CLIVET ELFOFresh2 CPAN-U 70-120 Series User manual

INSTALLATION AND OPERA-

TING MANUAL

Change living home

ELFOFresh2 70-120

ELFOFresh2200-500

make up and purification unit with active thermodynamic

recovery

ELFOFresh2CPAN-U 70-500

18-09-2019

M05E40C15-06

2

Dear Customer,

We congratulate you on choosing an ELFOSystem product, the air

conditioning system at annual cycle that offers the possibility in a sole

system of meeting all the heating, conditioning and domestic hot water

needs, purifies and renews the air

Clivet is being working for years to offer systems able to assure the

maximum comfort for long time with high reliability, efficiency , quality and

safety. The target of the company is to offer advanced systems, that assure

the best comfort, reduce the energy consumption, the installation and

maintenance costs for all the life-cycle of the system.

With this manual, we want to give you information that are useful in all the

phases: from the reception, to the installation and use until the disposal so

that a system so advanced offers the best procedure of installation and use.

Best regards and have a nice reading !

CLIVET Spa

3

1 - GENERAL

It is advisable to read it carefully so you will save time during

operations.

Follow the indications so you will not cause damages to things

and injuries to people

Before going ahead with operations, read the GENERAL

WARNINGS on page 97

Pay particular attention to :

WARNING, identifies particularly important operations or

information

PROHIBITIONS, identifies operations that must not be

carried out, that compromises the operating of the unit or

may cause damages to persons or things.

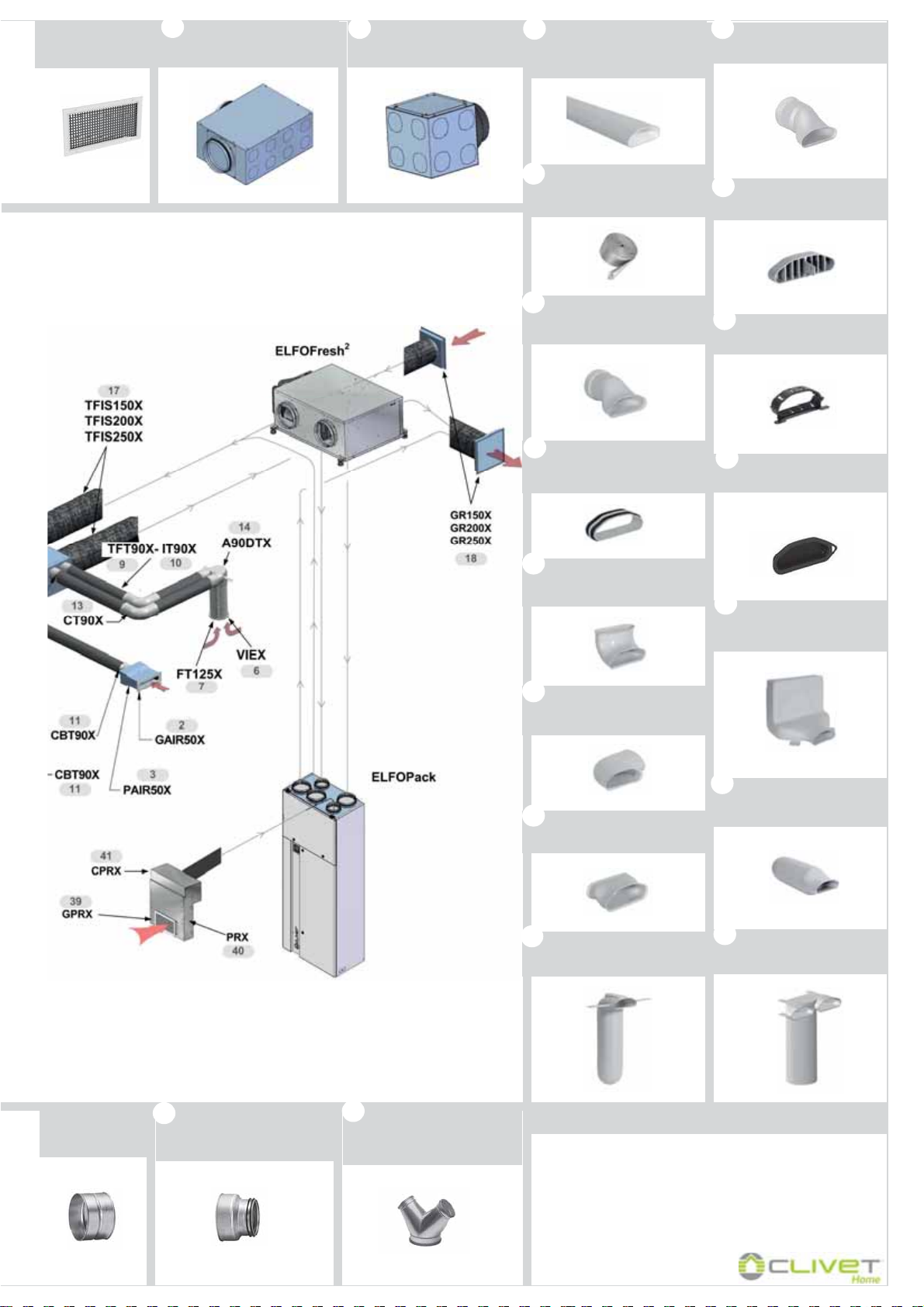

GF150X

GF200X

GF250X

GPRX

TFT90X

DN90 round flexible tube (Int. diam.

