CLIVET ELFOFresh EVO CPAN-YIN Reference manual

Change living home

MANUAL

FOR INSTALLATION,

USE AND MAINTENANCE

ELFOFresh EVO

CPAN-YIN Size2

Dear Customer,

We congratulate you on choosing an ELFOSystem product, the air

conditioning system at annual cycle that offers the possibility in a sole

system of meeting all the heating, conditioning and domestic hot water

needs, purifies and renews the air .

Clivet is being working for years to offer systems able to assure the

maximum comfort for long time with high reliability, efficiency , quality and

safety. The target of the company is to offer advanced systems, that assure

the best comfort, reduce the energy consumption, the installation and

maintenance costs for all the life-cycle of the system.

With this manual, we want to give you information that are useful in all the

phases: from the reception, to the installation and use until the disposal so

that a system so advanced offers the best procedure of installation and use.

Best regards and have a nice reading !

CLIVET Spa

The data contained in this manual is not binding and may be changed by the manufacturer without prior notice.

All reproduction, even partial, is prohibited. © Copyright - CLIVET S.p.A. - Feltre (BL) - Italy

Safety considerations 5

1 General 9

2 Reception 13

3 Positioning 15

4 Water connections 21

5 Aeraulic connections 22

6 Electric connections 27

7 Start-up 29

8 Control 34

9 Maintenance 53

10 Decommissioning 62

11 Residual risks 63

12 Technical date 64

13 ELFOAir 69

INSTALLER use

Pay particular attention to:

USER use

Consider sound emissions

Aeraulic ducts

Respect the spaces to conduct normal and extraordinary maintenance

Avoid air bypass

Avoid installations next to

bedrooms

Rapid guide

A

Avoid tight bends

Safety grilles

Should not be tilted towards unit

HMI ambient keyboard

ø 32

Electric connections

C

Siphon

** Insulated ducts

Install in a local or compartment where the temperature can't drop

below 5° C.

E

For details see the manual

sections

Unit fixing points

Functional spaces

B

Install supplied antivibration

Anti-vibration joint when used rigid pipes

Dimensions connections

Condensate discharge

D

F

Connect the ambient keyboard to the main board

Insulated ducts

Size. A B

Size 2 310 276

Positions

1,5 m

OK

The keyboard must be placed:

• at a height of 150 cm

• preferably on an internal wall

• Positions to avoid:

• next to heat sources

• points exposed to direct sunlight

• Etc….

Connections

Cable 5x0,75 mm2 shielded

Max. length 50m

** minimum service clearance

A Air expulsion Ø 200 mm

B Ambient air return Ø 200 mm

C Ambient air

distribution Ø 200 mm

D Fresh air intake Ø 200 mm

C

B

A

D

Customer connections

HMI

5

1 - SAFETY CONSIDERATIONS

The precautions in this manual are

divided as indicated on the side.

They are important, so make sure you

follow them closely.

Please read these instructions carefully

before installing.

Keep this manual handy for future

reference.

This unit contains fluorinated gases.

For specific information on gas types

and quantities, please refer to the

plate found on the unit.

Please contact your dealer for future

assistance.

Meaning of the symbols DANGER,

WARNING, CAUTION and NOTE

DANGER

It indicates a situation of imminent

danger that, if not avoided, will

cause death or serious lesions.

WARNING

It indicates a potentially dangerous

situation that, if not avoided, may

cause death or serious lesions.

CAUTION

It indicates a potentially dangerous

situation that, if not avoided, may

cause slight or moderate injury. Also

used to warn against unsafe

practices.

NOTE

It indicates situation that may cause

accidental damage to the equipment

or property.

DANGER

An incorrect installation of

equipment or accessories may

provoke electric shocks, short

circuits, leaks, fire or other damages

to the equipment. Make sure you

only use accessories provided by

the supplier - which are designed

specifically for the equipment - and

make sure they are installed by a

professional.

All activities described in this

manual must be performed by

authorised technicians. Make sure to

wear suitable personal protection

such as gloves and safety goggles

while installing the unit or

performing maintenance operations.

Switch off the power switch before

touching electrical components and

terminals.

When the service panels are

removed, the live parts can easily

be touched by mistake.

Never leave the unit unattended

during installation or maintenance

operations while the service panel is

removed.

Do not touch the water pipes during

and after performing welding or

junction work as the pipes may be

very hot and you may burn your

hands. To avoid lesions, wait until

the pipes return to a normal

temperature or make sure you are

wearing protective gloves.

Do not touch any switch with wet

hands. Touching a switch with wet

hands may lead to electric shock.

WARNING

Maintenance operations must be

performed as recommended by the

manufacturer. Maintenance and

reparation operations requiring the

assistance from specialized

personnel must be performed under

the supervision of the person

competent as regards flammable

refrigerants.

