Clinton 970 User manual

CLINTON

MODEL 970

VARIABLESPEED

DC SERVO MOTOR

SERVICE MANUAL

ML970-3

NEEDLE POSITIONER THREAD TRIMMER

40-0258-01

TABLE OF CONTENTS

®

ML970-4

SECTION I - INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SECTION II - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

A.

B.

C.

D.

E.

F.

MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCH BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER AND CABLE CONNECTIONS . . . . . . . . . . . . . . . . .

MOTOR ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEACH-IN MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1

2-2

2-2

2-2

2-3

SECTION III - PROGRAMMABLE LCD DISPLAY . . . . . . . . . . . . . . . . . . . . . . . 3-1

A.

B.

C.

DIRECT ACCESS PARAMETERS . . . . . . . . . . . . . . . . . . . .

HIDDEN PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . .

MASTER RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-2

3-3

SECTION IV - TEST PROGRAM 4-1

1. TREADLE TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. INDEX SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. ENCODER TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. MOTOR BALANCE TEST . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

4-1

4-1

4-1

SECTION V - CONNECTOR DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

SECTION VI - DRAWINGS AND PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

A.

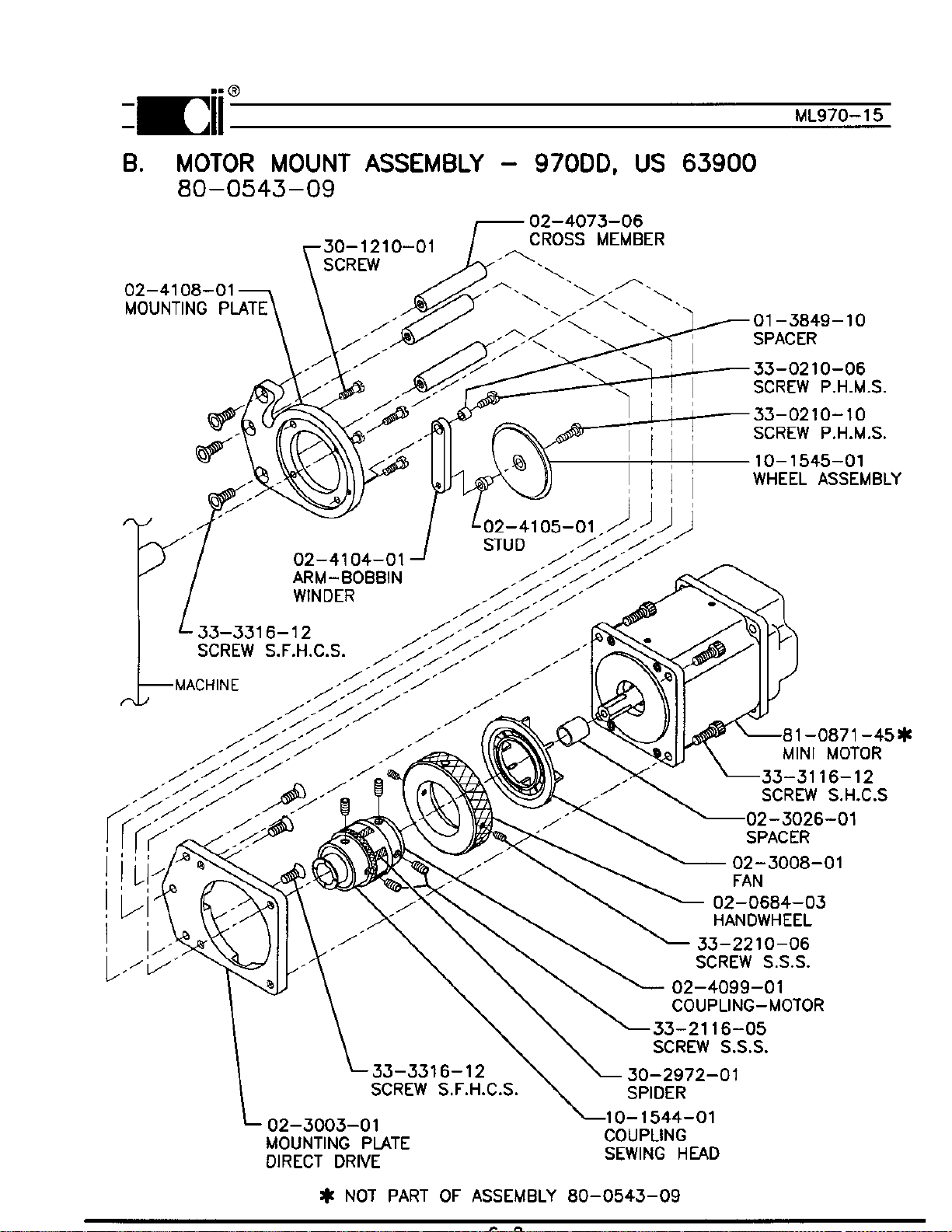

B.

