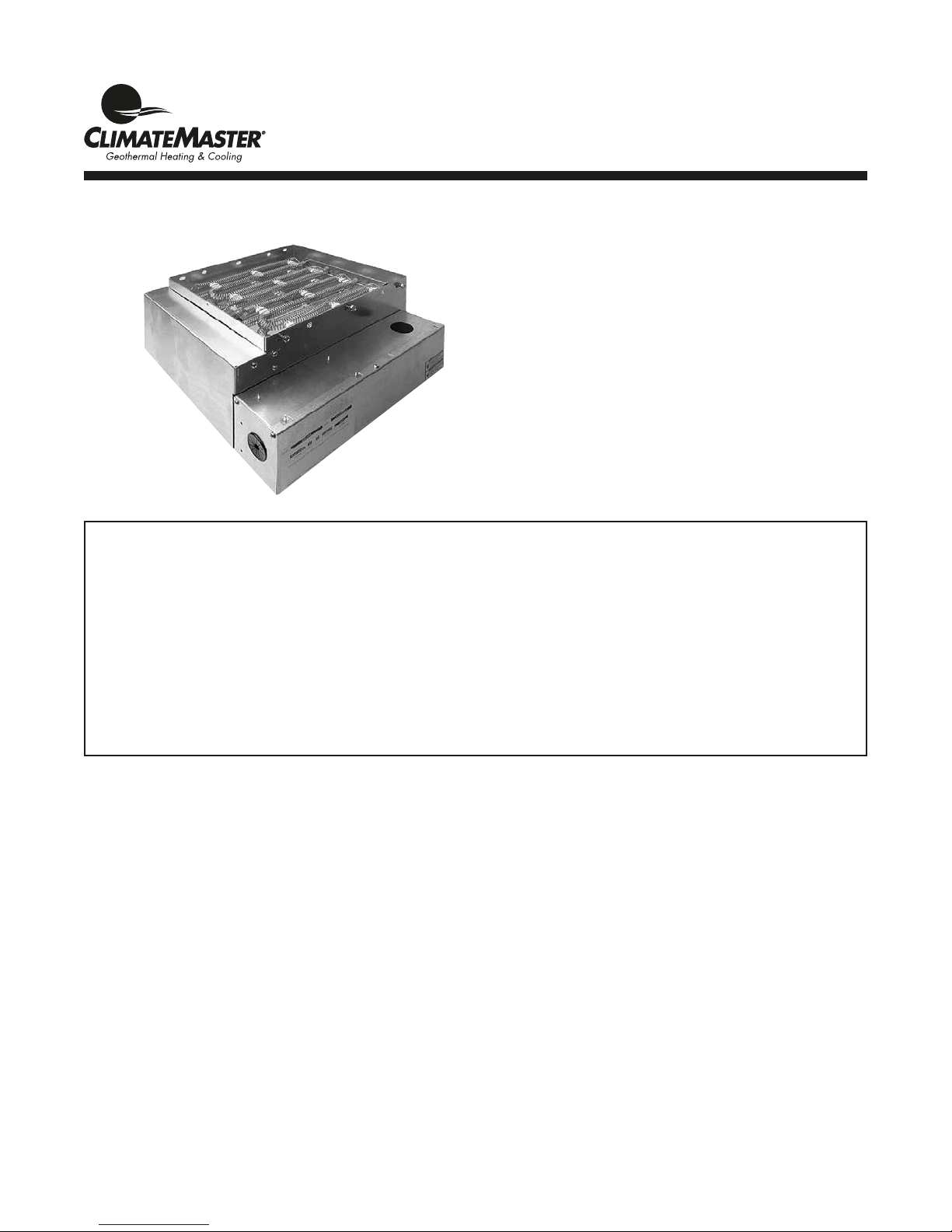

ClimateMaster AG Series General instructions

Auxiliary Electric Heat

Installation, Operation &

Maintenance Instructions

97B0005N04

Revised: 04 August, 2015

AG Series Electric Heaters

Table of Contents

Overview 3

Vertical Upow or Downow

Installation - Internal 3

Vertical Upow Installation - External 4

Horizontal Installation - External

Wiring 6

Setup 6

Ratings 7

Electrical Data 7

Staging Options 7-8

Accessory Heater Dimensions 9

Warranty 10

Revision Log 12

This page was intentionally left blank.

