Gast SOA Series Manual

KEEPTHIS DOCUMENT FOR FUTURE REFERENCE

CONTENTS:

General Information and Installation....................................................................................................... 2

Operation ................................................................................................................................................. 3

Maintenance and Shut-Down Procedures................................................................................................ 4

SAA/LAA Exploded View and Parts Ordering Information ................................................................... 5

SOA/LOA Exploded View and Parts Ordering Information ................................................................... 6

Service Kit Installation and Troubleshooting Guide ............................................................................... 7

Warranty andAuthorized Service Facilities ............................................................................................ 8

Visit us at our website

www.gastmfg.com

70-7050 G505PL (Rev. E)

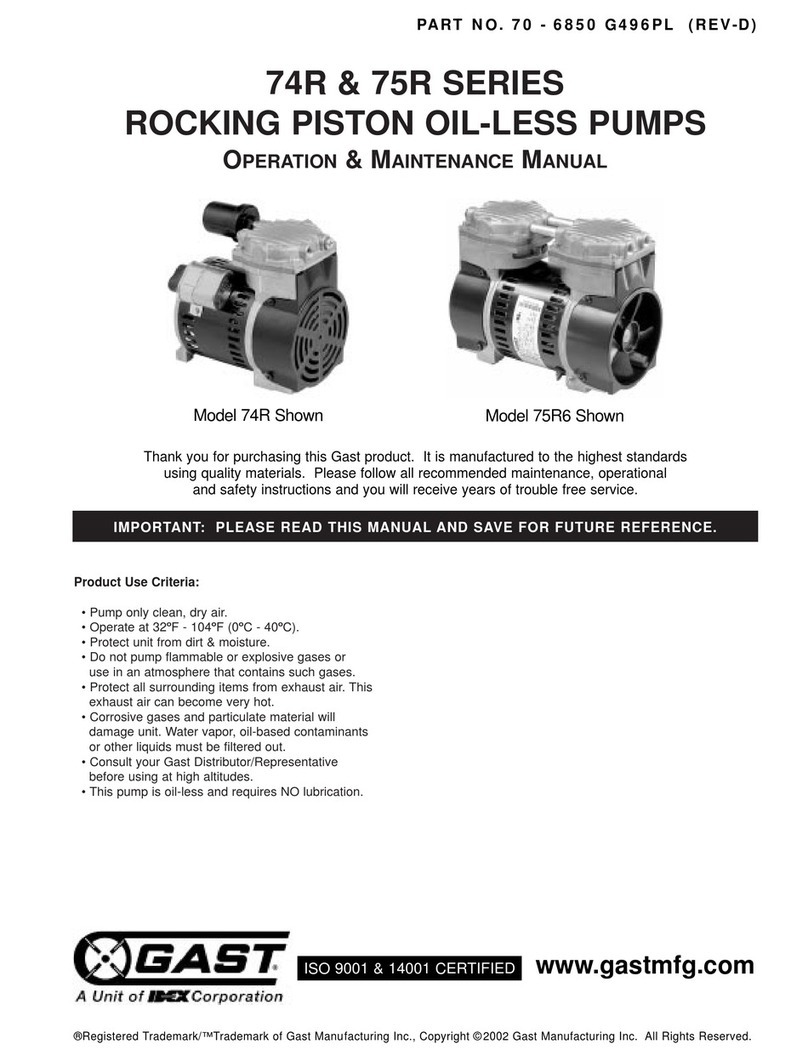

SOA/SAA/LOA/LAA OIL-LESS

VACUUM PUMPS &

COMPRESSORS

OPERATION &

MAINTENANCE MANUAL

2

This is the hazard alert symbol: m. When you see this

symbol, be aware that personal injury or property

damage is possible. The hazard is explained in the text

following the symbol. Read the information carefully

before proceeding.

The following is an explanation of the three

different types of hazards:

mDANGER Severe personal injury or death will

occur if hazard is ignored.

mWARNING Severe personal injury or death can

occur if hazard is ignored.

mCAUTION Minor injury or property damage

can occur if hazard is ignored.

