Negative Pressure Only: Connect the

sample line to L; Hremains open to the

atmosphere.

Two Negative Samples: Connect higher

negative sample to L; lower sample to H.

Two Positive Samples: Connect higher

positive sample to H; lower sample to L.

One Positive and One Negative: Connect

positive sample to H; connect negative

sample to L.

ELECTRICAL CONNECTIONS

(FIGURE 3)

Before pressure is applied to the diaphragm,

the switch contacts will be in the normally

closed (NC) position as shown in Figure 3.

Connect the application wiring to the corre-

sponding switch terminals, NC, NO, and C.

FIELD ADJUSTMENT (FIGURE 4)

The adjustable set point range of the RSS-

495 is 0.20" w.c. to 1.0" w.c., ±0.05" w.c.

The switch leaves the factory calibrated

at 0.20" w.c. To adjust the set point, insert

the 1⁄16" hex wrench (provided with the kit)

into the adjusting screw located between

the mounting feet on the underside of

the switch. Holding the switch so that the

diaphragm is vertical, rotate the adjusting

screw clockwise to the desired set point. The

maximum number of turns is 4-½, covering

the set point range of 0.20" w.c. to 1.0" w.c.

Do not exceed the maximum number of

turns. Each full turn represents approxi-

mately 0.18" w.c. Determine the number of

turns required to approximately position the

adjusting screw as follows:

Model

RSS-495-011

AIR PRESSURE SENSING SWITCH KIT WITH ADJUSTABLE SET POINT

(REQUIRED SET POINT– INITIAL SET POINT @ 0.20)

0.18

= NUMBER OF TURNS CLOCKWISE

EXAMPLE:

REQUIRED SET POINT = 0.65" w.c.

INITIAL (FACTORY) SET POINT = 0.20" w.c.

(0.65 – 0.20) / 0.18 = 2.5 TURNS

Please note:

(1) Use a digital manometer and multi meter

(such as the Cleveland Controls Series 6650

Digital Manometer/Multi Meter) to achieve

precise set point calibration. Have the RSS-

495 switch as close to actual operating tem-

perature as possible during the calibration.

(2) Warning: Never place an air pressure

sensing switch into operation without

conrming the set point rst. An incor-

rect setting could result in a hazardous

condition.

SPECIFICATIONS

MODEL RSS-495-011

Mounting Position:

Mount with the diaphragm in any vertical plane.

Field Adjustable Set Point Range:

0.20 ±0.05" w.c. to 1.0 ± 0.05" w.c.

Factory Set Point for RSS 495-011:

Ships factory set at 0.20" w.c.±0.05" w.c.

Measured Media:

Air or combustion by-products that will not

degrade Polyisoprene and Thermoplastic

Maximum Pressure:

1 psi (0.06 bar)

Operating Temperature Range:

-40 ºF to 190 ºF (-40 ºC to 88 ºC)

Life:

100,000 cycles minimum at 1 psi

maximum pressure each cycle and

at maximum rated electrical load

Electrical Rating:

5 amp noninductive 120 to 277 VAC

1 amp pilot duty (120 Va) at 120 VAC

Contact Arrangement: SPDT

Electrical Connections:

(3) male quick-connect spade terminals,

90°, in compliance with NEMA standards.

Sample Line Connectors:

Barbed ttings will accept ¼" ID or

⅜" ID exible, slip-on tubing.

Approvals: UL, CUL, CSA, CE,

Australian Gas Association.

Shipping Weight:

¼ lb., approx.

Nominal Dimensions in Inches (Millimeters)

Fig. 2 (left): Duo-barbed sample line

connectors, located on either side of

the diaphragm, accept ¼" ID or ⅜" ID

exible, slip-on tubing.

Fig. 3 (right): Before pressure is applied to the

diaphragm, the switch contacts are in

the NC position, as shown here.

Fig. 1: Mount with the diaphragm in any vertical

plane. Sample line connections must not

point upward.

