Clipper HHD323 User manual

1

OWNERS

MANUAL

Handheld Drill

MODEL:

HHD323

FORM <<HHD323 rev 10/2009

2

WARRANTY

Norton warrants all products manufactured by it against defects in

workmanship or materials for a period of one (1) year from the date of

shipment to the customer.

The responsibility of Norton under this warranty is limited to

replacement or repair of defective parts at Norton's Stephenville,

Texas factory, or at a point designated by it, of such part as shall

appear to us upon inspection at such point, to have been defective in

material or workmanship, with expense for transportation borne by the

customer.

In no event shall Norton be liable for consequential or incidental

damages arising out of the failure of any product to operate properly.

Integral units such as gasoline engines, electric motors,batteries,

tires, transmissions, etc., are excluded from this warranty and are

subject to the prime manufacturer's warranty.

This warranty is in lieu of all other warranties, expressed or implied,

and all such other warranties are hereby disclaimed.

Important: Before placing equipment in operation, record the following

information.

MODEL:_________ SERIAL NO.___________

PURCHASE FROM: _____________________

ADDRESS: ____________________________

CITY_______ STATE ______ ZIP ________

TELEPHONE NO. ______________________

Before using this equipment, make sure that person using it

read and understand the instructions in this owner’s manual.

3

Table Of Contents

CONTENTS PAGE

I. Preparation

A. Safety Precautions 4-6

B. Assembly 7

C. Specifications 7

D. Electrical Supply 8-10

F. Generator 8

G. Grounding Instructions 8

H. Electrical Connections 8-10

II. Operation

A. Core Bit Installation 10-11

B. Water Supply 11

C. Drilling Operation 11-12

D. Hand Held Drilling Technique 12-13

III. Component Description

A. Diagram 14

IV. Parts List Section

A. Ordering Information 15

B. HHD323 Exploded View Parts Drawing 16

C. HHD323 Parts Listing 17-18

Read Owners Manual Before Use

Safety Alert Symbol: Information Following This Symbol Is Very

Important.

4

I. PREPARATION

A. Safety Precautions

Important! The following safety precautions must always be observed.

Hazard Symbols

Fuel (gasoline) is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well-ventilated, unoccupied approved

areas, and away from sparks or flames. Do not fill the

fuel tank while the engine is hot or running. Do not

start the engine near spilled fuel. Never use the fuel as a cleaning

agent.

Engine components can get extremely hot from operation. To

prevent burns, do not touch the engine or related parts while the

engine is running or immediately after it is turned off. Never operate

the engine with any heat shields or guards removed.

Keep all guards in place when operating any piece of equipment

Keep hands, feet, hair, and clothing away from all rotating parts

Lethal Exhaust Gas use only in well ventilated areas. Engine

exhaust gases contain poisonous carbon monoxide, which is

orderless, colorless, and can cause death if inhaled. Avoid inhaling

exhaust fumes, and never run the engine in a closed building or

confined area

Never tamper with the governor components of settings to increase

the maximum speed. Severe personal injury and damage to the

engine or equipment can result if operated at speed above

maximum. Always obey the maximum speed rating of blade.

5

Dust and Silica Warning

Grinding/cutting/drilling of masonry, concrete, metal and other materials can

generate dust, mists and fumes containing chemicals known to cause serious or

fatal injury or illness, such as respiratory disease, cancer, birth defects or other

reproductive harm. If you are unfamiliar with the risks associated with the

particular process and/or material being cut or the composition of the tool being

used, review the material safety data sheet and/or consult your employer, the

material manufacturer/supplier, governmental agencies such as OSHA and

NIOSH and other sources on hazardous materials and make certain to comply

with all product warnings and instructions for the safe and effective use of the

material being cut. California and some other authorities, for instance, have

published lists of substances known to cause cancer, reproductive toxicity, or

other harmful effects.

Control dust, mist and fumes at the source where possible. In this regard use

good work practices and follow the recommendations of the manufacturer/supplier,

OSHA/NIOSH, and occupational and trade associations. Water should be used

for dust suppression when wet cutting is feasible. When the hazards from

inhalation of dust, mists and fumes cannot be eliminated through engineering

controls such as vacuum and/or water mist, the operator and any bystanders

should always wear a respirator approved by NIOSH/MSHA for the material being

cut.