GENERAL INFORMATION

This unit is designed for moving air only and under no

circumstances is to be used with any other gases, fluids,

particles, solids, or any substance mixed with air.

mDANGER Pumping flammable or explosive gases or

operating this unit in an atmosphere

containing them can result in fire or

explosion damage to unit and surrounding

environment.

mCAUTION Do not allow corrosive gases or particulate

material to enter unit.Water vapor, oil-

based contaminants, or other liquids must

be filtered out. Foreign materials will

damage unit by gumming up parts and

causing unit to fail.

mCAUTION This unit’s exhaust air can become very hot.

Hot exhaust air can damage temperature-

sensitive equipment and will burn skin if

exposed to air stream.

Ambient temperature should not exceed 40˚C (104˚F).

For operation at high temperatures, consult the factory.

Performance is reduced by low atmospheric pressure

found at high altitudes. Consult a Gast distributor for

details.

Never lubricate this oil-less piston unit. Most

components are made of aluminum and valves are

stainless steel.

INSTALLATION

mWARNING To avoid risk of electrocution do not use

this product in an area where it could

come in contact with water or other liquids.

If exposed to the elements unit must be weather-protected.

mWARNING Beware of any exposed and/or movable

parts. Proper guards should be in place to

prevent personal and/or property damage.

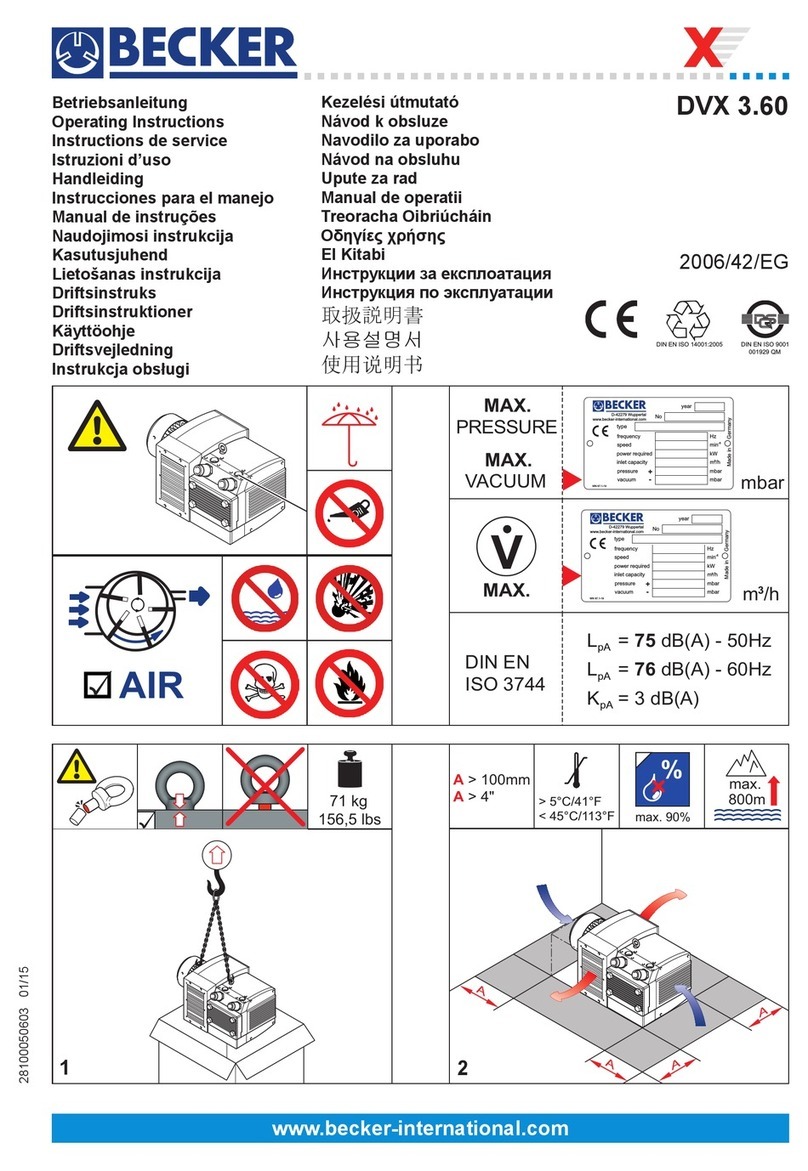

mCAUTION Do not block flow of cooling air over unit in

any way.This will cause unit to overheat.

