Cleveland Motion Controls Cleveland-Kidder TMI User manual

INSTRUCTION mm. A800-7425 J (Page 1 of 16)

1.0 GENERAL INFORMATION

1.1 RECEIVING AND UNPACKING

Handle and unpack the equipment carefully.Operating Conditions

Immediatelyuponarrival,check theshipment against the

packing list. Any damage should be reported

immediately to the carrier and to the nearest CMC

representative.

Equipmentwhich willnot be installedimmediately should

be stored in a clean, dry location. Precautions should be

taken to prevent moisture, dust and dirt from

accumulating in storage and installation areas.

1.2 SPECIFICATIONS

Electrical

AC Supply -100/115/230VAC ±10%,

50/60Hz, Jumper selectable

Input Power -15 VA

Transducer

Excitation -5.6 VDC

Tension

Output Signal -0-10 VDC, 5 mA

Conditioned -0-10 VDC, 5 mA or adjustable

Tension Output 0-2 VDC, approximately 2K

Signal Ohm output impedance

Calibration -Full scale range of 8:1

TLD Output -1 N.O. & 1 N.C. 5 Amp,

Contactor 250 VAC resistive (each limit)

(Optional)

Isolation -0-10 VDC, 5 mA or 4 to

Amplifier 20 mADC, 1500 VRMS

(Optional) (2000V peak) isolated

Ambient

Temperature -0-40EC (32-104EF)

Relative

Humidity -5%to 95% (w/ocondensation)

Altitude -to 6600 Ft. (2000 meters)

Weight

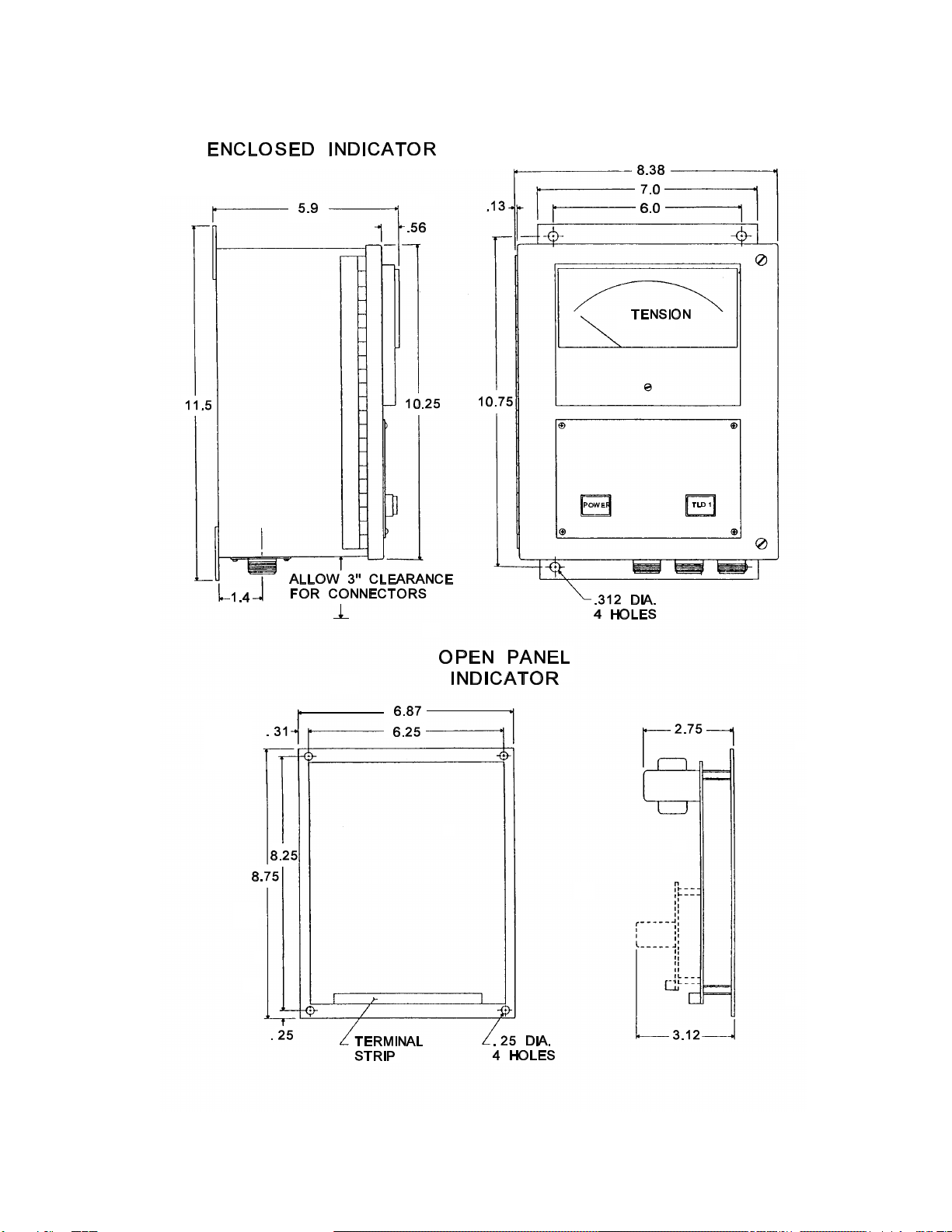

Enclosed Indicators -12 Lbs.

Open Panel

Indicators -3 Lbs.