6

1 - SAFETY CONSIDERATIONS

Tear and dispose of plastic bags so

that children may not play with

them. Children playing with plastic

bags risk choking.

Some products use PP packaging

straps. Do not pull the straps or

use them to lift or move the

product. It may be dangerous

should the straps break.

Dispose safely of packaging material

such as nails or other metal or

wooden parts that may cause

lesions.

Ask your dealer or qualified

personnel to perform installation

operations according to this manual.

Do not install the unit yourself. An

incorrect installation may cause

water leaks, electric shock or fire.

Make sure to only use accessories

and parts specified for installation

operations. Failing to use specific

parts may cause

water leaks, electric shock, fire or

the unit falling from its support.

Install the unit on a structure that

can withstand its weight. An

insufficiently robust structure may

lead to the unit falling causing

possible lesions.

Perform installation operations

considering the possibility that

strong winds, hurricanes or

earthquakes may occur. Incorrect

installation operations may lead to

accidents caused by falling

equipment.

Make sure all electrical operations

are performed by qualified

personnel in accordance with the

law, local regulations and this

manual.

Connect the unit to a separate

power supply circuit. An insufficient

capacity of the power supply circuit

or incorrect connections may lead

to electric shock or fire.

Make sure to install an additional

differential circuit-breaker against a

leakage to earth compliant with the

law and local regulations: omnipolar

circuit breaker, at least 3 mm

separation in all poles, residual

current device (RCD) with a rated

value not exceeding 30 mA.

Failing to install a differential circuit

-breaker may lead to electric shock

and fire.

Make sure all the wiring is safe. Use

the specified wires and make sure

terminal connections and wires are

protected against the water, external

forces or other phenomena.

Incomplete connections or fixing

may cause a fire.

When connecting the power supply,

arrange the wires so that the front

panel can be fixed properly. If the

front panel is not in position, it may

lead to terminals overheating,

electric shock or fire.

People working or intervening on a

cooling circuit must hold a suitable

certification issued by an authorised

assessment centre proving their

suitability to handle refrigerants

safely in compliance with a specific

assessment recognised by industry

associations.

After installation operations are

over, verify that there are no

refrigerant leaks.

Never touch the leaking refrigerant

directly, as it may lead to serious

frostbite injuries. Do not touch the

7

1 - SAFETY CONSIDERATIONS

refrigerant pipes during and right

after functioning, as they may be

hot or cold depending on the

conditions of the refrigerant flowing

through the pipes, compressor and

other parts of the cooling circuit.

Burns or frostbite may occur if you

touch the refrigerant pipes. If it is

necessary to touch the pipes, wait

for them to return to a normal

temperature or wear protective

gloves and clothes.

Do not touch the internal parts

during and immediately after

functioning. Touching internal parts

may cause burns. To avoid lesions,

wait until the internal parts have

returned to a normal temperature

or, if touching them is necessary,

wear protective gloves.

Do not pierce nor burn.

Be aware that refrigerants are

odourless.

CAUTION

Place the unit on the ground.

The earth resistance should comply

with the law and local regulations.

Do not connect the earth cable to

gas or water mains, lightning rods

or phone earth cables.

Incomplete earthing may cause

electrical shocks.

• G a s m a i n s : f i r e s o r e x p l o s i o n s m a y

occur in case of a gas leak.

• Water mains: rigid vinyl tubes are not

effective.

• Lightning rods or phone earth cables:

the electrical threshold can increase

abnormally if hit by lightning.

Do not wash the unit as it may

cause electric shocks or fires.

Do not install the unit in the

following places:

• Where there is mineral oil, even in form

of vapour. Plastic parts may

deteriorate, disperse and cause water

leaks.

• Where corrosive gases (such as

sulphurous acid) are produced.

• Where the corrosion of copper pipes

or welded parts may cause refrigerant

leaks.

• Where there are devices emitting

electromagnetic waves.

Electromagnetic waves may disturb the

control system and cause

malfunctions.

• Where flammable gases may leak, or

carbon fibre or flammable powers may

b e f o u n d i n t h e a i r o r w h e r e v o l a t i l e

flammable materials such as paint

thinners or petrol are handled. These

gases may cause a fire.

• Where the air contains high levels of

salt, such as the seaside.

• Where the power supply voltage is

subject to fluctuations, such as in

factories.

• On vehicles or ships.

• Where there are acid or alkaline

vapours.

Prior to installation, verify if the

user’s power supply meets the unit’s

installation requirements (including

reliable earthing, differential circuit-

breaker, component size, wire

section, etc.). If the electrical

installation requirements are not

met, the unit cannot be installed

until the electrical system is

rectified.

