ClimateMaster Tranquility Low-Profile Series Owner's manual

Tranquility®

Low-Profile

(TRL) Series

Models TRL 006 - 015

60Hz - HFC-410A

INSTALLATION, OPERATION

& MAINTENANCE

97B0001N15

Created: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

2

This page intentionally left blank.

climatemaster.com 3

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Table of Contents

Model Nomenclature - General Overview.......................................................................................4

General Information............................................................................................................................ 5-7

Unit Physical Data....................................................................................................................................8

TRL – Horizontal Dimensional Drawing...........................................................................................9

TRL – Horizontal Service Access..................................................................................................... 10

Horizontal Installation ...................................................................................................................11-13

Condensate Installation....................................................................................................................... 14

Ductwork Installation ....................................................................................................................15-17

Unit Access.......................................................................................................................................18-20

Piping Installation ...........................................................................................................................21-22

Internal Water Pump Performance ................................................................................................. 23

Water-Loop Heat Pump Applications.....................................................................................24-25

Ground-Loop Heat Pump Applications..................................................................................26-27

Electrical - Line Voltage....................................................................................................................... 28

Electrical Data ........................................................................................................................................ 29

Electrical - Power Wiring.............................................................................................................30-31

Electrical - Power & Low Voltage Wiring ..............................................................................32-33

Electrical - Low Voltage Wiring........................................................................................................ 34

Electrical - Thermostat Wiring.......................................................................................................... 35

Blower Performance Data ................................................................................................................. 36

TRL Series Wiring Diagram Matrix ................................................................................................. 37

CXM2 Controls ................................................................................................................................38-42

Safety Features - CXM2 Controls.............................................................................................43-45

Unit Starting and Operating Conditions.................................................................................46-47

Water Quality Standards.............................................................................................................48-51

Piping System Cleaning and Flushing ....................................................................................52-53

Unit and System Checkout..........................................................................................................54-55

Unit Start-Up Procedure ..............................................................................................................56-58

Unit Operating Conditions...........................................................................................................59-61

Preventive Maintenance...............................................................................................................62-63

Functional Troubleshooting.........................................................................................................64-67

Performance Troubleshooting....................................................................................................68-70

Start-Up Log Sheet............................................................................................................................... 71

Functional Troubleshooting Form .............................................................................................72-73

Warranty (U.S. & Canada) .................................................................................................................. 74

Revision History..................................................................................................................................... 76

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

4

Model Nomenclature – General Overview

NOTES:

1. All products come standard with Braze Plate Heat Exchangers (BPHE).

2. Products with the Extended Range option come with the BPHE and all copper tubing insulated.

The units are equipped with low temperature discharge line/low pressure sensors for extended

operating range conditions.

T R

1 2

L

3

0 1 2

4 5 6

A

7

G

8

C

9

3

10

0

11

C

12

S

15

S

13

2

14

TR = TRANQUILITY

HIGH

EFFICIENCY 410A

MODELTYPE

L - HORIZONTAL LOW PROFILE

CONFIGURATION

006 - G

009 - G

012 - G

015 - G

UNIT SIZE

A = CURRENT REVISION

REVISION LEVEL

G = 208-230/60/1

VOLTAGE

S = LEFT RETURN, STAINLESS STEEL DRAIN PAN

T = RIGHT RETURN, STAINLESS STEEL DRAIN PAN

RETURN AIR OPTIONS

0 = None

7 = Internal Circulating Pump

M = Motorized Water Valve

F = 2.5 GPM/Ton Auto Flow Regulator

L = 3.0 GPM/Ton Auto Flow Regulator

W = 2.5 GPM/Ton Auto Flow Regulator & Motorized Water Valve

V = 3.0 GPM/Ton Auto Flow Regulator & Motorized Water Valve

WATER CIRCUIT OPTIONS

CONTROLS

CABINET INSULATION

WATER FLOW SWITCH & AIR COIL OPTIONS

SUPPLY AIR OPTIONS

S = STANDARD

STANDARD DISCONNECT

CXM2

CXM2 w/MPC

C

N

A

R

K

A

STANDARD

M

C

ULTRA QUIET

P

E

STANDARD

S

G

ULTRA QUIET

EXTENDED RANGE STANDARD RANGE

1” FILTER FRAME

2” FILTER FRAME

Option Supply

A

Straight

C

NON

COATED

AIR COIL

Standard A

TIN

COATED

AIR COIL

E

E-COATED

AIR COIL

High Pressure

WATER FLOW

SWITCH TYPE

5 6 7

B

C

D

Straight + Back

E

F

G Back

0 Field Configured

Opening

Area (in)

006 or

009

012 or

015

8x6

16x6

24x6

8x6 + 7x6

16x6 + 7x6

24x6 + 7x6

7x6

-

X

X

N/A

X

N/A

N/A

X

X

N/A

X*

X

X*

X

X

N/A

X

* For sizes 012-015 this configuration will have internal static pressure

losses up to 0.2.

Note: Above model nomenclature is a general reference. Not all congurations are available on all models.

Consult selection software for detailed information.

climatemaster.com 5

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

General Information

Safety

Warnings, cautions, and notices appear

throughout this manual. Read these

items carefully before attempting any

installation, service, or troubleshooting of

the equipment.

DANGER: Indicates an immediate

hazardous situation, which if not avoided

will result in death or serious injury.

DANGER labels on unit access panels

must be observed.

WARNING: Indicates a potentially

hazardous situation, which if not avoided

could result in death or serious injury.