Use Approved:

Eye Protection Hearing

Protection Respiratory

Protection Head Protection

6

1. Know your drilling machine! Read the Owner’s manual carefully. Learn

the operation, application and limitations, as well as the specific potential

hazards peculiar to this equipment.

2. NEVER connect the green [or green & yellow] wire to a live terminal.

3. Use only three-wire grounded extension cords suitable for use outdoors

and of sufficient gage to accommodate power requirements.

4. Replace frayed or damaged extension cords.

5. Keep the work area clean avoiding cluttered work areas.

6. Consider the work area environment!

- Do not expose power tools to rain.

- Wear rubber boots to further insulate yourself from the drill.

- Mop up all excessive water around the work area before and after

drilling.

- Keep the work area well lit.

7. Use extreme caution when drilling through floors. Provide for protection

of all personnel and material below the area. Cores generally drop from

the drill bit at the completion of the hole.

8. Keep visitors away. Do not let visitors contact tool or extension cord. All

visitors should be kept at a safe distance from the work area.

9. Do not force the bit into drilling surface.

10.Dress properly for the work being performed.

- Do not wear loose clothing or jewelry which can get caught in moving or

rotating parts.

11.Don’t abuse the cord. Never carry the tool by the cord or yank the cord to

disconnect the plug from the receptacle.

12.Don’t overreach! Keep proper footing and balance at all times. The

slippery surface created during the drilling operation results in unstable

footing.

13.ALWAYS disconnect the power before servicing or changing accessories

or bits.

14.ALWAYS check, then make sure wrenches are removed from the motor

spindle and bit adapter before connecting power or starting the drill

motor.

15.ALWAYS make sure power switch is in “off” position before connecting

drill to power.

16. Never drill by hand a bit that is over 4” (100 mm) in diameter. Use a drill

stand for bits over 4” (100 mm) in diameter.

You Are Responsible For Your Safety!!!

7

I. PREPARATION

B. Assembly

The HHD323 handheld drill is shipped completely assembled except for core

bit adapters, core bit, and the collar handle. Inspect the drill for shipping

damage. If any damage is found, contact the shipper immediately and file a

freight claim. Saint-Gobain Abrasives, Inc. is not responsible for any freight-

related damages.

Be sure you have the following items:

1. HHD323 handheld drill

2. 27mm Wrench

3. 12” Adjustable wrench

4. 5mm Allen wrench

5. Adapter M18 female to 5/8” male

6. Adapter M18 female to 1-1/4” male

7. Quick Detach Water Hose Adapters

8. Carrying case

Read and understand the remaining sections of this Owner's Manual.

C. Specifications

Dimensions/Weight

Length 18.11" (460 mm)

Width 4.33" (110 mm)

Height 9.84" (250 mm)

Weight 12.1 lbs

Engine

Engine Type Single Phase

Volt 115 v

Amp 12 amp

Demand 1350 w

RPM 0-2200 rpm

Bit Capacity 1” (25 mm) – 3” (76 mm)

8

D. Electrical Supply

The HHD323 handheld drill is furnished with a 115 volt, single phase motor.

This motor operates within a power range of 110 to 120 volts. Serious damage

can result if the supply line voltage does not fall within this range.

The following wire sizes are recommended when using an extension cord:

Wire Gauge (AWG) Length Of Wire

Number 14 25 Feet

Number 12 50 Feet

Number 10 75 Feet

Number 08 100 Feet

For Best performance use 50 feet of 10 gauge extension cord. All extension

cords must be one piece, free of any damage (frays, cracks, breaks, burn

marks, exposed wires, and loose ends).

F. Generator:

If a generator must be used, it must be of 4.1kW (4,100 W) or larger. The

generator must have a 15A circuit or greater and capable of providing a

minimum of 4.1kW at the required voltage. Under size generators will cause

motor damage and is not covered under warranty.

