Bulletin LT-AFS-460-136-07

Cleveland Controls

1111 Brookpark Rd

Cleveland OH 44109

Tel: 216-398-0330

Fax: 216-398-8558

Email:saleshvac@clevelandcontrols

.com

Web page: http://www.clevelandcontrols.com

Are you

reading a FAX

or a COPY of this

bulletin? DOWNLOAD

the full-color PDF ver-

sion of this and other

literature at our

website!

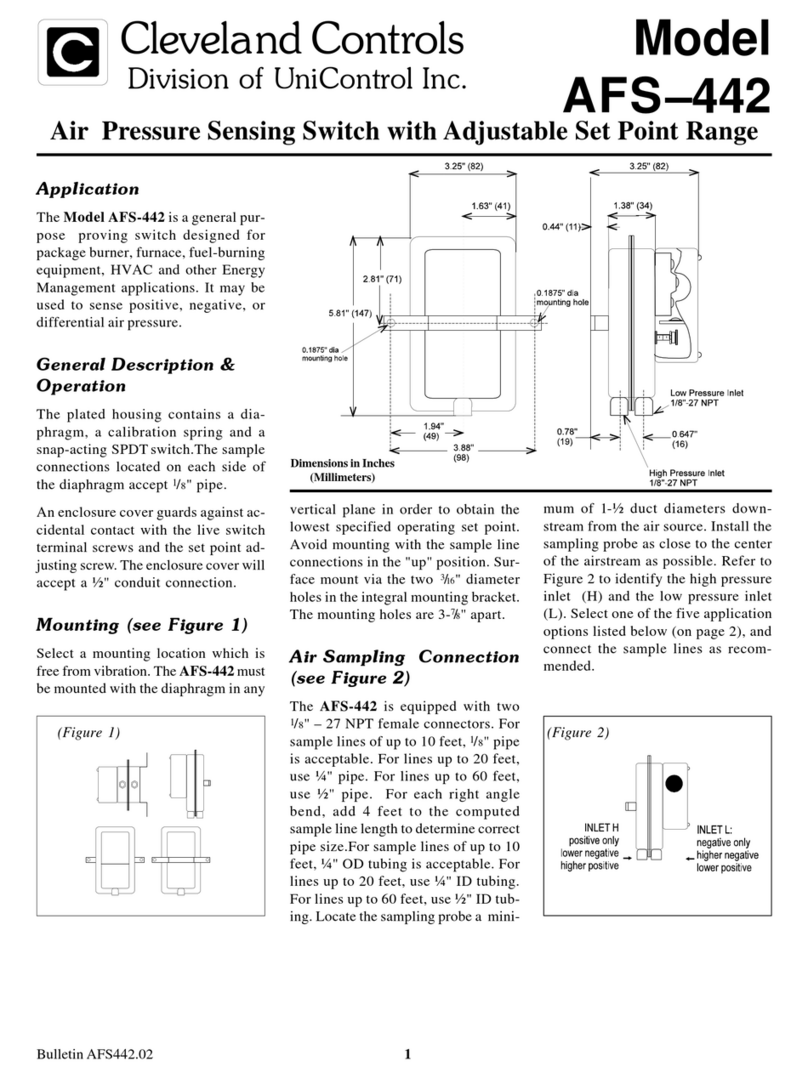

(Figure 1)

APPLICATION

The Model AFS-460–136 is a general pur-

pose airow proving switch designed for

120 VAC HVAC and Energy Management

applications where a manual reset switch

with DPDT contacts is desirable. It may be

used to sense positive, negative, or differ-

ential air pressure.

GENERAL DESCRIPTION &

OPERATION

The plated housing contains a diaphragm, a

calibration spring, a snap-acting switch with

manual reset button, and a dpdt relay.

The sample connections located on each

side of the diaphragm accept .25" OD tub-

ing via the integral compression ferrule and

nut.

An enclosure cover guards against acci-

dental contact with the live switch terminal

screws and the set point adjusting screw.

The enclosure cover will accept a 0.5" con-

duit connection. The manual reset button is

located on the top surface of the enclosure

cover.

MOUNTING (SEE FIGURE 1)