3

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

climatemaster.com

Overview

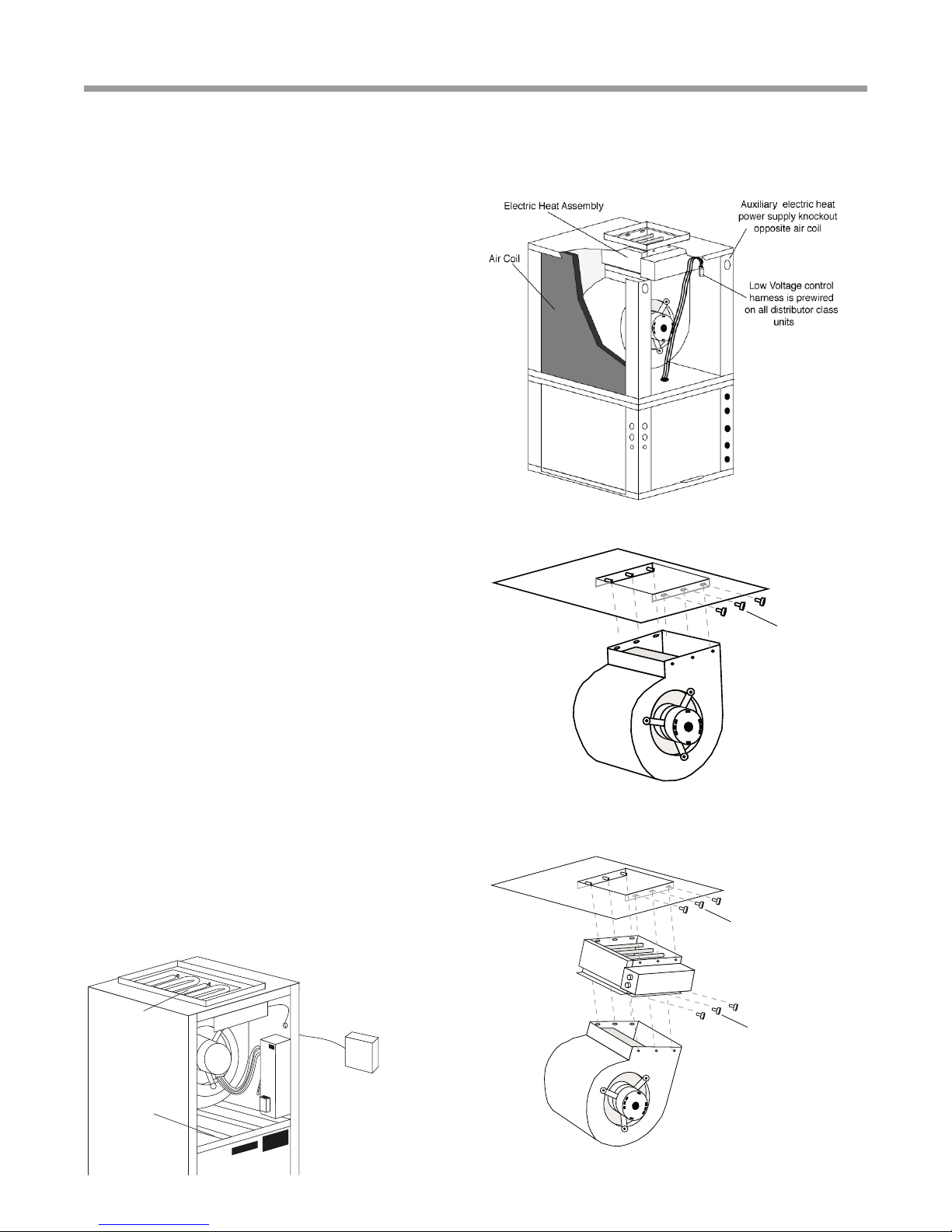

The AG Series Auxiliary Electric Heat mounts internally on

TS, TE and TT upow (Figure 1b) or downow units and all

TAH units. It mounts directly to the blower outlet of TS, TE

and TT horizontal units (Figure 8) and on all TZ units. Note

the model compatibility Table 1. Horizontal units are rated

for zero clearance at the unit and 1" clearance for rst three

feet of duct, vertical units rated for zero clearance for both

unit and duct. Downow units can not be located directly

over a discharge register. The discharge plenum must be

constructed from non combustible material. The AG electric

heat contains a four stage relay control board which activates

the elements directly via an internally wired low voltage

harness. Low voltage signals (W1 and W2) are staged from

the CXM or DXM control of the unit.

