ClimateMaster AG Series Manual

Auxiliary Electric Heat

Installation, Operation &

Maintenance Instructions

97B0005N02

Revision: 1/14/13

AG Series Electric Heaters

Table of Contents

Overview 3

Vertical Upflow or Downflow

Installation - Internal 3

Vertical Upflow Installation - External 4

Horizontal Installation - External

Wiring 6

Setup 6

Ratings 7

Electrical Data 7

Staging Options 7-8

Accessory Heater Dimensions 9

Warranty 10

Revision Log 12

This page was intentionally left blank.

3

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

Overview

The AG Series Auxiliary Electric Heat mounts internally on

TS, TE and TT upflow (Figure 1b) or downflow units and all

TAH units. It mounts directly to the blower outlet of TS, TE

and TT horizontal units (Figure 8) and on all TZ units. Note

the model compatibility Table 1. Horizontal units are rated

for zero clearance at the unit and 1" clearance for first three

feet of duct, vertical units rated for zero clearance for both

unit and duct. Downflow units can not be located directly

over a discharge register. The discharge plenum must be

constructed from non combustible material. TheAG electric

heat contains a four stage relay control board which activates

the elements directly via an internally wired low voltage

harness. Low voltage signals (W1 and W2) are staged from

the CXM or DXM control of the unit.

