CLIVET HRV-2B-Mi Series User manual

M0H200002-00 - 06/21

HRV

HRV-2B-Mi D200÷D2000

MANUAL

FOR INSTALLATION,

USE AND MAINTENANCE

Directive 2002/96/EC (WEEE):

The symbol depicting a crossed-out waste bin that is underneath the appliance indicates

that this product, at the end of its useful life, must be handled separately from domestic

waste, must be taken to a recycling centre for electric and electronic devices or handed

back to the dealer when purchasing an equivalent appliance

WARNING

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent

or a similarly qualified person in order to avoid a hazard.

An all-pole disconnection device which has at least 3mm separation distance in all pole and

a residual current device(RCD)with the rating of above 10mA shall be incorporated in the

fixed wiring according to the national rule.

Disconnect the power supply before cleaning and maintenance.

The appliance shall be installed in accordance with national wiring regulations.

This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the appliance in a safe way

and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

DISPOSAL: Do not dispose this product as unsorted municipal waste.

Collection of such waste separately for special treatment is necessary.

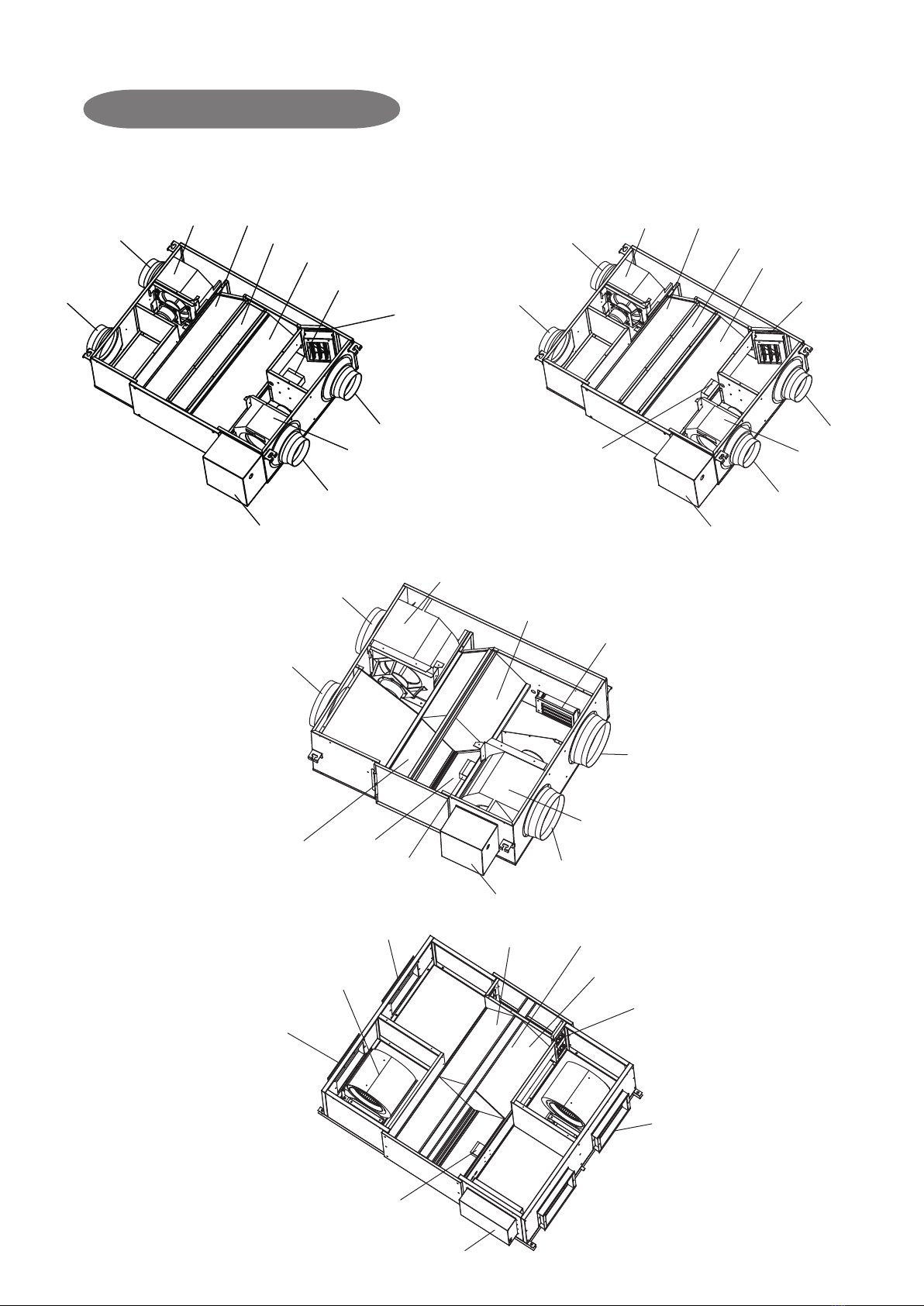

MAIN PARTS OF THE UNIT

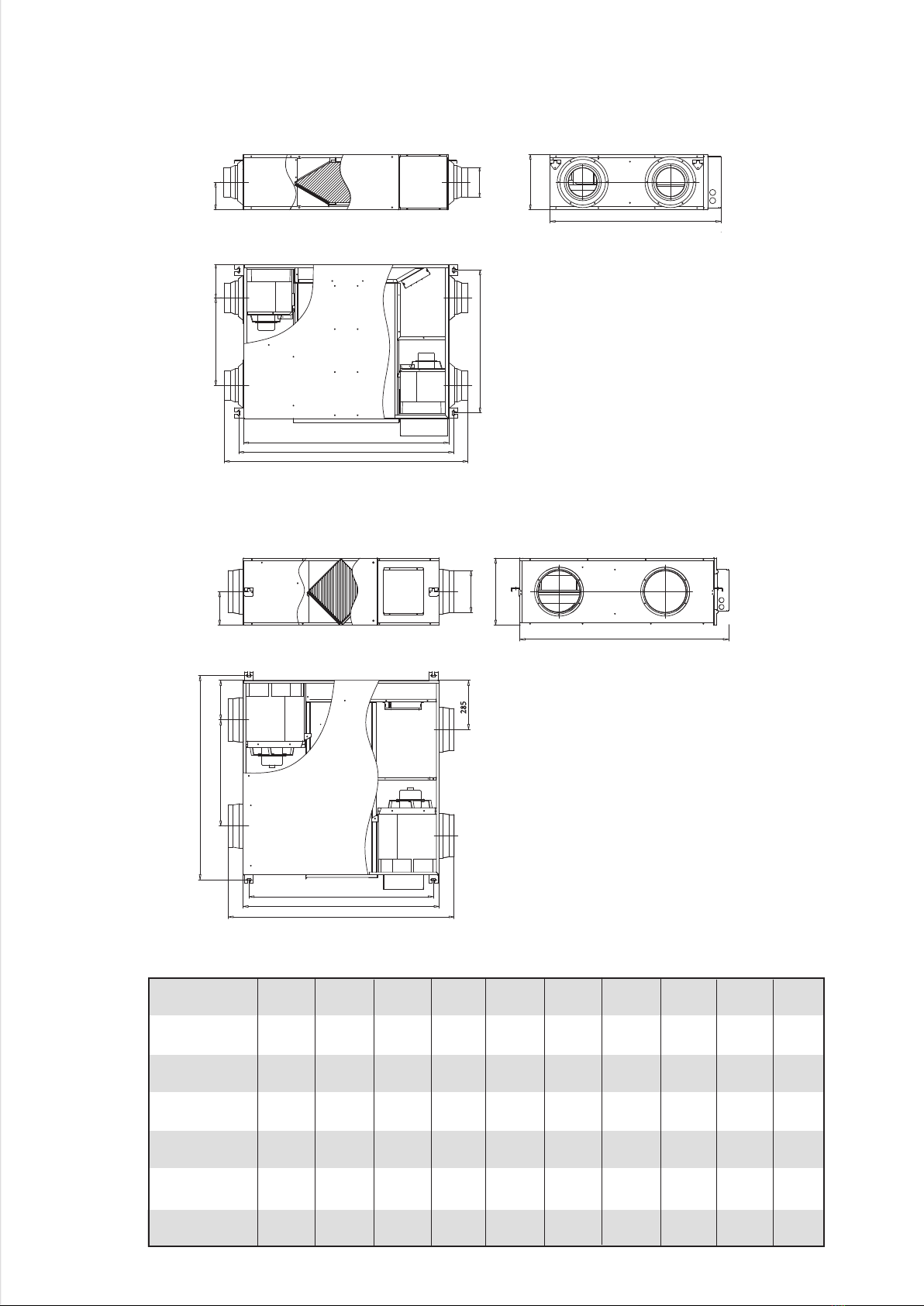

HRV-2B-Mi D200~D300 HRV-2B-Mi D400

HRV-2B-Mi -D500~D1000

HRV-2B-Mi -D1500~D2000

Return air inlet

Supply air outlet

Electric control box

By-pass

CO2 sensor

Fan

Exaust air filter

Heat exchanger core

Fresh Air filter

Fan

Exhaust air outlet

Fresh air inlet

Return air inlet

Supply air outlet

Electric control box

By-pass

CO2 sensor Fan

Exaust Air filter

Heat exchanger core

Fresh Air filter

Fan

Exhaust air outlet

Fresh air inlet

Return air inlet

Fan

Supply air outlet

Electric control box

Fresh air inlet

Exhaust air outlet

CO2 sensor

Exaust Air filter

Heat exchanger core

By-pass

Fan

Fresh Air filter

Exhaust air outlet

Return air inlet

Fan

Supply air outlet

Exaust Air filter

Fresh Air filter

By-pass

Heat exchanger core

Electric control box

CO2 sensor

1. PRECAUTIONS

To prevent injury to the user or other people and property

damage, the following instructions must be followed. Incorrect

operation due to ignoring of instructions may cause harm or

damage. The appliance should be installed by a professional

in accordance with the specified instructions.