TS ,TT and TE Vertical Upow or Downow and TAH

Installation - Internal

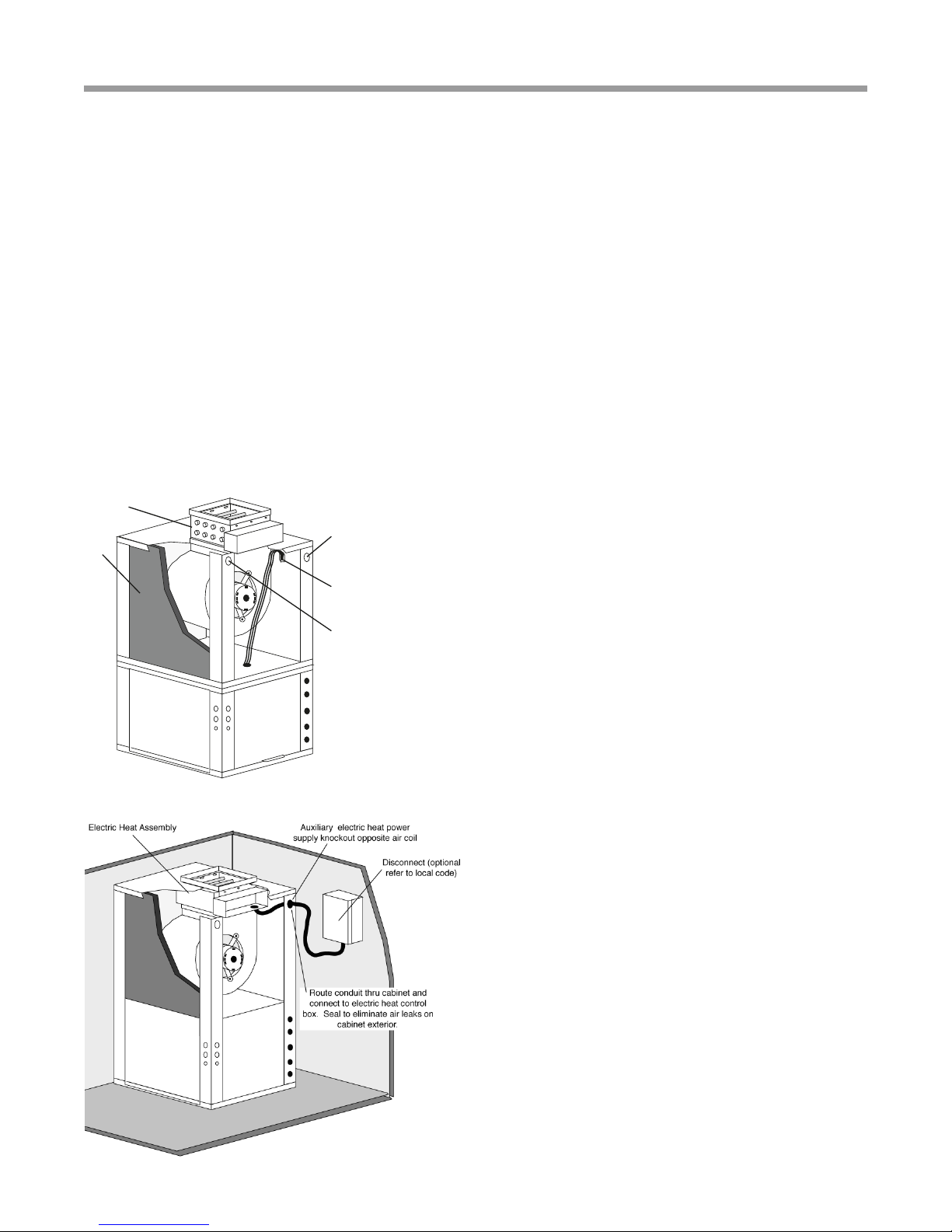

1. Disconnect power to the unit.

2. Remove blower access panel(s) from the unit and

control box cover from the electric heater.

3. Remove blower mounting bolts and drop blower

assembly as shown in gure 2. Removal of electrical

wiring should not be necessary.

4. Position the electric heater as illustrated in gure 3 with

its control box facing the front access panel of the unit.

Attach heater to unit using the support pins on the back

and bolts on the front.

The electric heater air inlet dimensions should match the

unit blower outlet, installer should stop and refer to the

unit/heater compatibility chart later in this instruction or

consult factory if they do not match.

5. Re-install blower assembly on to electric heater using

pins and bolts as before. Check blower electrical wiring

for proper connection and remedy any pinched wire(s) or

contact with sharp edges.

6. Route the low voltage control harness through one of the

‘pie’ bushings in the heater control box and plug on to

the P2 connector. See gure 6.

7. Install power conduit through the unit cabinet as shown

in gure 7 and attach directly to the electric heater

control box. See gures 9a-c.

8. Replace all covers and panels, heater installation is

complete. Proceed to wiring and setup.

Remove bolts

and drop blower

Locate electric heat assembly

on pins in discharge panel

and insert bolts

Relocate blower in electric

heat assembly in same

manner

Figure 2: Blower removal

Figure 3: AG electric heat mounting and

blower re-installation

Figure 1b: Typical vertical unit installation

Overview

Air Coil

Electric Heat

Assembly

Field-supplied

disconnect

(refer to local codes)

