1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Web Site: www.clevelandrange.com

Cleveland Range, LLC

SINCE 1922 INNOVATIVE STEAM COOKING SOLUTIONS

Cook/Chill Systems

SECT. XIV PAGE 51

0402

GAS FIRED STEAM BOILERS

MODELS:

GFB-6

GFB-15

GFB-30

GFB-10

GFB-20

GFB-50

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Cleveland Standard Features

■Complete skid-mounted and piped, gas fired Steam Boiler with

Vertical Return System and Blow Down Separator

■Available for Pressure Ratings from 15 to 150 psi

■Vertical Tubeless design

■Fully insulated Boiler with top mounted, down-fired burners

■High Temperature Insulation assists thermal efficiency of 80%

■Spinning Cyclonic Flame travels down the entire length of the

Combustion Chamber

■Top Flame Retainer increases occupancy time of flue gases to

complete combustion process

■Operating Pressure Control and High Limit Pressure Control

with Manual Reset

■Water Column with Water Gauge Assembly

■All necessary valves are included

■Automatic Water Feed System with probe type Water Level

Controls and single phase Motor for Pump

■Steam Outlet conveniently located at top of Boiler

■Control Panel factory mounted and wired, ready for power con-

nection

■Built and stamped to A.S.M.E. Code

■Registered with the National Board of Boiler & Pressure Vessel

Inspectors

Options & Accessories

❐Stainless Steel outer Jacket

❐Automatic Boiler Blow-down Controls

❐Applicable Controls to meet the various special insurance,

local, state or federal code requirements

❐Electric heated Steam Boilers

❐Oil-fired Steam Boilers

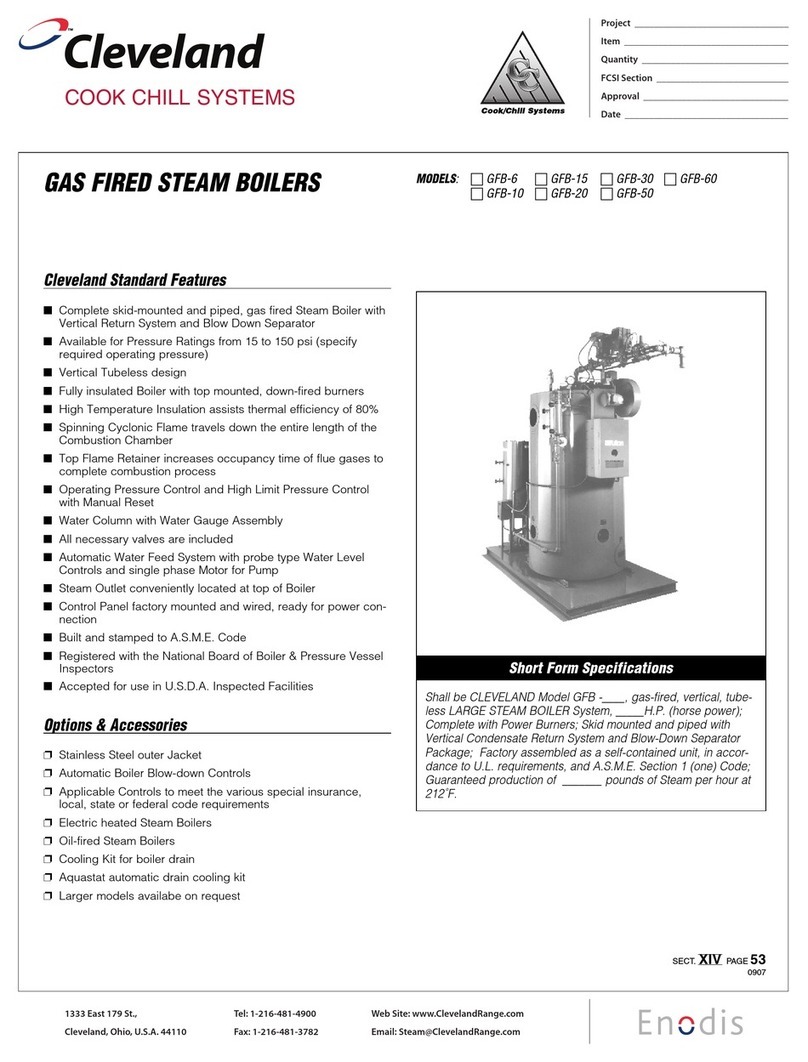

Shall be CLEVELAND Model GFB -____, gas-fired, vertical, tube-

less LARGE STEAM BOILER System, _____H.P. (horse power);

Complete with Power Burners; Skid mounted and piped with

Vertical Condensate Return System and Blow-Down Separator

Package; Factory assembled as a self-contained unit, in accor-

dance to U.L. requirements, and A.S.M.E. Section 1 (one) Code;

Guaranteed production of _______ pounds of Steam per hour at

212˚F.

Short Form Specifications