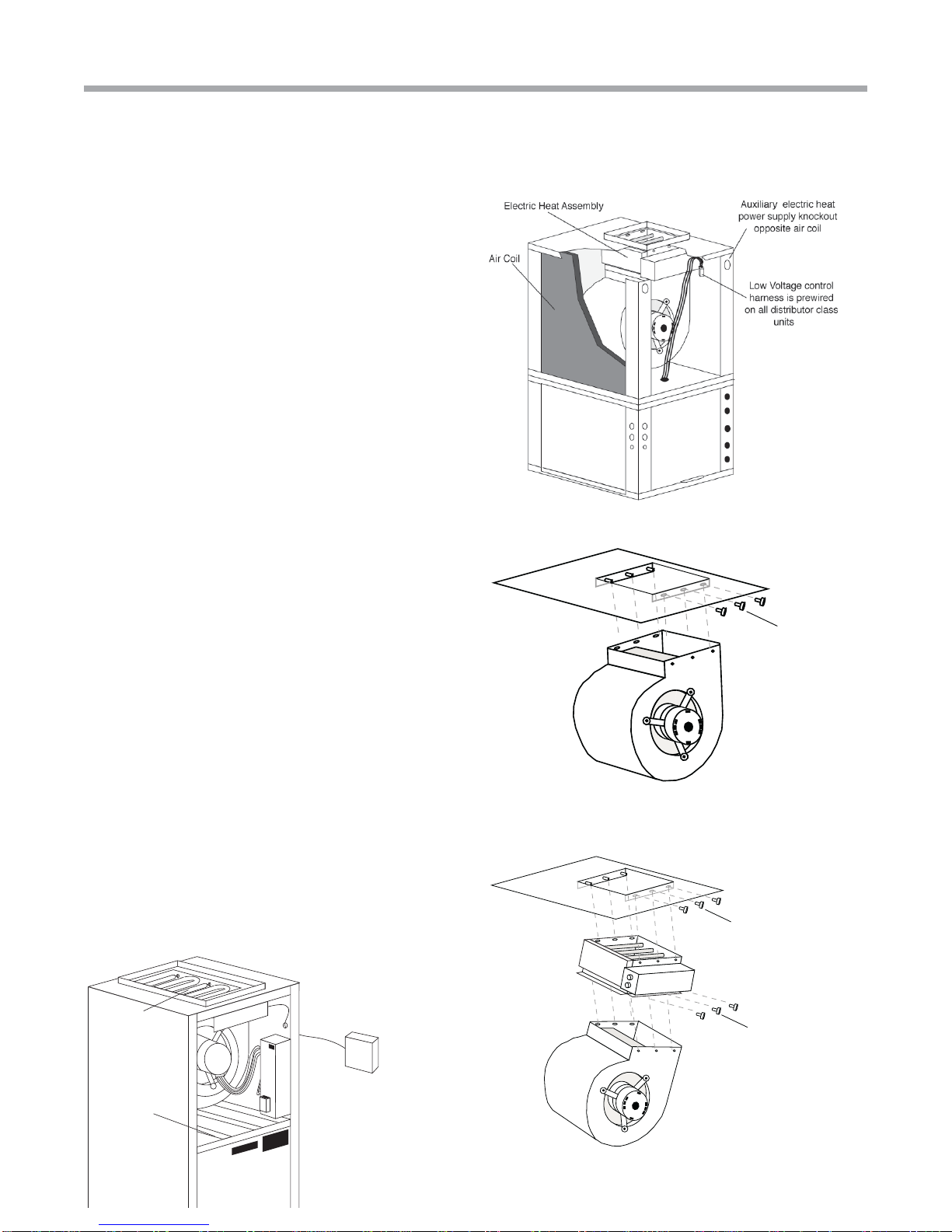

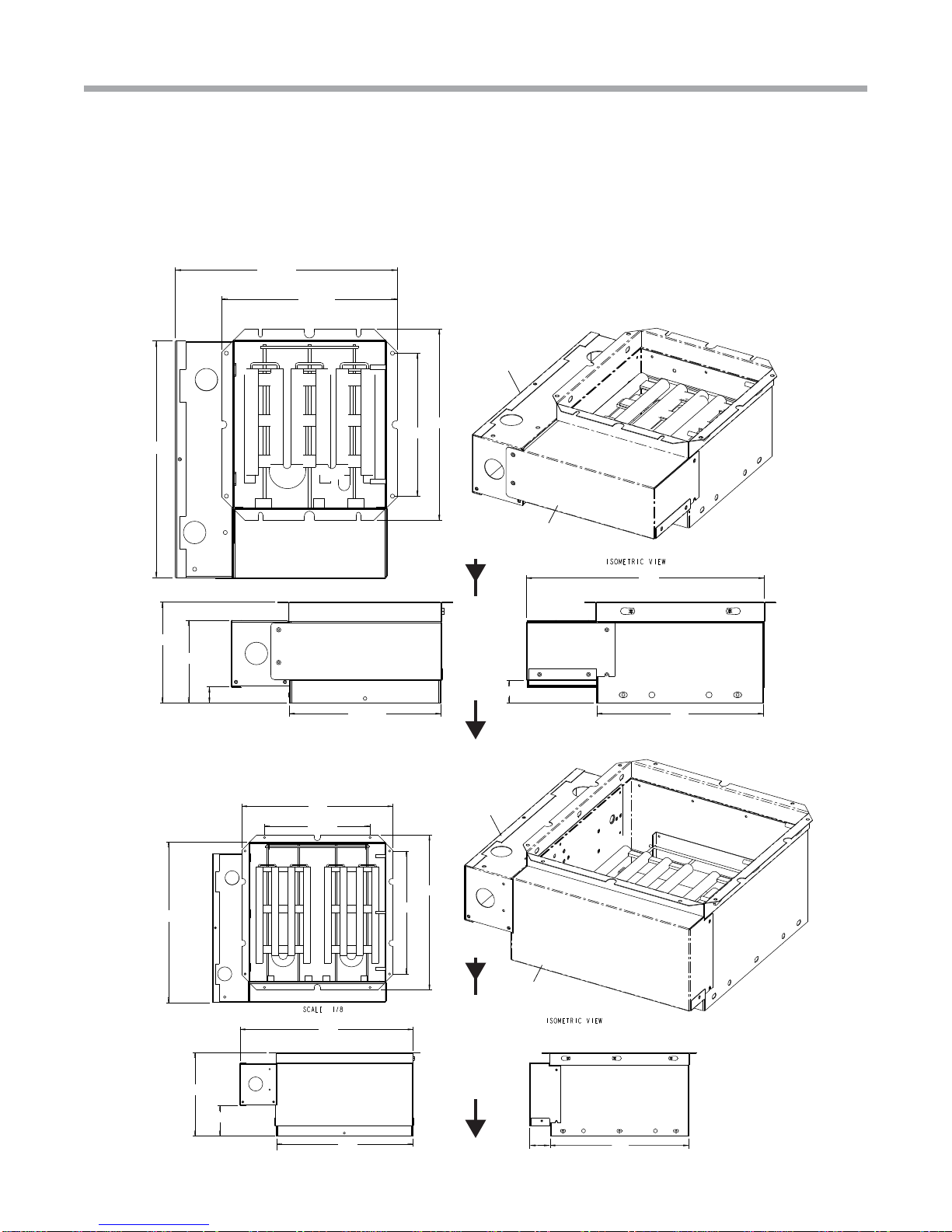

TS ,TT and TE Vertical Upflow or Downflow and TAH

Installation - Internal

1. Disconnect power to the unit.

2. Remove blower access panel(s) from the unit and

control box cover from the electric heater.

3. Remove blower mounting bolts and drop blower

assembly as shown in figure 2. Removal of electrical

wiring should not be necessary.

4. Position the electric heater as illustrated in figure 3 with

its control box facing the front access panel of the unit.

Attach heater to unit using the support pins on the back

and bolts on the front.

The electric heater air inlet dimensions should match the

unit blower outlet, installer should stop and refer to the

unit/heater compatibility chart later in this instruction or

consult factory if they do not match.

5. Re-install blower assembly on to electric heater using

pins and bolts as before. Check blower electrical wiring

for proper connection and remedy any pinched wire(s) or

contact with sharp edges.

6. Route the low voltage control harness through one of the

‘pie’ bushings in the heater control box and plug on to

the P2 connector. See figure 6.

7. Install power conduit through the unit cabinet as shown

in figure 7 and attach directly to the electric heater

control box. See figures 9a-c.

8. Replace all covers and panels, heater installation is

complete. Proceed to wiring and setup.

5HPRYHEROWV

DQGGURSEORZHU

/RFDWHHOHFWULFKHDWDVVHPEO\

RQSLQVLQGLVFKDUJHSDQHO

DQGLQVHUWEROWV

5HORFDWHEORZHULQHOHFWULF

KHDWDVVHPEO\LQVDPH

PDQQHU

Figure 2: Blower removal

Figure 3: AG electric heat mounting and

blower re-installation

Figure 1b: Typical vertical unit installation

Overview

$LU&RLO

(OHFWULF+HDW

$VVHPEO\

)LHOGVXSSOLHG

GLVFRQQHFW

UHIHUWRORFDOFRGHV

/RZYROWDJHFRQWUROKDUQHVV

LVSUHZLUHGRQDOO

GLVWULEXWRUFODVVXQLWV

Figure 1a: Typical air handler installation

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

4Geothermal Heat Pump Systems

Vertical Installation - External

Auxiliary electric heat

power supply knockout

opposite air coil

Electric Heat Assembly

Air Coil

Low Voltage control harness

is prewired on all distributor

class units.

*

Figure 4: Typical Vertical External Mount Installation

TZ Vertical Upflow External Installation

1. Disconnect power to the unit.

2. Remove blower access panel(s) from the unit and control

box and element covers from the electric heater.

3. Locate remove and discard blower discharge flanges

from the unit but save the screws. Flanges will be

packaged loose inside the blower compartment of

vertical upflow units. TZ036 and 042 units require a

transition bracket between the cabinet top and the

electric heater. This bracket is packaged inside the

blower compartment for field installation.

4. Position the electric heater as illustrated herein. Heater

control box should be facing the front access panel of

vertical units.

The electric heater air inlet dimensions should match

the unit air outlet, installer should stop and refer to the

unit/heater compatibility chart later in this instruction or

consult factory if they do not match.

5. Use the saved blower flange screws to attach the heater

by its flanges to the unit panel except do not fasten

flange on control box side.

6. Use aluminum tape (not provided) to seal all four heater

flanges to the blower panel.

7. Locate and route the low voltage control harness through

the top panel knockout(s). Seal the penetration ‘air tight’.

This harness is factory installed on all TZ units (wire-tied

to the fan housing).

8. Route the control harness through one of the ‘pie’

bushings in the heater control box and plug on to the P2

connector. See figure 5.

9. Install power conduit and attach directly to the electric

heater control box. See figures 5a-c.

10. Replace all covers and panels, heater installation is

complete. Proceed to wiring and setup.

Figure 5: Power Conduit And Wire Routing

(internal mount)

5

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

Horizontal External Installation

1. Disconnect power to the unit.

2. Remove blower access panel from the unit and control box

and element covers from the electric heater.

3. Remove and discard blower discharge flanges from the

unit but save the screws. TZ036 and 042 units require

a transition bracket between the cabinet top and the

electric heater. This bracket is packaged inside the

blower compartment for field installation.

4. Position the electric heater as illustrated herein. Notice

that the discharge air opening is off centered in the

blower panel. The electric heater must be positioned so

that its control box is located vertically over the wide

side of this panel.

The electric heater air inlet dimensions should match

the unit air outlet, installer should stop and refer to the

unit/heater compatibility chart later in this instruction or

consult factory if they do not match.

5. Use the saved blower flange screws to attach the heater

by its flanges to the unit panel except do not fasten

flange on control box side.

6. Use aluminum tape (not provided) to seal all four heater

flanges to the blower panel.

7. Locate and route the low voltage control harness

through one of the unit corner post or blower panel

knockout(s). Seal the penetration ‘air tight’. This harness

is factory installed and wire-tied to the fan housing.

8. Route the control harness through one of the ‘pie’

bushings in the heater control box and plug on to the P2

connector. See figure 6.