78mm) in a 20m. coil without insulation

A90DTX

90-degree adaptor, double

DN90 round tube for DN125 valve + cap

VIEX

Extraction/intake valve in ABS

DN125 without air filter

CBT90X

Connector to distribution box for

DN90 round tube

DAIR50X - DAIR80X

AIRJET 50/I - 80/l supply diffuser -

white frame and black inside

PAIR50X- PAIR80X

Suction/supply plenum with AIRJET 50

- 80 control damper - rear connection

GIUTX

Connecting joint for DN90 round tube

GINOX - GIVEX

Suction/supply rectangular grill

350x130mm stainless or white

CT90X

Printed curve of 90-degree

angle for DN90 round tube

IT90X

Insulation in a 20mt. coil for

DN90 round flexible tube

GAIR50X - GAIR80X

Intake grille + extractable filter AIRJET

50/A - 80/A - white frame and black

inside

ANFTX

DN90 seal O-Ring (10 pcs.)

FREX

Filter for rectangular

grilles 350x130mm (5 pcs.)

FT125X

Filter for DN125 valve (5 pcs.) TACTX

Cap for DN90 round tube (5 pcs.)

2

3

5

4

6

7

10

11

12

13

14

15

16

GR150X-GR200X- GR250X

Exhaust / return squared wall grig with

circular coupling DN150/200/250

TFIS150X - TFIS200X -

TFIS250X

DN150/200/250 soundproofing insulated

flexible tube in a 10mt. coil

17

18 19

PRX

Soundproofed plenum for air

recirculation

CPRX

Manifold for DN150-200 air

recirculation plenum

1 41 40 39

GQIEX

Extraction/intake squared grill of

DN125 joint with air filter

8

9

MTOA40M14-02 04-05-16

R2015X - R2520X

DN200-DN150 reducer

DN250-DN200 reducer

DY200X

DN200-DN200-DN200 Y-joint

DY250X

DN250-DN200-DN200 Y-joint

20 21

A90GPX

90-degree adaptor, single tube

for flat grill 350x130 mm

RTPTX

Round/flat tube connecting joint

A90DPX

90-degree adaptor, double flat

tube for DN125 valve

ADMPX

Straight adaptor, single flat tube

for DN125 valve

TACPX

Cap for flat tube (5 pcs.)

A90MPX

90-degree adaptor, single tube

for DN125 valve

REPPX

Flow controller for flat tube

ANFPX

Fixing ring for flat tube (10 pcs.)

29 22

23

25

26

27

24

BD14CX

14-output distribution box,

DN200 joint

BD8CX

8-output distribution box,

DN150-200 joint

ELFOAir

TFPNX

Flat flexible tube 132x52mm

in a 20m. coil without insulation

IT100X

Insulation in a 20mt. coil

for flat flexible tube 132x52

35

COBPX

DN90 connector joint

(CBT90X) --> flat tube

34

GIUPX

Seal and connecting joint

for flat tube (10 pcs.)

33

CVP90X

Vertical 90-degree curve

for flat tube

32

COP90X

Horizontal 90-degree curve

for flat tube

31

CTP180X

Joint for 180-degree

flat tube rotation

30

38 37 36 28

Grill for recirculation air

return plenum 325x175

mm white

F/F DN150/200/250

joint

!

! Filter

Filter only on the

intake grille

!

Cover the plenum, openings, grilles with cardboard,

adhesive tape, etc...

Remove caps

Consider sound emissions

CPAN-U 70-120

Aeraulic ducts

Respect the spaces to conduct normal and extraordinary maintenance

Avoid air bypass

Avoid installations next to

bedrooms

Trapdoor opening

9

A

Should not be tilted towards unit

L = 1,5 m = max. distance between resistances and electrical panel

CPAN-U 200-500

Remote electric panel

CPAN-U 200-500

Humidifier (option)

Water supply Condensate discharge

C

** Insulated ducts

Install in a local or compartment where the temperature can't drop below 0 ° C.

F

For details see the manual

sections

Size 70-120 200-300 500

A (mm) 636 666 710

B (mm) 755 760 993

B

* extraction air filters from below

Anti-vibration joint when used rigid pipes

Size 70-120

A Air expulsion Ø 150 mm

B Ambient air

return Ø 150 mm

C Ambient air

distribution Ø 150 mm

D Fresh air

intake Ø 150 mm

200-300

Ø 200 mm

Ø 200 mm

Ø 200 mm

Ø 200 mm

500

Ø 250 mm

Ø 250 mm

Ø 250 mm

Ø 250 mm

Filter size 200-500

Electric heaters (option)

E

HID-P1 ambient thermostat

H

Connect the ambient thermostat to the terminal block of the

customer connections

Terminal block of

the customer

Connections

Cable 3x0,34 mm2 shielded

Max. length 80 m

Unit fixing points

Install supplied antivibration

Dimensions connections

Install an air filter upstream. This should be at

least a G2 class filter to protect the heating

elements (provided by the customer)

ATTENTION

Don't invert downwards

MT5E40M15-06 19-09-19

Condensate discharge

CPAN-U 70-120

Rapid guide

ELFOFresh2

CPAN-U 200-500 Space to access:

* 700 - filter access from below, electrical panel on

board unit

* 200 - filter access from below, remote electrical

panel

Sloping tube

D

Avoid tight bends

Safety grilles CPAN-U 200-500

CPAN-U 70-120

Front

Rear

I

BEFORE REQUESTING START-UP

Completed system

Completed aeraulic system and free of dirt

Electric connections

AE fresh air intake

ES air expulsion

Mambient air distribution

Rambient air return

Pipe length

If there are electric heaters,

increase access space

Trapdoor opening

Sifón

Document reference

M05E40C15

** extraction air filter from below

Insulate the

steam-pipe

Slope min. 20°

Electric connections

G

Insulated ducts

Size A B

70-120 226 206

200-300 310 276

500 370 336

Positions thermostat

1,5 m

OK

The thermostat must be placed:

x at a height of 150 cm

x preferably on an internal wall

x Positions to avoid:

x next to heat sources

x points exposed to direct

sunlight

x Ecc….

