Electrical - Controls

19

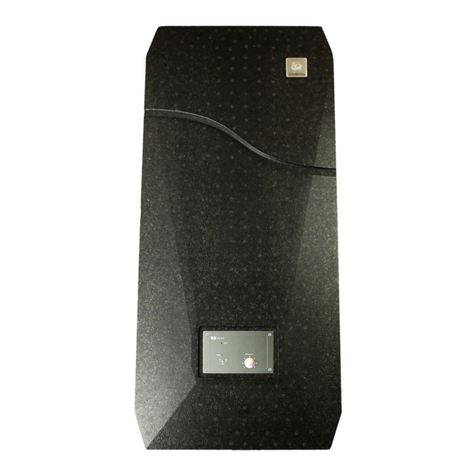

Tranquility®High Temperature Water-to-Water (THW) Series

Rev.: 28 Aug., 2014

climatemaster.com

Warm weather shutdown (WWSD): Radiant floor systems are

the most comfortable type of heating available today. However,

they do have one disadvantage – quickly switching from

heating to cooling is not possible due to the mass heat storage

in the slab. For example, in the spring or fall, there could be

times where heating is required at night, but cooling is required

during the day. With a warm floor, the cooling system has

to work much harder to cool the space. WWSD shuts down

the water-to-water heat pump at a pre-determined outdoor

air temperature (adjustable at the user interface). When a

water-to-air heat pump is used for space cooling, this unit can

be enabled when WWSD is activate, allowing the water-to-air

heat pump to heat via forced air during the shoulder seasons,

avoiding the warm slab/cooling dilemma (see cooling enable,

below). A normally closed contact is provided in the THW

unit to de-energize the heating system controls (e.g. radiant

floor control panel) during WWSD. WWSD does not affect

DHW heating. In other words, the water-to-water unit can still

operate for generating DHW, even if the heating distribution

(e.g. radiant floor) system is disabled.

The WWSD activation (i.e. when the WWSD feature is

enabled) outdoor air temperature range is 40-100°F [4-38°C]

with a default value of 70°F [21°C]. The WWSD deactivation

(i.e. when the radiant heating returns to operating mode)

temperature range is 35-95°F [2-35°C] with a default value

of 65°F [18°C] and a minimum difference between activation

and deactivation temperatures of 5°F [3°C]. If the outdoor air

temperature (OAT) rises above the activation temperature, the

cooling enable signal (see below) is enabled, and the control

no longer controls the buffer tank temperature. If the OAT

falls below the deactivation temperature, the control resumes

monitoring the buffer tank temperature.

Cooling enable: Cooling enable is tied to the WWSD feature.

If desired, the water-to-air unit controls can be wired to the

THW unit controls, which will allow the water-to-air unit to

operate during WWSD, but will disable the water-to-air unit

when the THW unit is not in WWSD mode. When a heat

pump thermostat is connected to the water-to-air unit, forced

air heating may be used for the shoulder seasons, allowing

quick heating to cooling changeover. If this feature is used,

the consumer will easily be able to tell when WWSD is enabled

because the water-to-air unit thermostat will only be active

during WWSD. Otherwise, the water-to-air unit thermostat will

be disabled, indicating that the consumer should utilize the

hydronic heating (e.g. radiant floor) thermostat.