CAUTION

WARNING

WARNING

Failure to observe a warning may cause electric shock,

fire hazard or personal injury

CAUTION

CONTENTS PAGE

PRECAUTIONS........................................................................................

ACCESSORY...........................................................................................

INSTALLATION........................................................................................

WIRING...................................................................................................

SPECIFICATION PARAMETER................................................................

HRV APPLICATION................................................................................

MAINTENANCE AND UPKEEP....................................................................

TRAIL RUN.............................................................................................

ERP INFORMATION..............................................................................

1

1

2

6

8

9

9

9

10

The safety precautions listed here are divided into two categories. In

either case, important safety informations are listed which must be

read carefully.

Failure to observe a caution may cause injury or damage

to the equipment.

● Ask your dealer or qualified personnel to carry out

installation work. Do not try to install the machine by.

Incorrect installation may result in leakage, electric shocks

or fire.

● Installation should be done by following the installation

manual and no changes should be made to the unit.

Incorrect installation may cause leakage, electric shock, or

fire. If the HRV falls, it may cause damage and injury.

● Install the unit on a foundation that is strong enough to

withstand the weight of the unit.

A foundation of insufficient strength may result in the

equipment falling and causing injuries.

● Do not allow exhaust air to enter the outside air inlet.

This may cause the air of the room to become contaminated

, harming the health.

● Locate the outside air intake vent so that it does not take in

exhaust air which contains combustion air, etc.

Incorrect installation may cause a loss of oxygen in the

room, leading to serious accidents.

● Make sure that a separate power supply circuit is provided

for this unit and that all electrical work is carried out by

qualified personnel according to local laws and regulations

and this installation manual.

Insufficient power capacity, improper electrical works, or

incorrect wiring may cause electric shock or fire.

● Make sure Earth Leakage Breaker is the type of all poles drop-out.

● Be sure to ground.

Do not connect the ground wire to gas or water pipes, lightning rod

or a telephone ground wire.

Incomplete grounding may result in electric shocks.

● Make sure that all wiring is secured, the specified wires are used,

and no external forces act on the terminal connections or wires.

Improper connections or installation may result in overheating or

fore.

● When wiring the power supply and connecting the remote

controller wiring and transmission wiring, position the wires so that

the electric parts box lid can be securely fastened.

Improper positioning of the electric parts box lid may result in

electric shocks, fire or the terminals overheating.

● Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in

electric shocks.

● Install the indoor and outdoor units, power supply wiring and

connecting wires at least 1 meter away from television or

radio in order to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not

be sufficient enough to eliminate the noise.)

● Install the two outdoor ducts with down slope to prevent

rainwater from entering the unit.

If this is not done completely, water may enter the building,

may damage furniture, etc.

● Insulate the duct and the wall electrically when a metal duct is

to be penetrated through the metal lattice and wire lattice or

metal lining of a wooden structure wall.

Improper duct work may cause electric shocks or short

circuits.

● Make sure that a snow protection measure is taken. If no

protection snow may enter through the outdoor ducts, and

cause damaging furniture and electric shock and fire.

2. ACCESSORY

Name Qty. Shape Purpose

This

manual

must be delivered to the

customer

Installation

and owner’s

manual

1

Name

PVC drain pipe

Damper

Purpose

Table 2-1

For connecting unit’s drain pipe, which length

is selected according to your actual

requirement (Only required for Model 1500

and 2000

For vibration damping, when lift the unit.

Prepare the following on site.

Table 2-2

Notes:Wired controller should be purchased separately.

1

3. INSTALLATION

3.1 Installation Preparation

WARNING

Keep all the accessories and tools until installation work is

completed.

● Leave the unit inside its packaging while moving, until

reaching the installation site. Where unpacking is

unavoidable, use a sling of soft material or protective

plates together with a rope when lifting, to avoid damage

or scratches to the unit.

● Hold the unit by the hanger brackets when opening the

crate and moving it, and do not lift it holding on to any

other part (especially the duct connecting flange).

NOTE

Be sure to instruct customers how to properly operate the unit

(especially maintenance of air filter, and operation procedure)

by having them carry out operations themselves while looking

at the manual.

3.2 Select The Installation Site

CAUTION

When moving the unit during or after unpacking, make sure to

lift it by holding its hanger brackets. Do not exert any pressure

on other parts, especially duct connecting flange.

● Select an installation site where the following conditions

are fulfilled and meet with your customer’s approval.

HRV should be installed far away from office, recreation

or any other places where silent environment are

required. (install that in special machine room or wash

room is recommended)

install in a place which has sufficient strength and

stability. (Beam, ceiling and other locations capable of

fully supporting the weight of the unit.) Insufficient

strength is dangerous. It may also cause vibration and

unusual operating noise.

Do not install the unit directly against a ceiling or wall. (If

the unit is in contact with the ceiling or wall, it can cause

vibration.)

Where sufficient clearance for maintenance and service

can be ensured.

CAUTION

● Install the units, power supply wiring and connecting wires

at least 1 meter away from televisions or radios in order to

prevent interference or noise. (Depending on the

radio waves, a distance of 1 meter may not be sufficient

enough to eliminate the electric interference.)

● The bellows may not be able to be used in some districts,

so exercise caution. contact your local government office

or fire department for details.

● When discharging exhaust air to a common duct, the

Building Standard Law requires the use of fire proof

materials, so attach a 2m copper plate standing duct.

● Do not install the unit in the following locations:

● Place subjected to high temperature or direct flame. May

result in fire or overheating.

● Place such as machinery plant and chemical plate where

gas, which contains noxious gas or corrosive components

of materials such as acid, alkali organic solvent and plaint,

is generated. Place where combus tible gas leakage is

likely.

Copper piping and brazed joins may corrode, causing

refrigerant to leak or poisoning and fore due to leaked gas.

● Place such as bathroom subjected to moisture.

Electric leak or electric shocks and other failure can be

caused.

● Near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of the

control system and result in a malfunction of the

equipment.

3.3 Preparations Before Installation

Confirm the positional relationship between the unit and

suspension bolts.

Leave space for servicing the unit and include

inspection hatches. (Always open a hole on the side of

the electric parts box so that the air filters, heat

exchange elements, fans, be easily be inspected and

serviced.)

Make sure the range of the unit’s external static

pressure is not exceeded.

Open the installation hole (Pre-setting ceilings)

Once the installation hole is opened in the ceiling where

the unit is to be installed, pass transmission wiring, and

remote controller wiring to the unit’s wiring holes.

After opening the ceiling hole, make sure ceiling is level

if needed. It might be necessary to reinforce the ceiling

frame to prevent shaking.

Please consult architect or woodworker, if necessary.

Install the suspension bolts. (Use M10 to M12

suspension bolts.) Use a hole-in anchor, sunken insert

anchor for existing ceilings, or other parts to be

procures in the field to reinforce the ceiling to bearing

the weight of the unit.

Install vibration damping feet. (For vibration damping)