C.

D.

E.

F.

G.

MAJOR ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOTOR MOUNTING ASSEMBLY . . . . . . . . . . . . . . . . . . . . .

CONTROL BOX ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . .

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMABLE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . .

MISCELLANEOUS PARTS . . . . . . . . . . . . . . . . . . . . . . . . . .

E-PROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-2

3-3

6-4

6-5

6-5

6-5

INTRODUCTION

Clinton's Model 970 is an electronically controlled variable speed drive for industrial sewing machines.

The drive consists of a brushless DC Servo Mini-Taurus motor, controller with a microprocessor, speed

control and a programmable LCD display as an option. No clutches, brakes or synchronizer are used.

All components interact to give a fast accurate and reliable sewing machine drive. The components of

the system are shown in figure below.

The model 970 has outputs for a trimmer, footlift, wiper and needle cooler. It can be used to operate all

Clinton trimmers, as well as the Singer, Union Special, Pfaff, Juki and Brother undertrimmers and chain

stitch machines.

The programmable LCD display is used to select the trimmer type and other parameters.

See section III.

1-1

®

SECTION I ML970-5

MINI-TAURUS

SWITCH BOX

CONTROL BOX

LCD

DISPLAY

INSTALLATION

A. MOTOR INSTALLATION

1. Remove the handwheel from the machine.

2. Remove the four screws that hold the bearing housing to the machine, see ML970-15. Attach

the sewing head mounting plate, 02-4108-01 to the machine with the screws provided

30-1210-01.

3. Attach the sewing head coupling assembly 10-1544-01 to the machine removing all play from

the main shaft.

4. Rotate the machine in the standard direction of rotation until the point of the needle is even with

the top of the throat plate.

5. With power to the system and the motor detached from the machine press the "arrow right" and

"SBT" buttons simultaneously. The display will read "TEST SYSTEM" briefly the "PRESS

SET".

6. Press the "SET" button twice, the display will read "TEST INDEX" briefly then show a broken

line (---------) rotate the motor slowly by hand until the display reads (---INDEX---).

7. Align the motor coupling with the sewing head coupling, keeping the motor in the INDEX posi

tion, and attach the motor to the machine.

Note: The sewing head may have to be rotated slightly in order to align the couplings but

the INDEX signal must be between the needle up and the needle down positions.

B. LCD DISPLAY

Mount the LCD display console at

a convenient location on the table top

as shown in figure 2-2.

SECTION II

®

ML970-6

2-1

Fig. 2-2

NEEDLE UP

NEEDLE DOWN

TRIM

INDEX

DIRECTION OF

ROTATION

Fig. 2-1

C. SWITCH BOX

Install switch box at a convenient

location under the table. See fig. 2-3.

D. POWER AND CABLE CONNECTIONS

Refer to figure 2-4 and connect all cables as shown. The system can be operated from 230V, 3

phase or 230V, single phase power.

2-2

E. MOTOR ROTATION

Before attaching the motor to the sewing head, turn power on, then move the pedal forward and

note the direction of motor pulley rotation. If incorrect, do the following:

1. Turn power off.

2. Refer to section III-B, Hidden Parameters, and follow the instructions to change motor rotation.

The parameter is in the "**** Toggle Switches" group.

3. Install the motor.

FIG. 2-4

®

ML970-7

Fig. 2-3

CABLE DIAGRAM

F. TEACH-IN MODE

(SETTING THE NEEDLE UP, NEEDLE DOWN AND TRIM POSITIONS)

Note: The index signal from the motor must be set prior to setting the needle up and down posi-

tions. (See systems test section for instruction on setting the index signal).

1. NEEDLE DOWN

To set the needle down position access the "****MISC." group of the hidden parameters then

select the "NEED.dwn" parameter. Rotate the handwheel of the machine until the needle is in

the down position. Press the treadle forward, the machine will make one revolution then save

the needle down position.

2. NEEDLE UP

To set the needle up position access the "****MISC." group of the hidden parameters then select

the "NEEDLEup" parameter. Rotate the handwheel of the machine until the take-up lever is in

dead center position. Press the treadle forward, the machine will make one revolution then save

the needle up position.

3. TRIM

To set the trim position access the "****MISC." group of the hidden parameters then select the

"TRIMcnt." parameter. Rotate the handwheel of the machine until the needle thread is posi

tioned between the 5 and 6 o'clock position across the hook. The needle is used for the refer

ence point of 12 o'clock position. Press the treadle forward, the machine will make one revolu

tion then save the trim position.

Note: Any of the above positions may be "Fine Tuned" by accessing their respective parameter and

using the or button to change the displayed value.