CAUTION: Indicates a potentially

hazardous situation or an unsafe

practice, which if not avoided could

result in minor or moderate injury or

product or property damage.

NOTICE: Notication of installation,

operation, or maintenance information,

which is important, but which is not

hazard-related.

WARNING! The EarthPure®

Application and Service Manual

should be read and understood

before attempting to service

refrigerant circuits with HFC-410A.

⚠

WARNING!

⚠

⚠

WARNING!

⚠

WARNING! To avoid the release of

refrigerant into the atmosphere, the

refrigerant circuit of this unit must

be serviced only by technicians

who meet local, state, and federal

prociency requirements.

⚠

CAUTION!

⚠

CAUTION! To avoid equipment

damage, DO NOT use these units

as a source of heating or cooling

during the construction process. The

mechanical components and lters

can quickly become clogged with

construction dirt and debris, which

may cause system damage and void

product warranty.

⚠

WARNING!

⚠

WARNING! The installation of water-

source heat pumps and all associated

components, parts, and accessories

which make up the installation shall

be in accordance with the regulations

of ALL authorities having jurisdiction

and MUST conform to all applicable

codes. It is the responsibility of the

installing contractor to determine and

comply with ALL applicable codes

and regulations.

⚠

WARNING!

⚠

WARNING! All refrigerant discharged

from this unit must be recovered

WITHOUT EXCEPTION. Technicians

must follow industry accepted

guidelines and all local, state, and

federal statutes for the recovery

and disposal of refrigerants. If a

compressor is removed from this unit,

refrigerant circuit oil will remain in

the compressor. To avoid leakage of

compressor oil, refrigerant lines of the

compressor must be sealed after it is

removed.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

6

General Information, Cont’d.

Inspection - Upon receipt of the

equipment, carefully check the shipment

against the bill of lading. Make sure all

units have been received. Inspect the

packaging of each unit, and inspect each

unit for damage. Ensure that the carrier

makes proper notation of any shortages

or damage on all copies of the freight

bill and completes a common carrier

inspection report. Concealed damage

not discovered during unloading must be

reported to the carrier within 15 days of

receipt of shipment. If not led within 15

days, the freight company can deny the

claim without recourse.

Note: It is the responsibility of the

purchaser to le all necessary claims

with the carrier. Notify your equipment

supplier of all damage within fteen (15)

days of shipment.

Storage - Equipment should be stored in

its original packaging in a clean, dry area.

Store units in an upright position at all

times. Stack units a maximum of 3 units

high.

Unit Protection - Cover units on the job

site with either the original packaging or

an equivalent protective covering. Cap

the open ends of pipes stored on the job

site. In areas where painting, plastering,

and/or spraying has not been completed,

all due precautions must be taken to

avoid physical damage to the units

and contamination by foreign material.

Physical damage and contamination may

prevent proper start-up and may result in

costly equipment clean-up.

Examine all pipes, ttings, and valves

before installing any of the system

components. Remove any dirt or debris

found in or on these components.

Pre-Installation - Installation, Operation,

and Maintenance instructions are

provided with each unit. Horizontal

equipment is designed for installation

above false ceiling or in a ceiling plenum.

Other unit congurations are typically

installed in a mechanical room. The

installation site chosen should include

adequate service clearance around the

unit. Before unit start-up, read all manuals

and become familiar with the unit and its

operation. Thoroughly check the system

before operation.

Prepare units for installation as follows:

1. Compare the electrical data on the

unit nameplate with ordering and

shipping information to verify that

the correct unit has been shipped.

2. Keep the cabinet covered with the

original packaging until installation is

complete and all plastering, painting,

etc. is nished.

3. Verify refrigerant tubing is free of

kinks or dents and that it does not

touch other unit components.

4. Inspect all electrical connections.

Connections must be clean and tight

at the terminals.

5. Remove any blower support

packaging (water-to-air units only).

6. Conrm supply air conguration

matches duct design plans.

7. Locate and verify the hanger kit

and other provided eld installed

parts have been removed from the

compressor and blower sections of

the unit.

8. The unit is shipped with plastic plugs

(hand-tightened) to protect the water

lines from debris or contaminant

agents that might affect the BPHE,

remove before connecting the unit to

the main water loop.

climatemaster.com 7

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

General Information, Cont’d.

⚠

CAUTION!

⚠

CAUTION! DO NOT store or install

units in corrosive environments or

in locations subject to temperature

or humidity extremes (e.g., attics,

garages, rooftops, etc.). Corrosive

conditions and high temperature or

humidity can signicantly reduce

performance, reliability, and service

life. Always move and store units in an

upright position. Tilting units on their

sides will cause equipment damage.

⚠

CAUTION!

⚠

CAUTION! CUT HAZARD - Failure

to follow this caution may result in

personal injury. Sheet metal parts

may have sharp edges or burrs. Use

care and wear appropriate protective

clothing, safety glasses and gloves

when handling parts and servicing

heat pumps.

⚠

WARNING!