9. Install power conduit and attach directly to the electric

heater control box.

10. Replace all covers and panels, heater installation is

complete. Proceed to wiring and setup.

Figure 6: Low Voltage Harness Connection

Figure 8: Typical Horizontal Installation

Horizontal Installation - External

Locate electric heat

harness in air handler

and route through

one of the provided

bushing

Field-supplied disconnect

(refer to local codes)

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

6Geothermal Heat Pump Systems

21

2))

21

2))

3

,QDQGN:XQLWV

WZRSRZHUFLUFXLWVDUH

HPSOR\HGWRUHGXFHZLUHV

VL]HDQGFRVWRIEUHDNHUV

/

/

/

/

3

&RQGXLW

Figure 8a: Power Wiring, Dual Circuits, 15, 20kw Figure 8b: Power Wiring, Single Circuit, 12, 15, 20kw

Wiring and Setup (all models)

1. Install power wiring and connect to power block or

circuit breakers. In 15 or 20kW models two power

circuits may be used to reduce wiring and breaker

costs as in Figure 8a. If a single circuit supply is

desired, install the optional single circuit accessory kit

(P/N 16B0002N02), as shown in Figure 8b, that can be

obtained from your distributor.

Optional for TAH: AG**C kits only. Blower power may

be supplied from T3 & T4 CB5 breaker. Refer to wiring

diagram 96B0143N01.

2.

Ensure unit airflow setting is above minimum airflow rating

for the electric heat model from Table 1.

3. Check staging jumpers for the application. Typically

only 5 kW (factory setting on all models except 10kW on

20kW models) is needed for first stage electric (W1) to

minimize electric demand. This staging can be adjusted

by moving the staging jumpers as shown in Figure 9.

Whatever is jumped to P1 pin 1 will be energized on

1st stage of electric heat, and P1-2 will be energized as

stage 2 electric heat. See Table 4 for staging options.

4. Mark the appropriate box of the electric heat model

installed on the additional serial plate on the exterior of

the unit.

5. Turn on the power to the unit and the auxiliary

electric heat.

Auxiliary Electric Heat Start-up

Put thermostat in emergency heat mode (or jumper t-stat

input R to W and R to G) and setpoint to high setting. ‘Touch-

jumper' the test pins of the CXM or DXM into test mode to

reduce time delays. Unit will require 15-20 seconds before

engaging emergency heat mode stage 1 (W1) and then

another 15-20 seconds to engage stage 2 (W2) when in ‘Test

mode’. Verify proper electric heat operation.

NO

Com ER1

NO

Com ER2

NO

Com ER3

NO

Com ER4

123

Tan

Ora

Factory Staging

(see Table 2)

Low Voltage Connector

(from Unit Control Board)

AG Electric Heat

Relay Board P1P2

24V

W1

W2

4

5kW (‘ER1’ 5kW & ‘ER4’ 0kW) and W2 (second stage)

will have 10kW (‘ER2 & 3’ 5kW each)

1234

Tan

Ora

P2

Side View as seen in Control Box

P1

Staging Example on a 15kW unit W1 (first stage) has

blank

Figure 9: Staging Jumpers

Figure 8c: Power Wiring, 4, 5, 8, and 10kw

Wiring

In 15 and 20 kW units, optional

single power circuit is employed to

reduce the number of wires needed.