Mounting

Unit may be installed in any orientation as long as flow

of cool, ambient air over unit is not blocked. To reduce

noise and vibration, use shock mounts and affix unit to a

stable, rigid operating surface.

mCAUTION Remove plastic plugs in ports before

starting unit to avoid flying projectile and/

or lack of performance.

Wiring

mWARNING Incorrect wiring can result in electric shock

and cause permanent damage to unit.

Wiring must conform to all required safety codes and be

installed by a qualified person. Grounding is required.

All power to motor must be de-energized and

disconnected when servicing.

Grounding Instructions

These instructions apply to 120-volt units and where

indicated to units wired for 220-240 volts. See motor

nameplate on unit for voltage requirements.

For all grounded, cord-connected products:

This product should be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current this product is

equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into

an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

mDANGER

Improper installation of the grounding plug

can result in a risk of electric shock. If

repair or replacement of the cord or plug is

necessary, do not connect the grounding

wire to either flat blade terminal.The wire

with insulation having an outer surface that

is green with or without yellow stripes is

the grounding wire.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if in

doubt as to whether the product is properly grounded. Do not

modify the plug provided; if it will not fit the outlet, have the

proper outlet installed by a qualified electrician.

3

Plumbing

To prevent air flow restriction, use pipe and fittings

that are same size or larger than unit’s threaded ports.

NOTE: Be sure to connect intake and exhaust plumbing

to correct inlet and outlet ports.

Accessories

Filters and mufflers are supplied on some models. Check

periodically and replace when necessary. Consult a Gast

Representative for filter recommendations. For best

results, install relief valves and gauges at inlet or outlet, or

both, to monitor performance.

Electric Motor Control

Motor must be protected against short circuit, overload

and excessive temperature rise. Fuses, motor-protective

switches and thermal-protective switches provide

necessary protection in these circumstances. Fuses only

serve as a short circuit protection of motor (wiring

fault). Fuses in the incoming line should be chosen so as

to be able to withstand the starting current of the motor,

not as a protection against overload.

Motor starters, incorporating thermal-magnetic overload

or circuit breakers protect motor from overload or

reduced voltage conditions.

Selection of correct overload setting is required to

provide best possible protection. Refer to motor starter

manufacturer’s recommendations.

OPERATION

mWARNING Solid or liquid material exiting unit can

cause eye or skin damage. Keep away

from air stream.

mWARNING Disconnect power before servicing to

avoid electric shock or accidental start-

up.The motor may be thermally pro-

tected and will restart automatically when

it cools if the thermal protection switch is

tripped.

mWARNING Do not operate without grille(s), if pro-

vided, in place.Failure to do so could

result in severe personal injury.

mWARNING Head surface(s) can be very hot depend-

ing on unit duty and speed. Do not touch

these parts during operation.

mCAUTION Do not operate units above recom-

mended pressures or vacuum duties.

This will overheat unit.

For a grounded, cord-connected product rated less than 15

amperes and intended for use on a nominal 120 volt

supply circuit:

This product is for use on a nominal 120-volt circuit and has

a grounding plug that looks like the plug illustrated in Figure

1. Make sure that the product is connected to an outlet having

the same configuration as the plug. No adapter should be used

with this product

Figure 1

For all other grounded, cord-connected products:

This product is for use on a circuit having a nominal rating

more than I20 volts (or 220-240 volts) …and is

factory-equipped with a specific electric cord and plug to

permit connection to a proper electric circuit. Make sure that

the product is connected to an outlet having the same

configuration as the plug. No adapter should be used with this

product if the product must be reconnected for use on a

different type of electric circuit, the reconnection should be

made by qualified service personnel.