2-3

®

ML970-7-1

PROGRAMMABLE LCD DISPLAY

The LCD display, shown in fig. below is used to program and set the various parameters of the 970;

SPEEDS, TIMERS, COUNTERS, and TOGGLE SWITCHES.

Two (2) different modes of operation are

available. They are:

1. Operating Mode

2. Programming Mode

When power is turned on, the display

is in the operating mode.

There are two (2) groups of parameters that are accessed in different ways. They are : (1) parameters

with direct access and (2) hidden parameters with indirect access. In addition a master reset is avail-

able to reset all parameters to their default values.

A. DIRECT ACCESS PARAMETERS

The direct access parameters are divided into four (4) groups. They are (1) SPEEDS, (2) TIMERS,

(3) COUNTERS, and (4) TOGGLE SWITCHES. Table 3-1 describes each parameter, shows

the default value and range of adjustment for each parameter.

3-1

®

SECTION III ML970-8

To change a parameter, follow the sequence described below.

1. Press the key to enter the programming mode. Continue pressing this key until the para-

meter group that is to be changed is displayed. As an alternative; press the key to enter

the programming mode and display the last changed parameter.

2. Press the key to step to the next parameter in the selected group.

3. Press the key to increase or the key to decrease the contents of the displayed para-

meter. Both keys are used to toggle parameters between states in the Toggle Switches group.

Hold the key down to make the display step automatically.

4. Press the key to return to the operating mode.

®

3-2

B. HIDDEN PARAMETERS

The parameters in this section are separated from the Direct Access parameters because they are

infrequently changed and should not be changed by the operator. The parameters are listed in

table 3-2.

1. Turn power off, if it is on, then wait until the display goes blank.

2. Press the key and the key simultaneously. Keep pressed then,

3. Turn power on. A series of "***" will appear on the display. They will slowly dissapear.

4. Release the keys then press the key before all the stars dissapear.

5. Press the key repeatedly, until the first hidden parameter group (****SPEEDS) is dis

played.Note that 4 stars (*) as described in section "A" above.

PARAMETER DESCRIPTION DEFAULT RANGE

SPEED GROUP RPM RPM

SOFTSTRT Sets the RPM of the machine while in the soft

start option. 500 140-2000

TIMER GROUP MS MS

START DEL

TRIM TIME

WIPER TIME

Delays machine start to allow presser foot to

drop.

Sets the amount of time that the trimmer is on.

Sets the amount of time that the wiper is on.

80

90

80

10-500

50-250

10-250

COUNTER GROUP STITCHES STITCHES

SOFTSTRT Number of stitches sewn at soft start speed. 31-50

TOGGLE SWITCHES

PF/SEAM

PF/EOC

SOFT STRT

HEEL 2

Presser foot UP or DOWN in the seam, treadle

neutral.

Presser foot UP or DOWN at the end of cycle,

pedal neutral.

Turns the soft start function On or OFF.

Turns the trim function On or OFF.

DOWN

DOWN

OFF

ENABLED

UP/DOWN

UP/DOWN

ON/OFF

ENABLED/

DISABLED

TABLE 3-1

ML970-9

3-3

®

C. MASTER RESET

In some cases it may be necessary to reset all parameters to their default values. This is done as

follows:

1. Turn power off, if it is on, then wait until the display goes blank.

2. Press the key, key and key simultaneously. Keep pressed then,

3. Turn power on. The display alternates between "Push Set" and "For Reset".

4. Push the key within 10 cycles.

5. The word "Programming" is displayed. The parameters will be reset to their default values after

a few seconds.

TABLE 3-2

ML970-10

PARAMETER DESCRIPTION DEFAULT RANGE

****SPEED GROUP RPM RPM

TRIM/POS

MAXIMUM

Sets the

p

ositionin

g

s

p

eed of the achine

Sets the axi u s

p

eed of the achine

220

4200

100-250

500-9900

****MISCELLANEOUS

POS. DOWN

POS. UP

TRIM COUNT

PF DUTY

REVERSE COUNT

Sets the Needle Down

p

osition.*

Sets the Needle U

p

p

osition.*

Sets when the tri er activates.*

Avera

g

e volta

g

e a

pp

lied to the

p

resser foot

solenoid.

Sets the a ount the achine will turn back

if the reverse ode is activated.

130

210

140

5

3

0-255

0-255

0-255

1-10

0-255

****TOGGLE SWITCHES

DIRECTION

TRIM

REVERSE MODE

Sets the otor direction.

++CW = Clockwise

--CCW = Counterclockwise.

2 Position = The achine will not sto

p

when

the tri er is activated.

3 Position = The achine sto

p

s when the

tri er is activated.

Turns the reverse function On or Off.

--CCW

2 POS.

DISABLED

++CW / --CCW

2 POS. / 3 POS.

ENABLED /

DISABLED

* See Section II, Teach-in mode.