Pag. 22/26/30

Ceiling access

Standard pump

10

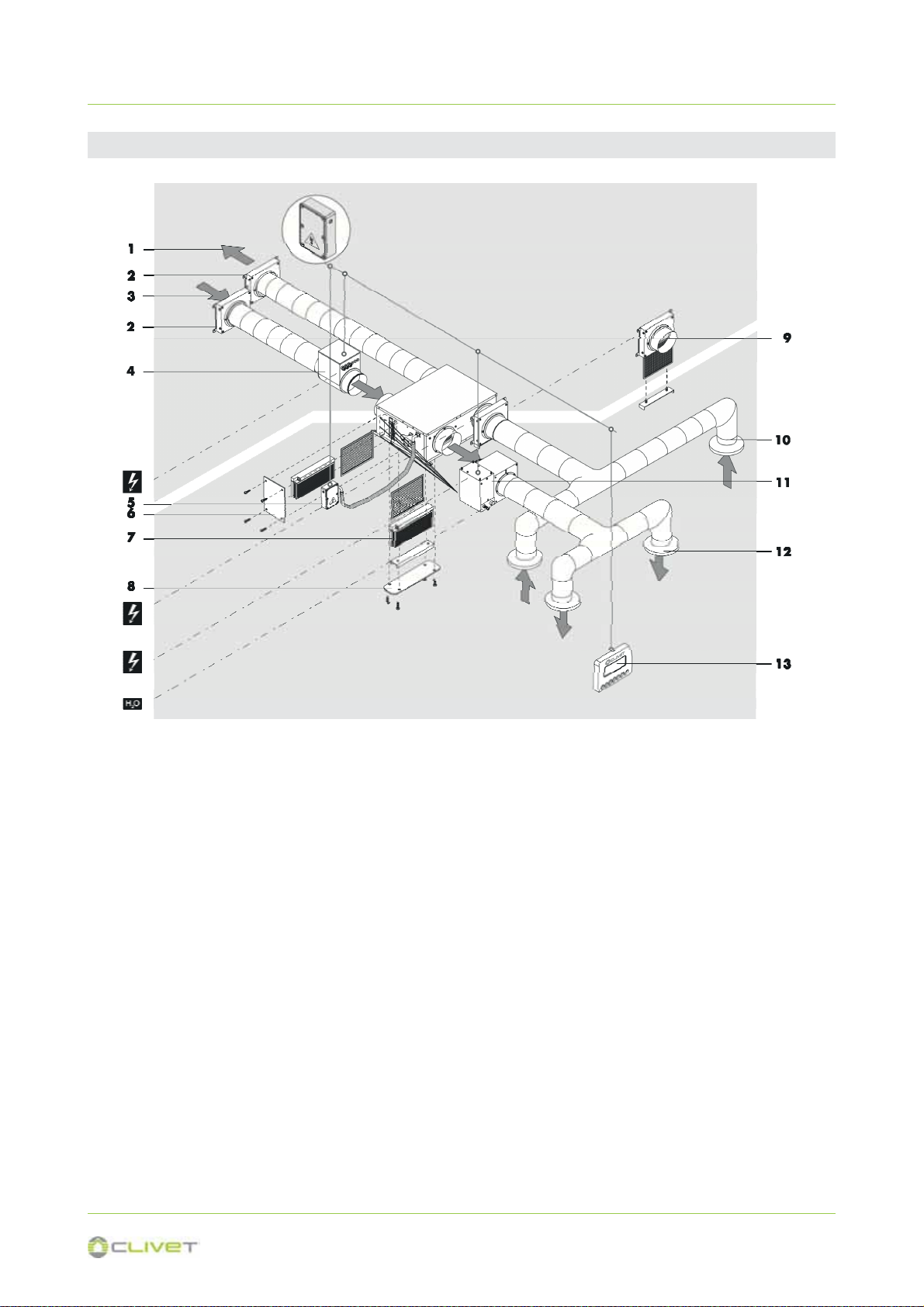

CPAN-U 70 - 120

1 - GENERAL

1.1 UNIT DESCRIPTION

1 Serial number label

2 Exhaust air fan

It rejects the unhealthy air outdoors.

3 Internal exchanger

It transfers energy (heat / cool) to the fresh air .

4 Compressor

5 Supply fan

It blows treated air in the rooms.

CPAN-U 200 - 500

7 Electrical remote panel

It is possible to remove the electrical panel and

make it remote to facilitate the installation

8 External exchanger

It recovers energy (heat / cool) from the exhaust air.