G. Grounding Instructions:

Grounding protects the operator from electric shock. At the time of delivery

of the motor is equipped with an approved three-conductor cord and three-

prong grounding type plug. The green (green/yellow in CEE-Versions)

conductor in the cord is the grounding wire. NOTE: Never connect the green

(green/yellow) ground conductor (wire) to a live terminal. In case of doubt

concerning the ground of the receptacle, call a qualified electrician and have it

checked for proper ground.

zBefore connecting the drill to the power source, make sure that the

voltage and cycles shown on the name plate of the motor are the same

as the available electrical power supplied.

zAlways properly ground the core drill before attempting to start the

motor. The presence of water during the drilling operation requires that

the drill always be properly grounded.

zNEVER connect the green (ground) wire to a live terminal!

H. Electrical Connections:

9

The installation of cables, plugs, and switches must be made ONLY by an

authorized electrician. All installations must be made according to the local

regulations for electrical equipment. All components must meet local

requirements. For additional information see the National Electrical Code

(NEC) for the United States and Canadian Electrical Code for Canada.

The use of a 3-prong adapter is prohibited in Canada by the Canadian

Electrical Code.

Fig. A shows a standard NEMA 5-15 plug (male) and receptacle (female),

which should be used with the HHD323 Hand Held Core Drill. If the electrical

receptacle has two (2) conductors as shown in Fig. B an adapter is available

from a local electrical supplier for connecting the NEMA 5-15 plug to an NEMA

1-15. When using a NEMA 1-15 two prong receptacles the green grounding

ear extending from adapter must be connected to a permanent ground. No

adapter is available for Fig. C plugs as this is a 230v receptacle.

To connect twist lock plugs like those shown in figures D and E, insert the plug

into a matching outlet. When the plug is fully inserted, turn it clockwise until it

locks. This prevents the plug from being pulled out accidentally. To remove

the plug, twist it counterclockwise to unlock it and remove it from the outlet.

Adapters are available from a local electrical suppler to convert a NEMA 5-15

plug to a twist lock.

NOTE: RECEPTACLE MUST BE GROUNDED FOR SAFE USE OF

ADAPTER:

IF IN DOUBT CALL A QUALIFIED ELECTRICIAN AND HAVE THE

RECEPTACLE CHECKED FOR GROUND

10

•For Additional Safety Use A Ground Fault-Interrupter (GFCI ) Device.

•Do Not Use The Drill In Inflammable, Gaseous, Or Explosive Atmosphere

•Do Not Expose The Drill Motor To Rain Or Use In Damp Or Wet Locations

•Do Not Abuse The Cord, Or Carry Or Lift The Motor By The Cord

•Keep The Power Supply Cord Away From Humidity And Water

•Make Sure That The ON/OFF Switch Is In The “OFF” Position Before Plugging

Into A Power Supply

•Unplug The Drill Before Changing A Drill Bit

•Unplug The Power Cord When Attaching The Water Supply, Also Turn The

Water Valve To The “Off” Position Before Attaching

•Do Not Use If Parts Of The Motor Housing Are Missing Or Damaged

•Do Not Use If The Power Cable Or Extension Cable Is Damaged

•Do Not Make Any Attachments, Adjustments, Or Accessory Changes With The

Unit Plugged In

•Always Use The Proper Length/AWG For Extension Cords (See The Section

Titled Electrical Supply)

♦If Water Comes Out Of The Over Flow Bore (Item 3) Stop The Drill Operation

And Replace The Water Ring Seal Immediately

♦DO NOT Use Or Reuse Waste Water. Dirt And Slurry May Damage The Ring

Seals

•Prevent Water From Spraying On Any Part Of The Electrical Motor Or Cables

II. OPERATION

A. Core Bit Installation

Adapters are needed to install specific sized core bits.

1. Using a wrench to firmly hold the output shaft, screw the core bit onto the

spindle until snug.

11

2. Placing one wrench on the machined flats of the output shaft and one

wrench on the end adapter of the core bit tighten the bit on the spindle.

Note: Attempting to turn the bit by the barrel rather than by the adapter nut

may break the weld between the adapter nut plate and the barrel.

When using any Hand Held Drill never hand drill a bit larger than 4” (100 mm)

in diameter. Only use a Drill Stand for drill bits larger than 4” (100 mm) in

diameter.

B. Water Supply:

Always disconnect the power supply before attaching or detaching the

water

system to the Clipper HHD323 Hand Held Drill

1. Attach the Female Quick Coupler to the water supply hose. NOTE: A

pressure tank can only be used for small hole drilling. The pressure tank

should not be lower than 7 PSI (0.5 bar)

2. Place the Water Valve (Tap) in the “Closed” position

3. Attach the Female Quick Coupler to the Male Quick Coupler by pulling back

on the Female Quick Coupler retaining ring and pressing it gently into the

Male Quick Coupler.