1.3 DESCRIPTION

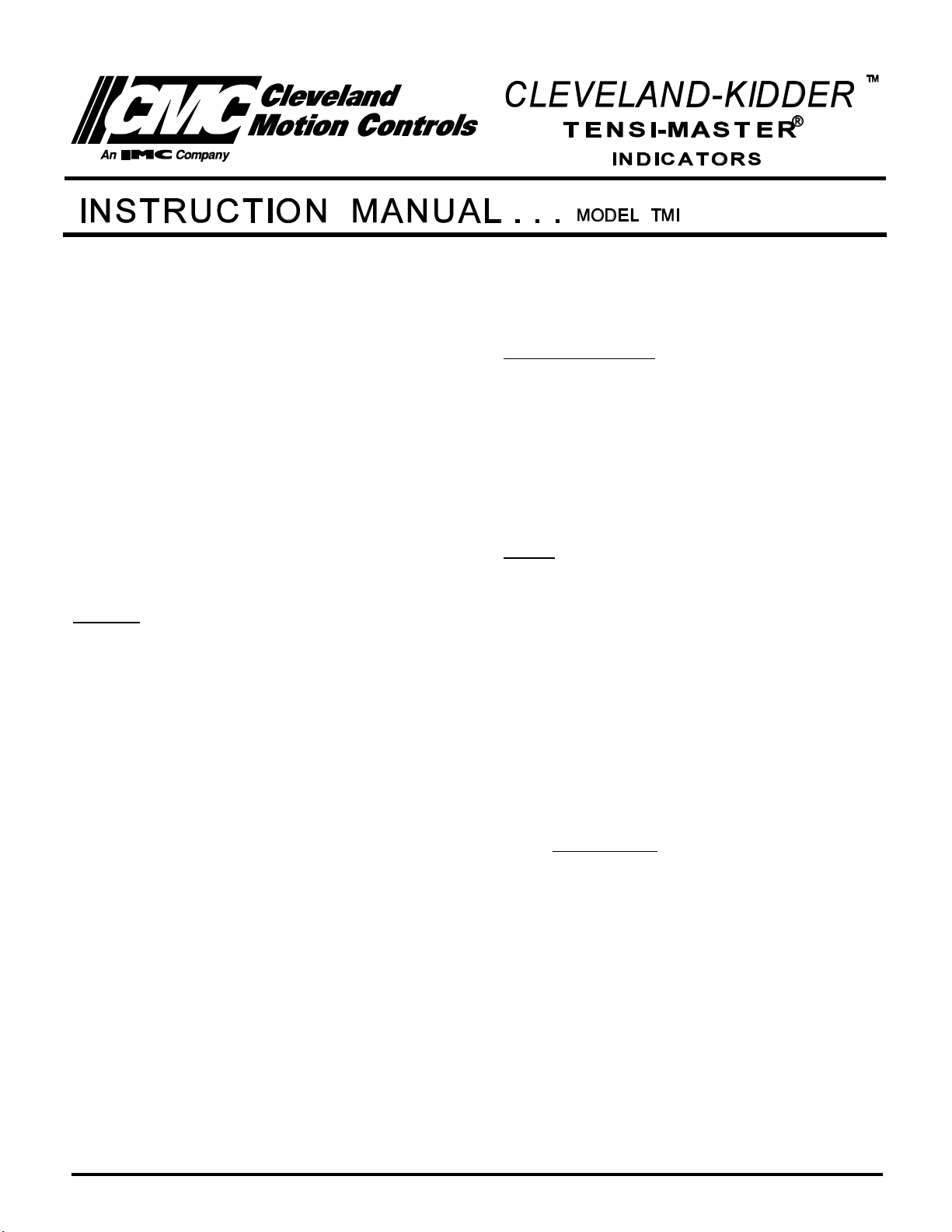

The indicators are assembled from modules as shown in

Figure 1 on page 2. The modular approach improves

versatility by increasing the combinations of features

available.

1.3.1 Circuit Boards - There are two circuit boards

available. - Standard Circuit Board

- TRL Circuit Board

The Standard circuit board amplifiesthe signals from the

transducer(s) and provides a tension output signal which

represents the total tension measured by the

transducers.

TheTRL circuit board independently amplifies the

signalsfrom each oftwo transducers, theleft transducer

andthe right transducer of the sensing roll. There are

three tension output signals from this circuit board, one

for the left transducer, one for the right transducer, and

one for the total of the left and the right.