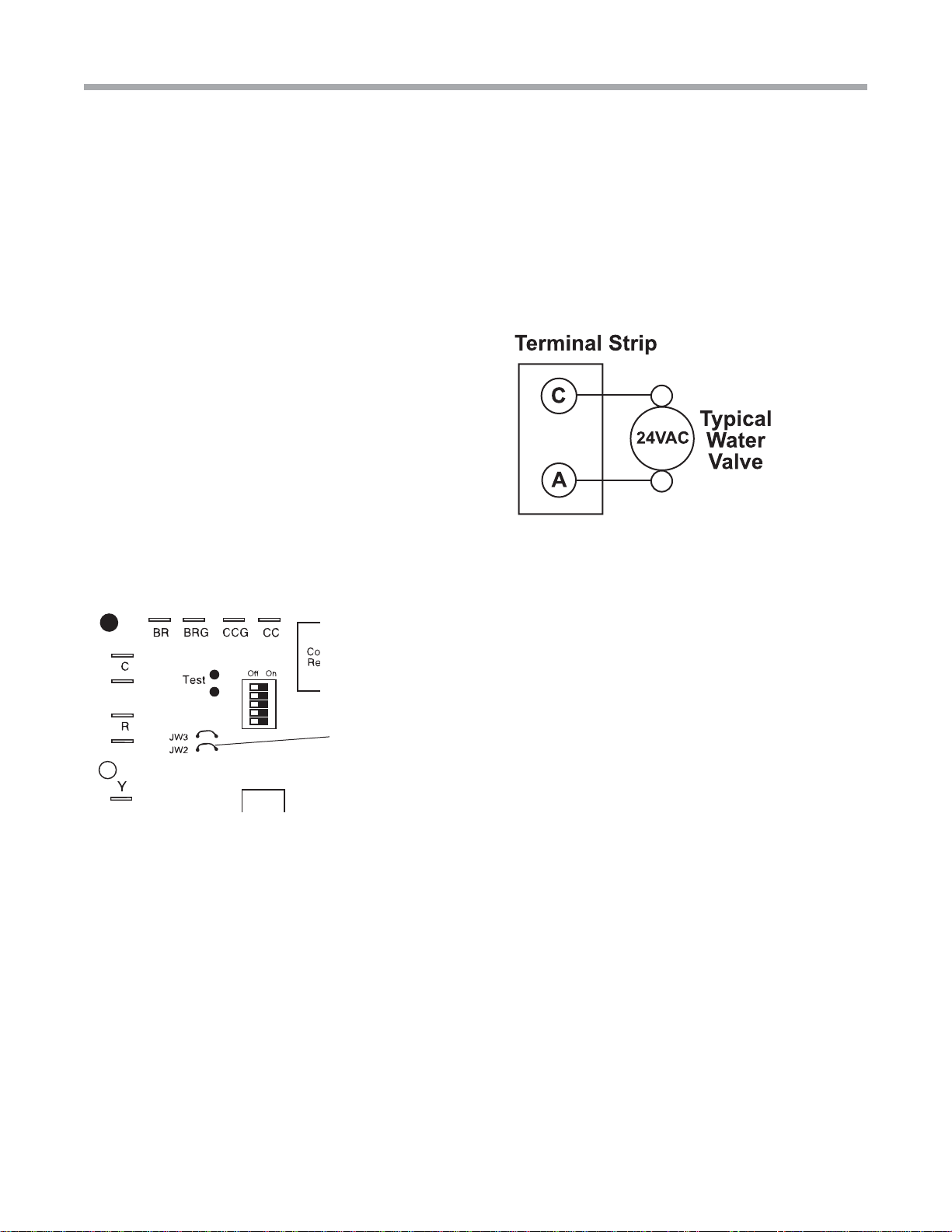

Second stage heating (backup boiler): Optimal heat pump

sizing may not include a water-to-water heat pump that can

handle 100% of the heating load. When a backup boiler is

used to supplement the heating capacity, a 24VAC output

from the THW unit can energize the boiler. The boiler control

box simply needs a relay that can be used to interface with

the THW unit.

DHW priority: By default, DHW heating always takes priority

over space heating. Normally, the hot water load will be

satisfied quickly, and the unit can then switch back to space

heating.

Time schedule: DHW temperatures may be adjusted

during occupied/unoccupied times via the user interface to

save energy costs.

Vacation mode: DHW generation may be disabled when the

user interface is placed in vacation mode. A return date and

time may be set to restore normal DHW temperatures.

Emergency DHW generation: If the THW unit is locked out, a

24VAC signal can be sent to a contactor at the water heater

to allow the operation of the electric elements and associated

thermostat.