Before the hydraulic connection and

electrical wiring operations, verify

that the installation area is safe

8

1 - SAFETY CONSIDERATIONS

and without hidden dangers such as

water, electricity and gas conduits.

Do not touch the fins of the heat

exchanger as they may cause injury.

If installing multiple units in a

centralised manner, adjust the

electric load on the various phases.

Do not connect multiple units to the

same phase of the three-phase

supply.

The following subjects may use the

unit if supervised or instructed on

safe usage and capable of

understanding the possible dangers:

children who are minimum 8 years

old, people with no experience or

knowledge, people with limited

physical, sensory or mental abilities.

Children must not play with the unit.

Cleaning and maintenance

operations to be carried out by the

user must not be performed by

unsupervised children.

Once the installation is complete,

the unit tested and functioning is

normal, instruct the client as

regards the use and maintenance of

the unit as indicated in this manual.

In addition, make sure that the

manual is suitably kept for future

reference.

DISPOSAL: do not dispose of this

product as unsorted waste. Contact

the local authorities for information

on the collection systems available.

If electrical equipment is disposed

of in landfills, dangerous substances

may infiltrate the waste water and

enter the food chain, harming the

health and well-being of people and

animals.

9

1 - GENERAL

1 Electrical panel

2 Serial number label

3 Exhaust fan

4 Supply fan

5 Compressor

6 External exchanger

7 Internal exchanger

8 ambient air supply air filter

9 exhaust air filter

10 Condensate drain pump

11 Air shutter actuator

12 Upper closing housing

UNIT DESCRIPTION

10

1 - GENERAL

ACCESSORIES

ELFOAir

Is the air distribution system.

Fairing for in-view installation

1 Grid to prevent small animals or leaves from

entering inside (option)

2 Outdoor air intake

3 Ambient exhaust air

4 Air filter

5 HMI keyboard

6 Ambient air supply

7 Ambient air intake

8 Distribution box (option)

9 Customer connections

11

UNIT IDENTIFICATION

Serial number

It identifies uniquely each unit.

It identifies specific spare parts for the unit.

Intervention requests

Note data from the serial number label and write them

in the table sideways, so you will find them easily when

needed.

Serie

Size

Serial number

Year of manufacture

Wiring diagram

1 - GENERAL

When ordering repair parts please always give the fol-

lowing information:

Model, serial and product number.

Parts name.

User training

The installer has to train the user on:

• start-up / shutdown

• set points change

• standby mode

• Maintenance

• what to do / what not to do in case of breakdown

Data updating

Continuous product improvements may imply manual

data changes.

Visit manufacturer web site www.clivet.it for the data

updating

Serial number label

The serial number label is positioned on the unit,

generally next to the electrical panel, and allows you to

indentify all the unit features.

The serial number label it reports the regulations

indications such as:

• Type of unit

• serial number (12 characters )

• year of manufacture

• wiring diagram number

• electrical data

• Type of refrigerant

• Charge of refrigerant

• manufacturer logo and address

The serial number label has not to be removed for any

reason.

It contains fluorinated greenhouse gases

Type of refrigerant R32

Characteristics of R32 refrigerant:

• minimum environmental impact thanks to the low

Global Warming Potential GWP

• low flammability, class A2L according to ISO 817

• low combustion speed

• low toxicity

The total amount of the charge of the unit is 0,3Kg.

The value is lower than the maximum critical value

declared inside EN 603335-2-40 m1 (1,23Kg).

According this standard there are no limitations of the

minimum space to be installed.

Physical characteristics of the R32 refrigerant

Safety class (ISO 817) A2L

GWP 675

LFL Low flammability limit 0.307

BV Burning velocity 6,7

Boiling point -52

GWP 675

GWP 677

Self-ignition temperature 648

kg/m3 @ 60°C

cm/s

°C

100 yr ITH

ARS 100 yr ITH

°C

The refrigerant quantity is indicated on the unit plate

Quantity factory-loaded refrigerant and equivalent CO2

tons:

Size Refrigerant (Kg) Equivalent CO2

tons

Size 2 0,3 0,2

12

1 - GENERAL

Operate in compliance with safety regulations in force .

Use single protection devices.

BEFORE REQUESTING START-UP

• Completed system

• Completed aeraulic system and free of dirt

• Electric connections

Before beginning the work, ensure you that have the

final project for installing the aeraulic, hydraulic, elec-

tric,drains and positioning the units.

Recommended instruments

Set of Philips and flathead screwdrivers;

Cutters;

Drill;

Scissors;

Set of open spanners or pipe wrenches;

Range;

Hydraulic material for the sealing of the threads;

Electrical equipment for the connections;

Cut prevention gloves;

Tester and amperometric pliers.