4. Turn on the water supply

5. Slowly turn the Water Tap to the “Open” position

To remove the water supply from the Clipper Hand Held Drill:

1. Slowly turn the Water Tap to the “Closed” position

2. Turn “Off” the water supply

3. Detach the Female Quick Coupler from the Male Quick Coupler by pulling

back on the Female Quick Coupler retaining ring and pulling it gently way

from the Male Quick Coupler.

4. If the job is finished for the day see the section Water System Maintenance

C. Drilling Operation:

The performance of any diamond core bit depends heavily on the use of proper

drilling technique. Although drilling conditions and materials may vary,

following specific guide lines insures faster drilling speeds and longer bit life.

1. Make sure there is no movement in the drill that would cause the core bit to

bind in the hole.

2. Insure that the hole is constantly flushed of abrasive fines by supplying a

sufficient flow of water.

12

3. Slowly guide the bit into the hole so that there is no skidding or movement

of the drill. The entire circumference of the core bit should penetrate the

drilling surface before additional pressure is applied to the handle.

4. Exert steady pressure while drilling. NEVER force the bit into the material!

5. Do not stop the flow of water or rotation of the bit while the core bit is

drilling.

6. Check the core bit if the drilling rate decreases noticeably. The slowing

penetration rate generally indicates that the bit is in need of reconditioning.

D. Hand Held Drilling Technique:

Most drill problems occur due to improper starting, drilling method, and the wrong

power supply and/or extension cord length/AWG. To extend the life of the drill the

following Hand Held drilling operation instructions must be followed. Not following

these instructions will damage the tool and void the warranty!!!

Keep The Drill Perpendicular To The Work At All Times.

Do Not Force The Drill

13

1. Start The Drill At 45°To The Work Surface With

The Bit About 1/2” From The Work Surface. The

Drill Must Be Running At Full Speed Before The

Bit Comes In Contact With The Work Piece

2. Slowly Lower The Bit Into The Work Piece Until

The Drill Bit Has Cut About 1/4” In To The Wok

Piece

3. Slowly Bring The Drill Perpendicular To The

Work Piece (Slide Friction Due To Drilling At An

Angle Will Cause The HD Hand Held Drill Unit To

Vibrate And Possibly Shut The Drill Unit Off)

Let The Drill Do All Of The Work DO NOT

FORCE THE DRILL INTO THE WORK

PIECE!!!!

4. Remove The Core From The Hole About Every

2” To 3”

Do Not Stop The Drill Until It Is Out Of The Hole

5. When Restarting The Hand Held Drill Bring The

Drill Up To Full Speed With The Bit About 1/2”

From The Bottom Of The Hole And

Perpendicular With The Hole. Slowly Lower The

Drill Unit It Comes In Contact With The Work

Piece

Repeat Steps 4 and 5 Until The Job Is Completed

14

If Steel Is To Be Drilled Use The Lowest Speed And Reduce Feed Pressure

When drilling by hand use a drill bit that is has a bond that is one (1) class softer

than you would normally use with a Rig Mounted drill.

III. COMPONENT DESCRIPTION

A. Diagram

15

IV. PARTS LIST SECTION

A. Ordering Information

1. List model number and serial number of machine.

2. List part number and serial number of part not the item number.

3. Wherever alternate parts are shown due to product improvement, inspect

the part you have and provide additional description as necessary.

4. Specify mode of shipping desired, such as, parcel post, truck, U.P.S., best

way, etc.