2 of 18 A800-7425 J

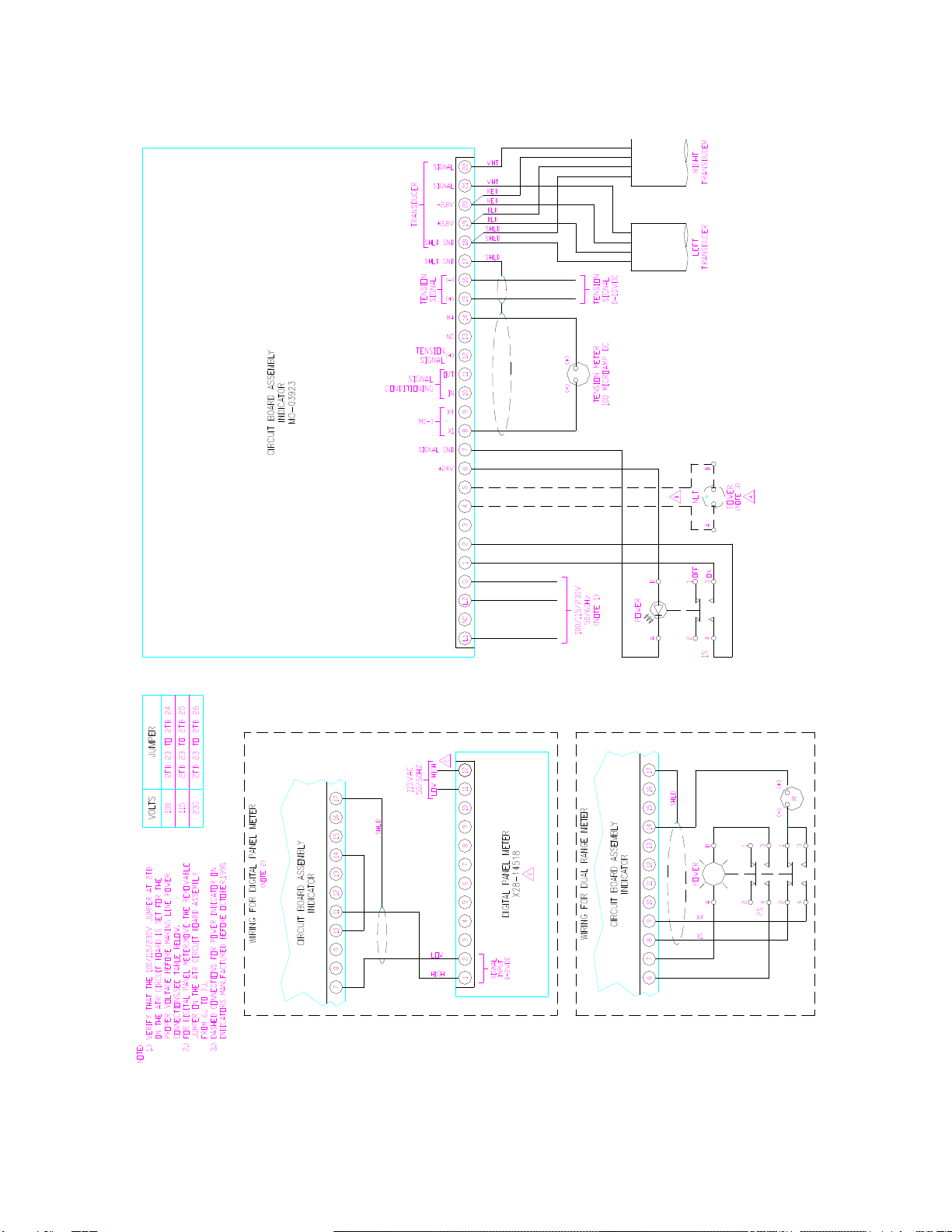

Figure 1

1.0 GENERAL INFORMATION

3 of 18 A800-7425 J

1.0 GENERAL INFORMATION

1.3.2 Operator Panels - There is a selection of fivewiringharnessextensionareused.Shieldedwire should

operator panels which have the following switches. be used as shown on the installation wiring diagram.

- ON/OFF 1.3.6 Connector Plate Option - The connector plate has

- ON/OFF + TLD two 5 pin receptacles for transducer cables and a 3 pin

- ON/OFF + TLD + TLD receptacle for the tension output signal. It includes a

- ON/OFF + DUAL RANGE wiring harness for connections to the circuit board, and

- ON/OFF + TRL mounts on the bottom of the enclosure.

The operator panels consist of the nameplate, switches 1.3.7 AC Power Card (115 VAC only) Option - This

and attached wiring harness. option includes a 115 VAC line cord and bushing. It

The ON/OFF switch controls the line power

The TLD switch enables or disables the tension limit

relay card.

The dual range switch increases the analog meter

sensitivity by 4 times. It cannot be used with a digital

meter.

The TRL switch changes the meter display to left, total

orright transducer tension(requires TRL circuit board).

1.3.3 Output Card Option - There are two plug-in

output option cards available.

- Tension Limit Detection Relay Card

- Isolation Amplifier Card

Up to two output option cards can be used per indicator

except that only one isolation amplifier card can be used

per indicator.

The TENSION LIMIT DETECTION RELAY card

can be used for low or high tension limit detection. The

ISOLATION AMPLIFIER card provides an isolated

0-10 VDC or a 40-20mADC output.

1.3.4 Digital/AnalogMeter/BlankPlateOption -A 3½

inch digit panel meter or a 5½ inch analog meter are

available. The blank meter plate can be installed if the

meter is not mounted to the enclosure.

1.3.5 Enclosure/Open Panel - The enclosure is used for

wall mounting and the open panel is used for mounting

insidea console. The meters, operator panels and

connector plate can be used with the open panel

provided that a customer supplied terminal block and

mounts in the bottom of the enclosure.