PRELIMINARY INFORMATION

13

2 - RECEPTION

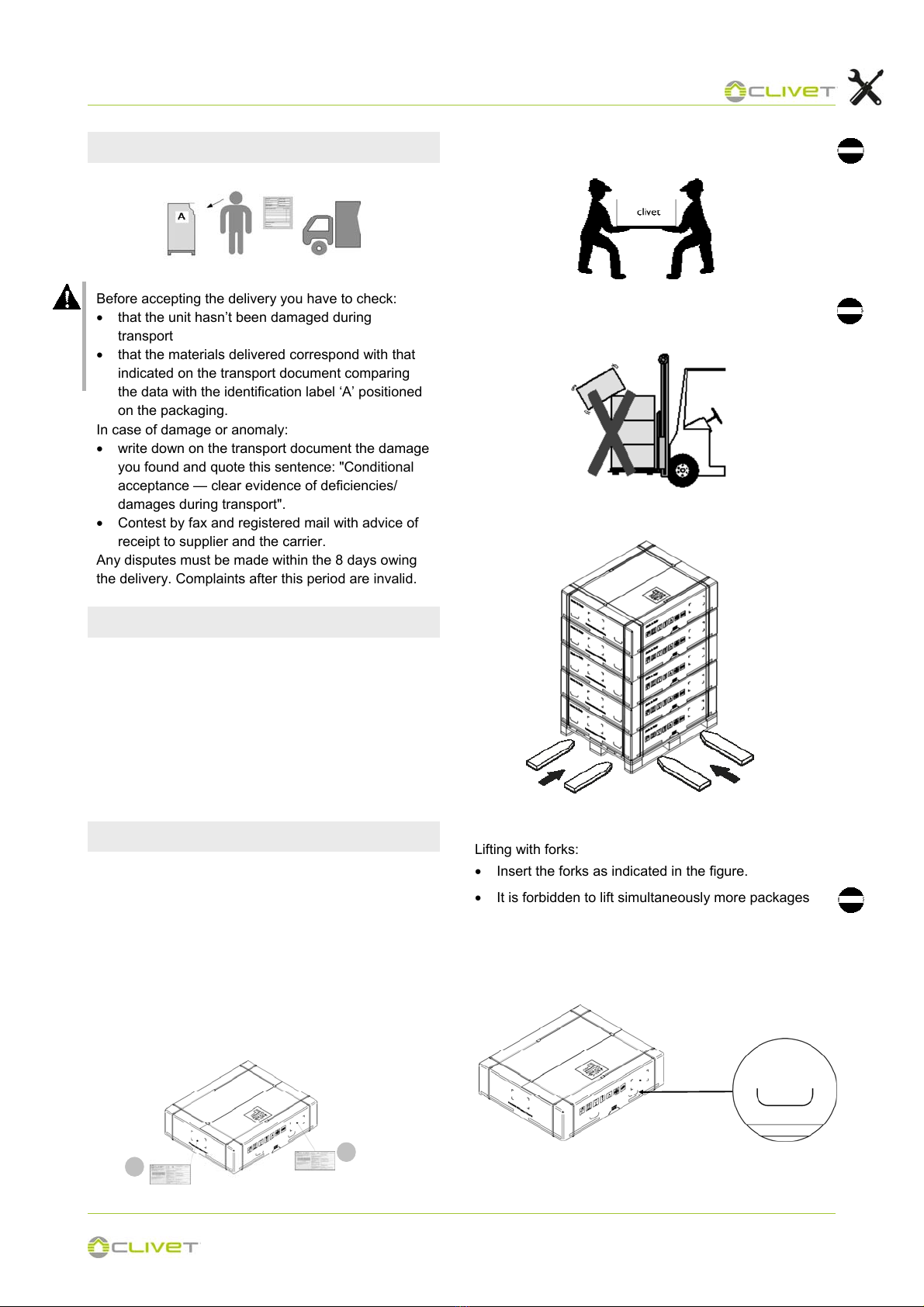

Lifting with forks:

• Insert the forks as indicated in the figure.

• It is forbidden to lift simultaneously more packages

letting them looses.

• In case of lifting of more units at the same time, an

appropriate container must be used.

Before accepting the delivery you have to check:

• that the unit hasn’t been damaged during

transport

• that the materials delivered correspond with that

indicated on the transport document comparing

the data with the identification label ‘A’ positioned

on the packaging.

In case of damage or anomaly:

• write down on the transport document the damage

you found and quote this sentence: "Conditional

acceptance — clear evidence of deficiencies/

damages during transport".

• Contest by fax and registered mail with advice of

receipt to supplier and the carrier.

Any disputes must be made within the 8 days owing

the delivery. Complaints after this period are invalid.