For the nearest Clipper distributor call 1-800-554-8003

NOTE: All parts are sold as individual (each) unless noted otherwise

16

19 20 21

22

23

26

25

24

30

34

33

36

39

40

44

45

47

41

42

43

48

49

27

29

35

31

32

2

1

61

18

17

62

4

5

6

7

8910

11

12

13

14

15

16

54

52

53

50

51

55

56

57

60

51-1

58

59

37

27

38

46

62-1

27

28

16-1

16-1

3

B. HHD323 Explode View Parts Drawing

17

C. HHD323 Parts Listing

Item DESCRIPTION Qty Part No

1 GEAR CASE HHD323 1 244004

2 SPINDLE HHD323 1 244005

3 OIL SEAL 32D 22d DOUBLE LIP SEAL (7SS) 2 244006

4 HANDLE COLLAR HHD323 1 244001

HANDLE AND ATTACHMENT BAR HHD323 1 244000

5 BEARING RADIAL 6003LLU D35 d17 1 244007

6 BEARING RADIAL 6003ZZ D35 d17 1 244008

7 INTERNAL C-CLIP M35 1 244009

8 EXTERNAL C-CLIP M17 1 244010

9 EXTERNAL C-CLIP M9 1 244011

10 PLATE HHD323 2 244012

11 PLATE FRICTION HHD323 2 244013

12 METAL COLLAR HHD323 1 244014

13 GEAR FIRST HHD323 1 244015

14 WASHER CONICAL D28 d12.2 2 244016

15 NUT SLOTTED 1 244017

16 BEARING RADIAL 608ZZ D22 d8 (CM) 1 244018

16-1 BEARING RADIAL 608ZZ D22 d8 (C2) 2 244019

17 PIN M5X15 DOWEL 1 244020

18 DIAPHRAGM HHD323 1 244021

19 BAFFLE HHD323 1 244022

20 O-RING 24x2mm DIN3771 NBR872 207254 1 207254

21 BEARING RADIAL 609ZZ (C3) 1 244023

22 ARMATURE HHD323 1 244024

23 BEARING RADIAL 608ZZ (C3) 1 244025

24 WASHER M15 WAVE 1 244026

25 MAGNETIC FIELD HHD323 1 244027

26 SCR 3/16"-12 X 2-1/2" SELF TAPPING PHILLIPS

HEAD 2 244028

27 WASHER M5 LOCK DIN127B 2 502088

28 WASHER M5 DIN125 FLAT 2 235065

29 PINION BUSHING SECOND HHD323 1 244030

30 KEY 3Xx16mm 1 244031

31 GEAR SECOND HHD323 1 244032

32 MOTOR HOUSING HHD323 1 244033

33 SCR M5 X 10 0.8 DIN916 CUP POINT SET 2 241027

34 BRUSH HOLDER HHD323 2 244034

35 BRUSH (2) HHD323 2 244035

36 BRUSH CAP (2) HHD323 2 244035

37 SCR M5 X 10 0.8 DIN912 SHCS 4 244036

18

C. HHD323 Parts Listing

Item DESCRIPTION Qty Part No