Conduit

7

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

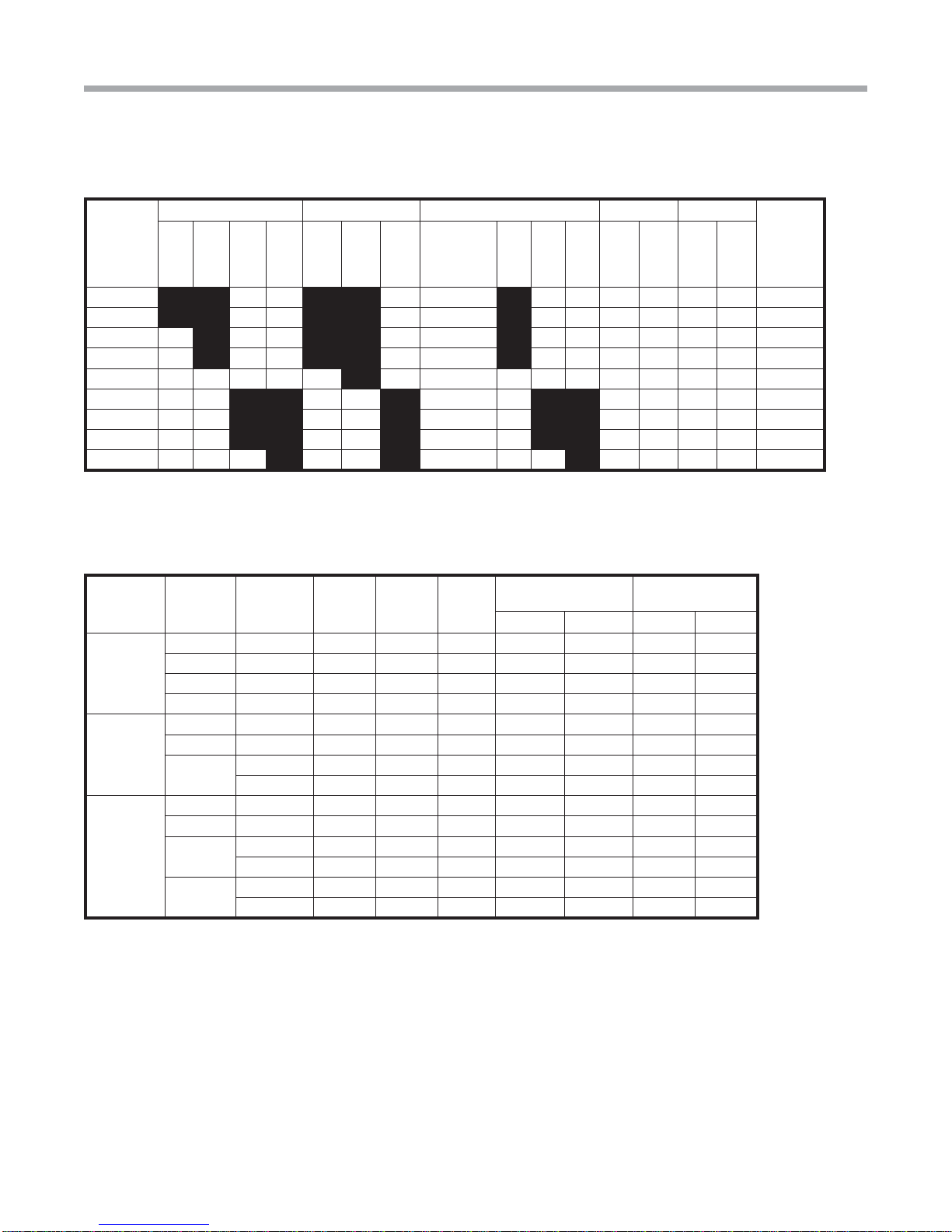

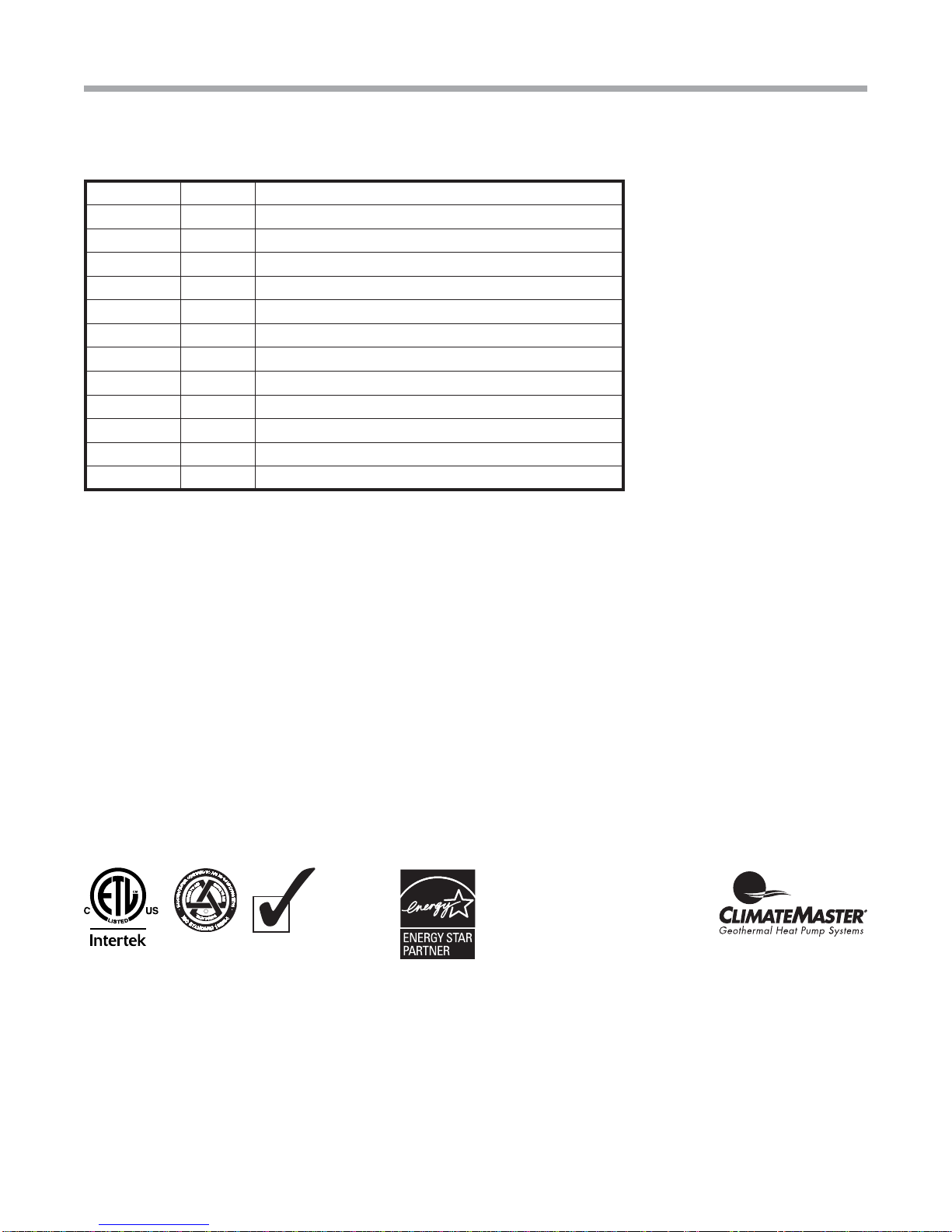

Table 2: AG Electric Heat Electrical Data - TAH

Table 1: AG Electric Heat Ratings

Staging Options

Auxiliary

Electric

Heat

Model

TS, TT, TE Models TZ Models TAH Models kW Rating Btuh Rating Minimum

CFM

Required

018 024-

030 036-

038 042-

072 024 030-

042 048-

060

Auxiliary

Electric

Heat

Model*

026 038 049-

064 240V 208V 240V 208V

AGM4A AGM4C 3.8 2.9 13000 9900 500

AGM5A AGM5C 4.8 3.6 16300 12300 500

AGM8A AGM8C 7.6 5.7 25900 19400 650

AGM10A AGM10C 9.6 7.2 32700 24600 650

AGM12A 11.4 8.6 38900 29200 750

AGL4A AGL4C 3.8 2.9 13000 9900 500

AGL10A AGL10C 9.6 7.2 32700 24600 1300

AGL15A AGL15C 14.4 10.8 49100 36900 1350

AGL20A AGL20C 19.2 14.4 65500 49200 1350

Black area denotes compatibility

Note: Horizontal units rated for zero clearance unit and 1” clearance for the first three feet of duct,

Vertical units rated for zero clearance for both unit and duct.

* Can be used on corresponding TZ, TE, TS and TT models

Unit Model Head Kit

Model Supply Heater

Amps

240

Heater

Amps

208

Blower

FLA Minimum Circuit Amps Maximum Breaker

Size

240 V 208 V 240 V 208 V

TAH026

AGM4C SINGLE 15.8 14 4.3 25 23 25 25

AGM 5C SINGLE 20 17.3 4.3 30 27 30 30

AGM 8C SINGLE 31.7 27.5 4.3 45 40 45 40

AGM 10C SINGLE 40 34.7 4.3 55 49 60 50

TAH038

AGL4C SINGLE 15.8 14 4.3 28.5 26.25 30 30

AGL10C SINGLE 40 34.7 4.3 59 52 60 60

AGL15C DUAL L1/L2 40 34.7 0 50 43 50 45

L3/L4 20 17.3 4.3 34 30 35 30

TAH049 and

TAH060

AGL4C SINGLE 15.8 14 7 28.5 26.25 30 30

AGL10C SINGLE 40 34.7 7.0 59 52 60 60

AGL15C DUAL L1/L2 40 34.7 0.0 50 43 50 45

L3/L4 20 17.3 7.0 34 30 35 30

AGL20C DUAL L1/L2 40 34.7 0.0 50 43 50 45

L3/L4 40 34.7 7.0 59 52 60 60

All heaters rated single phase 208-240V 60Hz All Fuses UL Class K general purpose