⚠

WARNING! This product can

expose you to chemicals including

formaldehyde, which is known to the

state of California to cause cancer. For

more information, go to

www.P65Warnings.ca.gov.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

8

Unit Physical Data

Tranquility®(TRL)Series (60 Hz)

Model TRL006 TRL009 TRL012 TRL015

Factory Charge R410A - (oz.) 19 19 26 28

Motor & Blower

ECM Constant Torque (HP) [W] 0.25 [186]

Blower Wheel Size (Dia x W) 5.7 x 7.98 (1pc) 5.7 x 7.98 (2pc)

Water Connection Size

Water volume (gal)* 0.037 0.042 0.049

FPT - All Other 1/2” FPT

Horizontal

Filter Standard - 1” Throwaway 8.5 x 28 x 1

Filter Standard - 2” Throwaway 8.5 x 28 x 2

Weight - Operating (lbs.) 145 146 152 159

Weight - Packaged (lbs.) 185 186 192 199

*Volume for BPHE only

Unit Maximum Water Working Pressure Max Pressure PSIG

[kPa]

Base Unit 500 [3447]

Internal Secondary Pump (ISP) 200 [1379]

Internal Motorized Water Valve (MWV) 300 [2068]

Internal Auto Flow Valve 300 [2068]

20 Mesh Y Strainer Valve 600 [4137]

Flow switch - Low Pressure System 160 [1103]

Flow switch - High Pressure System 360 [2482]

climatemaster.com 9

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TRL – Horizontal Dimensional Drawing

A

22.500

FRONT

WATER OUT

1/2"fpt

WATER IN

1/2"fpt

CEP

HIGH VOLTAGE

WIRING K.O.

LOW VOLTAGE

WIRING K.O.

J4.532

K

3.157

H

.975

E

1.781

D

6.408

2.377

F

REAR

BACK FIELD CONFIGURED

SUPPLY AIR KNOCK OUT

CONDENSATE

DRAIN

RETURN

AIR

ASP

AA

2.540

BB

.471

V

21.155

U

54.718

TOP

HANGER POINTS 4X

RETURN

AIR

BOTTOM

BAP

WRP

CEP

C

9.000

B

53.006

RIGHT AIR DISCHARGE 3X

FIELD CONFIGURABLE

KNOCKOUTS

ASP

N

24.000

O

2.978

.906

M

6.000

1.578 P

Q

26.378

ASP

LEFT

S

1.742

R

7.052

T

.811

RIGHT RETURN

BOTTOM ISO VIEW

ASP

WRP

BAP

SUPPLY AIR

KNOCKOUTS

LEFT RETURN

BOTTOM ISO VIEW

CEP

ASP

BAP

SUPPLY AIR

KNOCKOUTS

CEP

WRP

CEP

SERVICE TOOL

CONNECTION

CEP

SERVICE TOOL

CONNECTION

Notes:

1. While clear access to all removable panels is not required, installer should take care to comply with all

building codes and allow adequate clearance for future eld service.

2. Units shipped with lter frames with duct mounting collar for connection to return air duct connection.

3. Hanger brackets are designed into the top panel of the unit.

4. Units are provided with a 1/2” MPT condensate connection. There is also a condensate connection kit

provided in the unit which contains a exible coupling that can be used to connect to 3/4” PVC or 1” Copper.

5. Blower service access can be from the bottom, side, or top.

6. Bottom blower access allows blower assembly to be dropped, disconnected, and removed for servicing.

7. An installation kit that includes the hanger hardware and condensate coupling is attached the unit side

access panel. Remove before installing.

Legend:

CEP = Controls & Electrical Service Panel

BAP = Blower, Air Coil & Drain Pan Service Panel

WRP = Water & Refrigerant Service Panel

*ASP = Additional Service Panel (not required)

Note:

*ASP are removable panels that provide additional

access to the units interior. Clear access to ASP panels

is not required and they are not to be used in place of

the mandatory CEP, WRP, or BAP panels.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

10

TRL – Horizontal Service Access

Air Coil

Front

ASP ASP

CEP

ASP

Return

Air Flow

Supply

Air Flow

Top View - Left Return Straight Discharge Top View - Right Return Straight Discharge

Ceiling Hung - Left Return Straight Discharge

ASPRETURN AIR

BAP CEP

Front Access Panel

Ceiling Hung - Right Return Straight Discharge

ASP RETURN AIR

BAP

CEP

Front Access Panel

ASP ASP

CEP

ASP

Return

Air Flow

Supply

Air Flow

Air Coil

Front

= Mandatory 3′Service Access = Optional 2′Service Access= Mandatory 1′Service Access

(front access service should be

increased if external pumps,

valves, etc. are applied)

Notes:

1. While clear access to all removable panels is not required, installer should take care to comply with all

building codes and allow adequate clearance for future eld service.

2. CEP and BAP requires 2’ bottom service access. CEP requires 2’ front service access as well. Ceiling

mounted service access doors are acceptable. BAP side service access is optional.

3. ASP are removable panels that provide additional access to the units interior. Clear access to ASP panels

is not required and they are not to be used in place of the mandatory CEP and BSP panels.

4. For back discharge congurations, supply air is delivered to the back of the unit (side opposite of the

controls) and all blower service access is from the bottom. Not all sizes available in back discharge only.

Please see the Ductwork Installation section for details.

5. For back and straight combined discharge congurations, all blower service access is from the bottom.

Legend:

CEP = Controls & Electrical Service Panel

BAP = Blower, Air Coil, & Drain Pan Service Panel

WRP = Water & Refrigerant Service Panel

ASP = Additional Service Panel (not required)

climatemaster.com 11

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Horizontal Installation

Horizontal Unit Location

Units are not designed for outdoor

installation. Locate the unit in an INDOOR

area that allows enough space for service

personnel to perform typical maintenance

or repairs without removing unit from

the ceiling. Horizontal units are typically

installed above a false ceiling or in a

ceiling plenum. Never install units in areas

subject to freezing or where humidity

levels could cause cabinet condensation

(such as unconditioned spaces subject to

100% outside air). Consideration should

be given to access for easy removal of the

lter and access panels. Provide sufcient

room to make water, electrical, and duct

connection(s).