Low voltage control harness

is prewired on all

distributor class units

Figure 1a: Typical air handler installation

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

4ClimateMaster Geothermal Heating and Cooling

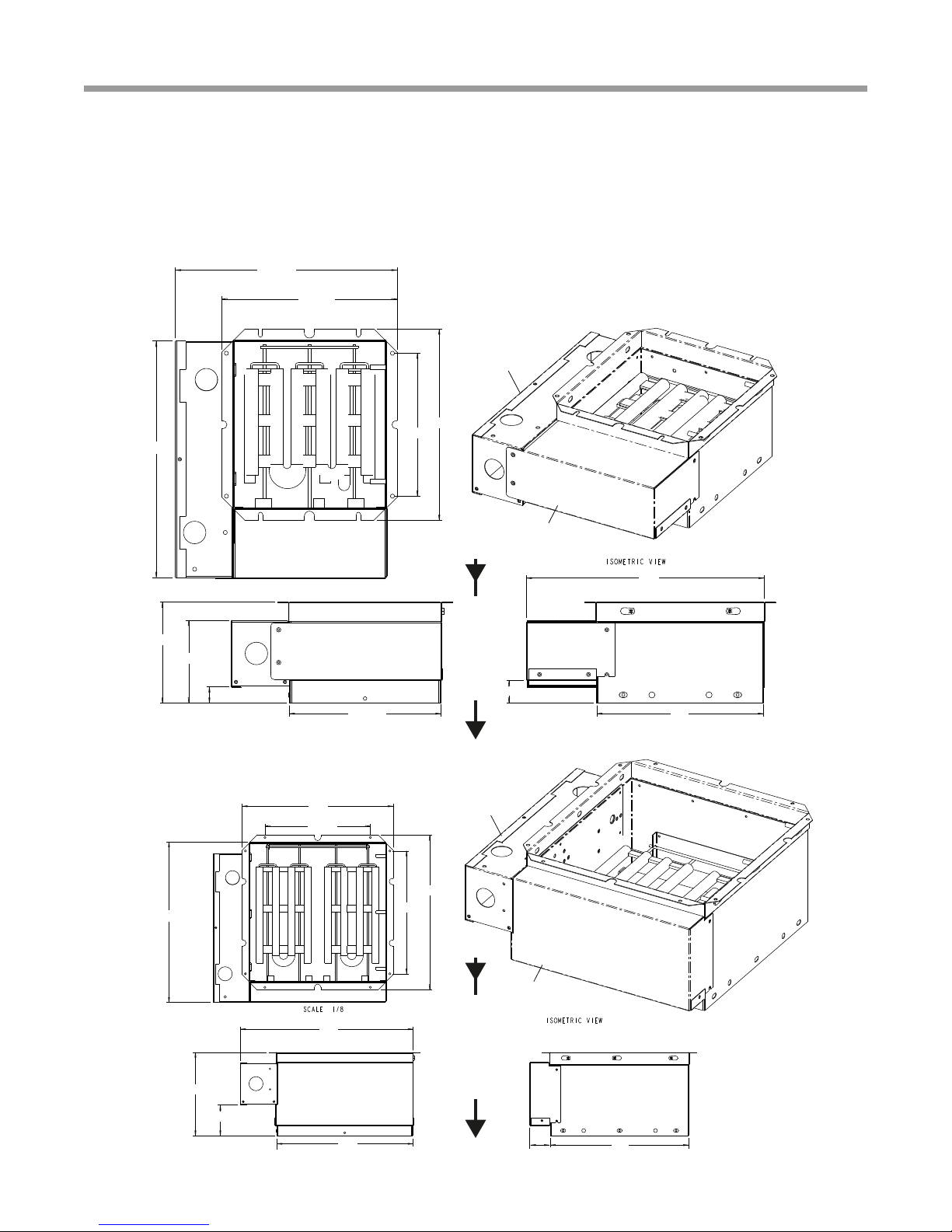

Vertical Installation - External

Auxiliary electric heat

power supply knockout

opposite air coil

Electric Heat Assembly

Air Coil

Low Voltage control harness

is prewired on all distributor

class units.

*

1. Disconnect power to the unit.

2. Remove blower access panel(s) from the unit and control

box and element covers from the electric heater.

3. Locate remove and discard blower discharge anges

from the unit but save the screws. Flanges will be

packaged loose inside the blower compartment of

vertical upow units. TZ036 and 042 units require a

transition bracket between the cabinet top and the

electric heater. This bracket is packaged inside the

blower compartment for eld installation.

4. Position the electric heater as illustrated herein. Heater

control box should be facing the front access panel of

vertical units.

The electric heater air inlet dimensions should match

the unit air outlet, installer should stop and refer to the

unit/heater compatibility chart later in this instruction or

consult factory if they do not match.

5. Use the saved blower ange screws to attach the heater

by its anges to the unit panel except do not fasten

ange on control box side.

6. Use aluminum tape (not provided) to seal all four heater

anges to the blower panel.

7. Locate and route the low voltage control harness through

the top panel knockout(s). Seal the penetration ‘air tight’.

This harness is factory installed on all TZ units (wire-tied

to the fan housing).

8. Route the control harness through one of the ‘pie’

bushings in the heater control box and plug on to the P2

connector. See gure 5.

9. Install power conduit and attach directly to the electric

heater control box. See gures 5a-c.

10. Replace all covers and panels, heater installation is

complete. Proceed to wiring and setup.

5

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

climatemaster.com

Horizontal External Installation

1. Disconnect power to the unit.

2. Remove blower access panel from the unit and control box

and element covers from the electric heater.

3. Remove and discard blower discharge anges from the

unit but save the screws. TZ036 and 042 units require

a transition bracket between the cabinet panel and

the electric heater. This bracket is packaged inside the

blower compartment for eld installation.

4. Position the electric heater as illustrated herein. Notice

that the discharge air opening is o centered in the

blower panel. The electric heater must be positioned so

that its control box is located vertically over the wide

side of this panel.

The electric heater air inlet dimensions should match

the unit air outlet, installer should stop and refer to the

unit/heater compatibility chart later in this instruction or

consult factory if they do not match.

5. Use the saved blower ange screws to attach the heater

by its anges to the unit panel except do not fasten

ange on control box side.

6. Use aluminum tape (not provided) to seal all four heater

anges to the blower panel.

7. Locate and route the low voltage control harness

through one of the unit corner post or blower panel

knockout(s). Seal the penetration ‘air tight’. This harness

is factory installed and wire-tied to the fan housing.

8. Route the control harness through one of the ‘pie’

bushings in the heater control box and plug on to the P2

connector. See gure 6.

9. Install power conduit and attach directly to the electric

heater control box.

10. Replace all covers and panels, heater installation is

complete. Proceed to wiring and setup.

