English (GB)

8

3.1.4 Permanent, vertical or horizontal, dry

installation in a pump room

Pumps in dry installation are installed permanently in

a pump room.

The pump motor is enclosed and watertight and will

not be damaged if the installation site is flooded with

water.

Proceed as follows:

1. Mark and drill mounting holes in the concrete

floor or concrete foundation.

2. Fit the bracket or base stand to the pump.

3. Fasten the pump with expansion bolts.

4. Check that the pump is vertical or horizontal.

5. Fit the inlet and outlet pipes and isolating valves,

if used, and ensure that the pump is not stressed

by the pipes.

6. Adjust the length of the power cable by coiling it

up on a relief fitting to ensure that the cable is not

damaged during operation. Fasten the relief

fitting to a suitable hook. Make sure that the

cables are not sharply bent or pinched.

7. Connect the power cable and the control cable, if

any.

Pull-out strength for anchor bolts

Recommendation for pump foundations

Note: This applies for pumps above 15 kW.

All rotating equipment generates vibrations when an

impeller or rotor is turning at high speeds. Proper

installation and anchorage of the pumps and

installation accessories is critical to limit vibrations

and achieve reliable installation. To ensure

acceptable vibration levels, all parts of the system

must be sufficiently stiff and firmly anchored to

minimize vibrations:

• The foundation and concrete must be of

adequate strength to support the weight of the

pump including accessories, the weight of the

liquid passing through the pump, and the forces

generated by the pump.

• The mass of the concrete foundation must be a

minimum of three to five times the mass of the

supported equipment and must have sufficient

rigidity to withstand the axial, transverse, and

torsional loadings generated by these machines.

• The foundation must be 15 cm wider than the

base plate for pumps up to 350 kW and 25 cm

wider for larger pumps.

• The concrete used in the foundation must have a

minimum tensile strength of 250 N/cm2.

• Epoxy grout must always be used to mate the

pump base plate to the foundation.

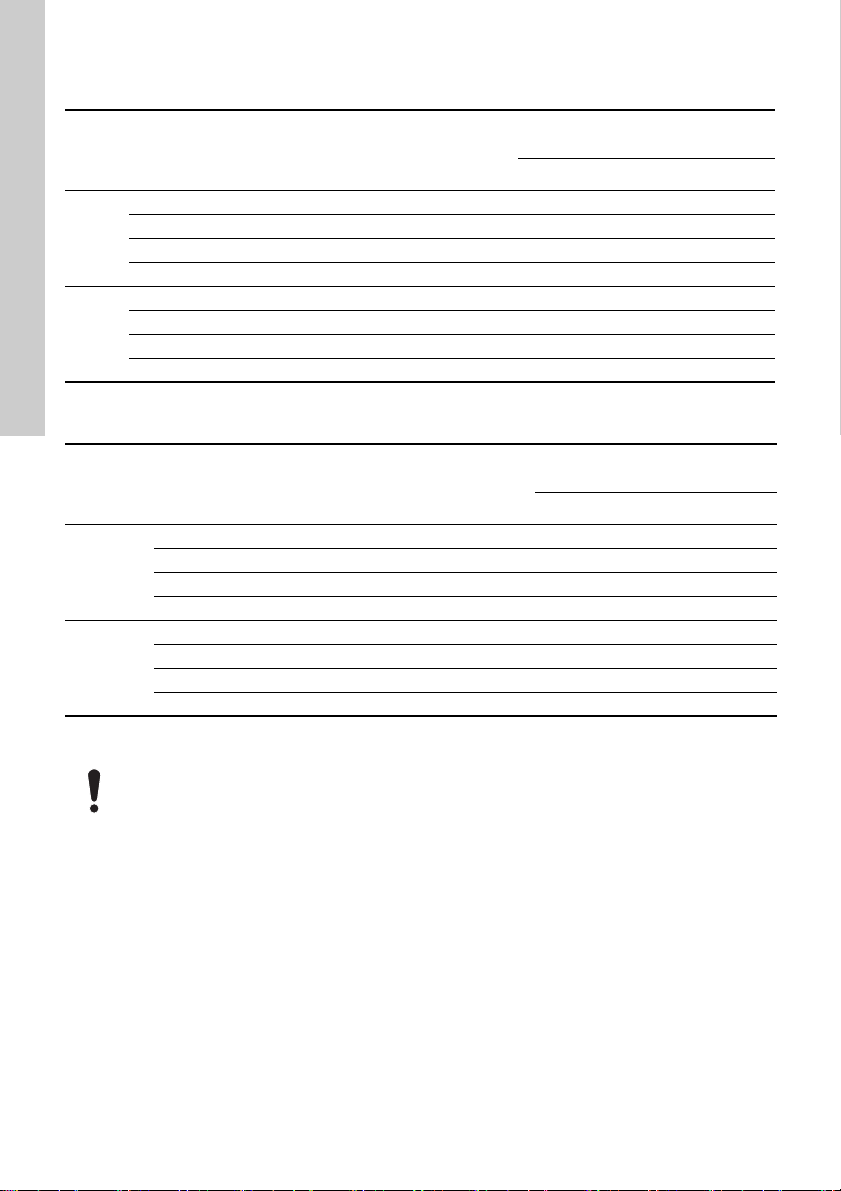

Fig. 7 Eccentric reducer in horizontal

installation

In order to facilitate service on the pump,

we recommend that you use isolating

valves on either side of the pump.

Installation

types D and H Bolts

Pull-out strength for

a single bolt

[kN]

-- 5.0

The pull-out strengths stated are without

safety factor. The required safety factor

may depend on the materials and method

used for anchoring.

We recommend that you use a reducer

between the inlet pipe and the pump in

horizontal installations. The reducer must

be of the eccentric type and must be

installed so that the straight edge is

upwards. In this way, the accumulation of

air in the inlet pipe is avoided and the risk

of disturbance of operation is eliminated.

See fig. 7.

TM05 2540 0212

Reducer of the eccentric type

≥0.2 m