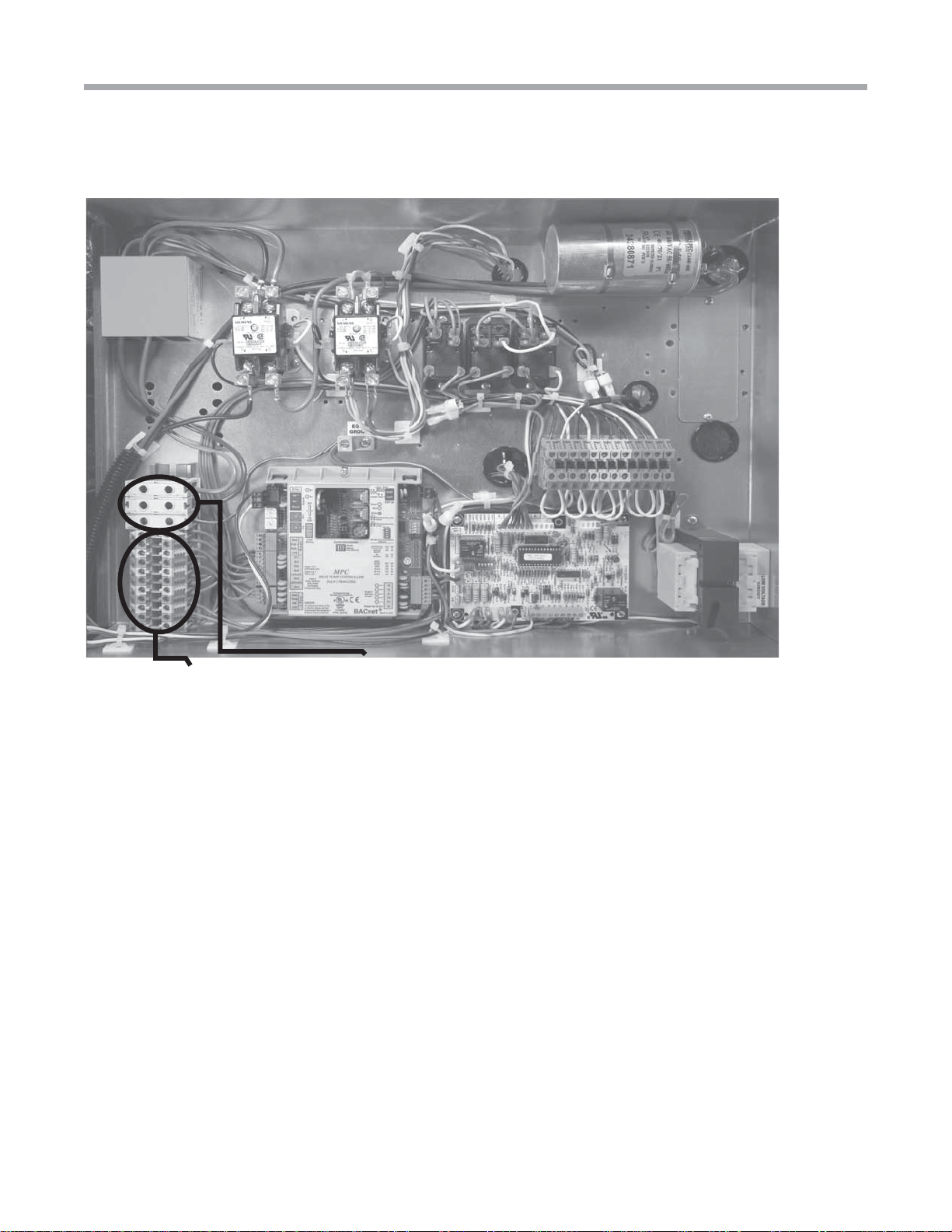

Enhanced heat pump lockouts: Like any ClimateMaster

unit, the CXM board locks out the compressor any time a

lockout condition occurs. The MPC reads the lockouts from

the CXM, and reports the condition to the user interface.

The user interface changes from a blue backlight to a red

backlight, indicating a lockout. The actual lockout is reported

(e.g. High Pressure) at the interface. In addition to the

standard CXM faults, the MPC checks for bad thermistors

and high compressor discharge temperature, which are also

reported at the user interface.

Pump control: If the optional load and source pump(s) are

selected, the control energizes the pumps any time the

compressor is operating.

Variable speed floor pump (VSFP) output: Some radiant floor

systems utilize a variable speed pump on the floor system,

which changes flow based upon the number of zones open

or closed. Since the pump has built-in controls, only a power

supply is needed. An optional power terminal is available for

VSFP applications.