®

ML970-11

SECTION IV

TEST MODE

A. BUILT-IN TEST PROGRAM

A test program is available to test the major functions for a proper operation. To access the program

press the and buttons simultaneously.

The display will read "SYSTEM TEST" briefly then press "SET", after which the following may be

tested: TREADLE, INDEX SIGNAL, ENCODER, MOTOR BALANCE

1. Treadle Test

Press the button until "TEST TREADLE" will be displayed briefly then "NEUTRAL".

a. Move the pedal from neutral to heel 1 then to heel 2. The display should show each position.

b. Move the pedal forward slowly. As the pedal is moved, a number (0 to 255) will be dis

played.

Note: This number is proportional to how far the pedal is moved. The lowest number should

be no more than "8" and the highest number greater than "250".

2. Index Signal

Press the button. The display will read "TEST INDEX" briefly then show a broken line

"-------". Rotate the motor by hand until the display shows "----INDEX----" signal. If this signal is

not displayed within one revolution of the handwheel, the encoder has failed.

3. Encoder Test

CAUTION:Separate the coupling. The coupling must be separated because the motor may not

develop sufficient torque to turn the machine.

Press the button. The display will read "TEST ENCODER" briefly then "PUSH START

(enc)".

Press the button, the motor will begin to rotate slowly and the display will read "PLEASE

WAIT".After 2 or 3 seconds the motor will stop and the display shows the number of counts.

The number should be between 240 and 260 pls.

4. Motor Balance Test

Press the button. The display will read "CHECK BALANCE" briefly then "PUSH

START(bal)".

Press the button. The motor will begin to rotate slowly in one direction and then the other,

the display will read "PLEASE WAIT". When the motor stops the display will show a balance

number (0-255). The balance number should be below 10.

Note: If the motor is to far out of balance the display may read "DIRECTION FAILED". This

error message will also occur if the motor is unplugged from the control box when the

balance is being tested.

5-1

®

CONNECTOR DIAGRAMS

Listed below are the pinouts for the Model 970 control box connectors.

SECTION V ML970-12

NO. TOTAL PINS CONNECTOR PIN NO. FUNCTION

1 ------------- NOT USED ----------------- NOT USED

2 6 AUX INPUTS 1

2

3

4

5

6

+5

GND

CHASSIS GND

I 1

I 2

I 3

3 4 AUX OUTPUTS 1

2

3

4

+48 V

R1

+48 V

R2

4 2 FOOTLIFT 1

2FOOTLIFT SOL.

+48V

59TRIM,WIPER,

BACKTACK

SOLENOIDS, AND

MANUAL BACKTACK

SW.

1

4

2

5

3

6

7

8

9

WIPER SOL. -

WIPER SOL. +(48V)

TRIMMER SOL. -

TRIMMER SOL. +(48V)

BACKTACK SOL. -

BACKTACK SOL. +(48V)

+ MANUAL BACK

- TACK SWITCH

NOT USED

5-2

®

ML970-13

NO. TOTAL PINS CONNECTOR PIN NO. FUNCTION

68ENCODER 1

2

3

4

5

6

7

8

+5V

ENCODER (S1)

ENCODER (S2)

SIG. GND

PHASE C

PHASE B

PHASE A

INDEX

7 16 LCD DISPLAY 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

EXT1

CHASSIS GND

+5V

GND

D0

D1

D2

D3

D4

D5

D6

D7

CA1

E

ERD

CA0

8 4 AC POWER 220V 3 1

2

3

4

PHASE A

PHASE B

PHASE C

CHASSIS GND

94MOTORVOLTAGE 1

2

3

4

PHASE A

PHASE B

PHASE C

CHASSIS GND

DRAWINGS AND PARTS LIST

MODEL 970

6-1

®

SECTION VI ML970-14

A. MAJOR ASSEMBLIES

30-4400-01

SWITCH BOX

81-0904-01

CONTROL BOX

81-0871-45

MINI-TAURUS

30-4317-01

LCD DISPLAY

E. PROGRAMMABLE DISPLAY

6-5

®

ML970-17

ITEM DESCRIPTION PART NO. QUANTITY

1

2

3

4

PROGRAMMABLE DISPLAY

BRACKET, MOUNTING

SCREW M4 X 12

SCREW

30-4317-01

30-4286-01

30-4287-01

30-4288-01

1

1

1

2

F. MISCELLANEOUS PART

G. E-PROM

Most of the E-proms used in Clinton's Mini-Taurus are Cmos devices, thus subject to being dam-

aged by electrostatic discharges. Proper grounding practices should be followed when handling and

replacing them. Refer to figure below when replacing the E-prom.

Notes: 1. The notch on the E-prom chip and the other chips on the board all face towards the back

of the board (towards back of chassis).

2. Check to make sure that all of the E-prom chip's legs/pins are properly seated.

Table of contents