1.4 EQUIPMENT DESCRIPTION

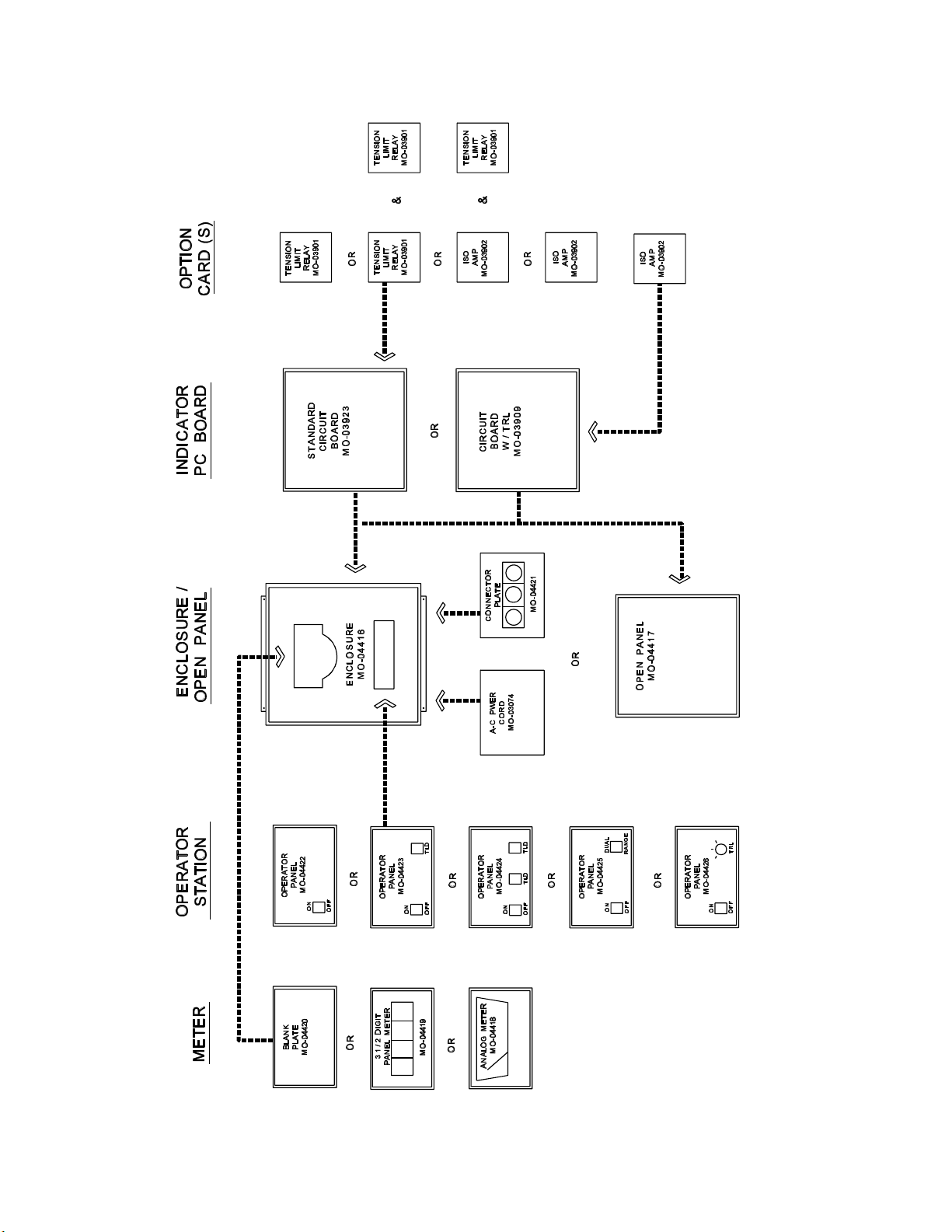

Refer to Figure 2 on page 4.

1. Terminal Block (2TB) - This terminal block has a

moveable jumper for selecting the proper line

voltage.

2. ZeroPot (1P) - This adjustment is used to

electronically zero out the tare weight of the

tension sensing roll during installation and

calibration. On TRL versions, it calibrates the left

transducer only.

3. Calibrate Pot (2P) - This adjustment is used to

calibrate the full scale tension reading. For

example, a 0-100 scale might be calibrated 1:1 to

read 100# full scale, or perhaps 2:1 to read 50# full

scale. On TRL versions, it calibrates the left

transducer only.

4. RightZero Pot -(3P) - This adjustment is installed

for TRL versions only. It is used to calibrate the

right transducer only.

5. Right Calibrate Pot (4P) - This adjustment is

installed for TRL versions only. It is used to

calibrate the right transducer only.

6. TLD Select Switch (SW) - For TLD (Tension

Limit Detection Relay) option only. For low limit

detection set switch to L position. For high limit

detection set switch to H position.

7. Tension Limit Detector Delay Pot - For TLD

option only. It determines the time delay between

4 of 18 A800-7425 J

Figure 2

when the tension level goes out of range and the

switching of the TLD relay.

1.0 GENERAL INFORMATION

8. Tension Limit Detector Level Pot - For TLD12. Jumper - This moveable jumper should be in

option only. This adjustment sets the tension levelposition 7J for use with digital tension meter.

at which the TLD relay switches. Position 6J provides a 0-10VDC tension signal

9. Isolation Amplifier Power Cable - For isolation

amplifieroption only.The cable must be connected13. Potentiometer 5P - Adjustment for the digital

between 22TB on the isolation amplifier and 3TBtension meter display.

on the indicator main circuit board. It supplies

power to operate the isolation amplifier.

10. IsolationAmplifier Selection Switch - For isolation

amplifier option only. Set switch to 0-10V position

for 0 to 10 VDC output, set switch to 4-20mA

position for 4-20mADC output.

11. Line Power Fuse - Replace with 3AG, 0.5A, 250

fuse only.

output.

1.5 PRINCIPLES OF OPERATION

The measurement of the actual tension in a web is made

by sensing, with strain gage transducers, the force on a

sensing roll caused by the tension in the web. The

electrical signal from the transducers is registered on the

tension indicator meter as the total tension.

5 of 18 A800-7425 J

Figure 3

WARNING

These Installation Instructions are for use by

qualifiedpersonnel only. Toreduce the risk of

electric shock, do not perform any servicing

other than that contained in the Operating

Instructions unless you are qualified to do so.

CAUTION

Before making any line power connections,

verifythat the 100/115/230V jumper at2TB on

theCircuit Board Assembly is set for the

proper voltage. Refer to the following table:

The indication system shown in Figure 3 utilizes two

strain gate transducers and sums the signals in the indicator.

The Tensi-Master indicators can also be used for

cantilever, wire, and single transducer applications.

1.0 GENERAL INFORMATION

2.0 INSTALLATION

AC VOLTS JUMPER

100 2TB-23 TO 2TB-24

115 2TB-23 TO 2TB-25

230 2TB-23 TO 2TB-26

Look in the back of the manual for the outline drawing

for mounting dimensions and the wiring diagram for

cable connections.

For indicators with terminal block connections, the ends

of the transducer cables having the shield lead are

connected to the indicator. For indicators which have

MSconnectors, the ends of the transducer cables that

are marked white are connected to the indicator. For

indicator mating connectors, refer to the following table.