Figure 6: Low Voltage Harness Connection

Figure 8: Typical Horizontal Installation

Horizontal Installation - External

Locate electric heat

harness in air handler

and route through

one of the provided

bushing

Field-supplied disconnect

(refer to local codes)

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

6ClimateMaster Geothermal Heating and Cooling

ON

OFF

ON

OFF

1234

P1

In 15 and 20 kW units

two power circuits are

employed to reduce wires

size and cost of breakers

L1

L2

L3

L4

P2

Conduit

Figure 8a: Power Wiring, Dual Circuits, 15, 20kw Figure 8b: Power Wiring, Single Circuit, 12, 15, 20kw

Wiring and Setup (all models)

1. Install power wiring and connect to power block or

circuit breakers. In 15 or 20kW models two power

circuits may be used to reduce wiring and breaker

costs as in Figure 8a. If a single circuit supply is

desired, install the optional single circuit accessory kit

(P/N 16B0002N02), as shown in Figure 8b, that can be

obtained from your distributor.

Optional for TAH: AG**C kits only. Blower power may

be supplied from T3 & T4 CB5 breaker. Refer to wiring

diagram 96B0143N01.

2.

Ensure unit airow setting is above minimum airow rating

for the electric heat model from Table 1.

3. Check heat staging for the application. Table 4 contained

later in this IOM shows the factory default staging and

the alternate eld selectable staging where applicable.

Staging changes are made by dip switch settings. See

gure 9. These are identied as either ER1, ER2, ER3 or

ER4 depending on the heater size.

4. Mark the appropriate box of the electric heat model

installed on the additional serial plate on the exterior of

the unit.

5. Turn on the power to the unit and the auxiliary

electric heat.

Auxiliary Electric Heat Start-up

Put thermostat in emergency heat mode (or jumper t-stat

input R to W and R to G) and setpoint to high setting. ‘Touch-

jumper' the test pins of the CXM or DXM into test mode to

reduce time delays. Unit will require 15-20 seconds before

engaging emergency heat mode stage 1 (W1) and then

another 15-20 seconds to engage stage 2 (W2) when in ‘Test

mode’. Verify proper electric heat operation.

Figure 9: Staging Dip Switches

Figure 8c: Power Wiring, 4, 5, 8, and 10kw

Wiring

In 15 and 20 kW units, optional

single power circuit is employed to

reduce the number of wires needed.

ER1

ER2

ER1

ER2 ER3

ER4

For AGM/L 4, 5, 8, 10kW.

For AGL 12, 15, and 20kW.

7

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

climatemaster.com

Table 2: AG Electric Heat Electrical Data - TAH

Table 1: AG Electric Heat Ratings

Staging Options

Auxiliary

Electric

Heat

Model

TS, TT, TE Models TZ Models TAH Models kW Rating Btuh Rating

Minimum

CFM

Required

018 024-

030

036-

038

042-

072 024 030-

042

048-

060

Auxiliary

Electric

Heat

Model*

026 038 049-

064 240V 208V 240V 208V

AGM4A AGM4C 3.8 2.9 13000 9900 500

AGM5A AGM5C 4.8 3.6 16300 12300 500

AGM8A AGM8C 7.6 5.7 25900 19400 650

AGM10A AGM10C 9.6 7.2 32700 24600 650

AGM12A 11.4 8.6 38900 29200 750

AGL10A AGL10C 9.6 7.2 32700 24600 1300

AGL15A AGL15C 14.4 10.8 49100 36900 1350

AGL20A AGL20C 19.2 14.4 65500 49200 1350

Black area denotes compatibility

Note: Horizontal units rated for zero clearance unit and 1” clearance for the rst three feet of duct,

Vertical units rated for zero clearance for both unit and duct.

* Can be used on corresponding TZ, TE, TS and TT models

Unit Model Head Kit

Model Supply

Heater

Amps

240

Heater

Amps

208

Blower

FLA

Minimum Circuit Amps Maximum Breaker

Size

240 V 208 V 240 V 208 V

TAH026

AGM4C SINGLE 15.8 14 4.3 25 23 25 25

AGM 5C SINGLE 20 17.3 4.3 30 27 30 30

AGM 8C SINGLE 31.7 27.5 4.3 45 40 45 40

AGM 10C SINGLE 40 34.7 4.3 55 49 60 50

TAH038

AGL10C SINGLE 40 34.7 4.3 59 52 60 60

AGL15C DUAL L1/L2 40 34.7 0 50 43 50 45

L3/L4 20 17.3 4.3 34 30 35 30

TAH049 and

TAH060

AGL10C SINGLE 40 34.7 7.0 59 52 60 60

AGL15C DUAL L1/L2 40 34.7 0.0 50 43 50 45

L3/L4 20 17.3 7.0 34 30 35 30

AGL20C DUAL L1/L2 40 34.7 0.0 50 43 50 45

L3/L4 40 34.7 7.0 59 52 60 60

All heaters rated single phase 208/240V 60Hz All Fuses UL Class K general purpose