All models 15kW or larger feature internal circuit breakers

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

8Geothermal Heat Pump Systems

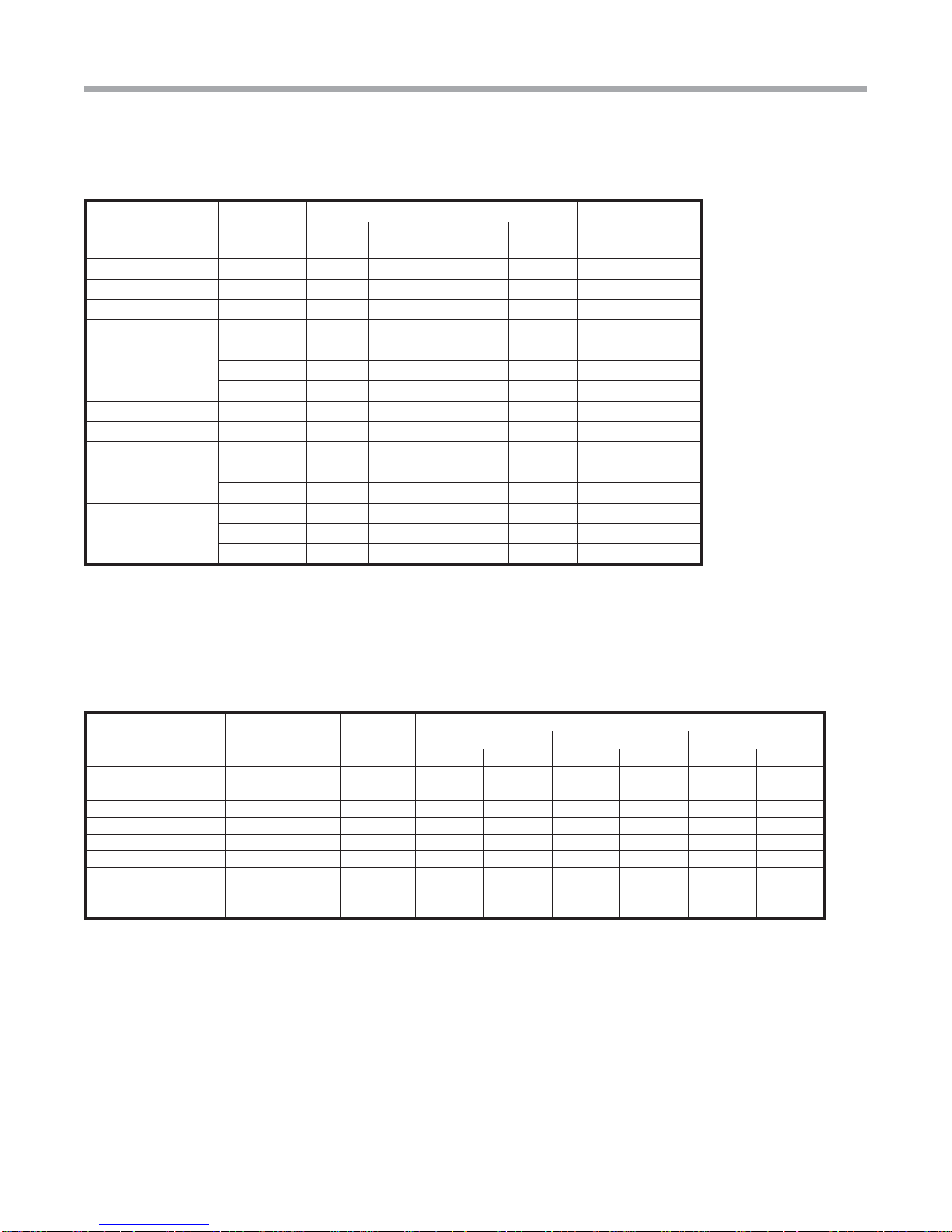

Table 4: AG Electric Heat Staging Options

Auxiliary Electric

Heat Model Staging

Options Factory

Settings

Stage 1

Staging in kW

Jumper 1-4, 2-3† Jumper 1-3, 2-4† Jumper 1-2-3

Stage 1 Stage 2 Stage 1 Stage 2 Stage 1 Stage 2

AGM4A or C 4 4 4 0 4 0 4 0

AGM5A or C 5 5 5 0 5 0 5 0

AGM8A or C 4 or 8 4 4 4 4 4 8 0

AGM10A or C 5 or 10 5 5 5 5 5 10 0

AGM12A or C 4, 8 or 12 4 4 8 8 4 12 0

AGL4A or C 4 4 4 0 4 0 4 0

AGL10A or C 5 or 10 5 5 5 5 5 10 0

AGL15A or C 5, 10 or 15 5 5 10 10 5 15 0

AGL20A or C 5, 10, 15 or 20 10 10 10 10 10 15 5

† Factory jumper setting

Auxiliary Electric

Heat Model Supply

Circuit

Heater Amps Minimum Circuit Amps Maximum Fuse

240V 208V 240V 208V 240V 208V

AGM4A Single 15.8 14.0 19.8 17.1 20 20

AGM5A Single 20.0 17.3 25.0 21.6 25 25

AGM8A Single 31.7 27.5 39.6 34.4 40 35

AGM10A Single 40.0 34.7 50.0 43.4 50 45

AGM12A

Single 47.5 41.2 59.4 51.5 60 60

Dual - L1/L2 31.7 27.5 39.6 34.4 40 35

Dual - L3/L4 15.8 13.7 19.8 17.1 20 20

AGL4A Single 15.8 14.0 19.8 17.1 20 20

AGL10A Single 40.0 34.7 50.0 43.4 50 45

AGL15A

Single 60.0 52.0 75.0 65.0 80 70

Dual - L1/L2 40.0 34.7 50.0 43.4 50 45

Dual - L3/L4 20.0 17.3 25.0 21.6 25 25

AGL20A

Single 80.0 69.3 100.0 86.6 100 90

Dual - L1/L2 40.0 34.7 50.0 43.4 50 45

Dual - L3/L4 40.0 34.7 50.0 43.4 50 45

All heaters rated single phase 208-240V 60Hz All Fuses UL Class K general purpose

All models 15kW or larger feature internal circuit breakers

Table 3: AG Electric Heat Electrical Data - TS/TT/TE

Staging Options

9

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

Accessory Heater Dimensions

Figure 10: Heater Dimensions

NOTE: The maximum recommended air velocity for a supply plenum is 900 fpm. When connecting a plenum to an

external supplemental heater, ensure that the air velocity in the plenum does not exceed 900 fpm. Noise and air

distribution issues may occur if supply plenum velocities exceed 900 fpm.