TRL units are designed to be accessed

from the bottom for servicing. Sufcient

clearance should be given underneath the

unit for access to bottom service panels.

If the unit is located in a conned space,

such as a closet, provisions must be made

for return air to freely enter the space by

means of a louvered door, etc. Any access

panel screws that would be difcult to

remove after the unit is installed should

be removed prior to setting the unit. Refer

to Figure 3 for an illustration of a typical

installation. Refer to unit submittal data for

dimensional data.

Conform to the following guidelines

when selecting unit location:

1. Provide a hinged access door in

concealed-spline or plaster ceilings.

Provide removable ceiling tiles in T-bar

or lay-in ceilings. Refer to horizontal

unit dimensions for specic series and

model in unit submittal data. Size the

access opening to accommodate the

service technician during the removal

or replacement of the compressor,

control, or blower assembly.

2. Provide access to hanger brackets,

water valves and ttings. Provide

screwdriver clearance to access

panels, discharge collars and all

electrical connections.

3. DO NOT obstruct the space beneath

the unit with piping, electrical cables

and other items that prohibit future

removal of components or the unit

itself.

4. Use a manual portable jack/lift to lift

and support the weight of the unit

during installation and servicing.

The installation of water source heat pump

units and all associated components,

parts and accessories which make up the

installation shall be in accordance with

the regulations of ALL authorities having

jurisdiction and MUST conform to all

applicable codes. It is the responsibility of

the installing contractor to determine and

comply with ALL applicable codes and

regulations.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

12

Horizontal Installation Cont’d.

Mounting Horizontal Units

Horizontal units have 4 hanger brackets

designed into the top panel of the unit,

one at each corner. Enclosed within the

unit there is a hanger kit hardware bag

containing vibration isolation grommets,

washers and a hanger installation

instruction page. See Figure 1. Refer to

the hanger installation instruction page

contained in the hardware bag for details

of nal hanger bracket attachment and

unit suspension. See Figure 1a.

Use four (4) eld supplied 3/8” diameter

threaded rods and factory provided

vibration isolators to suspend the unit.

Safely lift the unit into position supporting

the bottom of the unit. Ensure the top of

the unit is not in contact with any external

objects. Connect the top end of the 4

all-thread rods, slide rods through the

brackets and grommet then assemble

washers and double nuts at each rod.

Ensure that the unit is approximately level

and that the threaded rod extends past

the nuts.

Pitch the unit toward the drain as shown

in Figure 2 to improve the condensate

drainage. Ensure that unit pitch does

not cause condensate leaks inside the

cabinet. Cut any remaining all thread

below the lower nut so that it does not

interfere with any electrical or water

connections on the front of the unit.

Figure 1: Hanger Bracket

Figure 1a:

climatemaster.com 13

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Horizontal Installation, Cont’d.

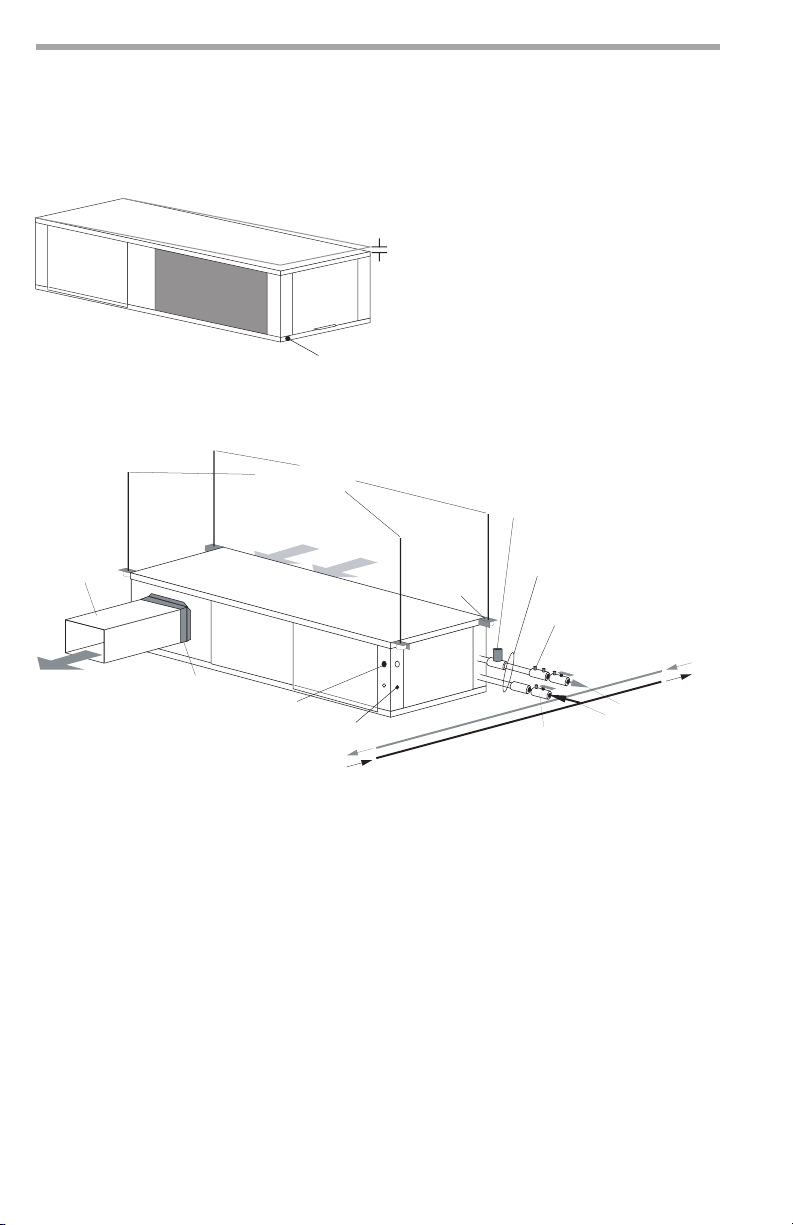

Figure 2: Horizontal Unit Pitch

(by others)