All models 15kW or larger feature internal circuit breakers

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

8ClimateMaster Geothermal Heating and Cooling

Table 4: AG Electric Heat Staging Options

Auxiliary Electric

Heat Model

Supply

Circuit

Heater Amps Minimum Circuit Amps Maximum Fuse

240V 208V 240V 208V 240V 208V

AGM4A Single 15.8 14.0 19.8 17.1 20 20

AGM5A Single 20.0 17.3 25.0 21.6 25 25

AGM8A Single 31.7 27.5 39.6 34.4 40 35

AGM10A Single 40.0 34.7 50.0 43.4 50 45

AGL10A Single 40.0 34.7 50.0 43.4 50 45

AGL15A

Single 60.0 52.0 75.0 65.0 80 70

Dual - L1/L2 40.0 34.7 50.0 43.4 50 45

Dual - L3/L4 20.0 17.3 25.0 21.6 25 25

AGL20A

Single 80.0 69.3 100.0 86.6 100 90

Dual - L1/L2 40.0 34.7 50.0 43.4 50 45

Dual - L3/L4 40.0 34.7 50.0 43.4 50 45

All heaters rated single phase 208/240V 60Hz All Fuses UL Class K general purpose

All models 15kW or larger feature internal circuit breakers

Table 3: AG Electric Heat Electrical Data - TS/TT/TE

Staging Options

Heater Model Staging Factory Setting Alternate Setting

kW Dip Position Stage 1 kW Stage 2 kW Dip Position Stage 1 kw Stage 2 kW

AGM4 4 ER1 4

AGM5 5 ER1 5

AGM8 4 or 8 ER1 4 4 ER2 8

AGM10, AGL10 5 or 10 ER1 5 5 ER2 10

AGM12 4, 8, or 12 ER1, ER4 48ER3, ER4 84

AGL15 5,10 or 15 ER1, ER4 510 ER3, ER2 10 5

AGL20 10 or 20 ER3, ER4 10 10

9

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

climatemaster.com

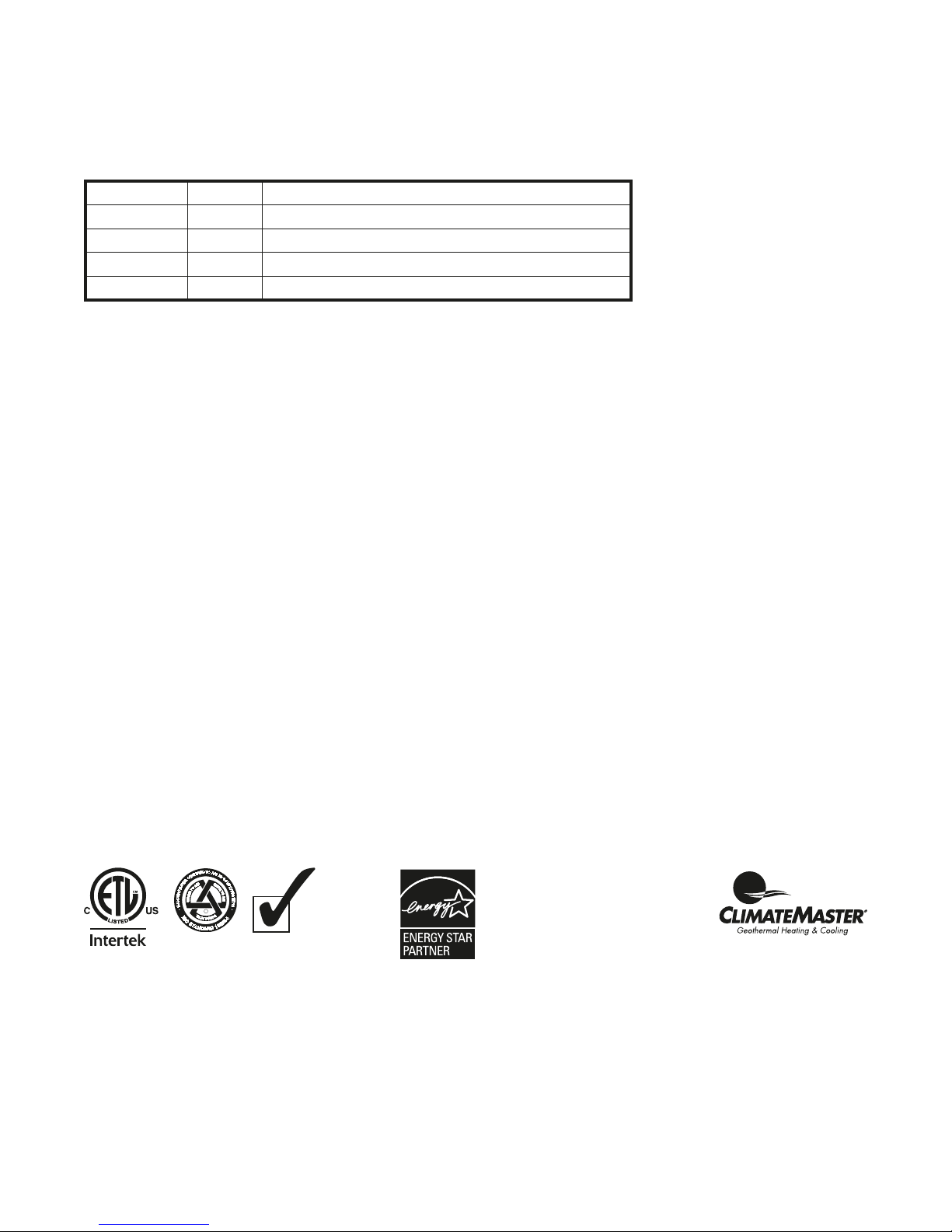

Accessory Heater Dimensions

The maximum recommended air velocity for a supply plenum is 900 fpm. When connecting a plenum to an external

supplemental heater, ensure that the air velocity in the plenum does not exceed 900 fpm. Noise and air distribution issues

may occur if supply plenum velocities exceed 900 fpm.