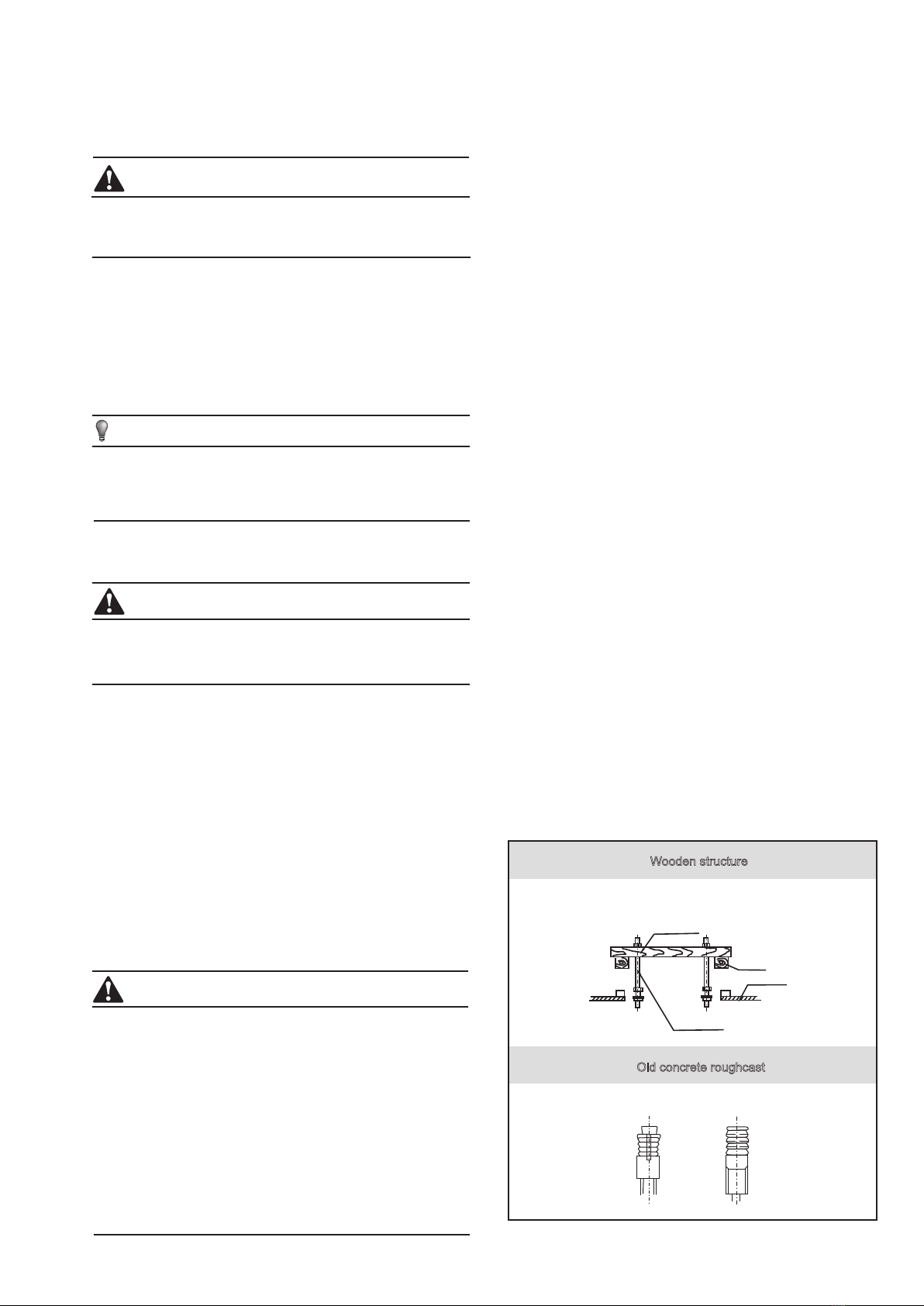

Wooden structure

Put rectangular sticks across the beams, and set pendant bolts.

Wooden span

Beam

Ceiling

Pendant bolt(M10 to M12)

Old concrete roughcast

Use embedded bolts and embedded pulling plugs.

Fig. 3-1

●

●

●

●

●

●

●

●

●

2

Set and use supportive angle steel.

Steel beam and girder structure

Suspended bolt

Pendant bolt Supportive angle steel

Set it with embedded bushes or embedded bolts.

New concrete roughcast

Flap type inser Slide type inser

Concrete iron

Embedded bolt

(With embedded

bolt in pipe)

Fig. 3-2

3.4 Installation

Before installation, please confirm all external parts are

stand in their place and without damage.

The surrounding environment of the unit, especially the

sides of wiring cabinet and water collecting side should

reserve sufficient wiring and maintenance and space;

additionally, one should ensure the removing space for

filter griller.

Unit should mount steadily and without sustain the weight

form condensate water pipe and air duct. The vents of air

inlet/outlet and return should be connected with flexible

tube.

Unit in AC 220-240V/50Hz, reliable grounding; each one

possesses of independent cut-off and protection device.

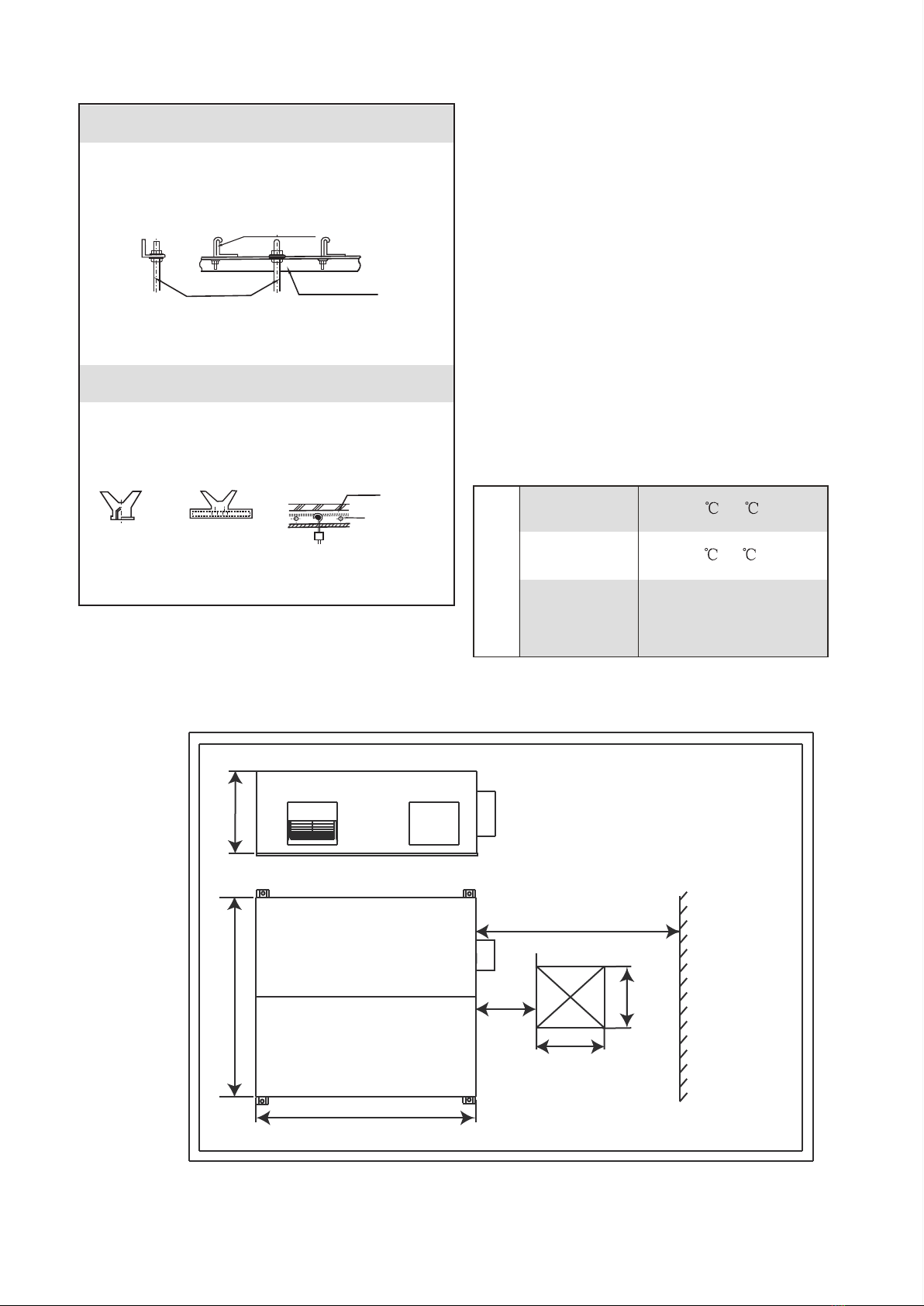

The installation dimension and maintenance space. (See

the following attached picture Fig.3-3 )

Unit:mm

Operating conditions

For proper performance, run the air conditioner under the

following temperature conditions:

Outdoor air TEMP

.

Room TEMP.

Room humidity

-7 ~43

0 ~43

Lower than 80%

If higher than 80%, the surface of

indoor unit may be condensed or

the condensate will be blown from

air outlet.

Protection or error may occur if running the unit beyond the above

condition, and will cause unit stop running.