Figure 4: Turns of the set point adjustment screw.

CARBON MONOXIDE (CO) GAS EXPOSURE

CAN CAUSE BRAIN DAMAGE OR DEATH

This pressure switch may control air ow into the combustion

chamber. Improper adjustment of the pressure switch in the

eld, or use of the switch for an application for which it was not

intended, may introduce carbon monoxide into the ventilation

system or combustion chamber. The U.S. Consumer Product

Safety Commission warns that carbon monoxide gas is an

“invisible killer.” Carbon monoxide (CO) is a colorless, odor-

less, deadly gas produced by burning fuel, including natural

gas and propane. Symptoms of carbon monoxide exposure

include dizziness, headache, nausea, weakness, sleepiness,

muscle twitching, vomiting and inability to think clearly. If you

experience these symptoms, turn the HVAC system off, exit

the building, and get into fresh air immediately. The pressure

switch must be tested thoroughly by an HVAC professional

before the HVAC system is restarted. Proper installation,

operation and maintenance of fuel-burning appliances and

HVAC systems is the most important factor in reducing carbon

monoxide poisoning. For safe operation, be sure all such de-

vices are installed by professionals and operated according to

manufacturer’s instructions and applicable local codes. Have

HVAC systems (including pressure switches) inspected and

serviced annually by a trained service technician. Examine

vents regularly for improper connections, visible cracks, rust

or stains, and blockage.

Install battery-operated carbon monoxide alarms certied to

the requirements of the most recent UL, lAS and CSA stan-

dard for carbon monoxide alarms. Test the alarms regularly

and replace the batteries annually.If you have any questions

regarding the installation, use or safety of this switch, please

call Cleveland Controls Customer Service at (216) 398-0330.

64 ESPCOMPANY.COM | (937) 898-0391 ESPCOMPANY.COM | (937) 898-0391 65

CLEVELAND CONTROLS AIR

PRESSURE SENSING SWITCH KIT

Series RSS-495-11 Air Sensing Switch Kit contains compact, economical switches designed

for a residential furnace and light commercial aftermarket applications. The RSS-495

switches have an adjustable set point range of 0.25” W.C. to 1.0” W.C. (they have been

factory set to activate on a pressure rise of 0.25” W.C.). The field adjustability makes these

switches ideal for aftermarket residential furnace applications, electronic air cleaners and

humidifiers

Adjustable range: 0.25 + 0.05” W.C. to 1.0 + 0.05” W.C.

Operating temperature range: -40°F to 190°F

Approvals: UL, CSA, CE, NRTL, AUST. GAS ASSOC>

RSS-495-11

CLEVELAND CONTROLS AIR

PRESSURE SENSING SWITCH KIT

Series RSS-498-13 Air Sensing Switch Kit contains compact, economical switches designed

for residential furnace and light commercial aftermarket applications. The RSS-498 switches

have an adjustable set point range of 1.0” W.C. to 4.0” W.C. (They have been factory set to

activate on a pressure rise of 1.0” W.C.) The field adjustability makes these switches ideal

for aftermarket residential furnace applications, electronic air cleaners and humidifiers

Adjustable range: 1.0 + 0.05” W.C. to 4.0 + 0.05” W.C.

Operating temperature range: -40° F to 180° F

Approvals: UL, CSA, CE, NRTL, AUST. GAS ASSOC.