AGM4A - 12A

AGL10A - 20A

14.7 Control

box

Element

cover

10.3

15.5

16.1

8.1

3

13.3 13.5

2

15.1

12

Discharge Air Opening Discharge Air Opening

14.7 Control

box

Element

cover

10.3

15.5

16.1

8.1

3

13.3 13.5

2

15.1

12

A

I

R

F

L

O

W

Discharge Air Opening

Discharge Air Opening

A

I

R

F

L

O

W

Rev. A 13.6

Rev. B 14.9

Rev. A 10.7

Rev. B 12.0

14.6

8.8

11.7

Control box

Element

cover

6.2

5.1

Rev. A 9.4

Rev. B 10.6

10.2

1

14.6

1.4

13.6

10.7

Rev. A 13.6

Rev. B 14.9

Rev. A 10.7

Rev. B 12.0

14.6

8.8

11.7

Control box

Element

cover

6.2

5.1

Rev. A 9.4

Rev. B 10.6

10.2

1

14.6

1.4

9.4

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

10 ClimateMaster Geothermal Heating and Cooling

CLIMATE MASTER, INC.

LIMITED EXPRESS WARRANTY/LIMITATION OF REMEDIES AND LIABILITY FOR

RESIDENTIAL CLASS PRODUCTS WITH LABOR ALLOWANCE

It is expressly understood that unless a statement is specically identied as a warranty, statements made by Climate Master, Inc. a Delaware corporation, (“CM”) or its representatives, relating to CM’s products, whether oral, written or contained

in any sales literature, catalog or agreement, are not express warranties and do not form a part of the basis of the bargain, but are merely CM’s opinion or commendation of CM’s products. EXCEPT AS SPECIFICALLY SET FORTH

HEREIN, THERE IS NO EXPRESS WARRANTY AS TO ANY OF CM’S PRODUCTS. CM MAKES NO WARRANTY AGAINST LATENT DEFECTS. CM MAKES NO WARRANTY OF MERCHANTABILITY OF THE

GOODS OR OF THE FITNESS OF THE GOODS FOR ANY PARTICULAR PURPOSE.

GRANT OF LIMITED EXPRESS WARRANTY

CM warrants its Residential Class products, purchased and retained in the United States of America and Canada, to be free from defects in material and workmanship under normal use and maintenance as follows: (1) Air conditioning, heating

and/or heat pump units built or sold by CM (“CM Units”) for ten (10) years from the Warranty Inception Date (as dened below); (2) Thermostats, auxiliary electric heaters and geothermal pumping modules built or sold by CM, when installed

with CM Units, for ten (10) years from the Warranty Inception Date (as dened below); and (3) Other accessories and parts built or sold by CM, when installed with CM Units, for one (1) year from the date of shipment from CM. The “Warranty

Inception Date” shall be the date of original unit installation, or six (6) months from date of unit shipment from CM, whichever comes rst.

To make a claim under this warranty, parts must be returned to CM in Oklahoma City, Oklahoma, freight prepaid, no later than ninety (90) days after the date of the failure of the part; if CM determines the part to be defective and within CM’s

Limited Express Warranty, CM shall, when such part has been either replaced or repaired, return such to a factory recognized distributor, dealer or service organization, F.O.B. CM, Oklahoma City, Oklahoma, freight prepaid. The warranty on

any part repaired or replaced under warranty expires at the end of the original warranty period.

This Limited Express Warranty shall cover the labor incurred by CM authorized service personnel in connection with the installation of a new or repaired warranty part that is covered by this Limited Express Warranty only to the extent

specically set forth in the then existing labor allowance schedule provided by CM’s Warranty Department and only as follows: (1) CM Units for ve (5) years from the Warranty Inception Date; (2) Thermostats, auxiliary electric heaters and

geothermal pumping modules built or sold by CM, when installed with CM Units, for ve (5) years from the Warranty Inception Date. Actual Labor costs are not covered by this Limited Express Warranty to the extent they exceed the amount

allowed under said allowance schedule, they are not specically provided for in said allowance schedule, they are not the result of work performed by CM authorized service personnel, they are incurred in connection with a part not covered by

this Limited Express Warranty, or they are incurred more than the time periods set forth in this paragraph after the Warranty Inception Date.

This warranty does not cover and does not apply to: (1) Air lters, fuses, refrigerant, uids, oil; (2) Products relocated after initial installation; (3) Any portion or component of any system that is not supplied by CM, regardless of the cause of the

failure of such portion or component; (4) Products on which the unit identication tags or labels have been removed or defaced; (5) Products on which payment to CM, or to the owner’s seller or installing contractor, is in default; (6) Products

subjected to improper or inadequate installation, maintenance, repair, wiring or voltage conditions; (7) Products subjected to accident, misuse, negligence, abuse, re, ood, lightning, unauthorized alteration, misapplication, contaminated

or corrosive air or liquid supply, operation at abnormal air or liquid temperatures or ow rates, or opening of the refrigerant circuit by unqualied personnel; (8) Mold, fungus or bacteria damages; (9) Corrosion or abrasion of the product;

(10) Products supplied by others; (11) Products which have been operated in a manner contrary to CM’s printed instructions; (12) Products which have insufcient performance as a result of improper system design or improper application,

installation, or use of CM’s products; or (13) Electricity or fuel costs, or any increases or unrealized savings in same, for any reason whatsoever.