For a permanently connected product:

This product should be connected to a grounded, metallic,

permanent wiring system, or an equipment-grounding

terminal or lead on the product

Extension Cords:

Use only a 3-wire extension cord that has a 3-blade grounding

plug, and a 3-slot receptacle that will accept the plug on the

product Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy,

enough to carry the current your product will draw. For

lengths less than 25 feet, No.18 AWG extension cords should

be used. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

Exception: A 2-conductor or 3-conductor extension cord may

be used for a double-insulated or 2-wire product.

Refer to wiring tag supplied with unit, for diagram

and capacitor option. For any DC unit - red lead goes

to positive side of power source.

4

Starting

If unit is extremely cold let it warm up to room

temperature before starting. If unit does not operate

properly, see troubleshooting guide on page 7. Do not

start against a vacuum or pressure load.

NOTE: Some of these models may exceed 70 dB(A).

When in close proximity to these models

hearing protection is required. Refer to

Technical Data Sheet for specific model.

MAINTENANCE

Filter Inspection and Replacement

Intake filter and mufflers require periodic inspection and

replacement. Initial inspection is suggested at 500

hours, then user should determine frequency thereafter.

Most problems can be prevented by keeping filters and

mufflers clean. Dirty filters and mufflers decrease unit

performance and can decrease unit life.

mWARNING Do not touch unit cylinders and heads as

they becomes very hot during operation

and will burn skin on contact.Wait until

unit has been turned off and allowed to

cool before touching it.

mWARNING Disconnect power before servicing to

avoid electric shock.

Some filter element(s) are held together by a snap fit.

Refer to exploded view during the following procedure.

1. Turn off unit.

2. Isolate from power source.

3. Release all pressure and vacuum from unit.

4. Remove filter cover.

5. Inspect filter felt.

6. Replace felt if it is completely covered with

contamination or has indicated an increase in

differential pressure.

7. Assemble felt and filter cover.

8. Check for any damage to external accessories such as

relief valves and gauges, before putting unit back into

service.

SHUTDOWN PROCEDURES

Proper shutdown procedures must be followed to prevent

unit damage. Failure to do so may result in premature unit

failure. Gast Manufacturing oil-less units are constructed of

ferrous metals or aluminum which are subject to rust and

corrosion when pumping condensable vapors such as water.

Follow steps below to assure correct storage and shutdown

between use:

1. NEVER oil this oil-less unit.

2. After using this unit, disconnect plumbing and allow unit

to run “open” for at least 5 minutes before shutdown.

3. Plug open ports to prevent dirt or other contaminants

from entering unit.

It is now ready for shutdown or storage.

5

SAA/LAA EXPLODED VIEW & PARTS ORDERING INFORMATION

feR oNoNoNoNoNnoitpircseDytQQN-901V-AASQN-701P-AASQN-101-AALQN-211P-AAL

1daeH2743JA743JA743JA743JA

•

2teksaGdaeH2A404JAA404JAA404JAA404JA

•

3ylbmessAetalPevlaV

(

*

)dedulcnisevlav 2A343JA343JA)1( A343JA)1( 397JA)1( 493KA)1( 397JA)1( 493KA)1(

4sevlaV

*

4718FA718FA379GA)2( 728JA)2( 379GA)2( 728JA)2(

•

5gnir-O2971HA971HA971HA971HA

6rednilyC2243JA243JAB573JAB573JA

7smihS

.qersa

543JA543JA543JA543JA

8ellirG2B477GAB477GAB477GAB477GA

9naF1658JA658JA658JA658JA

01etalPreniateR2B771HAB771HA773KA773KA

•

11puC2571HA571HA628JA628JA

21doRgnitcennoC2A833JAF803JAD083KAD083KA

31naF1B587FAB587FAB587FAB587FA

•

41swercSetalPreniateR4755BB755BB755BB755BB

tiKecivreS2757K)2(657K)1( 757K)1( 767K)1( 377K)1( 767K)1( 377K)1(

•

.yrotcafehttlusnocsledomMEOcificepsroF.sledomkcotsroferadetsilstraP.tiKecivreSnidedulcnistrapsetoneD .srebmunlairesdnaledometelpmocevigesaelp,strapgniredrorognidnopserrocnehW