Water In

Water Out

Optional Balancing Valve

Ball Valve with optional

integral P/T plug and strainer

Stainless steel braid hose

with integral "J" swivel

Building

Loop

Return Air

Supply Air

3/8" [10mm] threaded rods

Unit Power

Flexible Duct

Connector

Optional Low Pressure Drop Water

Control Valve

(can be internally mounted

on some models)

Insulated

Supply Duct

Thermostat

Wiring

Unit Hanger

Figure 3: Typical Horizontal Unit Installation

Air Coil - To obtain maximum

performance, the air coil should be

cleaned before start-up. A 10% solution

of dishwasher detergent and water is

recommended for both sides of the coil.

A thorough water rinse should follow.

UV based anti-bacterial systems may

damage e-coated air coils.

Notice! Installation Note - Ducted Return:

Many horizontal WSHPs are installed in a

return air ceiling plenum application (above

ceiling). All TRL products are equipped

with lter frames for ducted or non-ducted

returns. Canvas or exible connectors

should also be used to minimize vibration

between the unit and ductwork.

1/4” (6.4mm) pitch

toward drain for drainage

Drain Connection

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

14

Condensate Installation

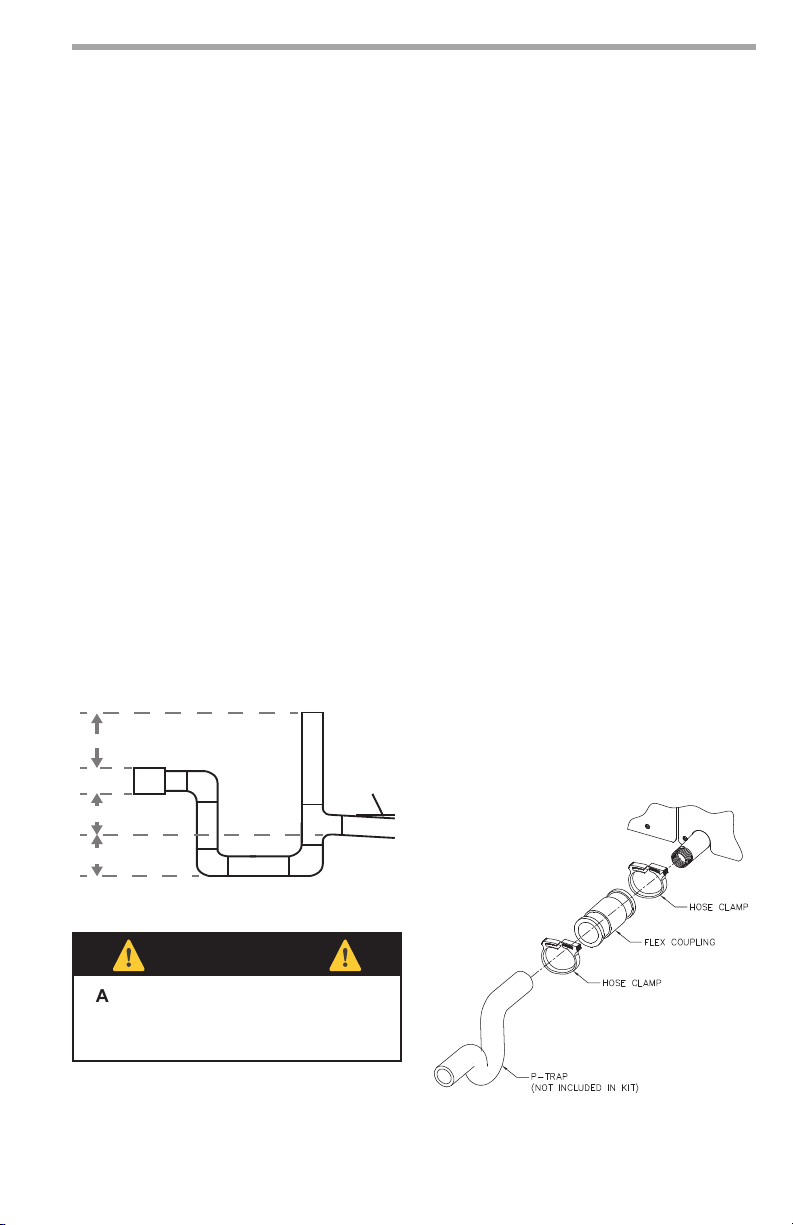

Condensate Piping - Horizontal Units -

A condensate drain line must be installed

and pitched away for the unit to allow for

proper drainage. This connection must

meet all local plumbing/building codes.

Pitch the unit toward the drain as shown

in Figure 2 to improve the condensate

drainage. Ensure that unit pitch does not

cause condensate leaks inside the cabinet.