MATING CONNECTORS FOR INDICATORS

Position

on wire

Squeeze

pliers

Push into

hole

AC POWER CORD HOOKUP

6 of 18 A800-7425 J

Figure 4

USE CMC P/N DESCRIPTION

Transducer X43-06825 5 Pin Connector

Cable MS-3106A-14S-5P

X43-06928 Clamp and Bushing

Amphenol 97-3057-1007-1

Tension X43-07181 3 Pin Connector

Output MS-3106A-14S-7P

Signal X43-06928 Clamp and Bushing

Amphenol 97-3057-1007-1

2.0 INSTALLATION

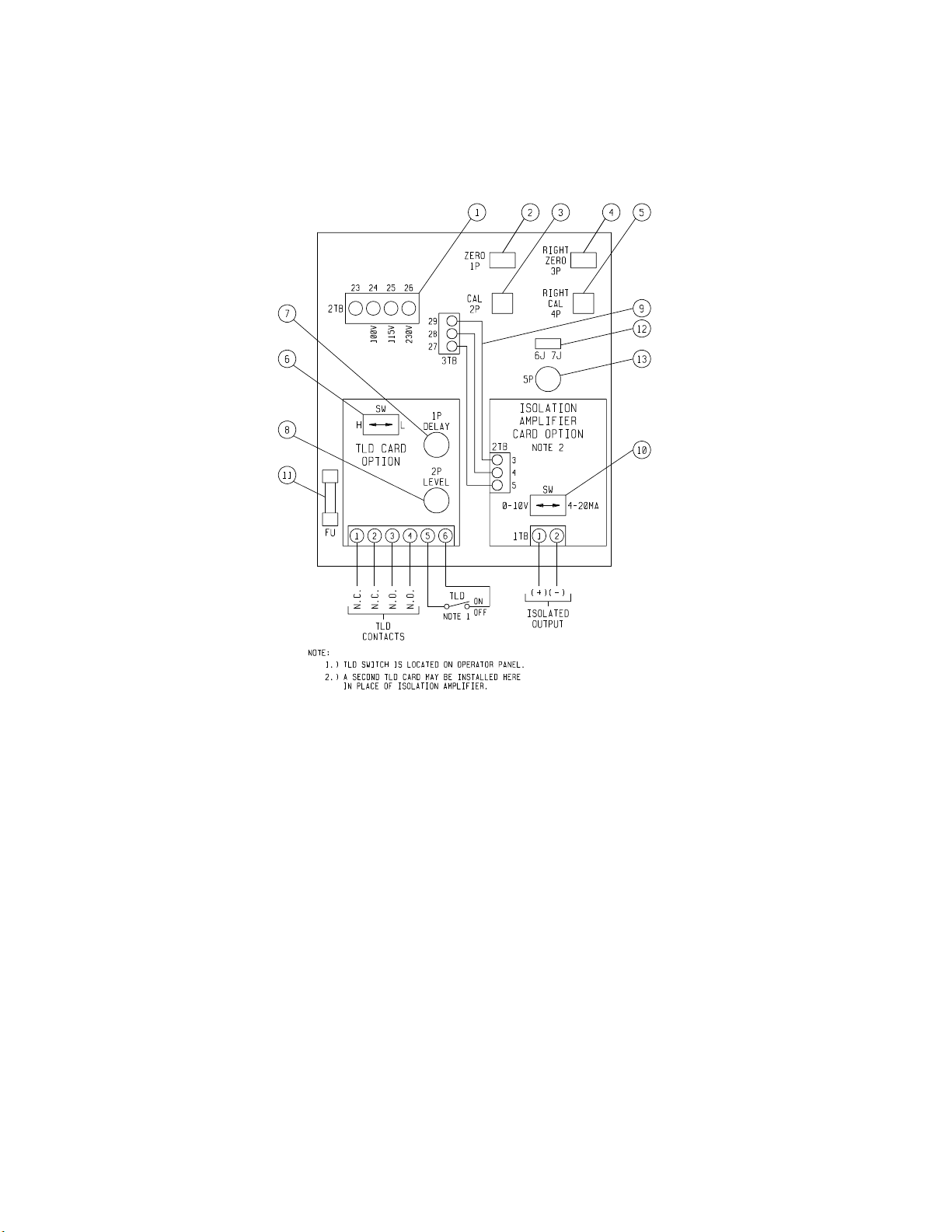

2.1 AC POWER CORD HOOKUP (MO-03074)

Positionthe strain relief bushing on the line cord as

shown. Insert the line cord into the rectangular hole in

the bottom of the enclosure. Refer to Figure 4.

Makethe following connections to terminal block 1TB.

Brown wire to L1

Blue wire to L2

Green wire to G

Using pliers, squeeze the mating halves of the strain

relief bushing together and insert intothe enclosure hole.

2.2 TENSION LIMIT DETECTION

RELAY OPTION

If the output contacts are to be used (See Section 3.4),

aconduit hole must be drilled in the enclosure bottom in

orderto bring the output contacts external to the tension

indicator.

Use ½ inch electrical trade size conduit. Refer to the

National Electric Code for guidelines governing

installation and wiring.

1 .7MOUNTING LOCATION, TLD OUTPUT CONTACTS

SIZE HOLE FOR 1/2 INCH ELECTRICAL CONDUIT

1 /2"

AC POWER

CORD

7 of 18 A800-7425 J

Figure 5

WARNING

The following Calibration Instructions are for

useby qualified personnelonly. To reduce the

risk of electric shock, DO NOT perform any

servicing other than that contained in the

Operating Instructions unless you are qualified

to do so.

Route the required output contact wiring from the

Tension Limit Detection Relay Card terminal block

through this conduit. See Figure 5.

3.0 ADJUSTMENTS

Check that the indicator has been wired correctly per

the installation wiring diagram and that the jumper at

2TB is set for the proper line voltage.

3.1 ANALOG METER MECHANICAL

ZERO-ADJUSTMENT

Before turning the unit on, check to see that the meter

needle is on zero. Make any required adjustments with

the small zero adjustment screw on the meter face.

3.2 ELECTRICAL ZERO-ADJUSTMENT

Switch the unit on and allow three or four minutes

warm-up time. The pilot light will indicate power is being

supplied to the indicator.