OPERATION

●

●

●

●

●

●

H

450

054

1000

400

Maintenance space

L

W

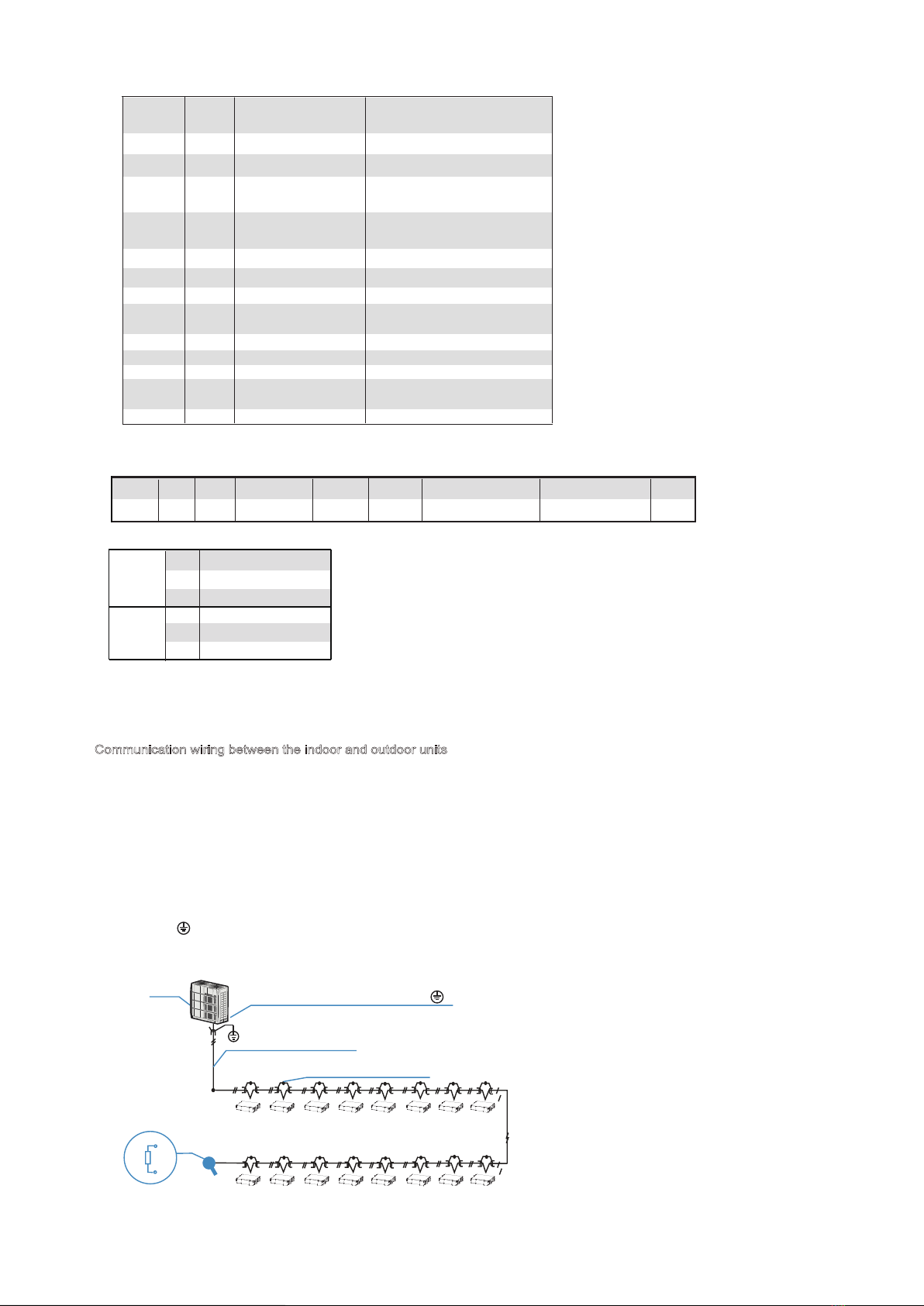

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

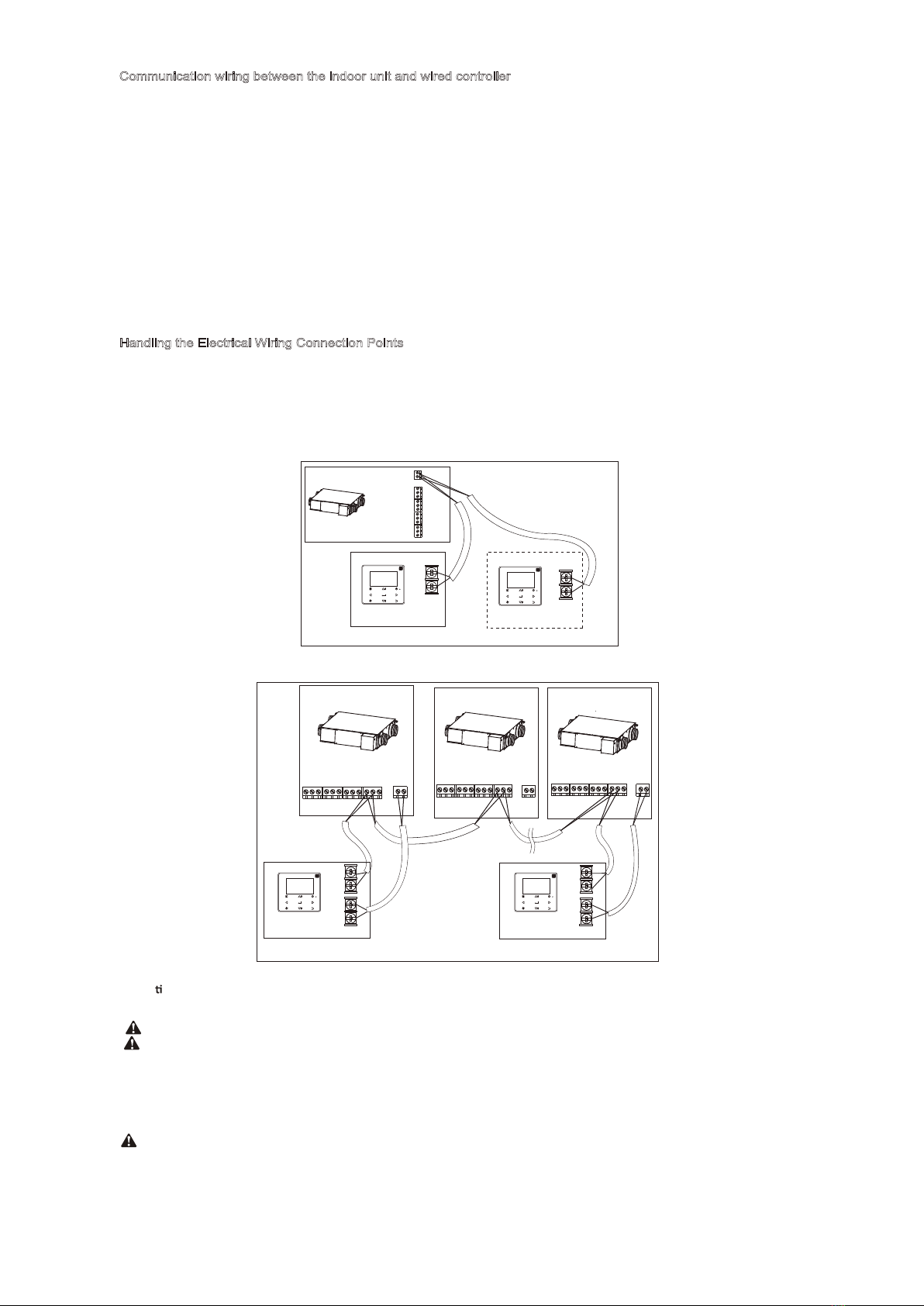

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

multiple indoor units (see Figure 7.8);

3

L L1 L2 W1 W2 W H H1 N

1007

1007

1081

1071

1071

1054

1054

1129

1138

1138

1195

1195

1276

1311

1311

588

701

991

1005

1185

356

431

595

465

616

801

914

1204

1106

1286

272

272

272

390

390

142

163

202

227

229

Φ144

Φ144

Φ198

Φ244

Φ244

N1

136

136

136

195

195

Fig. 3-4

Fig. 3-5

Table 3-1

Key dimensions of the unit and air duct installation. (See the following pictures Fig.3-4~3-7 & Table 3-1 )

Door

Electric

control

box

By-pass

system

Exhaust air outlet

Fresh air inlet

Return air inlet

Supply air outlet

Lifting lug

N

N1

H

W

W1

L

L1

L2

W2

H1

L1

L

L2

N1

N

W

Door

Electric

control

box

Return air inlet

Supply air outlet

Exhaust air outlet

Fresh air inlet

H1

W2

W1

H

195

Φ244230

390

1526

7641431

1138 1311

1071

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

By-pass

system

(Unit:mm)

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

Model

4

HRV-2B-Mi D200~D400

HRV-2B-Mi -D500~D1000

HRV-2B-Mi -D200

HRV-2B-Mi -D300

HRV-2B-Mi -D400

HRV-2B-Mi -D500

HRV-2B-Mi -D800

HRV-2B-Mi -D1000

Fig. 3-6

Fig. 3-7

615

252

320

320

300

300

60

1425

650

1690

1740

1300

1270

Door

Electric

control

box

Supply air outlet

Exhaust air

outlet

Return air inlet

Fresh air

inlet 120

320

346

370

350

326

300

Flange dimension

320

300

320

750

1625

60

685

252

300

1470

1500

1761

1811

120

320

346

370

350

326

300

Flange dimension

Supply air outlet

Exhaust air

outlet

Fresh air inlet

Door

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

Electric

control

box

Return air inlet

By-pass

system

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

5

HRV-2B-Mi -D1500

HRV-2B-Mi -D2000

4. WIRING

220-240V/50Hz

see 10. Electrical

Characteristics table

2.5

4.1 Electric data Specification

Table 4-1

Power supply

Phase

Voltage

/frequency

Input current

Main switch

/fuse(A)

Power supply

wireDimension

Wire’s qty

Wire

cross

-section

(mm

2

)

3 (Earthing line

should be used

yellow/green wire.)

Single phase

All the supplied parts, materials and electrical works must

comply with local regulations.

Only use copper wires.

Use a steady power supply for the air-conditioners. The

power voltage must be in line with the rated voltage.

The electrical wiring works must be carried out by a

professional technician, and must comply with the labels stated

in the circuit diagram.

Before the electrical connection works are carried out, turn

off the power supply to prevent injuries caused by electric

shock.

The external power supply circuit of the air conditioner must

include an earth line, and the earth line of the power cord

connecting to the indoor unit must be securely connected to

the earth line of the external power supply.

Leakage protective devices must be configured according to the

local technical standards and requirements for electrical and

electronic devices.

The fixed wiring connected must be equipped with an all-pole

disconnection device with a minimum 3 mm contact

separation.

The distance between the power cord and signal line must be

at least 300 mm to prevent the occurrences of electrical

interference, malfunction or damage to electrical

components. At the same time, these line must not be in

contact with the piping and valves.

Choose electrical wiring that conforms to the corresponding

electrical requirements.

Connect to the power supply only after all the wiring and

connections have been completed, and check carefully if the

connection is correct.

Warning

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

POWER INPUT

L

N

figure of the power supply terminal

+Power

cord

Insulation tube

Circular wiring

terminal

: Copper wire

Proper power wiring connections

When connecting to the power supply terminal, use the circular wiring

terminal with insulation.

Use power cord that conforms to the specifications and connect the

power cord firmly. To prevent the cord from being pulled out by

external force, make sure it is fixed securely.

If circular wiring terminal with insulation cannot be used, please make

sure that:

• Do not connect two power cords with different diameters to the

same power supply terminal (may cause overheating).