SAA-P107-NQ

6

SOA/LOA EXPLODED VIEW & PARTS ORDERING INFORMATION

feR oNoNoNoNoNnoitpircseDytQAM-501P-AOSAN-501V-AOSBH-101-AOLQN-201P-AOL

1daeH1743JA743JA743JA743JA

•

2teksaGdaeH1A404JAA404JAA404JAA404JA

•

3ylbmessAetalPevlaV

(

*

)dedulcnisevlav 1H343JAA343JA397JA397JA

4sevlaV

*

2396HA718FA379GA)1( 728JA)1( 379GA)1( 728JA)1(

•

5gnir-O1971HA971HA787JA787JA

6rednilyC1243JA243JAB573JAB573JA

7smihS

.qersa

543JA543JA543JA543JA

8ellirGtnorF1B477GAB477GAB477GAB477GA

9naF1658JA658JA658JA658JA

01ylbmessAdoRgnitcennoC1D803JAA833JAB083KA083KA

•

11puC1571HA571HA628JA628JA

21etalPreniateR1B771HAB771HA773KA773KA

31naF1B587FAB587FAB587FA

41naFaitrenI1 776JA

51gniRecnareloT1 409JA

•

61swercSetalPreniateR2755BB755BB755BB755BB

71ellirG1447GA447GA447GA

)detartsullItoN(niPlewoD1 784KA

tiKecivreS1067K757K767K767K

•

.yrotcafehttlusnocsledomMEOcificepsroF.sledomkcotsroferadetsilstraP.tiKecivreSnidedulcnistrapsetoneD .srebmunlairesdnaledometelpmocevigesaelp,strapgniredrorognidnopserrocnehW

7

TROUBLESHOOTING GUIDE

SERVICE KIT INSTALLATION

NOTE: Gast will not guarantee performance of a field-

rebuilt unit. Return unit to a Gast Authorized Service

facility, or perform rebuild procedures described below.

Kits contain most or all of the following: Head Gasket,Valve

PlateAssembly, Retainer Plate Screws, O-ring, and Cup.

Kits are used for several models and may contain extra

parts not applicable for your specific model. Refer to

exploded view.

Disassembly:

1. Disconnect unit from power source.

mWARNING Disconnect power before servicing to

avoid electric shock.

2. Vent all air lines to unit to remove pressure.

mWARNING Vent all air lines to unit to remove pressure

before servicing it. Failure to do so can

result in severe personal injury.

3. Remove head bolts.

4. Remove gasket, head, and valve plate assembly

(Note orientation of head assembly for re-assembly).

5. Carefully remove cylinder and shims (Be sure to

replace all shims, as they are matched to cylinder and

rod assembly height dimensions). Remove two retainer

plate screws on retainer plate (may require heat to

break adhesive on retainer screws) and discard old cup.

6. Clean residue from cylinder walls with soft cloth

using non-petroleum, non-oil-based solvent. DO NOT

use kerosene, gasoline, or any flammable substance.

Re-assembly:

7. Replace cylinder and shims.

8. Place retainer plate in new cup and push both down

into cylinder.

9. Install new retainer plate screws and torque to 35 in-lbs.

10. Install O-ring into groove of cylinder

11. Install valve plate, head gasket (note gasket orientation),

and head, on cylinder so ports are in original orientation.

12. Install and snug all head bolts and torque to 80 in-lbs.

NOTE: Before putting unit into service, ensure that any

external accessories such as relief valves and

gauges attached to head have not been damaged.