This Limited Express Warranty provides the limited labor allowance coverage as set forth above. Otherwise, CM is not responsible for: (1) The costs of any uids, refrigerant or system components supplied by others, or associated labor to repair

or replace the same, which is incurred as a result of a defective part covered by CM’s Limited Express Warranty; (2) The costs of labor, refrigerant, materials or service incurred in diagnosis and removal of the defective part, or in obtaining and

replacing the new or repaired part; (3) Transportation costs of the defective part from the installation site to CM, or of the return of that part if not covered by CM’s Limited Express Warranty; or (4) The costs of normal maintenance.

This Limited Express Warranty applies to CM Residential Class products ordered from CM on or after May 1, 2010 (this would generally include CM Units with serial numbers beginning with “N118” and higher), and is not retroactive to any

products ordered from CM prior to May 1, 2010 (this would generally include CM Units with serial numbers beginning with “N117” and lower). If you are unsure if this Limited Express Warranty applies to the product you have purchased,

contact CM at the phone number or address reected below.

Limitation: This Limited Express Warranty is given in lieu of all other warranties. If, notwithstanding the disclaimers contained herein, it is determined that other warranties exist, any such express warranty, including without limitation any

express warranties or any implied warranties of tness for particular purpose and merchantability, shall be limited to the duration of the Limited Express Warranty.

LIMITATION OF REMEDIES

In the event of a breach of the Limited Express Warranty, CM will only be obligated at CM’s option to repair the failed part or unit, or to furnish a new or rebuilt part or unit in exchange for the part or unit which has failed. If after written notice

to CM’s factory in Oklahoma City, Oklahoma of each defect, malfunction or other failure, and a reasonable number of attempts by CM to correct the defect, malfunction or other failure, and the remedy fails of its essential purpose, CM shall

refund the purchase price paid to CM in exchange for the return of the sold good(s). Said refund shall be the maximum liability of CM. THIS REMEDY IS THE SOLE AND EXCLUSIVE REMEDY OF THE BUYER OR PURCHASER

AGAINST CM FOR BREACH OF CONTRACT, FOR THE BREACH OF ANY WARRANTY OR FOR CM’S NEGLIGENCE OR IN STRICT LIABILITY.

LIMITATION OF LIABILITY

CM shall have no liability for any damages if CM’s performance is delayed for any reason or is prevented to any extent by any event such as, but not limited to: any war, civil unrest, government restrictions or restraints, strikes, or

work stoppages, re, ood, accident, shortages of transportation, fuel, material, or labor, acts of God or any other reason beyond the sole control of CM. CM EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGE IN CONTRACT, FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY, OR IN TORT, WHETHER FOR CM’s NEGLIGENCE OR AS STRICT LIABILITY.

OBTAINING WARRANTY PERFORMANCE

Normally, the dealer or service organization who installed the products will provide warranty performance for the owner. Should the installer be unavailable, contact any CM recognized distributor, dealer or service organization. If assistance is

required in obtaining warranty performance, write or call:

Climate Master, Inc. • Customer Service • 7300 SW 44th Street • Oklahoma City, Oklahoma 73179 • (405) 745-6000 • e-service@climatemaster.com

NOTE: Some states or Canadian provinces do not allow limitations on how long an implied warranty lasts, or the limitation or exclusions of consequential or incidental damages, so the foregoing exclusions and limitations may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state and from Canadian province to Canadian province.

Please refer to the CM Installation, Operation and Maintenance Manual for operating and maintenance instructions. Rev.: 4/10

Part No.: RP851

Warranty

11

Electric Heat - Installation, Operation, and Maintenance

Revised: 04 August, 2015

climatemaster.com

Revision History

R

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

I

S

O

S

T

A

N

D

A

R

D

1

3

2

5

6

-

1

H

E

A

T

P

U

M

P

S

W

A

T

E

R

T

O

A

I

R

B

R

I

N

E

T

O

A

I

R

97B0005N04

ClimateMaster works continually to improve its products. As a result, the design and specications of each product at the time for order may be

changed without notice and may not be as described herein. Please contact ClimateMaster’s Customer Service Department at 1-405-745-6000

for specic information on the current design and specications. Statements and other information contained herein are not express warran-

ties and do not form the basis of any bargain between the parties, but are merely ClimateMaster’s opinion or commendation of its products.

The management system governing the manufacture of ClimateMaster’s products is ISO 9001:2008 certied.

© ClimateMaster, Inc. 2014

*97B0005N04*

7300 S.W. 44th Street

Oklahoma City, OK 73179

Phone: 405-745-6000

Fax: 405-745-6058

climatemaster.com

ISO 9001:2008

Certified

Quality: First & Always

Date Page # Description

04 Aug., 2015 9 Updated Illustration Title AGL10A - 20A

09 Feb., 2015 All Misc Edits

22 Dec., 2014 5 External Installation Instructions Updated

29 Oct., 2014 All First Published

Other manuals for AG Series

2

Table of contents

Other ClimateMaster Electric Heater manuals