Fig. 4-1

Fig. 4-2 Fig. 4-3

ENC1 Settings for Capacity SW1 Setting for static pressure

• Positive Pressure: In the positive pressure mode, the supply fan

operating fan speed is higher than the exhaust fan.

• Negative Pressure: In the negative pressure mode, the exhaust fan

operating fan speed is higher than the supply fan.

• Balance Pressure: In the balance pressure mode, the supply fan

operating wind gear is equal to the exhaust fan.

Caution

Table 4-2

5

3

2

1

4

ENC1 Capacity sett ing

0

6

7

200

300

400

500

800

1000

1500

2000

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

SW1-1

SW1-2

SW2-1

SW2-2

SW2-3

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

OFF

HRV centralized control

HRV single unit operation

With PRO (reserved)

Without PRO (reserved)

Positive Pressure

Negative Pressure

SW2-2

Balance Pressure

1 2

ON

1 2

ON

3

1 2

ON

3

1 2

ON

3

1 3

ON

2

1 2

ON

3

1 2

ON

3

1 2

ON

1 2

ON

1 2

ON

Low static pressure

High static pressure

● After wiring, please confirm all connections are correct,

and then power to the unit.

● Pay attention to the power supply wire of three-phase

model; confirm the phase sequence of which is correct.

6

HRV-2B-Mi -D200~ D2000

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

Terminal Definition

Table 4-4

Code and Definitions

Table 4-3

Show on

centralized controller

Unit is ON

Unit is OFF

Operation

lamp

Indoor temperature

sensor error

Outdoor temperature

sensor error

EEPROM error

DC fan motor error

Explanation

○

●

★

★

★

★

★

★

/ /

//

E2

4

E5(new protocol)

EF(old protocol)

6 E7

8 E6

10 OFF LINE Without address

Communication error

with ODU

12 E1

NOTE:

●:Light ; ○:Extinguish ; ★:Quick flash

Flashing

times

★

★

★

14

16

18

E9

EU

FC

error with sensor board

error with CO2 sensor

wire controller

communication failure

Ip address Conflict

Ed Outdoor unit failure

reserved

Dry contact

(Out put)

Dry contact

(In put)

CN31

CN16

CN26

CN14

CN15

CN20

Remote ON/OFF

Force to exhaust air mode

Signal for inlet air Pre-heat

Alarm

Reserved

CODE

NAME Outdoor temp. SensorP Q E X Y E X1X2

CN8 CN9 CN32 CN33

- D1D2E

CN7 CN3 CN4

Indoor temp. Sensor

CN21

-

(P Q E)

(P Q E)

Only the last indoor unit requires adding

the build-out resistor at P and Q.

(open)

Indoor and

outdoor units

Communication wire

Connecting the shielded

layer of the shielded wire

(Connect the shielded end of the shielded wire to the

electronic controller box sheet metal " " here)

Signalling line

between outdoor units

Outdoor

unit

P

Q

Build-out

resistor

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

7

Max voltage: 220 VAC (consistent with power

supply) / Max current: 1A

CN16 Force expulsion air mode - closed contact: function active (this input has a

higher priority than the setting given by dip-switch SW2-2 / 3);

CN26 Remote On / Off - closed contact: unit forced off / open contact: normal

management;

CN15 Alarm - contact closed: alarm active / contact open: no alarm

CN20 Signal for inlet air preheating - contact closed: function active / contact open:

function not active

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

X1 X2

X1 X2

X1 X2

Master wired controller Slave wired controller

Indoor unit 1

Wired controller 2

Wired controller 1

Fig. 4-5

Master wired controller Slave wired controller

Wired controller 2

X2 X1 D2 D1

Wired controller 1

X2 X1 D2 D1

Indoor unit 1 Indoor unit 2 Indoor unit n(n<=16)

●

●

●

●

●

●

●

Fig. 4-4

Do not use this unit in locations where flammable gas may exist. If

flammable gas comes into contact with the unit, a fire may occur,

which could result in serious injury or death.

Opera o Manual

There are two types of precautions as described below:

Warning: Failure to comply may lead to death or serious injury.

Caution: Failure to comply may lead to injury or damage of the

unit. Depending on the situation, this may also lead to serious injury.

Once the installation is completed, please keep the manual properly

for future reference. When this air conditioner is handed over to other

users, make sure that the manual is included with the handover.

Warning

•

•

If this unit exhibits any abnormal behavior (such as emitting

smoke) there is a danger of serious injury. Disconnect the power

supply and contact your supplier or service engineer immediately.

• The refrigerant in this unit is safe and should not leak if the system

is designed and installed properly. However, if a large amount of

refrigerant leaks into a room, the oxygen concentration will

decrease rapidly, which can cause serious injury or death. The

refrigerant used in this unit is heavier than air, so the danger is

greater in basements or other underground spaces. In the event of

a refrigerant leak, turn off any devices that produce a naked flame

and any heating devices, ventilate the room, and contact your

supplier or service engineer immediately.

• Toxic fumes may be produced if the refrigerant in this unit comes

into contact with naked flames (such as from a heater, gas

stove/burners, or electric appliances).

X1 X2 X1 X2 X1 X2

XD1

TXR

PQX

ED2

EY EE D1

T

T

XX

XR

PQX

ED2

EY EE

D1

X

XR

PQX

ED2

EY EE

D1

TXR

PQX

ED2

EY EE

8

3. groups must consist of HRV-2B units only. Groups composed of mixed units of different types are not allowed

(eg 2nd gen. IDUs + HRV-2B).

1. Never turn screws too tightly, or else the cover would be dented or the Liquid Crystal breaks.

2. Please leave sufficient space for maintenance and service of wired controller.

CAUTION

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

3. Wired controller should be purchased separately.

4. Please follow the installation and owner’s manual of wired controller.

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

• If this unit is used in the same room as a cooker, stove, hob, or

burner, ventilation for sufficient fresh air must be ensured,

otherwise the oxygen concentration will fall, which may cause

injury.

• Dispose of this unit’s packaging carefully, so children cann’t play

with it. Packaging, especially plastic packaging, can be

dangerous, can cause serious injury or death. Screws, staples

and other metal packaging components can be sharp and should

be disposed of carefully to avoid injury.

• Dispose of this unit’s packaging carefully, so children cann’t play

with it. Packaging, especially plastic packaging, can be

dangerous, can cause serious injury or death. Screws, staples

and other metal packaging components can be sharp and should

be disposed of carefully to avoid injury.

• Do not attempt to inspect or repair this unit yourself. This unit

should only be serviced and maintained by a professional air

conditioning service engineer. Incorrect servicing or maintenance

can cause electric shocks, fire or water leaks.

• This unit should only be re-positioned or re-installed by a

professional technician. Incorrect installation can lead to electric

shocks, fire or water leaks. The installation and grounding of

electrical appliances should only be carried out by licensed

professionals. Ask your supplier or installation engineer for further

information.

• Do not allow this unit or its remote controller to come into contact

with water, as this can lead to electric shocks or fire.

• Turn off the unit before cleaning it to avoid electric shocks.

Otherwise, an electric shock and injury may result.

• To avoid electric shocks and fires, install an earth leakage

detector.

• Do not use paint, varnish, hair spray, other flammable sprays or

other liquids that may give off flammable fumes/vapor near this

unit, as doing so can cause fires.

• When replacing a fuse, ensure that the new fuse to be installed

completely complies with requirements.

• Do not open or remove the unit's panel when the unit is powered

on. Touching the unit's internal components while the unit is

powered on can lead to electric shocks or injuries caused by

moving parts such as the unit's fan.

• Ensure that the power supply is disconnected before any servicing

or maintenance is carried out.

• Do not touch the unit or its remote controller with wet hands, as

doing so can lead to electric shocks.

• Do not allow children to play near this unit, as doing so risks injury.

• Do not insert your fingers or other objects into the unit’s air inlet or

air outlet to avoid injury or damage to the equipment.

• Do not spray any liquids onto the unit or allow any liquids to drip

onto the unit.

• Do not place vases or other liquid containers on the unit or in

places where liquid could drip onto it. Water or other liquids that

come into contact with the unit can lead to electric shocks or fires.

• Do not remove the remote controller’s front or back overs and do

not touch the remote controller’s internal components, as doing so

can cause injury. If the remote controller stops working, contact

your supplier or service engineer.

• Ensure that the unit is properly grounded, otherwise electric

shocks or a fire may result. Electrical surges (such as those that

can be caused by lightning) can damage electrical equipment.

Ensure that suitable surge protectors and circuit breakers are

properly installed, otherwise electric shocks or a fire may result.

• Dispose of this unit properly and in accordance with regulations. If

electrical appliances are disposed of in landfills or dumps,

hazardous substances can leak into the groundwater and thus

enter the food chain.

• Do not use the unit until the qualified technician instructs you that

it is safe to do so.

• Do not place appliances that produce naked flames in the path of

the airflow from the unit. The airflow from the unit may increase the

rate of combustion, which may cause a fire and cause serious

injury or death. Alternatively, the airflow may cause incomplete

combustion which can lead to reduced oxygen concentration in

the room, which can cause serious injury or death.

Caution

• Only use the air conditioner for its intended purpose. This unit

should not be used to provide refrigeration or cooling for food,

plants, animals, machinery, equipment or art.

• Do not insert your fingers or other objects into the unit’s air inlet or

air outlet to avoid injury or damage to the equipment.