38 WASHER M5 DIN125 FLAT 4 235065

39 ARM BASE TELESCOPIC HHD323 1 244037

40 SCR 5/32”-16 X 5/8" SELF TAPPING PHILLIPS HEAD 4 244038

41 RUBBER COVER HHD323 1 244039

42 ARM TELESCOPIC HHD323 1 244040

43 RUBBER SHOULDER PAD HHD323 1 244041

44 SCR M3.5 X10 SELF TAP PHILLIPS DIN7981 1 244042

45 SPRING SHOULDER STOCK HHD323 1 244043

46 LOCK RELEASE LEVER HHD323 1 244044

47 SCR M6 X 35 1.0 DIN912 SHCS 1 244045

48 NUT M6 1.0 DIN934 HEX 2 300833

49 SCR M6 x 25 1.0 DIN933 HHC 1 300867

50 HAND GRIP HHD323 1 244003

51 SWITCH POWER HHD323 1 244002

51-1 WIRE SWITCH HHD323 1 244046

52 CIRCUIT BREAKER 9A HHD323 1 244047

53 WASHER THERMAL PROTECTOR HHD323 1 244048

54 CABLE CLAMP PLATE THERMAL PROTECTOR

HHD323 1 244049

55 SCR 5/32"-16 X 1/2" SELF TAPPING PHILLIPS HEAD 2 244050

56 SCR 5/32"-16 X 1-1/2" SELF TAPPING PHILLIPS

HEAD 4 244051

57 SCR 5/32"-16 X 3/4" SELF TAPPING PHILLIPS HEAD 2 244052

58 WIRE GROUND HHD323 1 244053

59 WIRE HHD323 1 244054

60 POWER CABLE MAIN HHD323 1 244055

61 PLUG 1 244056

61-1 SCR M5 X 25 0.8 DIN912 SHCS 1 244057

62 WATER HOSE ASSEMBLY HHD323 1 244058

Optional WRENCH 27mm OPEN END 1 244059

Optional WRENCH ADJUSTIBLE 12" 1 244060

Optional WRENCH 5mm HEX KEY (ALLEN) 1 244061

Optional ADAPTER M18 TO 5/8"-11 MALE 1 244062

Optional ADAPTER M18 TO 1-1/4"-7 MALE 1 244063

Optional CASE CARRYING HHD323 1 232176

NOTES:

Saint-Gobain Abrasives

2770 West Washington

Stephenville, TX 76401

Phone: 800-554-8003

Fax: 800-443-1092

Table of contents

Other Clipper Drill manuals

Popular Drill manuals by other brands

Storch

Storch 60 20 10 Translation of the original instruction

Meec tools

Meec tools 011625 operating instructions

Stanley

Stanley STDH8013 instruction manual

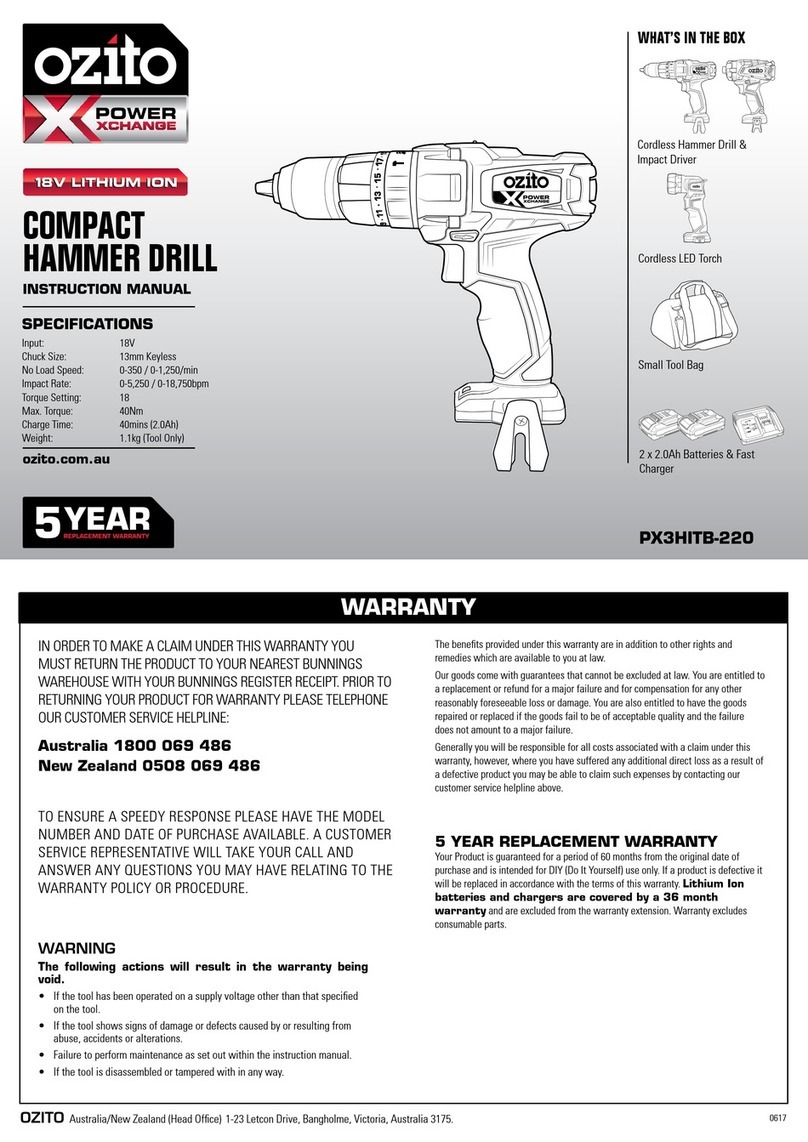

Ozito

Ozito PX3HITB-220 instruction manual

HIKOKI

HIKOKI DS 12DA Handling instructions

Kompernass

Kompernass PTBM 500 PARKSIDE Operation and safety notes