The models with the TRL feature have a zero and a

calibrate adjustment for both the left transducer and

8 of 18 A800-7425 J

Figure 6

3.0 ADJUSTMENTS

the right transducer. Calibrate the left transducer with be suitable to calibrate using a 100 lb. weight (or

the TRL switch in the left position and calibratethe right100 lbs. force on a spring scale).

transducer with the TRL switch in the right position.

Witha screwdriver, turn the calibrate adjustmentmeter needle to the desired reading.

potentiometer ¾ clockwise. Using the zero adjustment

potentiometer, zero the tension meter. D. Remove the load. The meter should return to zero.

Check to see that the system is operating properly byand C again checking meter zero. Two or three

applying a force to the sensing roll. Pushing or pulling inload applications are sometimes required to

the load direction of the web force should cause theproperly "seat" the transducers. With all

tension meter to move up scale. adjustments completed, remove any cords and

3.3 CALIBRATION

The unit should be calibrated so that normal running

tensions will be about mid-scale and the maximum

tensions will not go off scale.

For TRL models, calibrate each transducer for about

25% of scale so that the total signal is about mid-scale.

NOTE: It is recommended that the indicators be

calibrated with the transducers at the process operating

temperature.

Spring Scale or Weight Method of Calibration

A. Thread a length of rope or flat webbing over the

center of the sensing roll, as shown in Figure 6. Do

notthread over non-turningrollers, driven rolls, or

frame braces as any sliding friction will cause

inaccurate calibration.

B. Apply a known tension load using weights or a

spring scale. If possible, the applied load should be

approximately the same as the anticipated

operating tension. If, for example, a normal

operating tension of 100lbs is anticipated, it would

C. Usingthe CALIBRATE adjustment bring the

If necessary, readjust ZERO then repeat steps B

weights used in the calibration procedure.

If it is found during running that the operating tension is

much less (or greater) than estimated, a recalibration

may be required.

3.3.1 Calibration with Dual Range (Scale X4) Feature

-The calibration procedure is similar to that for standard

indicators except that the calibration should be made on

the most sensitive scale (lower scale). For example, with

0-25/0-100 meter scale, calibrate on the 0-25 scale.

3.3.2 Calibration with TRL Feature - The calibration

procedure issimilar to thatfor standard indicators. Note

that the calibration procedure can be made in either of

two ways. The quickest method is to apply a known

tension load exactly midway between the transducers.

Then calibrate on each side for ½ of the load. That is,

with the indicator on TOTAL apply a known load for

example, 50 Lbs. Switch to RIGHT and calibrateso the

meter reads 25 Lbs. Switch to LEFTand again calibrate

to 25 Lbs. If necessary, repeat the calibration.

Calibration can also be made by applying loads

simultaneouslytobothtransducers.TheTOTALshould

always be equal to the sum of the two applied loads.

3.4 CALIBRATION OF THE TLD CARD

OPTION

If the TLD card is not installed, mount it with the four

plastic standoffs to the indicator circuit board assembly

as shown in Figure 2. Connect a TLD on-off switch as

shown in Figure 2.

9 of 18 A800-7425 J

3.0 ADJUSTMENTS

3.4.1 TLD Low Limit Calibration - Put TLD select

switch to L position. In order for the TLD circuit to

operate, the TLD switch on the front cover must be on

(illuminated). If the switch is off the TLD function is

bypassed.

The tension limit detector level (2P) on the TLD card

shouldbeadjustedslightlybelowtheminimumoperating

tension. The tension limit detector delay (1P) on the

TLD card should be adjusted for the minimum time

delay without causing the TLD relay to trip on normal

tension transients.

Whenthe tension dropsbelow the tension limit detector

level set point, a set of normally open and normally

closed relay contacts on the TLD card will switch

states.

3.4.2 TLD High Limit Calibration - Put TLD select

switch to H position. In order for the TLD circuit to

operate, the TLD switch on the front cover must be on

(illuminated). If the switch is off the TLD function is

bypassed.

The tension limit detector level (2P) on the TLD card

should be adjusted slightly above the maximum operating

tension. The tension limit detector delay (1P) on the

TLD card should be adjusted for the minimum time

delay without causing the TLD relay to trip on normal

tension transients.

When the tension rises above the tension limit detector

level set point, a set of normally open and normally

closed relay contacts on the TLD card will switch

states.

3.5 ISOLATION AMPLIFIER OPTION

Mount the isolation amplifier card to the indicator circuit

board with the four plastic standoffs as shown in Figure

2. Connect the short 3 wire cable from 2TB on the

isolation amplifier card to 3TB on the indicator circuit

board.

Positionthe switch on the isolation amplifier card to the

0-10V position fora 0 to 10 VDC isolated tension output

signal, or to the 4-20mA position for a 4-20mADC

isolated tension output signal. 3.6.1 Decimal Point Selection

3.6 DIGITAL TENSION METER

Asignal conditioning circuit is included on the indicator

circuitboard for displayingthe tension on a digital meter.

The moveable jumper on the circuit board should be in

position 7J.

When the 0-10 VDC tension output signal is fed to 1TB-

10 on the circuit board a conditioned adjustable 0 to 2

VDC for the digital meter is present at 1TB-11.

Potentiometer 5P of the signal conditioning circuit

normally is factory adjusted for a 0-1 VDC output with

a0-10 VDC tension output signal as an input. This

allows a 3½ digit 0-2 VDC digital meter to display 100.0

at full scale.

By adjusting 5P, the full scale reading on the 2 VDC

digital panel meter can be changed to any reading

between 35.0 to 199.9 with a 10 VDC tension output

signal present at 1TB-10.

10 of 18 A800-7425 J

WARNING

These TroubleshootingInstructions are for use

by qualified personnel only.To reduce the risk

of electric shock, donot perform any servicing

other than that contained in the Operating

Instructions unless you are qualified to do so.

4.0 TROUBLESHOOTING

4.1 EXCESSIVE OUTPUT SIGNAL

WITH NO LOAD

Try to re-zero with zeroing pot(s).