9 Air filter

It purifies the fresh air before introducing it into the

rooms

10 Upper panel

11 Electronic filter (option)

12 Electrical panel

11

CPAN-U 70 - 120

1 - GENERAL

1.2 ACCESSORIES

1 Ambient exhaust air

2 Grid to prevent small animals or leaves from

entering inside (option)

3 Outdoor air intake

4 Kit of electric resistance (option)

5 Intake air filter

6 Customer connections

7 Electronic filter (option)

8 Exhaust air filter

9 Ambient air intake

10 Ambient air supply

11 HID-P1 ambient thermostat

CDPX : Discharge condensate pump (size 200-500)

EHPCX : Preheating elements 0,7 kW in duct (size 70-120)

Preheating elements 1,5/3 kW in duct (size 200-500)

FSEX : Electronic filter kit (size 70-500)

HSE3LX: Immersed electrode steam humidifier for Elfofresh DN200 (size 200-500)

HSE3MX: Immersed electrode steam humidifier for Elfofresh DN250 (size 200-500)

FAEX : Kit of exhaust air filter (size 200-500)

CMMBX : Serial communication moduleto supervisor (MODBUS)

ELFOAir

Is the air distribution system.

12

1 Ambient exhaust air

2 Grid to prevent small animals or leaves from entering inside (option)

3 Outdoor air intake

4 Kit of electric resistance (option)

5 Remote electrical panel

6 Filter extraction with remote electrical panel

7 Electronic filter (option)

8 Filter extraction with built-in remote electrical panel

9 Kit of exhaust air filter (optional)

10 Ambient air intake

11 Humidifier kit (optional)

12 Ambient air supply

13 HID-P1 ambient thermostat

CPAN-U 200 - 500

1 - GENERAL

13

1.3 UNIT IDENTIFICATION

Serial number label

The serial number label is positioned on the unit,

generally next to the electrical panel, and allows you to

indentify all the unit features.

The serial number label has not to be removed for any

reason.

It reports the regulations indications such as:

x Type of unit

x size ĺ

x serial number

xxxxxxxxxxxx

x year of manufacture

x wiring diagram number

x electrical data

x manufacturer logo and address

Serial number

It identifies uniquely each unit.

It identifies specific spare parts for the unit.

Intervention requests

Note data from the serial number label and write them

in the table sideways, so you will find them easily when

needed.

In case of intervention you have to provide the data

indicated sideways.

Serie

Size

Serial number

Year of manufacture

Wiring diagram

1 - GENERAL

When ordering repair parts please always give the fol-

lowing information:

Model, serial and product number.

Parts name.

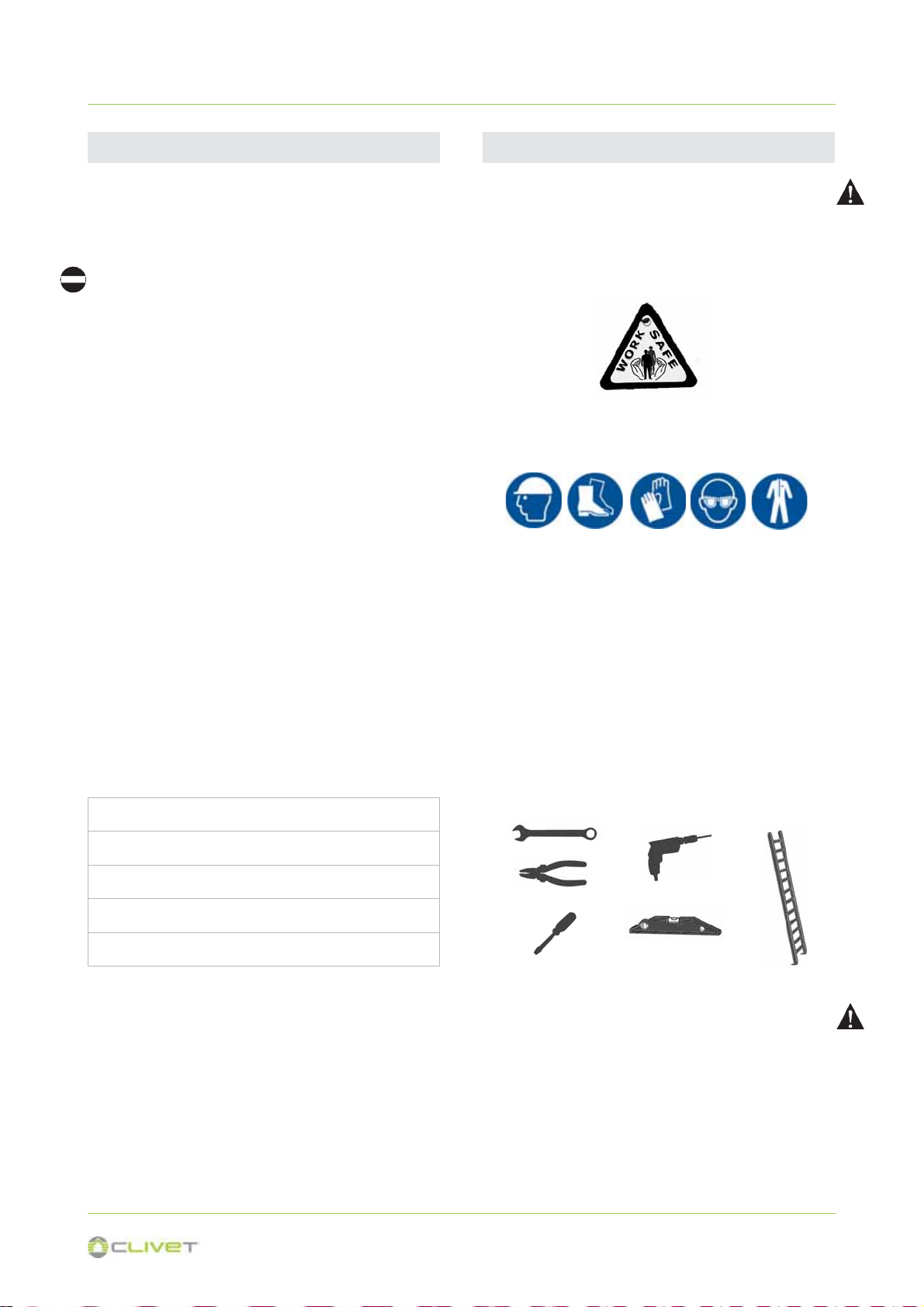

Operate in compliance with safety regulations in force .