• The fins on the unit’s heat exchanger are sharp and can cause

injury if touched. To prevent injury, when the unit is being serviced,

gloves should be worn or the heat exchanger should be covered.

• Do not place items which might be damaged by moisture under

the unit. When the humidity is greater than 80% or if the drain pipe

is blocked or the air filter is dirty, water could drip from the unit and

damage objects placed under the unit.

• Ensure that the drain pipe functions properly. If the drain pipe is

blocked by dirt or dust, water leaks may occur when the unit is

running in cooling mode. If this happens, turn the unit off and

contact your supplier or service engineer.

• Do not touch the internal parts of the controller. Do not remove the

front panel. Some internal parts may cause injury or be damaged.

• Ensure that children, plants and animals are not directly exposed

to the airflow from the unit.

• When fumigating a room with insecticide or other chemicals, cover

the unit well and do not run it. Failure to observe this caution could

lead to chemicals getting deposited inside the unit and later

emitted from the unit when it running, endangering the health of

any room occupants.

• Do not dispose of this product as unsorted waste. It must be

separately collected and processed. Ensure that all applicable

legislation regarding the disposal of refrigerant, oil and other

materials is adhered to. Contact your local waste disposal authorty

for information about disposal procedures.

• To avoid damaging the remote controller, exercise caution when

using it and replacing its batteries. Do not place objects on top of it.

• Do not place appliances that have naked flames under or near

the unit, as heat from the appliance can damage the unit.

• Do not place the unit’s remote controller in direct sunlight. Direct

sunlight can damage the remote controller’s display.

• Do not use strong chemical cleaners to clean the unit, as doing so

can damage the unit’s display or other surfaces. If the unit is dirty

or dusty, use a slightly damp cloth with very diluted and mild

detergent to wipe the unit. Then, dry it with a dry cloth.

• Children shall not play with the appliance.

9

220-240V~

50Hz

1275×880×420

1275×994×420

1360×1284×420

1390×1244×540

1390×1424×540

1390×1670×540

1830×1520×770

1900×1720×845

53.6

59

71.5

74.4

80

90

181.5

208.5

100

90

100

140

160

180

200

200

300

400

500

800

1000

1500

2000

81.1

75.5

77.7

80.6

78.7

82.8

75.5

77.2

77.5

72.1

73.5

74.0

72.3

76.0

69.4

74.7

45

48

48

50

55

54

69

70

0.07

0.10

0.32

0.38

0.68

0.95

0.15

0.64

0.84

0.97

2.4

2.9

3.8

5.7

1.2

Φ144

Φ144

Φ198

Φ244

Φ244

Φ244

346×326

346×326

5.1 Specification Parameter

90

0.11

5. SPECIFICATION PARAMETER

Table 5-1

Table 5-2

Model Power

supply

Packing

size(mm)

Air outlet

dimension

(mm)

Net

weight (kg)

Static

pressure

(Pa)

Nominal air flow

(m3/h)

Model Power input(kW)

Current(A)

Nominal temp.

efficiency

Nominal enthalpy

efficiency

10

Notes:

There are 3 steps of fan speed (High, Medium, Low), all the parameters

in the above table is measured at the high speed.

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

Sound power

level(dB)

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

10

HRV-2B-Mi -D200

HRV-2B-Mi -D300

HRV-2B-Mi -D400

HRV-2B-Mi -D500

HRV-2B-Mi -D800

HRV-2B-Mi -D1000

HRV-2B-Mi -D1500

HRV-2B-Mi -D2000

HRV-2B-Mi -D200

HRV-2B-Mi -D300

HRV-2B-Mi -D400

HRV-2B-Mi -D500

HRV-2B-Mi -D800

HRV-2B-Mi -D1000

HRV-2B-Mi -D1500

HRV-2B-Mi -D2000

6. HRV APPLICATION

6.1 Operation principle

HRV (Heat Recovery Ventilation) employ advanced

technique and technics, the heat exchanged core forming

by special paper that be processed with chemical

treatment, which could create the optimum result in

temperature, humidity and cooling recovery.

High efficiency heat exchanged core: When air flow formed

by exhaust air and outdoor air through the heat exchanged

core in cross way, because of temperature difference in

the two sides of flat partition board, the heat transmission

is occurred. In summer, outdoor air acquire cooling from air

exhaust to decrease environment temperature; In winter,

outdoor air acquire heat from air exhaust to increase

temperature, that is to say, it realizing the energy recovery

during air exhaust process to exchange the heat in heat

exchanged core to outdoor air.

6.2 Pay Attention To The Following Items Before

Operation

6.2.1. Before start-up, please clean up the duct and check

whether all air valves and devices are normal.

6.2.2. Carefully adjust the system air valves when start-up,

control the current of motor in rated range.

6.2.3. Three-phase model without by-pass function, therefore

the fan would delay 30 seconds to start up.

6.2.4. Connect the wired controller

Wired controller should be installed according to wired

controller owner’s manual, installation manual (Attached

in the package box in wire controller).

7 MAINTENANCE AND UPKEEP

7.1 During early use, one should check the fan operation

regularly.

7.2 The cleaning regulation for air filter depend on local

environment. It could be clean by vacuum dirt exhauster

or water, if heavy dust accumulates, it should use neutral

detergent to clean it, and then dry it in shady and cool

place for 20 to 30 minutes and replace it.

7.3 Clean the core at least 2 years a time by vacuum dirt

exhauster to remove dust and foreign substance in the

unit assemblies, do not touch the assemblies by

exhauster and flush by water to avoid core damage.

7.4 Check the fan every half a year to maintain the well

balance of it and check whether the axletree has loosed.

8. TRIAL RUN

8.1 Please Confirm The Following Points

Before Trial Run:

8.1.1 The unit is installed correctly completed.

8.1.2 Ducting and wiring are correctly completed.

8.1.3 The drainage is smooth.

8.1.4 The heating insulation works well.

8.1.5 The ground wiring is connected correctly.

8.1.6 The power voltage fits the rated voltage of HRV.

8.1.7There is no obstacle at the outlet and inlet of HRV.

8.2 Control The HRV By Wired controller,

Operate It According To Wired controller

Owner’s Manual.

8.2.1 Whether the switch on the remote controller works well.

8.2.2 Whether the room temperature is adjusted well.

8.2.3 Whether the indicator lights normally.

8.2.4 Whether there is vibration or abnormal noise during

operation.

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

11

9.Wiring Diagrams

LN

T1 T4

L

N

N-1

N-2

DC_FAN A

EXHUAST FAN

DC_FAN B

SUPPLY FAN

CN24 CN27

RA

E N C 1

5

3

2

1

4

ENC1

Capacity

setting

0

6

7

200

300

400

500

800

1000

1500

2000

SW1-1

CODE

NAME Outdoor temp.Sensor

POWER IN

220Vac 50Hz

Red

+

-~

~

BR1

Black

CN13

CN13

CN3

CN3

DC_FAN

DC_FAN

Module A

Module B

FM

FM

DC_FAN A

EXHUAST FAN

DC_FAN B

SUPPLY FAN

Bypass

damper

motor

CN19

Black

Red

Y/G

Blue

Xt1

27BWired

controller

+

~-

~

BR2

MOV 681

Blue

Brown

White

Red

Red RB

RC

Red

R1230

R1510

PGND

AC_2

AC_1

P

Black

Red

Blue

Blue

CN8

PQ E

Show on

Tim

e

entralized controller

Unit is ON

Unit is OFF

Indoor temperature

sensor error

Outdoor temperature

sensor error

EEPROM error

DC fan motor error

Explanation

○

●

★

★

★

★

★

★

/ /

//

2 2

E2

4 E5(new protocol)

EF(old protocol)

6 6

E7

8 8

E6

10 10

OFF LINE

Without address

ommunication error

12

12

h ODU

E1

NOTE:

●

:Light ;

○

:Extinguish ;

★

:Quick flash

Operation

Flash

lam p

XY E

CO2 Sensor

CN9 CN32 CN33 CN7 CN31 CN16

X1X2

CN26 CN21

PRO

S

W1

S

W2

CN14 CN15 CN20

CN10

CN34

SW1-2

SW2-1

SW2-2

SW2-3

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

OFF

★

★

★

14

16

18

E9

EU

FC

error with sensor board

error with CO2 sensor

wire controller

communication failure

CN8 CN9 CN32 CN33

-D1D2E

CN7 CN3 CN4

Indoortemp. Sensor

CN21

-

HRV centralized control

HRV single unit operation

With PRO

Without PRO

Positive Pressure

Negative Pressure

SW2-2

Balance Pressure

Ip address Conflict

Ed Outdoor unit failure

1 2

ON

1 2

ON

3

1 2

ON

3

1 2

ON

3

1 3

ON

2

1 2

ON

3

1 2

ON

3

1 2

ON

1 2

ON

1 2

ON

Low static pressure

Hige static pressure

1 2

ON

3

1 2

ON

12

* Reserved

1-2 1-3

reserved

Dry contact

(Out put)

Dry contact

(In put)

CN31

CN16

CN26

CN14

CN15

CN20

Remote ON/OFF

Force to exhaust air mode

Signal for inlet air Pre-heat

Alarm

Reserved

Max voltage: 220 VAC (consistent with power

supply) / Max current: 1A

CN16 Force expulsion air mode - closed contact: function active (this input has a

higher priority than the setting given by dip-switch SW2-2 / 3);

CN26 Remote On / Off - closed contact: unit forced off / open contact: normal

management;

