4

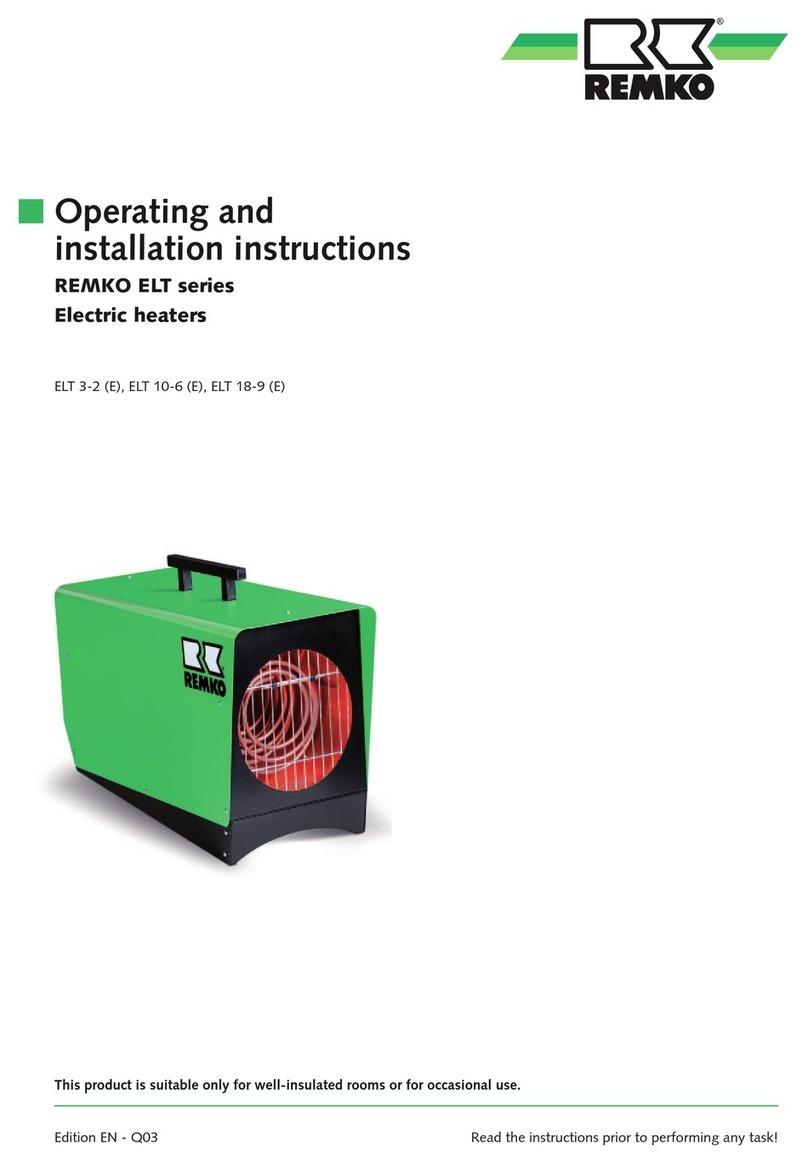

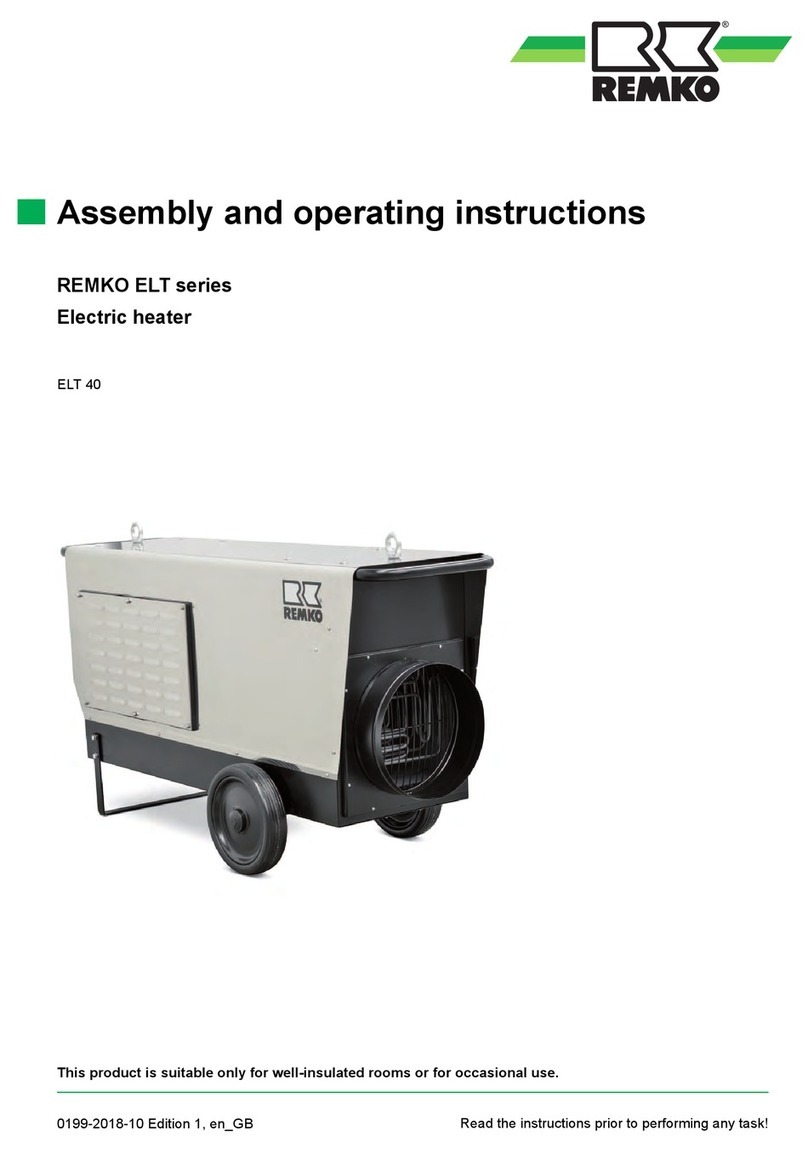

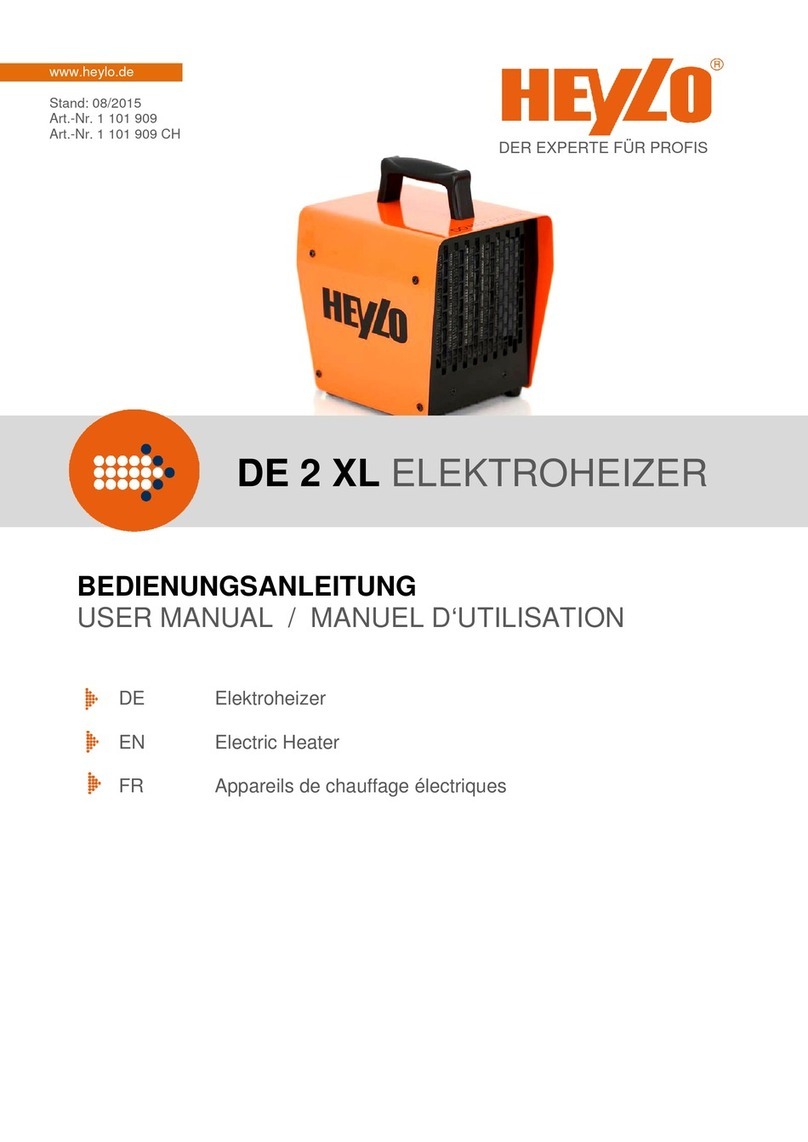

REMKO ELT series

Safety notes

Always observe the respective local building code and fire prevention

guidelines as well as the guidelines of the accident prevention and

insurance associations when using the units.

The units have been subjected

to extensive material, functional

and quality inspections prior

to delivery. However, dangers can

arise from the units if they are

used improperly or not as intended

by untrained personnel!

Please observe the following notes

■

The personnel tasked with

operating the units must check

the units for visible defects on

the operating and safety devices

as well as the presence and

function of the protective devices

prior to starting workInform

the supervisor if defects are

discovered!

■

In the event of defects that

endanger the operational safety

of the unit, operation must

be discontinued immediately

■

Observe the respective local

regulations and the relevant