DELIVERY CONTROL

HANDLING

• Do not leave loose packages during the transport

• Do not trample

The following examples are indications; the choice of

the means and of the handling modes will depend on

factors, such as:

• The unit weight

• Type and overall dimensions of the unit

• Place and route for the handling (dirt yard,

asphalted square, etc.)

• Condition of the place of destination (roof, square,

etc.) distances, drops and gradients.

Shelter from: direct sunlight, rain, sand and wind.

Stocking temperature:

maximum 50°C

minimum -10°C

The respect of the instructions on the exterior side of

the packaging assures the physical and functional

integrity of the unit for the final user’s advantage.

STORAGE Max 5

A

A Lifting handle

14

2 - RECEPTION

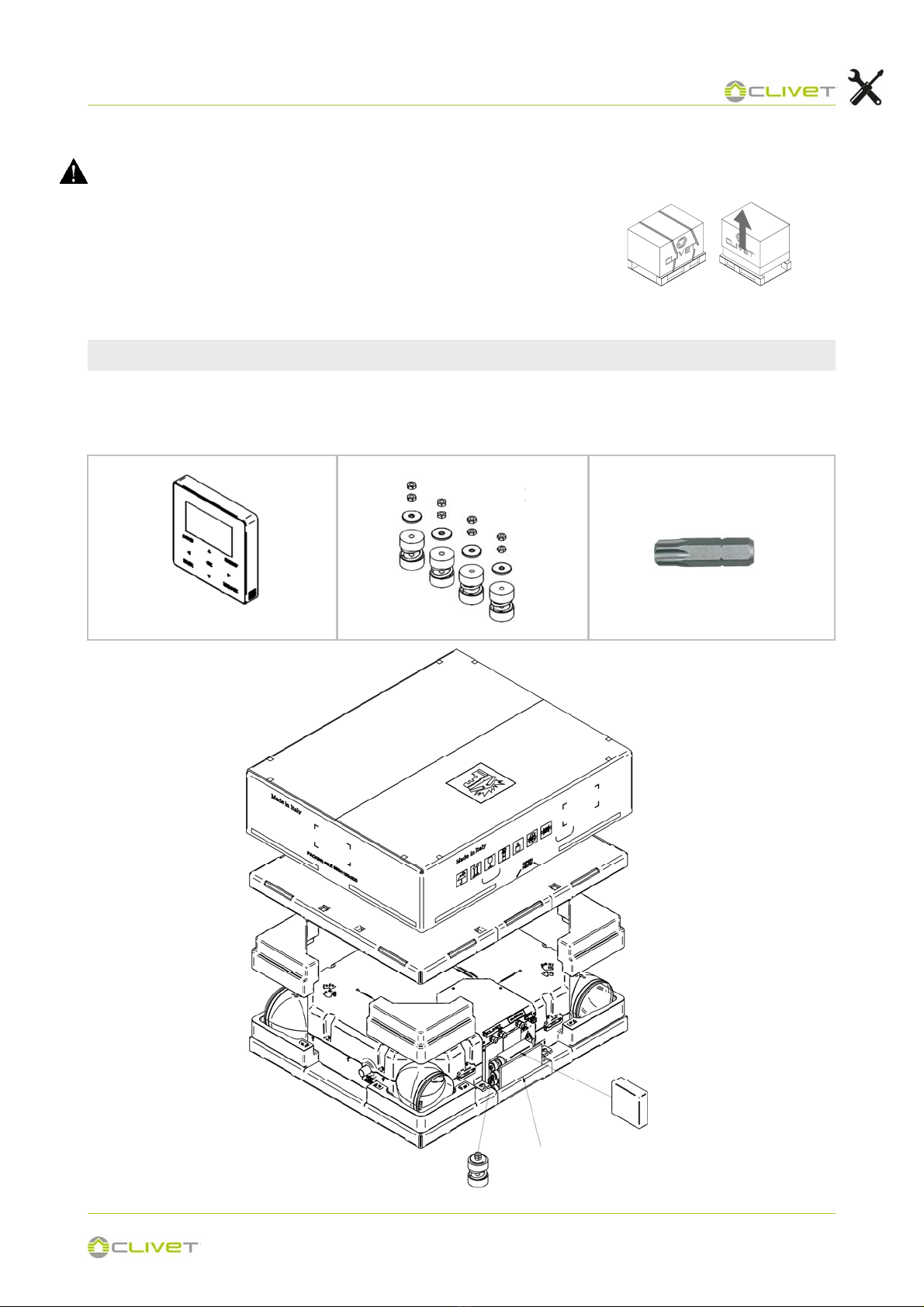

KIT REMOVAL

The unit is supplied in a single pack and is equipped with:

Packing removing

Be careful not to damage the unit.

• Cut the fixing strips.

• Remove the packaging lifting it upwards.

Keep packing material out of children's reach it may be dangerous.