Use single protection devices.

BEFORE REQUESTING START-UP

x Completed system

x Completed aeraulic system and free of dirt

x Electric connections

Before beginning the work, ensure you that have the

final project for installing the aeraulic, hydraulic, elec-

tric,drains and positioning the units.

Recommended instruments

Set of Philips and flathead screwdrivers;

Cutters;

Drill;

Scissors;

Set of open spanners or pipe wrenches;

Range;

Hydraulic material for the sealing of the threads;

Electrical equipment for the connections;

Cut prevention gloves;

Tester and amperometric pliers.

PRELIMINARY INFORMATION

14

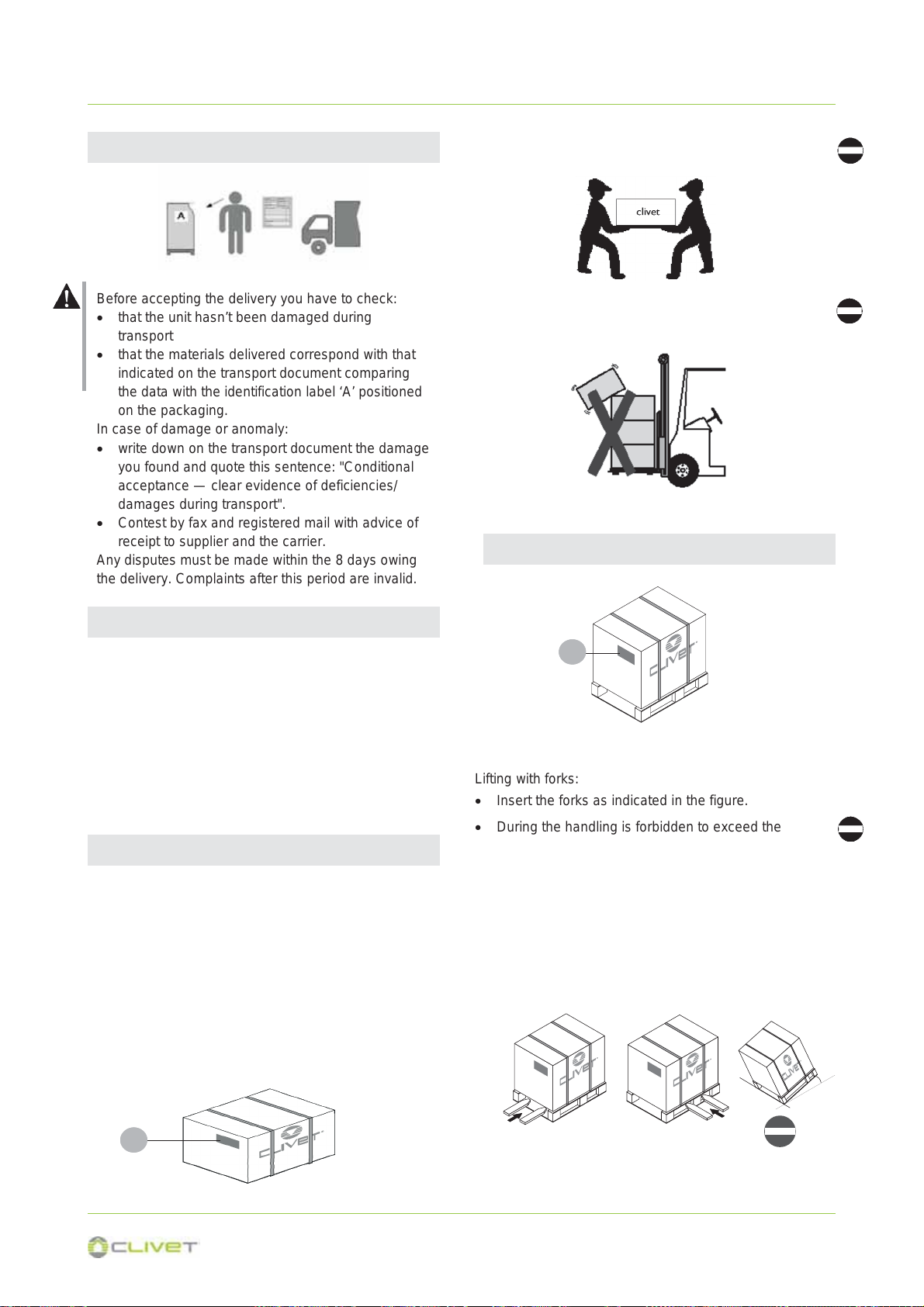

2 - RECEPTION

Lifting with forks:

x Insert the forks as indicated in the figure.

x During the handling is forbidden to exceed the

maximum allowable inclination as indicated in the

figure.

x It is forbidden to lift simultaneously more packages

letting them looses.

x In case of lifting of more units at the same time, an

appropriate container must be used.