AGM4A - 12A

AGL4A - 20A

14.7

Control box

Element

cover

10.3

15.5

15.1

12

Discharge Air Opening Discharge Air Opening

16.8

8.1

3

13.3 13.5

2

A

I

R

F

L

O

W

Discharge Air Opening Discharge Air Opening

A

I

R

F

L

O

W

Rev. A 13.6

Rev. B 14.9

Rev. A 10.7

Rev. B 12.0

14.6

8.8

11.7

Control box

Element

cover

13.6

10.7

6.2

5.1

Rev. A 9.4

Rev. B 10.6

10.2

1

14.6

1.4

9.4

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

10 Geothermal Heat Pump Systems

&/,0$7(0$67(5,1&

/,0,7('(;35(66:$55$17</,0,7$7,212)5(0(',(6$1'/,$%,/,7<)25

5(6,'(17,$/&/$66352'8&76:,7+/$%25$//2:$1&(

,WLVH[SUHVVO\XQGHUVWRRGWKDWXQOHVVDVWDWHPHQWLVVSHFL¿FDOO\LGHQWL¿HGDVDZDUUDQW\VWDWHPHQWVPDGHE\&OLPDWH0DVWHU,QFD'HODZDUHFRUSRUDWLRQ³&0´RULWVUHSUHVHQWDWLYHVUHODWLQJWR&0¶VSURGXFWVZKHWKHURUDOZULWWHQRUFRQWDLQHG

LQDQ\VDOHVOLWHUDWXUHFDWDORJRUDJUHHPHQWDUHQRWH[SUHVVZDUUDQWLHVDQGGRQRWIRUPDSDUWRIWKHEDVLVRIWKHEDUJDLQEXWDUHPHUHO\&0¶VRSLQLRQRUFRPPHQGDWLRQRI&0¶VSURGXFWV(;&(37$663(&,),&$//<6(7)257+

+(5(,17+(5(,612(;35(66:$55$17<$672$1<2)&0¶6352'8&76&00$.(612:$55$17<$*$,167/$7(17'()(&76&00$.(612:$55$17<2)0(5&+$17$%,/,7<2)7+(

*22'6252)7+(),71(662)7+(*22'6)25$1<3$57,&8/$5385326(

*5$172)/,0,7('(;35(66:$55$17<

&0ZDUUDQWVLWV5HVLGHQWLDO&ODVVSURGXFWVSXUFKDVHGDQGUHWDLQHGLQWKH8QLWHG6WDWHVRI$PHULFDDQG&DQDGDWREHIUHHIURPGHIHFWVLQPDWHULDODQGZRUNPDQVKLSXQGHUQRUPDOXVHDQGPDLQWHQDQFHDVIROORZV$LUFRQGLWLRQLQJKHDWLQJ

DQGRUKHDWSXPSXQLWVEXLOWRUVROGE\&0³&08QLWV´IRUWHQ\HDUVIURPWKH:DUUDQW\,QFHSWLRQ'DWHDVGH¿QHGEHORZ7KHUPRVWDWVDX[LOLDU\HOHFWULFKHDWHUVDQGJHRWKHUPDOSXPSLQJPRGXOHVEXLOWRUVROGE\&0ZKHQLQVWDOOHG

ZLWK&08QLWVIRUWHQ\HDUVIURPWKH:DUUDQW\,QFHSWLRQ'DWHDVGH¿QHGEHORZDQG2WKHUDFFHVVRULHVDQGSDUWVEXLOWRUVROGE\&0ZKHQLQVWDOOHGZLWK&08QLWVIRURQH\HDUIURPWKHGDWHRIVKLSPHQWIURP&07KH³:DUUDQW\

,QFHSWLRQ'DWH´VKDOOEHWKHGDWHRIRULJLQDOXQLWLQVWDOODWLRQRUVL[PRQWKVIURPGDWHRIXQLWVKLSPHQWIURP&0ZKLFKHYHUFRPHV¿UVW

7RPDNHDFODLPXQGHUWKLVZDUUDQW\SDUWVPXVWEHUHWXUQHGWR&0LQ2NODKRPD&LW\2NODKRPDIUHLJKWSUHSDLGQRODWHUWKDQQLQHW\GD\VDIWHUWKHGDWHRIWKHIDLOXUHRIWKHSDUWLI&0GHWHUPLQHVWKHSDUWWREHGHIHFWLYHDQGZLWKLQ&0¶V

/LPLWHG([SUHVV:DUUDQW\&0VKDOOZKHQVXFKSDUWKDVEHHQHLWKHUUHSODFHGRUUHSDLUHGUHWXUQVXFKWRDIDFWRU\UHFRJQL]HGGLVWULEXWRUGHDOHURUVHUYLFHRUJDQL]DWLRQ)2%&02NODKRPD&LW\2NODKRPDIUHLJKWSUHSDLG7KHZDUUDQW\RQ

DQ\SDUWUHSDLUHGRUUHSODFHGXQGHUZDUUDQW\H[SLUHVDWWKHHQGRIWKHRULJLQDOZDUUDQW\SHULRG

7KLV/LPLWHG([SUHVV:DUUDQW\VKDOOFRYHUWKHODERULQFXUUHGE\&0DXWKRUL]HGVHUYLFHSHUVRQQHOLQFRQQHFWLRQZLWKWKHLQVWDOODWLRQRIDQHZRUUHSDLUHGZDUUDQW\SDUWWKDWLVFRYHUHGE\WKLV/LPLWHG([SUHVV:DUUDQW\RQO\WRWKHH[WHQW

VSHFL¿FDOO\VHWIRUWKLQWKHWKHQH[LVWLQJODERUDOORZDQFHVFKHGXOHSURYLGHGE\&0¶V:DUUDQW\'HSDUWPHQWDQGRQO\DVIROORZV&08QLWVIRU¿YH\HDUVIURPWKH:DUUDQW\,QFHSWLRQ'DWH7KHUPRVWDWVDX[LOLDU\HOHFWULFKHDWHUVDQG

JHRWKHUPDOSXPSLQJPRGXOHVEXLOWRUVROGE\&0ZKHQLQVWDOOHGZLWK&08QLWVIRU¿YH\HDUVIURPWKH:DUUDQW\,QFHSWLRQ'DWH$FWXDO/DERUFRVWVDUHQRWFRYHUHGE\WKLV/LPLWHG([SUHVV:DUUDQW\WRWKHH[WHQWWKH\H[FHHGWKHDPRXQW

DOORZHGXQGHUVDLGDOORZDQFHVFKHGXOHWKH\DUHQRWVSHFL¿FDOO\SURYLGHGIRULQVDLGDOORZDQFHVFKHGXOHWKH\DUHQRWWKHUHVXOWRIZRUNSHUIRUPHGE\&0DXWKRUL]HGVHUYLFHSHUVRQQHOWKH\DUHLQFXUUHGLQFRQQHFWLRQZLWKDSDUWQRWFRYHUHGE\