Recycle and dispose of packing material in conformity with local regula-

tions.

HMI keyboard

The unit is supplied in a single pack and is equipped with:

Anti-vibration Torx insert for screwdriver

HMI keyboard

Anti-vibration Manuale

15

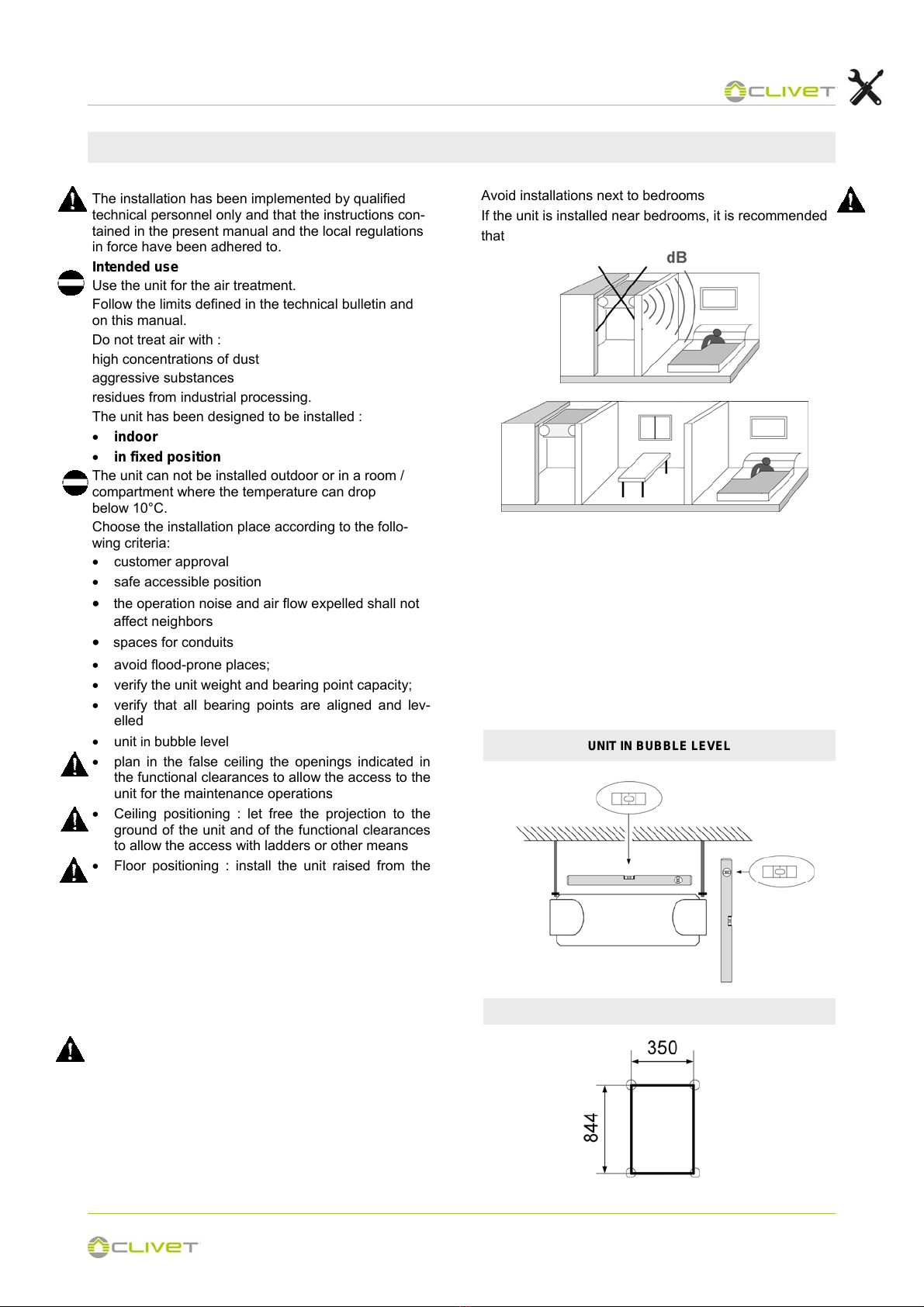

3 - POSITIONING

The installation has been implemented by qualified

technical personnel only and that the instructions con-

tained in the present manual and the local regulations

in force have been adhered to.

Intended use

Use the unit for the air treatment.

Follow the limits defined in the technical bulletin and

on this manual.

Do not treat air with :

high concentrations of dust

aggressive substances

residues from industrial processing.

The unit has been designed to be installed :

• indoor

• in fixed position

The unit can not be installed outdoor or in a room /

compartment where the temperature can drop

below 10°C.