EDIUGGNITOOHSELBUORT

nosaeRelbissoP erusserP woL muucaVmuucaV muucaV muucaVmuucaV evissecxE esioNesioN esioN esioNesioN gnitaehrevO t'noW tratStratS tratS tratStratS

woLhgiH

retliFytriDX X

relffuMytriDXXX

sevlaVytriDXX

sevlaVdegamaDXXXX

puCnroW/degamaDXX

gnimmihSrednilyCreporpmIXXXXXX

esoHykaeLXX

evlaVkcehCykaeL X

eniLerusserPromuucaVdeggulPXXXXX

egatloVwoLXXXX

evlaVfeileRykaeLXX

8

YOUR WARRANTY

Gast finished products, when properly installed and operated under normal conditions of use, are warranted by Gast to

be free from defects in material and workmanship for a period of twelve (12) months from the date of purchase from

Gast or an authorized Gast Representative or Distributor. In order to obtain performance under this warranty, the buyer

must promptly (in no event later than thirty (30) days after discovery of the defect) give written notice of the defect to

Gast Manufacturing Incorporated, PO Box 97, Benton Harbor Michigan USA 49023-0097 or an authorized Service

Center (unless specifically agreed upon in writing signed by both parties or specified in writing as part of a Gast OEM

Quotation). Buyer is responsible for freight charges both to and from Gast in all cases.

This warranty does not apply to electric motors, electrical controls, and gasoline engines not supplied by Gast. Gast’s

warranties also do not extend to any goods or parts which have been subjected to misuse, lack of maintenance, ne-

glect, damage by accident or transit damage.

THIS EXPRESS WARRANTY EXCLUDES ALL OTHER WARRANTIES OR REPRESENTATIONS EXPRESSED

OR IMPLIED BY ANY LITERATURE, DATA, OR PERSON. GAST’S MAXIMUM LIABILITY UNDER THIS

EXCLUSIVE REMEDY SHALL NEVER EXCEED THE COST OF THE SUBJECT PRODUCT AND GAST

RESERVES THE RIGHT, AT ITS SOLE DISCRETION, TO REFUND THE PURCHASE PRICE IN LIEU OF

REPAIR OR REPLACEMENT.

GAST WILL NOT BE RESPONSIBLE OR LIABLE FOR INDIRECT OR CONSEQUENTIAL DAMAGES OF

ANY KIND, however arising, including but not limited to those for use of any products, loss of time, inconvenience,

lost profit, labor charges, or other incidental or consequential damages with respect to persons, business, or property,

whether as a result of breach of warranty, negligence or otherwise. Notwithstanding any other provision of this

warranty, BUYER’S REMEDY AGAINST GAST FOR GOODS SUPPLIED OR FOR NON-DELIVERED GOODS

OR FAILURE TO FURNISH GOODS, WHETHER OR NOT BASED ON NEGLIGENCE, STRICT LIABILITY OR

BREACH OF EXPRESS OR IMPLIED WARRANTY IS LIMITED SOLELY, AT GAST’S OPTION, TO

REPLACEMENT OF OR CURE OF SUCH NONCONFORMING OR NON-DELIVERED GOODS OR RETURN

OF THE PURCHASE PRICE FOR SUCH GOODSAND IN NO EVENT SHALL EXCEED THE PRICE OR

CHARGE FOR SUCH GOODS. GAST EXPRESSLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR USE OR PURPOSE WITH RESPECT TO THE GOODS SOLD. THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTIONS SET FORTH IN THIS WARRANTY,

notwithstanding any knowledge of Gast regarding the use or uses intended to be made of goods, proposed changes or

additions to goods, or any assistance or suggestions that may have been made by Gast personnel.

Unauthorized extensions of warranties by the customer shall remain the customer’s responsibility.