WKLV/LPLWHG([SUHVV:DUUDQW\RUWKH\DUHLQFXUUHGPRUHWKDQWKHWLPHSHULRGVVHWIRUWKLQWKLVSDUDJUDSKDIWHUWKH:DUUDQW\,QFHSWLRQ'DWH

7KLVZDUUDQW\GRHVQRWFRYHUDQGGRHVQRWDSSO\WR$LU¿OWHUVIXVHVUHIULJHUDQWÀXLGVRLO3URGXFWVUHORFDWHGDIWHULQLWLDOLQVWDOODWLRQ$Q\SRUWLRQRUFRPSRQHQWRIDQ\V\VWHPWKDWLVQRWVXSSOLHGE\&0UHJDUGOHVVRIWKHFDXVHRIWKH

IDLOXUHRIVXFKSRUWLRQRUFRPSRQHQW3URGXFWVRQZKLFKWKHXQLWLGHQWL¿FDWLRQWDJVRUODEHOVKDYHEHHQUHPRYHGRUGHIDFHG3URGXFWVRQZKLFKSD\PHQWWR&0RUWRWKHRZQHU¶VVHOOHURULQVWDOOLQJFRQWUDFWRULVLQGHIDXOW3URGXFWV

VXEMHFWHGWRLPSURSHURULQDGHTXDWHLQVWDOODWLRQPDLQWHQDQFHUHSDLUZLULQJRUYROWDJHFRQGLWLRQV3URGXFWVVXEMHFWHGWRDFFLGHQWPLVXVHQHJOLJHQFHDEXVH¿UHÀRRGOLJKWQLQJXQDXWKRUL]HGDOWHUDWLRQPLVDSSOLFDWLRQFRQWDPLQDWHG

RUFRUURVLYHDLURUOLTXLGVXSSO\RSHUDWLRQDWDEQRUPDODLURUOLTXLGWHPSHUDWXUHVRUÀRZUDWHVRURSHQLQJRIWKHUHIULJHUDQWFLUFXLWE\XQTXDOL¿HGSHUVRQQHO0ROGIXQJXVRUEDFWHULDGDPDJHV&RUURVLRQRUDEUDVLRQRIWKHSURGXFW

3URGXFWVVXSSOLHGE\RWKHUV3URGXFWVZKLFKKDYHEHHQRSHUDWHGLQDPDQQHUFRQWUDU\WR&0¶VSULQWHGLQVWUXFWLRQV3URGXFWVZKLFKKDYHLQVXI¿FLHQWSHUIRUPDQFHDVDUHVXOWRILPSURSHUV\VWHPGHVLJQRULPSURSHUDSSOLFDWLRQ

LQVWDOODWLRQRUXVHRI&0¶VSURGXFWVRU(OHFWULFLW\RUIXHOFRVWVRUDQ\LQFUHDVHVRUXQUHDOL]HGVDYLQJVLQVDPHIRUDQ\UHDVRQZKDWVRHYHU

7KLV/LPLWHG([SUHVV:DUUDQW\SURYLGHVWKHOLPLWHGODERUDOORZDQFHFRYHUDJHDVVHWIRUWKDERYH2WKHUZLVH&0LVQRWUHVSRQVLEOHIRU7KHFRVWVRIDQ\ÀXLGVUHIULJHUDQWRUV\VWHPFRPSRQHQWVVXSSOLHGE\RWKHUVRUDVVRFLDWHGODERUWRUHSDLU

RUUHSODFHWKHVDPHZKLFKLVLQFXUUHGDVDUHVXOWRIDGHIHFWLYHSDUWFRYHUHGE\&0¶V/LPLWHG([SUHVV:DUUDQW\7KHFRVWVRIODERUUHIULJHUDQWPDWHULDOVRUVHUYLFHLQFXUUHGLQGLDJQRVLVDQGUHPRYDORIWKHGHIHFWLYHSDUWRULQREWDLQLQJDQG

UHSODFLQJWKHQHZRUUHSDLUHGSDUW7UDQVSRUWDWLRQFRVWVRIWKHGHIHFWLYHSDUWIURPWKHLQVWDOODWLRQVLWHWR&0RURIWKHUHWXUQRIWKDWSDUWLIQRWFRYHUHGE\&0¶V/LPLWHG([SUHVV:DUUDQW\RU7KHFRVWVRIQRUPDOPDLQWHQDQFH

7KLV/LPLWHG([SUHVV:DUUDQW\DSSOLHVWR&05HVLGHQWLDO&ODVVSURGXFWVRUGHUHGIURP&0RQRUDIWHU0D\WKLVZRXOGJHQHUDOO\LQFOXGH&08QLWVZLWKVHULDOQXPEHUVEHJLQQLQJZLWK³1´DQGKLJKHUDQGLVQRWUHWURDFWLYHWRDQ\

SURGXFWVRUGHUHGIURP&0SULRUWR0D\WKLVZRXOGJHQHUDOO\LQFOXGH&08QLWVZLWKVHULDOQXPEHUVEHJLQQLQJZLWK³1´DQGORZHU,I\RXDUHXQVXUHLIWKLV/LPLWHG([SUHVV:DUUDQW\DSSOLHVWRWKHSURGXFW\RXKDYHSXUFKDVHG

FRQWDFW&0DWWKHSKRQHQXPEHURUDGGUHVVUHÀHFWHGEHORZ

/LPLWDWLRQ7KLV/LPLWHG([SUHVV:DUUDQW\LVJLYHQLQOLHXRIDOORWKHUZDUUDQWLHV,IQRWZLWKVWDQGLQJWKHGLVFODLPHUVFRQWDLQHGKHUHLQLWLVGHWHUPLQHGWKDWRWKHUZDUUDQWLHVH[LVWDQ\VXFKH[SUHVVZDUUDQW\LQFOXGLQJZLWKRXWOLPLWDWLRQDQ\

H[SUHVVZDUUDQWLHVRUDQ\LPSOLHGZDUUDQWLHVRI¿WQHVVIRUSDUWLFXODUSXUSRVHDQGPHUFKDQWDELOLW\VKDOOEHOLPLWHGWRWKHGXUDWLRQRIWKH/LPLWHG([SUHVV:DUUDQW\

/,0,7$7,212)5(0(',(6

,QWKHHYHQWRIDEUHDFKRIWKH/LPLWHG([SUHVV:DUUDQW\&0ZLOORQO\EHREOLJDWHGDW&0¶VRSWLRQWRUHSDLUWKHIDLOHGSDUWRUXQLWRUWRIXUQLVKDQHZRUUHEXLOWSDUWRUXQLWLQH[FKDQJHIRUWKHSDUWRUXQLWZKLFKKDVIDLOHG,IDIWHUZULWWHQQRWLFH

WR&0¶VIDFWRU\LQ2NODKRPD&LW\2NODKRPDRIHDFKGHIHFWPDOIXQFWLRQRURWKHUIDLOXUHDQGDUHDVRQDEOHQXPEHURIDWWHPSWVE\&0WRFRUUHFWWKHGHIHFWPDOIXQFWLRQRURWKHUIDLOXUHDQGWKHUHPHG\IDLOVRILWVHVVHQWLDOSXUSRVH&0VKDOO