Install condensate trap at each unit with

the top of the trap positioned below

the unit condensate drain connection

as shown in Figure 4. As a general rule,

the minimum depth for traps is 1-1/2

inches. Each unit must be installed with

its own individual trap and connection

to the condensate line (main) or riser.

Provide a means to ush or blow out the

condensate line. DO NOT install units

with a common trap and/or vent.

Figure 4: Horizontal Condensate

Connection

2”

1.5”

1.5”

1/8” Per

Foot

Always vent the condensate line when

dirt or air can collect in the line or a long

horizontal drain line is required. Also vent

when large units are working against

higher external static pressure than other

units connected to the same condensate

main since this may cause poor drainage

for all units on the line.

WHEN A VENT

IS INSTALLED IN THE DRAIN LINE,

IT MUST BE LOCATED AFTER THE

TRAP IN THE DIRECTION OF THE

CONDENSATE FLOW.

Some applications will require condensate

pumping due to limited ceiling space or

the need to connect to a main drain line

higher in elevation. Condensate pumps

are to be eld provided and are mounted

externally to the unit.

Units are provided with a 1/2" MPT

condensate connection. There is also a

condensate connection kit provided in

the unit which contains a exible coupling

that can be used to connect to 3/4" PVC

or 1" Copper. Dispose of kit if not used.

See gure 5.

Figure 5: Condensate Kit

⚠

CAUTION!

⚠

CAUTION! Ensure condensate line

is pitched toward drain 1/8 inch per ft

[11mm per m] of run.

climatemaster.com 15

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

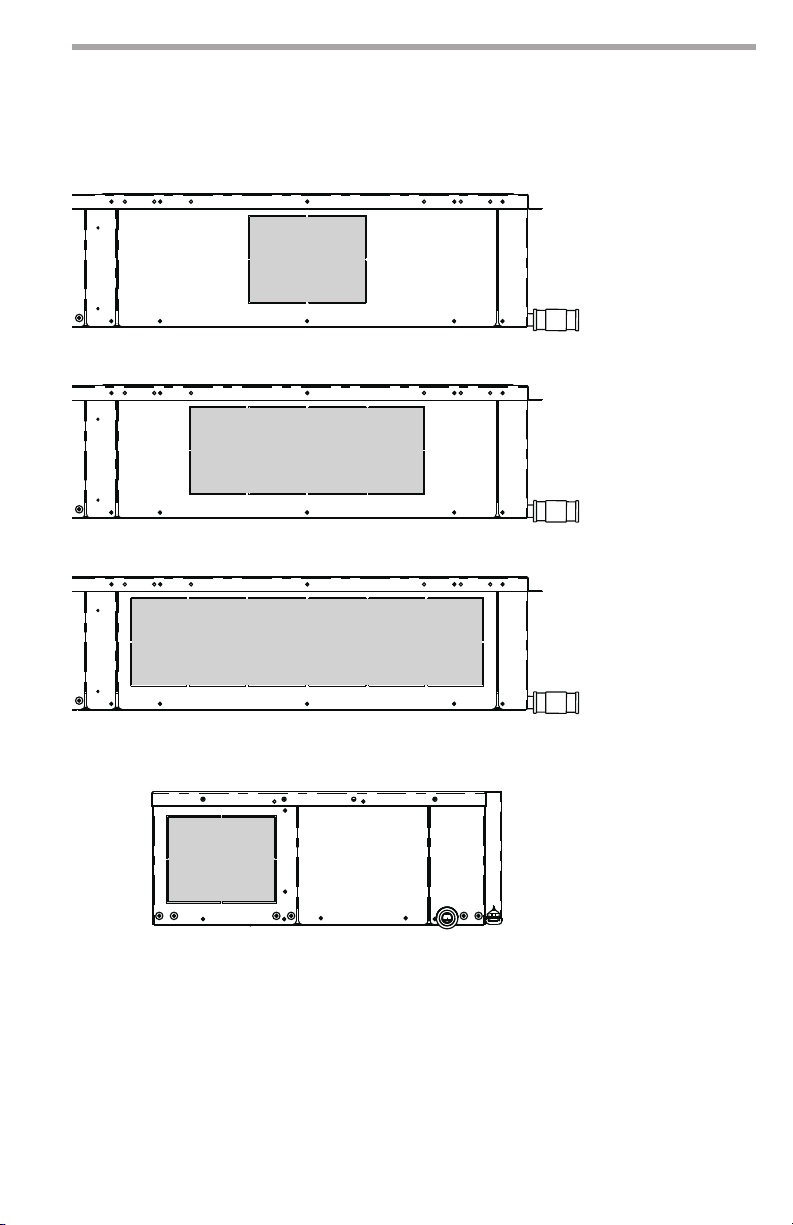

Duct Work Installation

Proper duct sizing and design is critical

to the performance of the unit. The duct

system should be designed to allow

adequate and even airow through the

unit during operation. Air ow through the

unit MUST be at or above the minimum

stated airow for the unit to avoid

equipment damage. Duct systems should

be designed for quiet operation. Refer to

Figure 6 for horizontal duct system details.

A exible connector is recommended

for both discharge and return air duct

connections on metal duct systems to

eliminate the transfer of vibration to

the duct system. To maximize sound

attenuation of the unit blower, the supply

and return plenums should include internal

berglass duct liner or be constructed

from duct board for the rst few feet.

Application of the unit to uninsulated

ductwork in an unconditioned space is not

recommended, as the unit’s performance

may be adversely affected.