A

30°

Before accepting the delivery you have to check:

x that the unit hasn’t been damaged during

transport

x that the materials delivered correspond with that

indicated on the transport document comparing

the data with the identification label ‘A’ positioned

on the packaging.

In case of damage or anomaly:

x write down on the transport document the damage

you found and quote this sentence: "Conditional

acceptance — clear evidence of deficiencies/

damages during transport".

x Contest by fax and registered mail with advice of

receipt to supplier and the carrier.

Any disputes must be made within the 8 days owing

the delivery. Complaints after this period are invalid.

2.1 DELIVERY CONTROL

CPAN-U 70 - 120

CPAN-U 200 - 500

A

A

x Do not leave loose packages during the transport

x Do not trample

The following examples are indications; the choice of

the means and of the handling modes will depend on

factors, such as:

x The unit weight

x Type and overall dimensions of the unit

x Place and route for the handling (dirt yard,

asphalted square, etc.)

x Condition of the place of destination (roof, square,

etc.) distances, drops and gradients.

Shelter from: direct sunlight, rain, sand and wind.

Stocking temperature:

maximum 50°C

minimum -10°C

The respect of the instructions on the exterior side of the

packaging assures the physical and functional integrity of the

unit for the final user’s advantage.

2.2 - STORAGE

15

2 - RECEPTION

A

G

B

C

D

E

F

2.2 KIT REMOVAL

CPAN-U 70 - 120 CPAN-U 200 - 500

The unit is supplied in a single pack and is equipped

with:

1 installation manual

2 installation kit - Ambient thermostat

Installation kit

A spring antivibrations n.4

B M8 nuts n.4

C plain washers n.4

D toothed washers n.4

E M8 bolts n.4

F ambient thermostat

The unit is supplied in a single pack and is equipped

with:

1 installation manual

2 installation kit - Ambient thermostat

1

2

Packing removing

Be careful not to damage the unit.

x Cut the fixing strips.

x Remove the packaging lifting it upwards.

x Remove the protective nylon.

Keep packing material out of children's reach it may be dangerous.

Recycle and dispose of packing material in conformity with local regula-

tions.

16

3 - POSITIONING

The installation has been implemented by qualified

technical personnel only and that the instructions con-

tained in the present manual and the local regulations

in force have been adhered to.

Intended use

Use the unit for the air treatment.

Follow the limits defined in the technical bulletin and

on this manual.

Do not treat air with :

high concentrations of dust

aggressive substances

residues from industrial processing.

The unit has been designed to be installed :

x indoor

x in fixed position

The unit can not be installed outdoor or in a room /

compartment where the temperature can drop

below 0 ° C.

Choose the installation place according to the follo-

wing criteria:

x customer approval

x safe accessible position

x the operation noise and air flow expelled shall not

affect neighbors

x spaces for conduits

x avoid flood-prone places;

x verify the unit weight and bearing point capacity;

x verify that all bearing points are aligned and lev-

elled

x unit in bubble level

x plan in the false ceiling (or in the floor) the open-

ings indicated in the functional clearances to allow

the access to the unit for the maintenance opera-

tions

x Ceiling positioning : let free the projection to the

ground of the unit and of the functional clearances

to allow the access with ladders or other means

x Floor positioning : install the unit raised from the

ground .

Limit vibration transmission:

x use antivibration devices on unit bearing/

supporting points

x install flexible joints on the hydraulic/aeraulic con-

nections.

Neglecting these aspects may decrease the unit per-

formances and life.