RSS-498-13

SERIES RSS SWITCHES

SERIES RSS SWITCHES

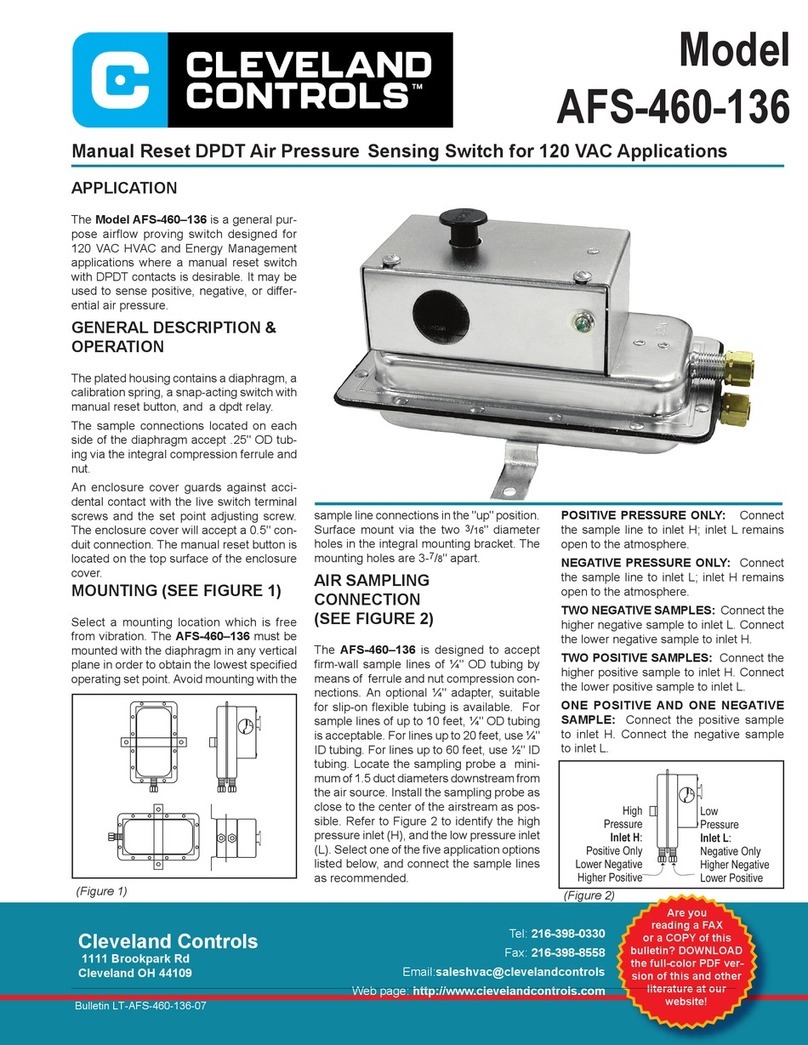

CLEVELAND CONTROLS AIR PRESSURE

SENSING SWITCH WITH MANUAL RESET

The model AFS-460 is a general purpose proving switch designed to require manual opera-

tor reset following activation. It can be used to sense positive, negative, or differential air

pressure in HVAC and Energy Management applications that require operator interface.

Installation kit included

Set point range: 0.40 + 0.06” W.C. to 12.0” W.C.

Operating temperature range: -40°F to 180°F

Approvals: UL, CSA

AFS-460-121

CLEVELAND CONTROLS AIR

PRESSURE SENSING SWITCH

The NS2 series, Universal Small Footprint Air Switch, replaces hundreds of other small

footprint exact replacement air switches today. Five separate springs cover ranges from

.05”WC to 10”WC. Set screw adjustment with allen wrench included. Eight different orifice

restrictors to set different time delays, and comes with two brackets for all applications

NS2-0000-03

AIR SWITCHES

SERIES AFS SWITCHES

AIR SWITCHES

STOCKED IN CDC

SH# RSS-495-011

Other Cleveland Controls Switch manuals

Cleveland Controls

Cleveland Controls AFS–460 User manual

Cleveland Controls

Cleveland Controls FS-751-112 User manual

Cleveland Controls

Cleveland Controls AFS-951 User manual

Cleveland Controls

Cleveland Controls AFS-460-137 User manual

Cleveland Controls

Cleveland Controls AFS–442 User manual

Cleveland Controls

Cleveland Controls AFS-961 Operating and installation instructions

Cleveland Controls

Cleveland Controls AFS-460-136 User manual

Cleveland Controls

Cleveland Controls AFS-951-1 User manual