There may be a high degree of misalignment of the

transducers causing a severe pre-load.

or

The sensing guide roll assembly may be excessively

heavy. The sensing guide roll should not weigh more

than ½ the maximum working force of the transducers

in most cases.

4.2 LOW OUTPUT SIGNAL

The transducer may have too large a maximum working

forcefor the application. Replace with a lower

maximum working force transducer or increase web

wrap angle.

4.3 OUTPUT SIGNAL FAILS TO INCREASE

WITH ADDED LOAD

The transducers are overloaded and are hitting their

stops. Replace the transducers with ones having a

higher maximum working force or reduce the load. This

may be accomplished by reducing the web wrap angle

and/or using a lighter sensing roll.

4.4 WRONG POLARITY OF OUTPUT

SIGNAL

Transducersmayhavebeenincorrectlyoriented.Rotate

transducers 180 degrees or if rotation is impossible,

interchangethe redand theblack transducer cableleads

at the tension indicator.

11 of 18 A800-7425 J

4.5 OUTPUT SIGNAL NOT LINEAR, OR

ZERO SHIFTS DURING OPERATION

Check transducer and tension roll mounting. All

mountingbolts must be tight. Check that there is no dirt

or foreign matter interfering with the transducer

mounting.

4.6 NO OUTPUT SIGNAL

Check to see that all connections have been made

completely. Check for places where the connecting

cables might be crimped or cut. Verify that AC

Voltage is present from 1TB-3 to 1TB-4.

4.7 VERY HIGH OUTPUT WITH NO LOAD

Check cables and connectors for good connections and

check continuity of cables with an ohmmeter. Check for

proper wiring to transducers.

Check transducer gage resistance as given in the

transducer instruction manual.

5.0 REPLACEMENT PARTS

Description Use P/N

Lamp Power ON/OFF X01-21443

Switch, PB Power ON/OFF X16-11705

Lens, Red Power ON/OFF X01-21442

Lamp, 28V TLD X01-11702

Switch, PB TLD X16-11705

Lens, Orange TLD X16-13943

Lamp, 28V Dual Range X01-11702

Switch, PB Dual Range X16-11739

Lens, Orange Dual Range X16-13943

Switch, 3 Position TRL X16-09930

Knob TRL X01-13944

Fuse, 250V, .25A Circuit Board X21-07231

6.0 SERVICE ASSISTANCE AND

REPAIR

For additional service assistance, please obtain the

Type, MWF, and Serial Number from the nameplate.

Contact the Factory Service Department.

Phone: (216) 524-8800

Fax: (216) 642-5155

Disassembly byimproperly trained personnel may result

in additional damage to these units. Should repairs be

required or for warranty repairs, contact the Customer

Service Department for a return authorization number

before returning the units.