Choose the installation place according to the follo-

wing criteria:

• customer approval

• safe accessible position

• the operation noise and air flow expelled shall not

affect neighbors

• spaces for conduits

• avoid flood-prone places;

• verify the unit weight and bearing point capacity;

• verify that all bearing points are aligned and lev-

elled

• unit in bubble level

• plan in the false ceiling the openings indicated in

the functional clearances to allow the access to the

unit for the maintenance operations

• Ceiling positioning : let free the projection to the

ground of the unit and of the functional clearances

to allow the access with ladders or other means

• Floor positioning : install the unit raised from the

ground, on a frame to permit the maintenance of

the filter (bottom extraction).

Ceiling positioning and Floor, the unit for these two

type of installation is selled with the protection fairing

in sheet metal

Limit vibration transmission:

• use antivibration devices on unit bearing/

supporting points

• install flexible joints on the hydraulic/aeraulic con-

nections.

Neglecting these aspects may decrease the unit per-

formances and life.

CLEARANCE ACCESS RECOMMENDED

UNIT IN BUBBLE LEVEL

UNIT FIXING POINTS

Consider sound emissions

Avoid installations next to bedrooms

If the unit is installed near bedrooms, it is recommended

that

The functional clearances have to :

• guarantee the unit good operating

• allow the maintenance operations

• safeguard the authorized operators and the ex-

posed person.

• position the unit taking into consideration the clear-

ances indicated in the dimensional

• consider the space necessary for filter extraction .

16

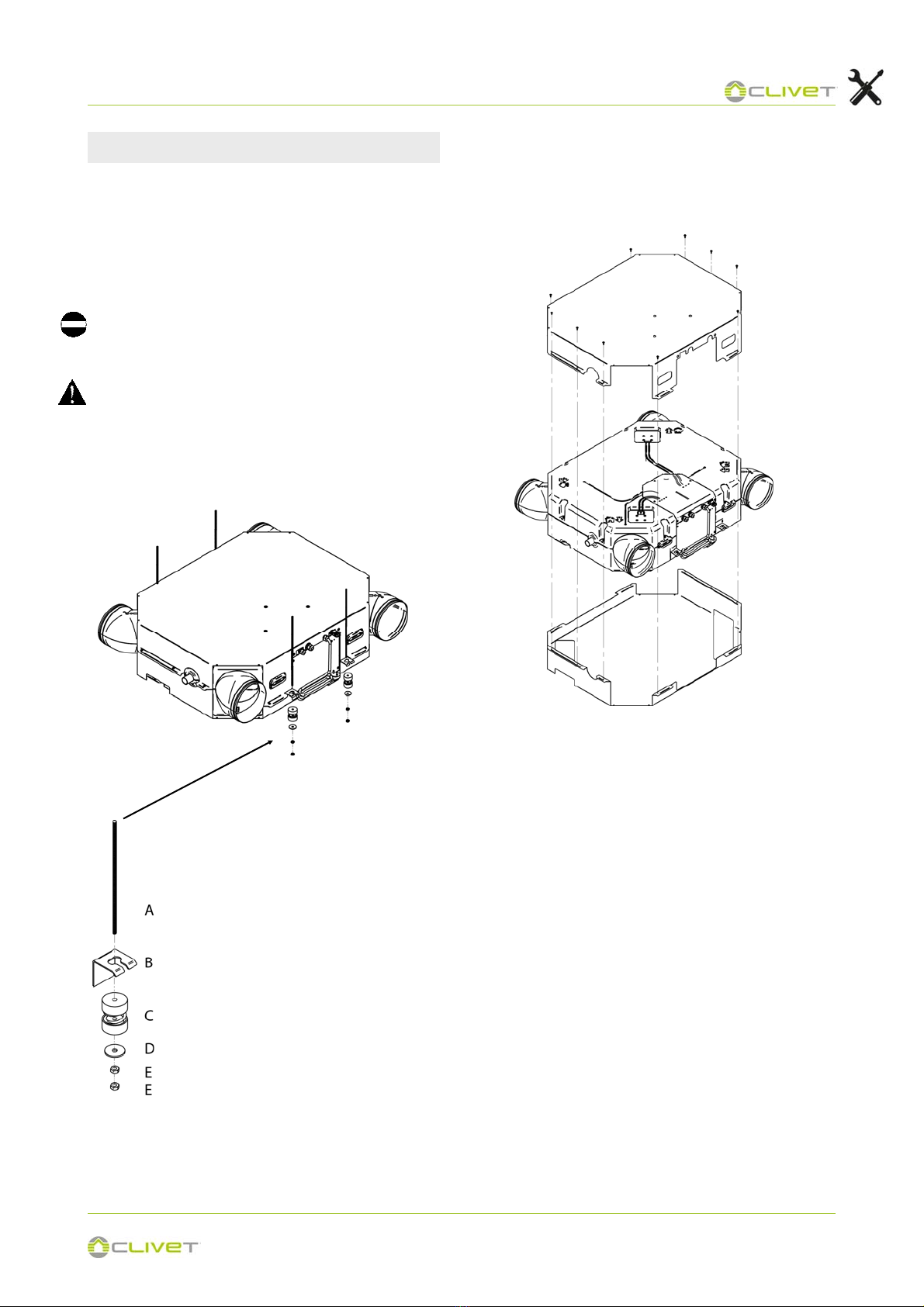

3 - POSITIONING

• Insert the M8 threaded bar (not supplied) to on the

support base.