Select a mounting location which is free

from vibration. The AFS-460–136 must be

mounted with the diaphragm in any vertical

plane in order to obtain the lowest specied

operating set point. Avoid mounting with the

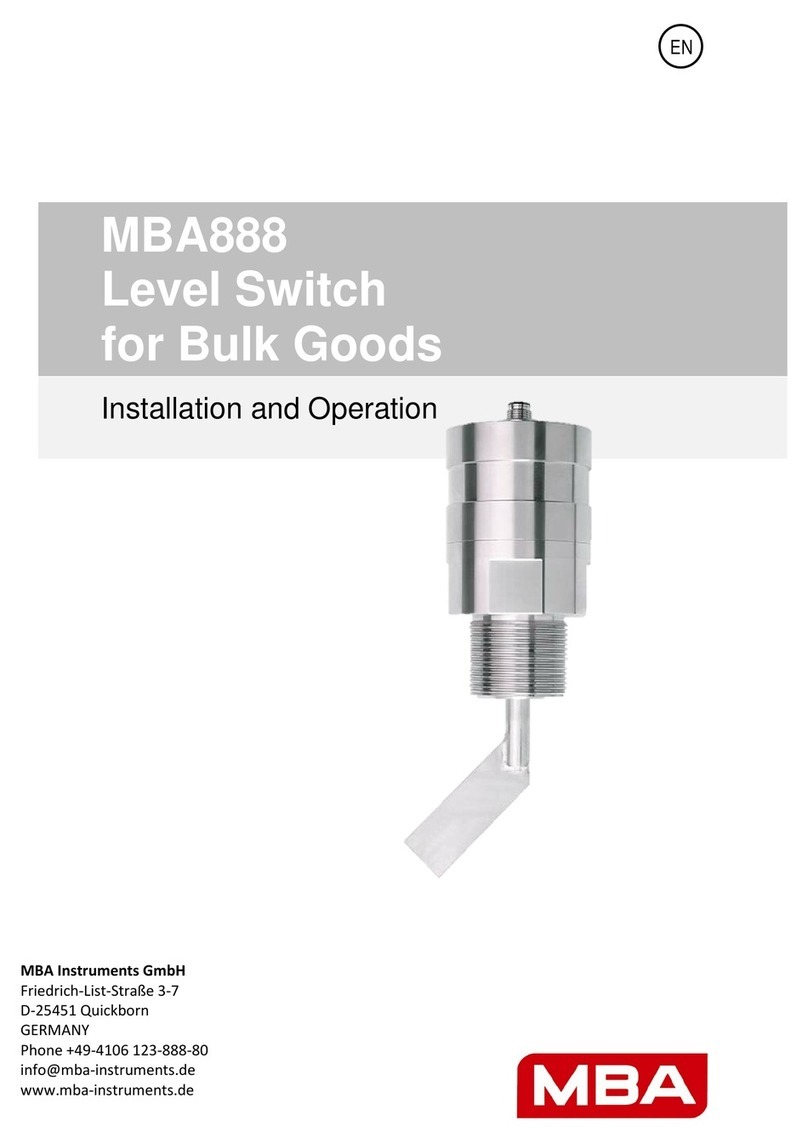

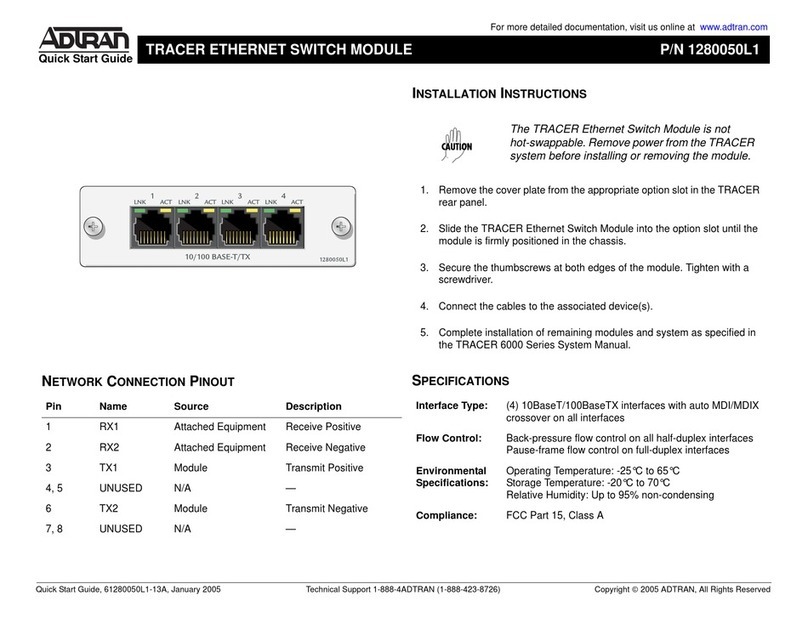

(Figure 2)

sample line connections in the "up" position.

Surface mount via the two 3/16" diameter

holes in the integral mounting bracket. The

mounting holes are 3-7/8" apart.

AIR SAMPLING

CONNECTION

(SEE FIGURE 2)

The AFS-460–136 is designed to accept

rm-wall sample lines of ¼" OD tubing by

means of ferrule and nut compression con-

nections. An optional ¼" adapter, suitable

for slip-on exible tubing is available. For

sample lines of up to 10 feet, ¼" OD tubing

is acceptable. For lines up to 20 feet, use ¼"

ID tubing. For lines up to 60 feet, use ½" ID

tubing. Locate the sampling probe a mini-

mum of 1.5 duct diameters downstream from

the air source. Install the sampling probe as

close to the center of the airstream as pos-

sible. Refer to Figure 2 to identify the high

pressure inlet (H), and the low pressure inlet

(L). Select one of the ve application options

listed below, and connect the sample lines

as recommended.

POSITIVE PRESSURE ONLY: Connect

the sample line to inlet H; inlet L remains

open to the atmosphere.

NEGATIVE PRESSURE ONLY: Connect

the sample line to inlet L; inlet H remains

open to the atmosphere.

TWO NEGATIVE SAMPLES: Connect the

higher negative sample to inlet L. Connect

the lower negative sample to inlet H.

TWO POSITIVE SAMPLES: Connect the

higher positive sample to inlet H. Connect

the lower positive sample to inlet L.

ONE POSITIVE AND ONE NEGATIVE

SAMPLE: Connect the positive sample

to inlet H. Connect the negative sample

to inlet L.

Model

AFS-460-136

Manual Reset DPDT Air Pressure Sensing Switch for 120 VAC Applications