CN15 Alarm - contact closed: alarm active / contact open: no alarm

CN20 Signal for inlet air preheating - contact closed: function active / contact open:

function not active

12.1

10.Electrical Characteristics

Model Indoor Unit Power Supply

Hz Voltage Min. Max. MCA MFA

50 220-240 220 240 1.3A 10A

50 220-240 220 240 1.7A 10A

50 220-240 220 240 2.0A 10A

50 220-240 220 240 2.5A 16A

50 220-240 220 240 5.0A 16A

50 220-240 220 240 6.0A 16A

50 220-240 220 240 8.0A 30A

50 220-240 220 240 10.0A 30A

Notes:

MCA: Max.Circuit Amps. (A)

MFA: Max. Fuse Amps. (A)

FLA = Full Load Amps. (A)

HRV-2B-Mi -D200

HRV-2B-Mi -D300

HRV-2B-Mi -D400

HRV-2B-Mi -D500

HRV-2B-Mi -D800

HRV-2B-Mi -D1000

HRV-2B-Mi -D1500

HRV-2B-Mi -D2000

FLA

1.4A

1.36A

1.6A

2A

4A

4.8A

6.4A

8A

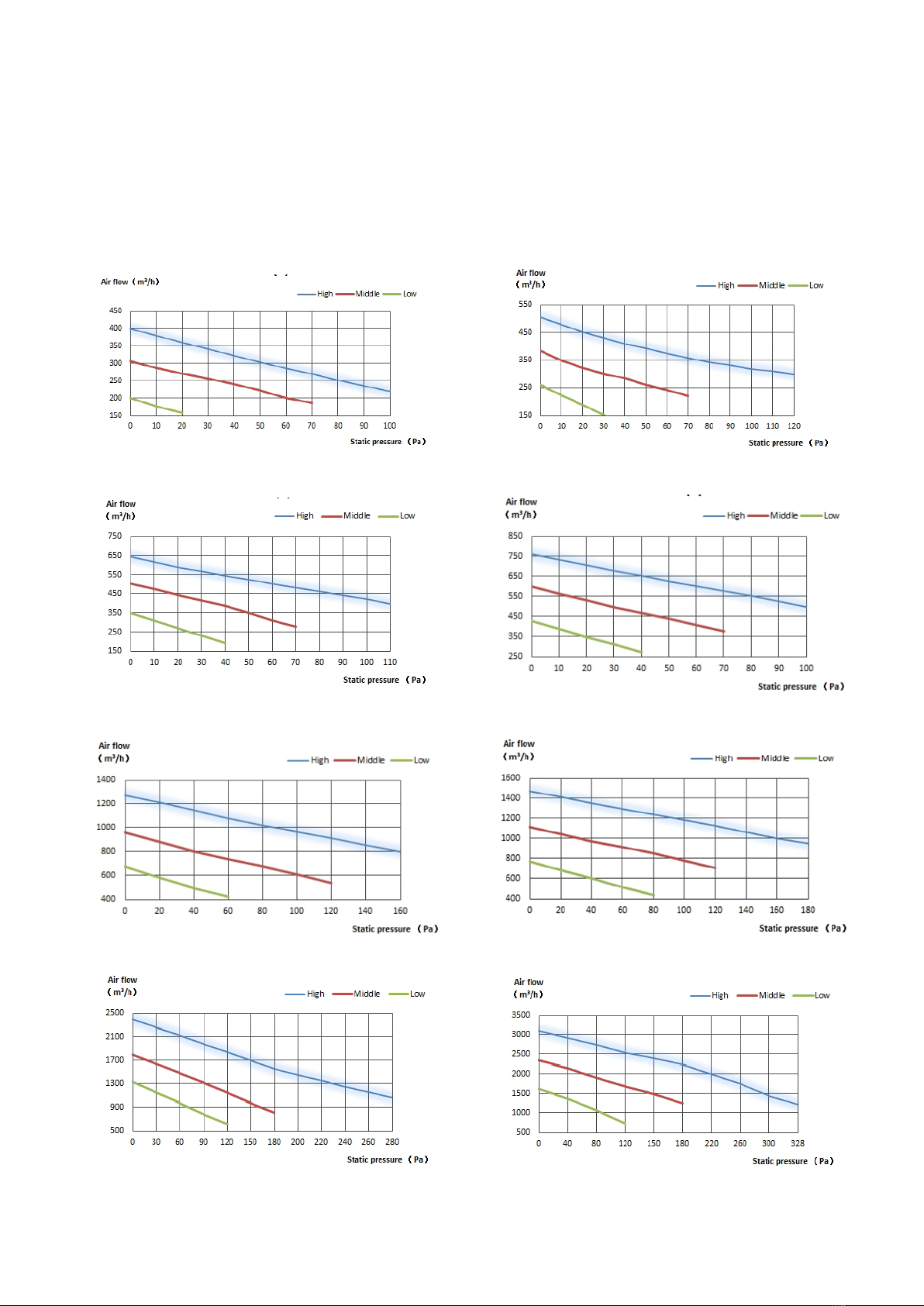

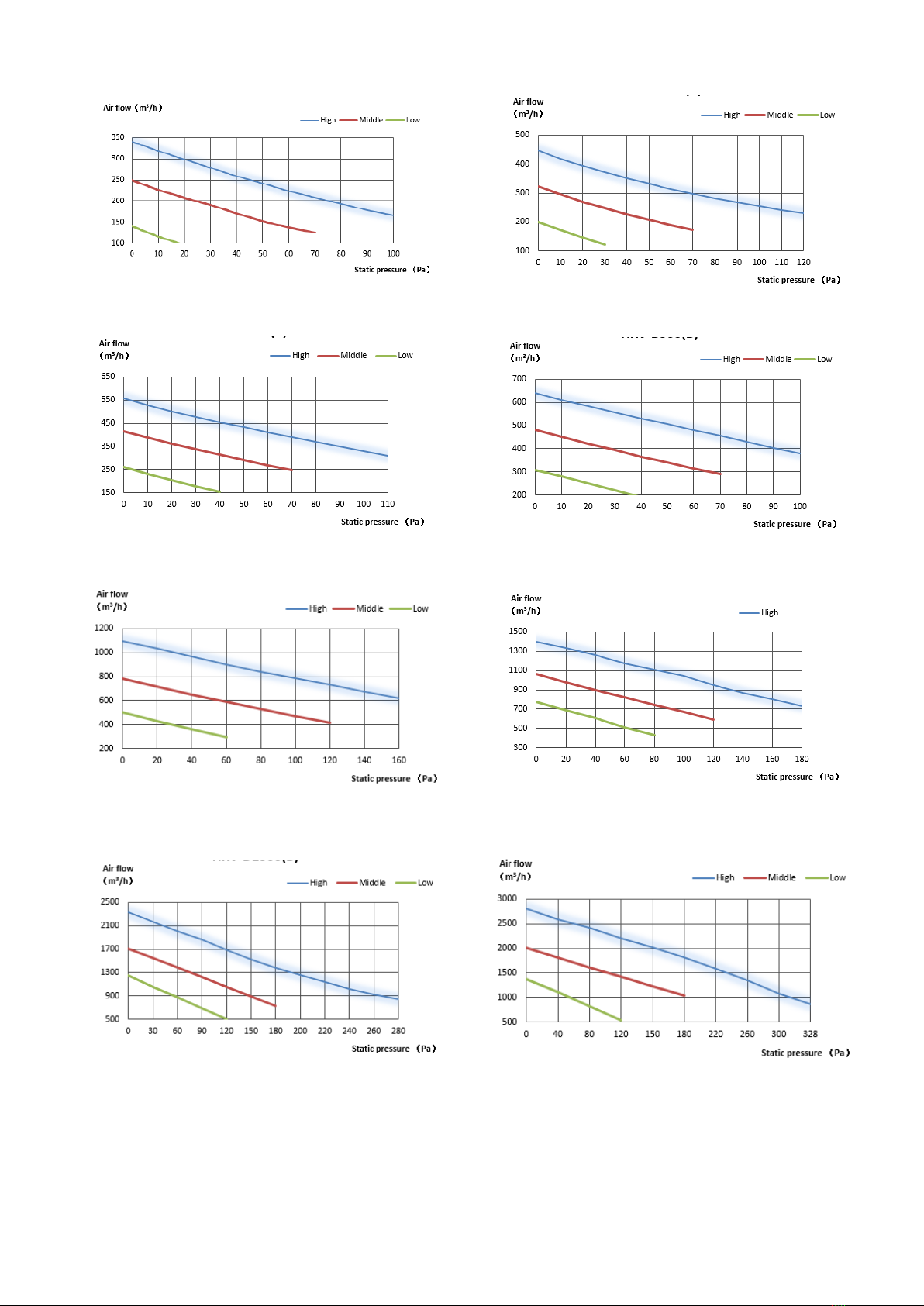

11 Fan Performance

11.1 How toRead the Diagram

The horizontal axis is the Static Pressure (Pa) while the vertical axis represents the Air Flow (m3/h). The characteristic curve

for the “H” “M” and “L” fan speed control.

11.2 Fan Performance Diagram

Notes: All the above fan performance diagrams are obtained under the condition of G4 filter.

13

HRV-2B-Mi -D200 HRV-2B-Mi -D300

HRV-2B-Mi -D400 HRV-2B-Mi -D500

HRV-2B-Mi -D800 HRV-2B-Mi -D1000

HRV-2B-Mi -D1500 HRV-2B-Mi -D2000

Notes: All the above fan performance diagrams are obtained under the condition ofF7 filter.