If air noise or excessive air ow is a

problem, the blower speed can be

changed. For airow charts, consult

submittal data for the series and model of

the specic unit.

If the unit is connected to existing

ductwork, a previous check should have

been made to ensure that the ductwork has

the capacity to handle the airow required

for the unit. If ducting is too small, as in

the replacement of a heating only system,

larger ductwork should be installed. All

existing ductwork should be checked for

leaks and repaired as necessary.

TRL products can be supplied with factory

or eld congured supply air openings. If

factory congured supply air openings are

desired, the congurations can be either left

or right return air with right or left supply

air. Back supply air can also be selected

as eld or factory congured but must be

paired with left or right supply air openings

on sizes 12 and 15. Please refer to Tables 1,

2, and 3 for minimum and maximum supply

air openings by size.

Flanges for connection to the supply air

are provided when factory congured

supply air openings are ordered. When

eld congured supply air openings

are selected, supply air anges are

integrated into the cabinet design.

Perforated supply air openings are

knocked out and then the supply air

anges are bent back for connection to

supply air plenum or duct work.

NOTES: Only TRL sizes 006-009 can

be applied as back discharge supply

air only. Sizes 012-015 must be

applied as side discharge supply air

with the option to be combined with

back discharge supply air. Return air

congurations can not be converted in

the eld.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

16

Duct Work Installation, Cont’d.

8 x 6

24 x 6

Figure 6: Side Discharge Supply Air Openings

16 x 6

7 x 6

Figure 6a: Back Discharge Supply Air Opening

climatemaster.com 17

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Duct Work Installation, Cont’d.

Size Right/Left SA Opening Sizes Back SA Opening

006-009 8 x 6 or 16 x 6 7 x 6

012-015 16 x 6 or 24 x 6 7 x 6

All dimensions shown in inches.

Table 1: Supply Air (SA) Opening Dimensional Data

Size Number of

Openings

Minimum Sq. in.

Opening*

Maximum Sq. in.

Opening

Recommended Sq. in.

Opening

006-009 1 or 2 42 96 48

012-015 1 or 2 90 186 144

All dimensions shown in inches.

* Less than minimum SA open area will cause unit to trip on safeties.

Table 2: Supply Air (SA) Square Inches

Supply Opening Area (in) 006 or 009 012 or 015

Straight

8x6 X

16x6 X X*

24x6 X

Straight + Back

8x6 + 7x6 X X*

16x6 + 7x6 X

24x6 + 7x6 X

Back 7X6 X

Field Congured - X X

* For sizes 012-015 this conguration will have internal static pressure losses up to 0.2. ClimateMaster recommends eld

wiring to motor speed tap four for highest fan motor CFM performance.

Table 3: Supply Air Options

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

18

Unit Access

The TRL series is unique to the

ClimateMaster product line in the way

installers and service technicians’ interface

with the product. Traditionally for horizontal

products unit controls/electrical connections

are accessed from the unit’s front access

panel, blowers are accessed through the

side or back panel, and water/refrigerant

circuit repairs require the unit to be brought

down from the ceiling installation.

On TRL products the unit controls,

electrical components, water components/

circuit, the refrigeration components/

circuit, optional power disconnect, service

tool connection, drain pan, air coil, air lter,

and blower motor can be accessed from

the bottom of the unit (see Figures 7 and

8). This greatly increases the installers

and service technicians’ ability to access

and interface the water source heat pump

while it is installed in the ceiling.

The product is also designed to be

accessed in many of the traditional ways

as well. The unique control box design

ships from ClimateMaster facing down for

bottom access but can be ipped up in

the eld for front access. This allows those

who interface with the product to access

the unit controls either from the bottom

or from the front of the unit. See Figures 9

and 10 for details.

Alternatively, if the unit requires tabletop

service on the control box, the TRL

product is designed with a rotation feature

to allow installer or service technician to

interact with the control panel from the

front of the unit. The user will need to

remove the top and front access panels

from the unit, remove the 2 screws that

hold the control panel facing down, rotate

the control panel and lock it at 45 degrees

with the pivotal element on the right side

of the panel control support. See Figure

11 for details.

The complete blower assembly can be

slid down from the bottom of the unit.

The is a safety latch in place to prevent

the blower assembly from dropping

when the bottom blower access panel

is removed. Remove the screw and pull

back on the latch to slide the blower

assembly down. The assembly will rest

on a service rail where the technician may

service the motor or remove the whole

assembly by disconnecting one electrical

quick connector.

The TRL condensate drain pan can be

accessed for service or removal from

the bottom of the unit. After removing

the external condensate line connection,

remove the drain pan access panel. First,

remove the condensate sensor clip from

the pan and set it to the side. Next remove

the drain pan set screw located next to

the compressor side of the unit. Then

hold the drain pan and slide it towards

the back of the unit until the condensate

pan is pushed all the way against the back

access panel. Lastly, allow the opposite

side of the pan to drop down and then

slowly slide the drain pan down allowing

the drain pan nipple to be pulled through

the access panel opening with out

damaging the connection threads.

Bottom Service Access

• Controls

• Electrical Components

• Water Circuit/Components

• Refrigerant Circuit/Components

• Power Disconnect (optional - not

shown)

• Service Tool Connection

• Drain Pan

• Air Filter

• Air Coil

• Blower Motor Assembly

climatemaster.com 19

Tranquility®(TRL)Series

Rev.: November 11, 2021

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Unit Access, Cont’d.