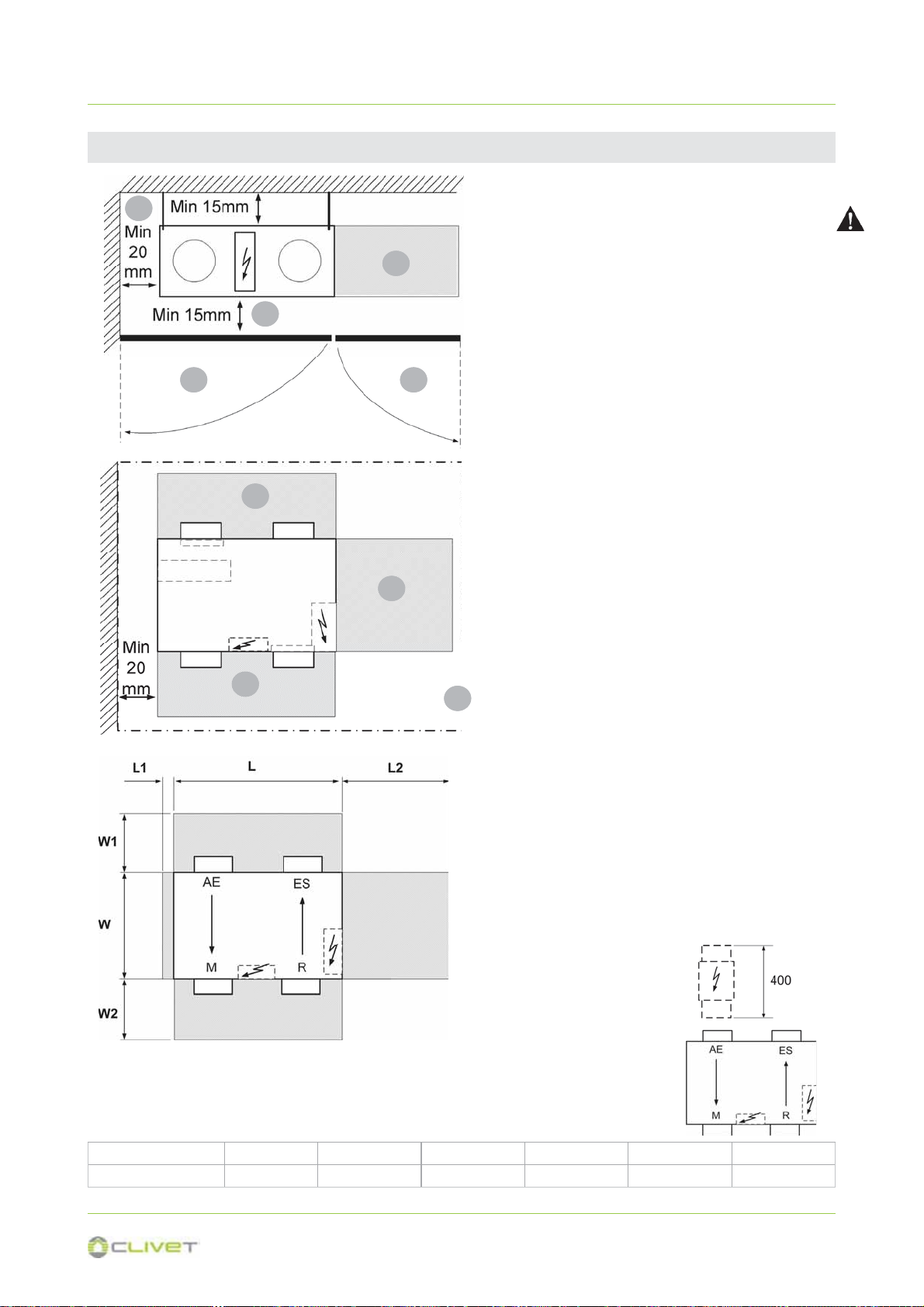

3.1 CLEARANCE ACCESS RECOMMENDED

UNIT IN BUBBLE LEVEL

Size 70-120 200-300 500

A (mm) 636 666 710

B (mm) 755 760 993

UNIT FIXING POINTS

Consider sound emissions

Avoid installations next to bedrooms

If the unit is installed near bedrooms, it is recommended

that acoustic insulation is arranged.

The functional clearances have to :

x guarantee the unit good operating

x allow the maintenance operations

x safeguard the authorized operators and the ex-

posed person.

x position the unit taking into consideration the clear-

ances indicated in the figure.(following pages)

x consider the space necessary for return ambient

filter extraction (see option).

17

3 - POSITIONING

Mod L1 L L2 W1 W W2

70 - 120 20 mm 800 mm 500 mm 300 mm 590 mm 300 mm

AE fresh air intake

ES air expulsion

MAmbient air distribution

RAmbient air return

CPAN-U 70 - 120

A Distance to prevent vibrations from being

transmitted.

B Trap door for routine maintenance (access to the

connections of the electrical panel, air filters and

the optional electronic filter)

C Trap door for extraordinary maintenance

D Access to the electrical panel

E Access to clean the filter (air filters)

F Access to conduct extraordinary maintenance (to

replace the fan, compressor, etc.)

Heat. el. = If there are heating elements, increase the W1

value (information on heating elements on page 71)

Heat. el.

D

A

A

CB

D

E

E F

18

3 - POSITIONING

Mod L1A L1B L1C L L2 W1 W W2

200 700 mm 400 mm 200 mm 920 mm 20 mm 300 mm 704 mm 300 mm

300 700 mm 400 mm 200 mm 920 mm 20 mm 300 mm 704 mm 300 mm

500 700 mm 400 mm 200 mm 1158 mm 20 mm 300 mm 741 mm 300 mm

CPAN-U 200 - 500

AE fresh air intake

ES air expulsion

MAmbient air distribution

RAmbient air return

CPAN-U 200 - 500

A Space to access the electrical panel

B Space necessary for the by-pass damper

C Distance to prevent vibrations from being transmitted

(insert a neoprene sheet)

D Trap door for routine maintenance (access to electrical

panel and optional electronic filter)

E Access to conduct extraordinary maintenance (to

replace the fan, compressor, etc.)

F Access to fan removal

G Access to clean the filter (exhaust air filter - option)

Heat. el. = If there are heating elements, increase the W1

value (information on heating elements on page 79)

Heat. el.

L1A ceiling installation, filter access from below, non-remote electrical control board at a distance

floor installation, lateral filter access, non-remote electrical control board at a distance

L1B floor installation, lateral filter access, remote electrical control board at a distance

L1C ceiling installation, filter access from below, remote electrical control board at a distance