HRV-2B-Mi -D200 HRV-2B-Mi -D300

HRV-2B-Mi -D400 HRV-2B-Mi -D500

HRV-2B-Mi -D800 HRV-2B-Mi -D1000

HRV-2B-Mi -D1500 HRV-2B-Mi -D2000

14

Communication wiring between the indoor and outdoor units

The HRV and outdoor units communicate via the RS485 serial port.

The communication wiring between the HRV and outdoor units should be connected one unit after

another in a daisy chain from the outdoor unit to the final HRV unit. And the shielded layer must be

properly grounded, and a build-out resistor must be added to the last HRV unit to enhance the stability

of the communication system.

Incorrect wiring such as a star connection or a closed ring will cause instability of the communication

system and system control anomalies.

Use a three core shielded wire (greater than or equal to 0.75 mm2) for the communication wiring

between the indoor and outdoor units. Make sure the wiring is connected correctly. The connecting lead

for this communication wire must come from the master outdoor unit.

All shielded wiring in the network are interconnected, and will eventually connect to earth at the same

point " ”.

12.ERP INFORMATION

Fan Types

Directive (or Standard) for Regulation

ErP Directive 2009/125/EC

COMMISSION REGULATION (EU) No 327/2011

Model Name

Rev.

Prepare by

Specified Information of Fan:

No.

Information Item

Comment

1

η

target

=

32.5%

2

3

Pass

4

Measurement

category (A -D)

A

5

Efficiency category (static or total)

Static

6

Efficiency grade at optimum energy efficiency point

N =44.52

7

VSD is integrated within the fan

YES

8

Year of Manufacture

Ref. to the Unit Nameplate

Ref. to the Unit Nameplate

10.1

Rated motor power input(s) (kW), at optimum energy

efficiency

0.1517 kw

10.2

Rated motor flow rate(s) at optimum energy efficiency

0.1614m3/s

10.3

Rated motor pressure(s) at optimum energy efficiency

270 Pa

11

Rotations per minute (R.P.M)at the optimum energy

efficiency point

1320r/min

12

Specific ratio

1.001

13

Information relevant for facilitating disassembly,

recycling or disposal at end-of-life

all materials can be recycled

14

Information relevant to minimize impact on the

environment and ensure optimal life expectancy as

regards installation, use and maintenance of the fan

For installation, the clearance of

500 mm shall be kept from inlet

15

Measurement category A, fan is free

inlet and outlet conditions

16

Motor manufacturer

NIDEC

SHIBAURA(ZHEJIANG)CORP.

Centrifugal forward curved fan

Manufacturer’s name and place of manufacture

8

9

Table 12-1

WZDK170-38G-2 +LX-245*203*12-

48J 1320

33.02%

Efficiency category (static or total)

Efficiency grade at optimum energy efficiency point

ηtarget=

Overall efficiencye(ηe )=

Pass or not (Criteria:ηe≧ηtarget)

Communication wiring between the indoor unit and wired controller

The wired controller and the indoor unit can be connected in different manners, depending on the forms of

communication.

1. For a bidirectional communication mode:

Use 1 wired controller to control 1 indoor unit or 2 wired controllers (one master and one slave

controller) to control 1 indoor unit.(see Fig.4-4)

Use 1 wired controller to control multiple indoor units or 2 wired controllers (one master and one slave

controller) to control multiple indoor units. The maximum number of connections is 16.(see Fig.4-5)

2. For single direction communication mode:

Use 1 wired controller to control 1 indoor unit

The X1/X2, D1/D2 ports on the sides of the main control board and single direction communication port

are for different types of wired controllers.

For the specific connection method, refer to the instructions in the corresponding wired controller

manual to carry out the wiring and connections.

Handling the Electrical Wiring Connection Points

Once the wiring and connections are done, use tie straps to secure the wiring properly so that the

connection joint cannot be pulled apart by external force. The connection wiring must be straight out so

that the cover of the electrical box is level and can be closed tightly.

Use professional insulation and sealing materials to seal and protect the perforated wires. Poor sealing

may lead to condensation, and entry of small animals and insects that may cause short circuits in parts

of the electrical system, causing the system to fail.

Description of additional items used when determining

the fan energy efficiency,such as ducts, that are not

described in the measurement category and supplied

with the fan.

15

Directive (or Standard) for Regulation

ErP Directive 2009/125/EC

COMMISSION REGULATION (EU) No 327/2011

Model Name

Rev.

Prepare by

Specified Information of Fan:

No.

Information Item

Comment

34.14%

2

49.7%

3

Pass

4

A

5

Efficiency category (static or total)

Static

6

Efficiency grade at optimum energy efficiency point

N =59.51

7

VSD is integrated within the fan

YES

8

Year of Manufacture

Ref. to the Unit Nameplate

Ref. to the Unit Nameplate

10.1

Rated motor power input(s) (kW), at optimum energy

efficiency

10.2

Rated motor flow rate(s) at optimum energy efficiency

0.34m3/s

10.3

Rated motor pressure(s) at optimum energy efficiency

360 Pa

11

Rotations per minute (R.P.M)at the optimum energy

efficiency point

12

Specific ratio

1.001

13

All materials can be recycled

14

15

Measurement category A, fan is free

inlet and outlet conditions

16

Motor manufacturer

Panasonic Appliances

Motor(Hangzhou)Co.Ltd.

Manufacturer’s name and place of manufacture

8

9

T

able 12-2

WZDK750-38G-W-1+LX-261*234*15

-48J 1300

0.276 kw

1300r/min

Measurement

category (A -D)

For installation,the clearance of

500 mm shall be kept from inlet

Information relevant to minimize impact on the

environment and ensure optimal life expectancy as

regards installation, use and maintenance of the fan

此页不做菲林

210*297 双胶纸黑白印 100g

版本号升级V1.0-V2.0(2020-9-2)

更改内容:1、P6-P9关于电控部分的描述细化

2、说明书整体模板更改

Overall efficiencye(ηe )=

Pass or not (Criteria:ηe≧ηtarget)

Fan Types

Centrifugal forward curved fan

1

ηtarget=

Information relevant for facilitating disassembly,

recycling or disposal at end-of-life

Description of additional items used when determining

the fan energy efficiency,such as ducts, that are not

described in the measurement category and supplied

with the fan.

16

This manual suits for next models

7

Table of contents

Other CLIVET Air Cleaner manuals

Popular Air Cleaner manuals by other brands

Electro-Air

Electro-Air SC-500 05C11E-01002 Tech sheet

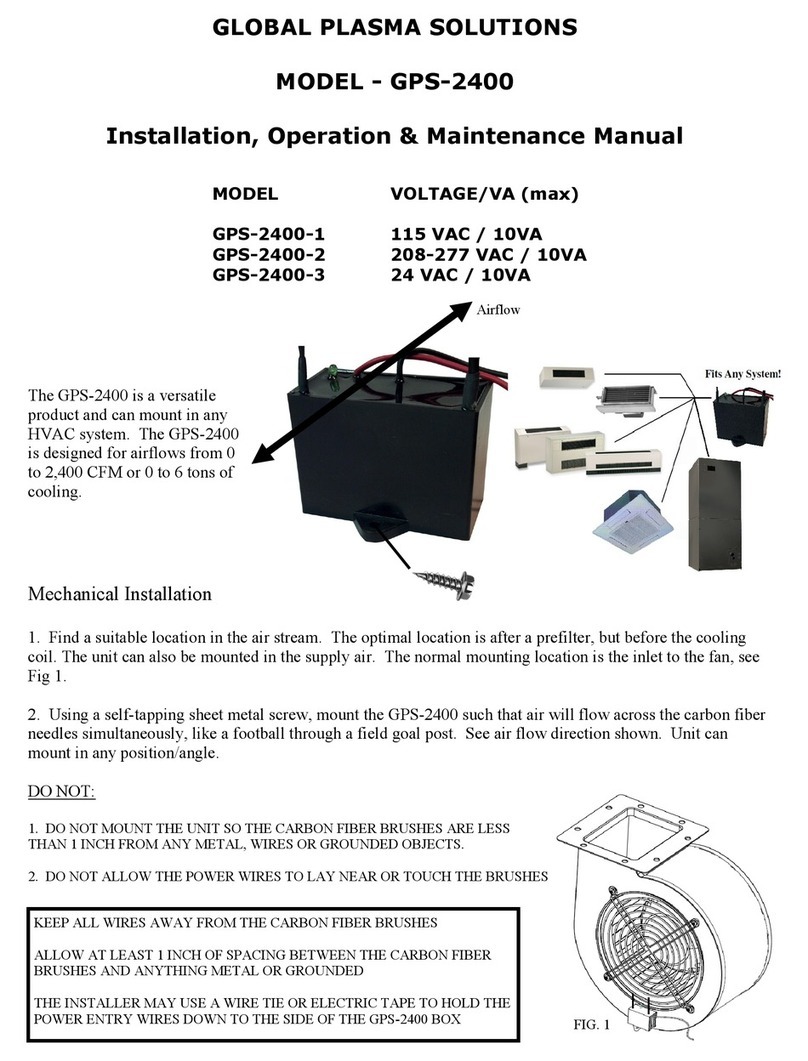

GLOBAL PLASMA SOLUTIONS

GLOBAL PLASMA SOLUTIONS GPS-2400 Installation, operation & maintenance manual

Oransi

Oransi EJ 120 user manual

Lifebreath

Lifebreath Lifebreath TFP3000 Operation and installation manual

TEFAL

TEFAL Intense Pure Air Turbo manual

Boneco

Boneco H300 manual