electrical safety measures when

using the units

■

Maintain safety distances

to combustible materials

■

An unobstructed air inlet and air

outlet must be guaranteed at all

times

■

The air outlet must not

be constricted or equipped with

pipe or hose lines

■

Never insert foreign objects into

the units

■

The units must not be covered

during operation

■

Safety devices must not

be bypassed or disabled

■

The units must not be operated

in the vicinity of bathtubs,

showers, swimming pools etc.

■

The units must not be operated

directly below a wall socket

■

The units must not be exposed

to direct jets of water

e.g. pressure washers etc.

■

Never allow water to enter

the units

■

The units must not be installed

or operated in potentially

flammable or explosive

environments

■

The units must not be installed

or operated in atmospheres

containing oil, sulphur or salt

■

All electrical cables for the

units must be protected against

damage, even damage caused

by animals

■

The units must be set up in

a stable, horizontal position

Unit description

The units are portable electric

heating units for industrial

applications.

The units are operated exclusively

with electric power and have been

designed in such a way that they

can be used fully automatically,

universally and in a straightforward

manner.

The units are equipped with

specially enclosed electric heating

resistors, low noise and low-

maintenance axial fans, a safety

and aftercooler thermostat, an

integrated room thermostat and

a power cable with protective

contact plug.

The units conform to

the fundamental health and safety

requirements of the appropriate

EU stipulations.

The units are dependable and offer

ease of operation.

The units may be used among

other things for the following:

■

Drying newly completed

buildings

■

Spot heating outdoor

workspaces or fire-proof

manufacturing facilities and

halls

■

Continuous or temporary room

heating

■

De-icing machines, vehicles and

non-combustible warehoused

goods while adhering to

the relevant safety distances

CAUTION

Safety devices must not be

bypassed or disabled.