CUSTOMER IS RESPONSIBLE FOR DETERMINING THE SUITABILITY OF GAST PRODUCTS FOR

CUSTOMER’S USE OR RESALE, OR FOR INCORPORATING THEM INTO OBJECTS OR APPLICATIONS

WHICH CUSTOMER DESIGNS,ASSEMBLES, CONSTRUCTS OR MANUFACTURES.

This warranty can be modified only by authorized Gast personnel by signing a specific, written description of any

modifications.

This manual suits for next models

11

Table of contents

Other Gast Water Pump manuals

Popular Water Pump manuals by other brands

Homa

Homa TCM Series Installation and operation instruction manual

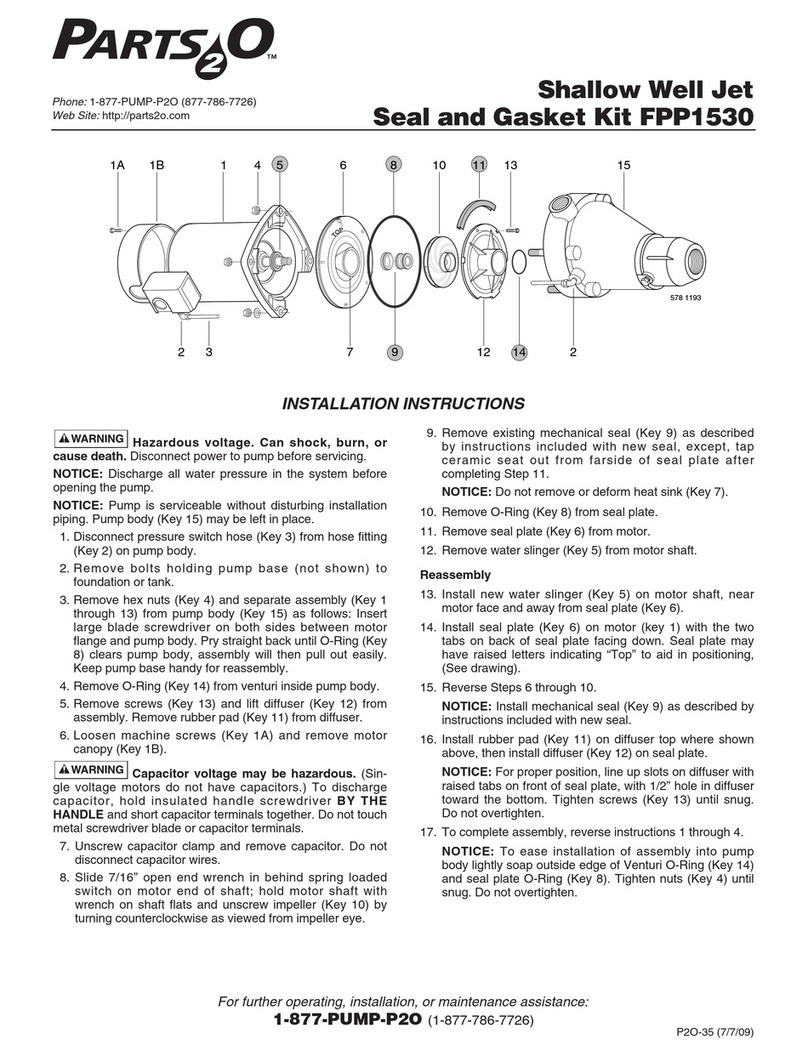

Parts2o

Parts2o FPP1530 installation instructions

Cosmo

Cosmo CPB Installation and operating instructions

Lux Tools

Lux Tools A-KPS-12/10 Original instructions

DIPRA

DIPRA SPID'O ECC PRO 300 operating instructions

Bestway

Bestway 58420E owner's manual

Thermo Scientific

Thermo Scientific Masterflex P/S 965-0000 operating manual

Ebmpapst

Ebmpapst ALPHA operating instructions

Wayne

Wayne CDUCAP Series Operating instructions and parts manual

SPX

SPX S2045 instruction manual

Ecolab

Ecolab Elados EMP KKS E60 operating instructions

Seko

Seko KOMPACT AMC 200 installation manual