A

B

C

E

D

A

F

G

F

G

19

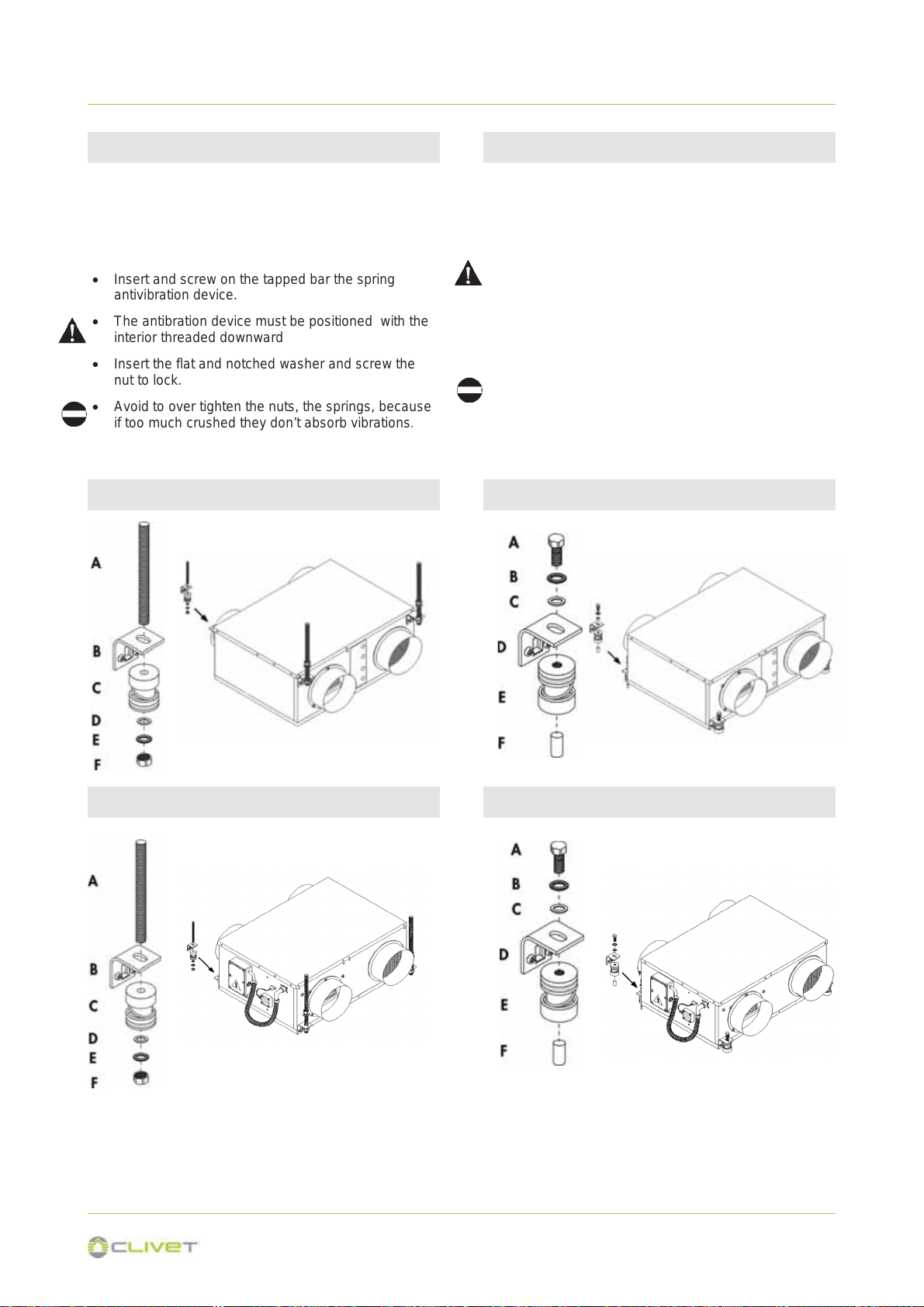

x Fix some M8 threaded bars (not supplied) to the

ceiling.

x Pass the M8 threaded bars in the brackets on the

unit.

x Insert and screw on the tapped bar the spring

antivibration device.

x The antibration device must be positioned with the

interior threaded downward

x Insert the flat and notched washer and screw the

nut to lock.

x Avoid to over tighten the nuts, the springs, because

if too much crushed they don’t absorb vibrations.

x Insert the M8 threaded bar on the support base.

x Match the upper hole of the antivibration device

with the hole of the support bracket.

x The antibration device must be positioned with the

interior threaded upward.

x Insert the flat and notched washer in the bolt.

x Screw the bolt in the top of the antivibration device

letting it pass through the hole on the bracket.

x Do not over tighten the nuts, the springs, because if

too much crushed they don’t absorb vibrations

3 - POSITIONING

3.2 CEILING POSITIONING 3.3 FLOOR POSITIONING

A threaded bar

B bracket

C antivibration foot

D flat washer

E notched washer

F nut

A bolt

B notched washer

C flat washer

D bracket

E antivibration foot

F threaded bar

CPAN-U 70 - 120 CPAN-U 70 - 120

CPAN-U 200 - 500 CPAN-U 200 - 500

20

The electrical panel is provided assembled on the unit

side but if necessary it can be remotely controlled up to

2 mt. away.

Electric panel

3 - POSITIONING

3.4 ELECTRIC PANEL

CPAN-U 70 - 120 CPAN-U 200 - 500

Remote positioning

x Unscrew the fixing screws and remove the

electrical panel cover.

x Unscrew the fixing screws (M6) and remove the

panel from the unit side.

x Fix the panel using screws and screw anchors

suitable for the characteristics of the used support.

x If later it is supposed the installation of the electric

elements (optional) consider that the cable to

connect to the electrical panel has a max length of

1,5 metres.

x In this case the filter removal for cleaning can be

performed either from the side or from below.

Access to the electrical panel:

Afrom below

Blateral

A

B

L = 2mt

Other manuals for ELFOFresh2 CPAN-U 70-120 Series

1

This manual suits for next models

2

Other CLIVET Air Cleaner manuals