UHIXQGWKHSXUFKDVHSULFHSDLGWR&0LQH[FKDQJHIRUWKHUHWXUQRIWKHVROGJRRGV6DLGUHIXQGVKDOOEHWKHPD[LPXPOLDELOLW\RI&07+,65(0('<,67+(62/($1'(;&/86,9(5(0('<2)7+(%8<(525385&+$6(5

$*$,167&0)25%5($&+2)&2175$&7)257+(%5($&+2)$1<:$55$17<25)25&0¶61(*/,*(1&(25,1675,&7/,$%,/,7<

/,0,7$7,212)/,$%,/,7<

&0VKDOOKDYHQROLDELOLW\IRUDQ\GDPDJHVLI&0¶VSHUIRUPDQFHLVGHOD\HGIRUDQ\UHDVRQRULVSUHYHQWHGWRDQ\H[WHQWE\DQ\HYHQWVXFKDVEXWQRWOLPLWHGWRDQ\ZDUFLYLOXQUHVWJRYHUQPHQWUHVWULFWLRQVRUUHVWUDLQWVVWULNHVRU

ZRUNVWRSSDJHV¿UHÀRRGDFFLGHQWVKRUWDJHVRIWUDQVSRUWDWLRQIXHOPDWHULDORUODERUDFWVRI*RGRUDQ\RWKHUUHDVRQEH\RQGWKHVROHFRQWURORI&0&0(;35(66/<',6&/$,06$1'(;&/8'(6$1</,$%,/,7<)25

&216(48(17,$/25,1&,'(17$/'$0$*(,1&2175$&7)25%5($&+2)$1<(;35(6625,03/,(':$55$17<25,17257:+(7+(5)25&0¶V1(*/,*(1&(25$6675,&7/,$%,/,7<

2%7$,1,1*:$55$17<3(5)250$1&(

1RUPDOO\WKHGHDOHURUVHUYLFHRUJDQL]DWLRQZKRLQVWDOOHGWKHSURGXFWVZLOOSURYLGHZDUUDQW\SHUIRUPDQFHIRUWKHRZQHU6KRXOGWKHLQVWDOOHUEHXQDYDLODEOHFRQWDFWDQ\&0UHFRJQL]HGGLVWULEXWRUGHDOHURUVHUYLFHRUJDQL]DWLRQ,IDVVLVWDQFHLV

UHTXLUHGLQREWDLQLQJZDUUDQW\SHUIRUPDQFHZULWHRUFDOO

&OLPDWH0DVWHU,QF&XVWRPHU6HUYLFH6:WK6WUHHW2NODKRPD&LW\2NODKRPDHVHUYLFH#FOLPDWHPDVWHUFRP

127(6RPHVWDWHVRU&DQDGLDQSURYLQFHVGRQRWDOORZOLPLWDWLRQVRQKRZORQJDQLPSOLHGZDUUDQW\ODVWVRUWKHOLPLWDWLRQRUH[FOXVLRQVRIFRQVHTXHQWLDORULQFLGHQWDOGDPDJHVVRWKHIRUHJRLQJH[FOXVLRQVDQGOLPLWDWLRQVPD\QRWDSSO\WR\RX

7KLVZDUUDQW\JLYHV\RXVSHFL¿FOHJDOULJKWVDQG\RXPD\DOVRKDYHRWKHUULJKWVZKLFKYDU\IURPVWDWHWRVWDWHDQGIURP&DQDGLDQSURYLQFHWR&DQDGLDQSURYLQFH

3OHDVHUHIHUWRWKH&0,QVWDOODWLRQ2SHUDWLRQDQG0DLQWHQDQFH0DQXDOIRURSHUDWLQJDQGPDLQWHQDQFHLQVWUXFWLRQV 5HY

3DUW1R53

Warranty

11

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

Electric Heat - Installation, Operation, and Maintenance

Rev.: 14 Jan., 2013

12 Geothermal Heat Pump Systems

Revision History

R

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

I

S

O

S

T

A

N

D

A

R

D

1

3

2

5

6

-

1

H

E

A

T

P

U

M

P

S

W

A

T

E

R

T

O

A

I

R

B

R

I

N

E

T

O

A

I

R

97B0005N02

ClimateMaster works continually to improve its products. As a result, the design and specifications of each product at the time for order may be

changed without notice and may not be as described herein. Please contact ClimateMaster’s Customer Service Department at 1-405-745-6000

for specific information on the current design and specifications. Statements and other information contained herein are not express warran-

ties and do not form the basis of any bargain between the parties, but are merely ClimateMaster’s opinion or commendation of its products.

The management system governing the manufacture of ClimateMaster’s products is ISO 9001:2008 certified.

© ClimateMaster, Inc. 2007

*97B0005N02*

7300 S.W. 44th Street

Oklahoma City, OK 73179

Phone: 405-745-6000

Fax: 405-745-6058

climatemaster.com

Rev.: 14 Dec., 2013

ISO 9001:2008

Certified

Quality: First & Always

Date Page # Description

14 Jan., 13 4-5 Installation Instructions Updated

14 Dec., 12 3, 4 Update TZ Text

8 May, 12 Various Added TE Mentions

25 Jan. 11 8 Dual Supply Circuit Updated

2 Nov. 11 Various TZ (Vertical External Install) Information Added

24 Sept, 10 8 Accessory Heater Dimension Information Added

20 July, 10 All Update Text, Add TAH and Size 4, Remove Size 12

24 June, 10 All Update Text,Add Size 4 Heater

05 June, 08 All Reformatted Document Size

03 Mar, 08 Various Various Minor Corrections

04 Mar, 07 6 Updated Table 1 for TT072 Models

01 Oct, 06 All First Published

Other manuals for AG Series

2

This manual suits for next models

9

Table of contents

Other ClimateMaster Electric Heater manuals

Popular Electric Heater manuals by other brands

Qlima

Qlima EOR 1515 LCD operating manual

Rointe

Rointe Giza OVAL 400 instruction & installation guide

DeLonghi

DeLonghi Electric oil filled heater instructions

Honeywell

Honeywell HZ-2302 - Electric Space Heater owner's manual

Sunbeam

Sunbeam Calefactor SEH402 instruction manual

ALPATEC

ALPATEC RBH 15 user manual

Reina

Reina MAIA instruction manual

Dyna-Glo

Dyna-Glo WHF100 Important instructions

NuTone

NuTone 665RP instruction manual

Roberts Gorden

Roberts Gorden Blackheat BH15UT Installation & servicing instructions

Paulin

Paulin 7500 Owner's manual & operating instructions

DeLonghi

DeLonghi ELECTRIC SUPER PANEL HEATER instruction manual