• Screw the nuts, insert the flat washer.

• Insert the antibration

• Pass the M8 threaded rods into of the support

bracket on the unit.

• Insert the flat washer

• Screw the nut

• Do not over tighten the nuts, the springs, because if

too much crushed they don’t absorb vibrations

FLOOR INSTALLATION

a) nut

b) flat washer

c) bracket

d) antivibration foot

e) flat washer

f) nut

g) nut

h) A threaded bar

Perfomer by customer

For floor positioning or installation not in false ceiling the

unit provided with sheet metal cover.

17

3 - POSITIONING

CEILING INSTALLATION

• Fix some M8 threaded bars (not supplied) to the

ceiling.

• Pass the M8 threaded bars in the brackets on the

unit.

• Insert on the threaded bar the antivibration .

• Insert the flat washer and tighten the nut to lock.

• Do not over tighten the nuts, the springs, because if

too much crushed they don’t absorb vibrations

For floor positioning or installation not in false ceiling

the unit provided with sheet metal cover.

a) A threaded bar

b) Bracket

c) Antivibration foot

d) Flat washer

e) Nut

Closing housing

18

3 - POSITIONING

ELECTRIC PANEL

Access to the electrical panel

Sheet metal cover of the electrical panel fixed by

4 torx screws.

Remove the 4 torx screws.

19

3 - POSITIONING

1,5 m

OK

AMBIENT KEYBOARD

The choice of the installation point is decisive for the

environmental comfort and the energy consumption.

The thermostat must be placed :

• In a room with medium temperature and humidity

conditions, representative of the other rooms

• at a height of 150 cm

• preferably on an internal wall

Positions to avoid :

• next to heat sources

• points exposed to direct sunlight

• in a position with air rejected from outlets or

diffusers

• behind curtains or pieces of furniture

• near windows and doors to the outside

• on walls crossed by fireplaces or heating ducts

• on external walls.

Use straight head screwdriver to insert into the buc-

kling position in the bottom of keyboard, and spin the

screwdriver to take down the back cover. (Pay atten-

tion to spinning direction, otherwise will damage the

back cover!)

Use three GB950-86 M4X20 screws to directly install

the back cover on the wall.

Use two M4X25 GB823-88screws to install the back

cover on the 86 electrician box, and use one GB950-

86 M4X20 screws for fixing on the wall.

Adjust the length of two plastic screw bars in the ac-

cessory to be standard length from the electrical box

screw bar to the wall. Make sure when install the screw

bar to the wall, make it as flat as the wall.

Use cross head screws to fix the keyboard bottom co-

ver in the wall through the screw bar. Make sure the

keyboard bottom cover is on the same level after in-

stallation, and then install the keyboard back to the

bottom cover.

Over fasten the screw will lead to deforma tion of back

cover.

20

3 - POSITIONING

Buckling

position

Straight head

screwdriver

Back cover

Front cover

Screw hole installed on the wall,use

three GB950-86 M4X20

Screw hole fixed on the wall,use one

GB950-86 M4X20

A- Screw hole installed on 86 Electri-

cian box, use two M4X25 GB823-88

Back cover

Signal

switching

wires

Cutting place of left

down side wire outlet

Left down side

wire outlet

Wiring hole

Wall hole and wiring hole

Diameter 8--10

After adjusting the front cover and then buckle the front

cover; avoid clamping the communication switching wire

during installation.

Sensor can not be

affected with damp.

A

Electrician box

B

C

B

C

B -Trap

C - Putty

C

B

Avoid the water enter into the

wired remote controller, use trap

and putty to seal the connectors

of wires during wiring installation.

Table of contents

Other CLIVET Air Cleaner manuals

Popular Air Cleaner manuals by other brands

Heylo

Heylo PF1000 Translation of the original instruction manual

Hunter

Hunter HEPAtech 30027 Manuel d'utilisation

Sharp

Sharp FP-J50 Operation manual

Guardian

Guardian AC151 Use & care instructions

Ionic Pro

Ionic Pro TA750 owner's manual

Ultravation

Ultravation Solaris SLX1024 Installation and owner's manual