12 of 18 A800-7425 J

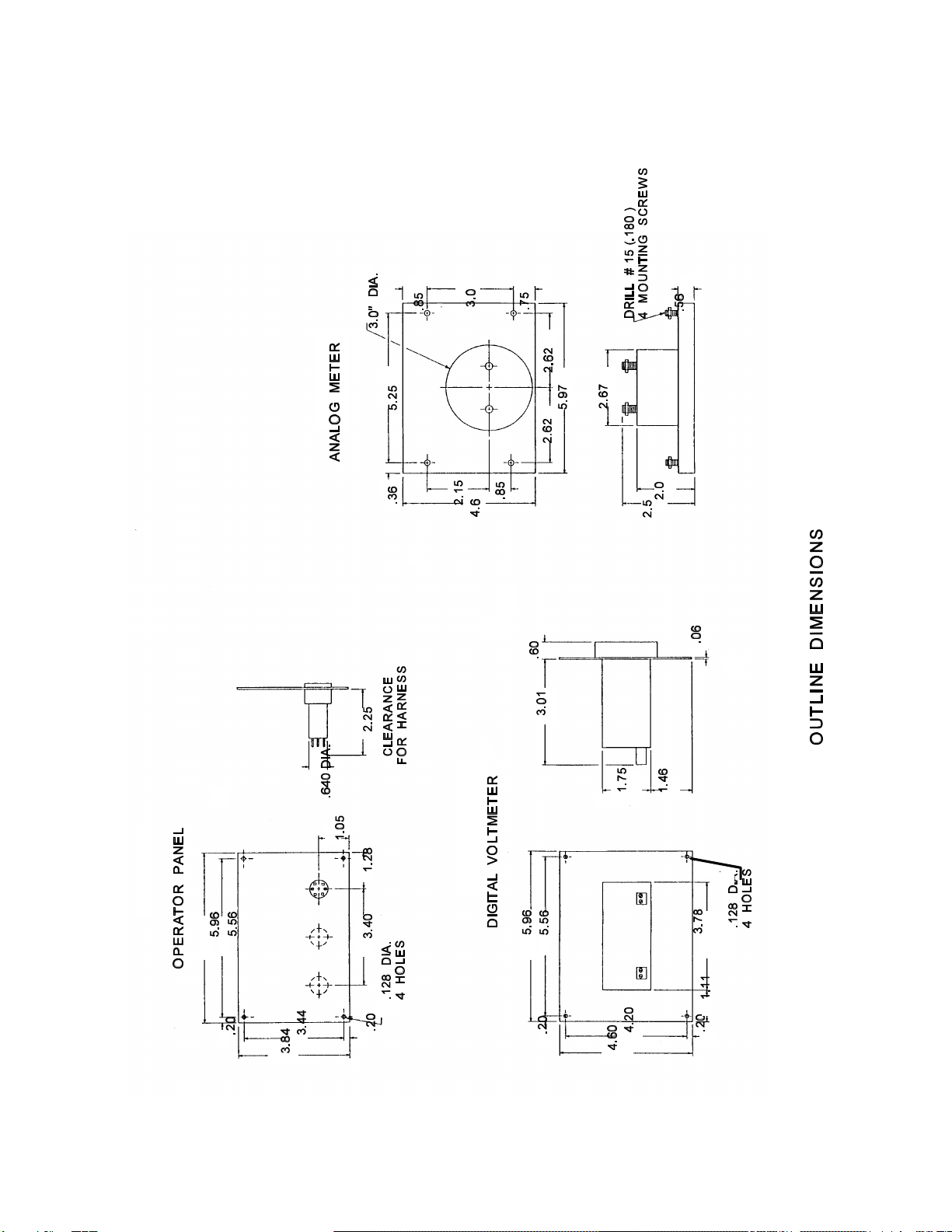

7.0 OUTLINE DIMENSIONS

13 of 18 A800-7425 J

7.0 OUTLINE DIMENSIONS

3 RECP2 RECP1 RECP

123 4 5 6

15 16 17 18 19 20 21 22

SIGNAL

TRANSDUCER

ABC D E A B C D E A B C

TENSION

D

LEFT RIGHT

TRANSDUCER TRANSDUCER TENSION

SIGNAL

0 - 10 VDC

1234 5 6

T L D

NOTE: T L D TERMINALS 1 & 2 NORMALLY CLOSED AND

3 & 4 NORMALLY OPEN WHEN TENSION IS

WITHIN THE NORMAL OPERATING LIMITS.

EACH CONTACT IS RATED AT 5 AMP , 115 VAC RESISTIVE.

12 3 4 5 6 7 8 9 10 11

T L D CARD

T L D

A B

2

4 3

1OFF

ON

CIRCUIT BOARD ASSEMBLY

T L D CARD

CIRCUIT BOARD ASSEMBLY

SCHEMATIC, TLD OPTION

INSTALLATION

WIRING DIAGRAM

FOR TLD CARD SCHEMATIC

CONNECTOR PLATE

14 of 18 A800-7425 J

8.0 INSTALLATION WIRING DIAGRAM

15 of 18 A800-7425 J

INSTRUCTION mm. A800-7425 J (Page 1 of 16)

8.0 INSTALLATION WIRING DIAGRAM

16 of 18 A800-7425 J

8.0 INSTALLATION WIRING DIAGRAM

17 of 18 A800-7425 J

9.0 WARRANTY AND LIMITATION OF LIABILITY

CLEVELAND MOTION CONTROLS, INC.

LIMITED WARRANTY.

ALLGOODS ARE SOLD SUBJECT TO

THE MUTUAL AGREEMENT THAT

THEY ARE WARRANTED BY THE

COMPANY TO BE FREE FROM

DEFECTS IN MATERIAL AND

WORKMANSHIP FOR ONE YEAR

FROM THE DATE OF SHIPMENT. THE

COMPANY'S WARRANTY DOES NOT

COVER, AND IT MAKES NO

WARRANTY WITH RESPECT TO ANY

DEFECT, FAILURE, DEFICIENCY OR

ERROR WHICH IS:

A) NOTREPORTED TO THE

COMPANY WITHIN THE

APPLICABLE WARRANTY

PERIOD; OR

B) DUE TO MISAPPLICATION,

MODIFICATION,

DISASSEMBLY, ABUSE,

MISUSE, IMPROPER

INSTALLATION,

UNAUTHORIZED REPAIR,

IMPROPER MAINTENANCE OR

ABNORMAL CONDITIONS OF

TEMPERATURE, DIRT OR

CORROSIVE MATTER; OR

C) DUETO OPERATION, EITHER

INTENTIONALOR

OTHERWISE, ABOVE RATED

CAPACITIES OR IN AN

OTHERWISE IMPROPER

MANNER.

THE FOREGOING WARRANTY IS IN

LIEUOF ALL OTHER WARRANTIES.

THE PARTIES AGREE THAT THE

IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS

FORA PARTICULAR PURPOSE AND

ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, ARE EXCLUDED FROM

THE

SAL

E

OF GOODS.

18 of 18 A800-7425 J

INSTRUCTION mm. A800-7425 J (Page 1 of 16)

LIMITATION OF REMEDY AND

LIABILITY.

THE REMEDY PROVIDED HEREIN IS

BUYER'S SOLE AND EXCLUSIVE

REMEDY. THE BUYER'S REMEDY

AND THE COMPANY'S LIABILITY

(WHETHER UNDER THE THEORIES

OF BREACH OF WARRANTY,

CONTRACT, TORT INCLUDING

NEGLIGENCE OR STRICT LIABILITY

OR ANY OTHER LEGAL THEORY)

SHALL BE LIMITED EXCLUSIVELY

AT THE COMPANY'S OPTION TO

REPLACING OR REPAIRING

WITHOUT CHARGE AT THE

COMPANY'S FACTORY OR

ELSEWHERE ANY MATERIAL OR

WORKMANSHIP DEFECTS WHICH

BECOME APPARENT WITHIN ONE

YEAR FROM THE DATE ON WHICH

THEGOODS WERE SHIPPED. THE

COMPANY SHALL NOT BE LIABLE

FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIALDAMAGES OF ANY

KIND INCLUDING BUT NOT LIMITED

TO DAMAGES FOR LOSS OF USE,

INCOME OR PROFIT, OR LOSSES

SUSTAINED AS A RESULT OF INJURY

(INCLUDING DEATH) TO ANY

PERSON OR DAMAGES TO

PROPERTY. THE COMPANY SHALL

HAVE NO LIABILITY FOR DAMAGES

OF ANY KIND ARISING FROM THE

INSTALLATION AND/OR USE OF THE

GOODS BY ANYONE. BY THE

ACCEPTANCE OF THE GOODS, THE

BUYER SHALL ASSUME ALL

LIABILITY FOR ANY DAMAGES

WHICH MAY RESULT FROM USE OR

MISUSE BY THE BUYER, ITS

EMPLOYEES OR BY OTHERS.

Table of contents