CONTROLS & ELECTRICAL

BOTTOM SERVICE PANEL

BLOWER, AIR COIL, &

DRAIN PAN SERVICE PANEL

SUPPLY AIR

OPENINGS/

KNOCKOUTS

ADDITIONAL

SERVICE

PANEL

CONTROLS & ELECTRICAL

FRONT SERVICE PANEL

OPTIONAL POWER DISCONNECT

(NON-REMOVABLE PANEL

WHEN OPTION IS SELECTED)

SERVICE TOOL

CONNECTION

WATER & REFRIGERANT

SERVICE PANEL

WATER STRAINER

BLOWER, AIR COIL, &

DRAIN PAN SERVICE PANEL

WATER &

REFRIGERANT

SERVICE PANEL

CONTROLS & ELECTRICAL

BOTTOM SERVICE PANEL

Figure 7: ISO View (Left Return Conguration w/ Optional Power Disconnect Shown)

Figure 8: Bottom View (without Optional Power Disconnect Shown)

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility®(TRL)Series

Rev.: November 11, 2021

ClimateMaster Water-Source Heat Pumps

20

Unit Access, Cont’d.

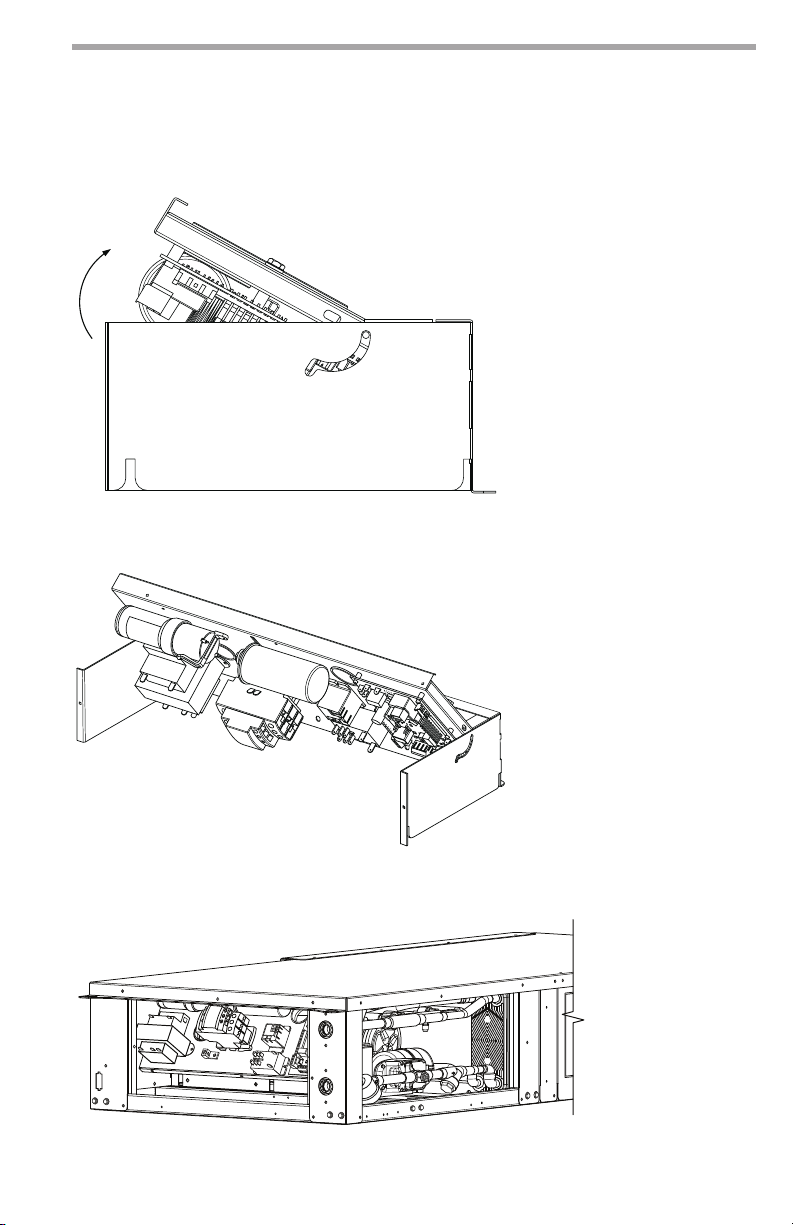

Figure 9: Unit Control Box Rotation - Side View

Figure 10: Unit Control Box Rotation - Front ISO View

Figure 11: Unit Control Box Rotation - Table Top Service Position

This manual suits for next models

5

Table of contents

Popular Water Pump manuals by other brands

EINHELL

EINHELL GC-DW 900 N Original operating instructions

SFA

SFA SANICONDENS PRO installation instructions

KSB

KSB RDLO Series operating instructions

Grundfos

Grundfos SPK Series Installation and operating instructions

Teryair

Teryair SDP50PPT-BF Operation and maintenance guide

MAXIMATOR

MAXIMATOR GX35 operating instructions

bluefin

bluefin THBF701 Master Series installation manual

REED

REED EHTP500 Operator's manual

Wilo

Wilo Wilo-RainSystem AF Comfort MC 304 EM Installation and operating instructions

Gast

Gast SOA Series Operation & maintenance manual

Ingersoll-Rand

Ingersoll-Rand ARO 666300 C Series Operator's manual

Goulds Pumps

Goulds Pumps 3498 Installation, operation and maintenance manual