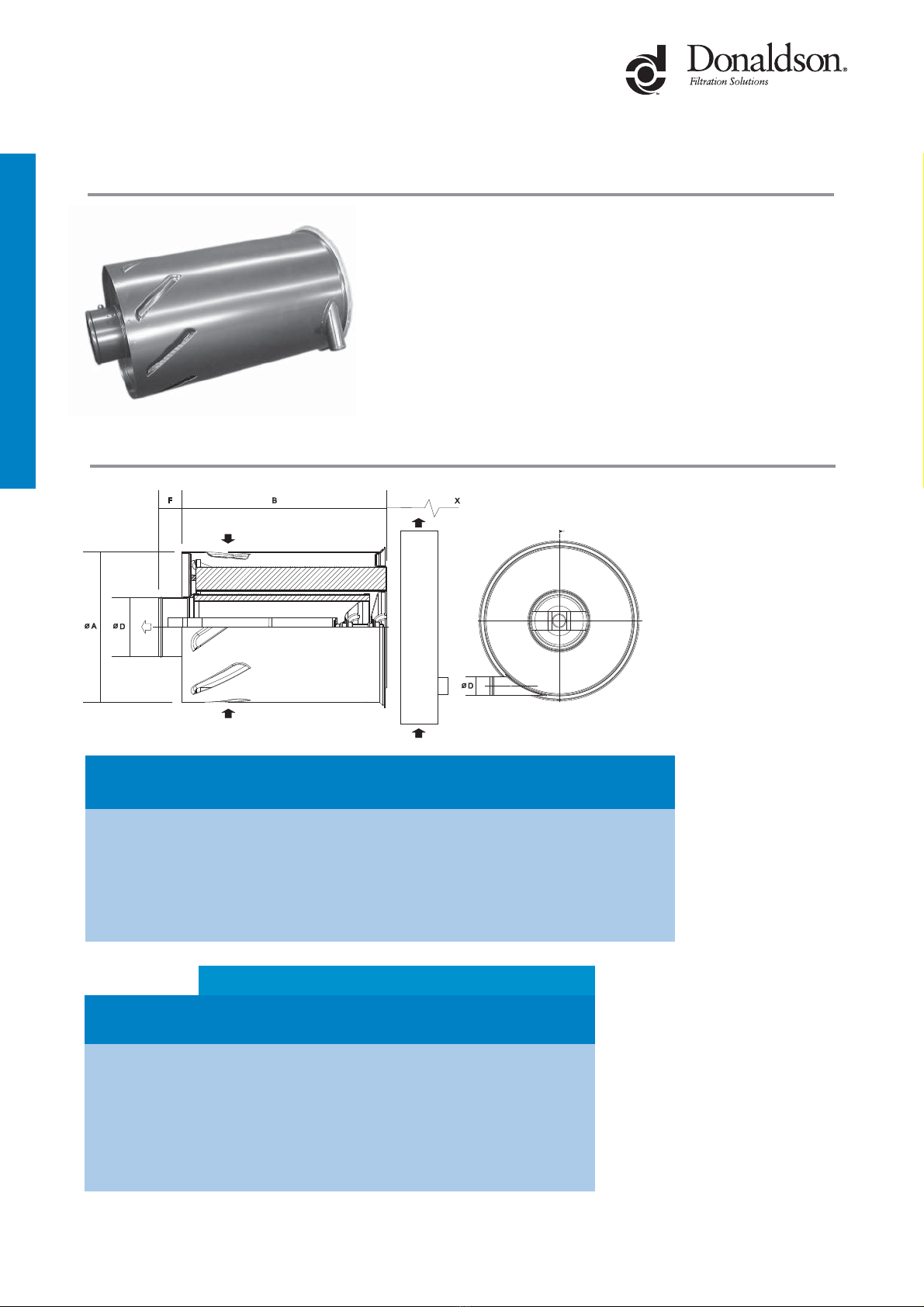

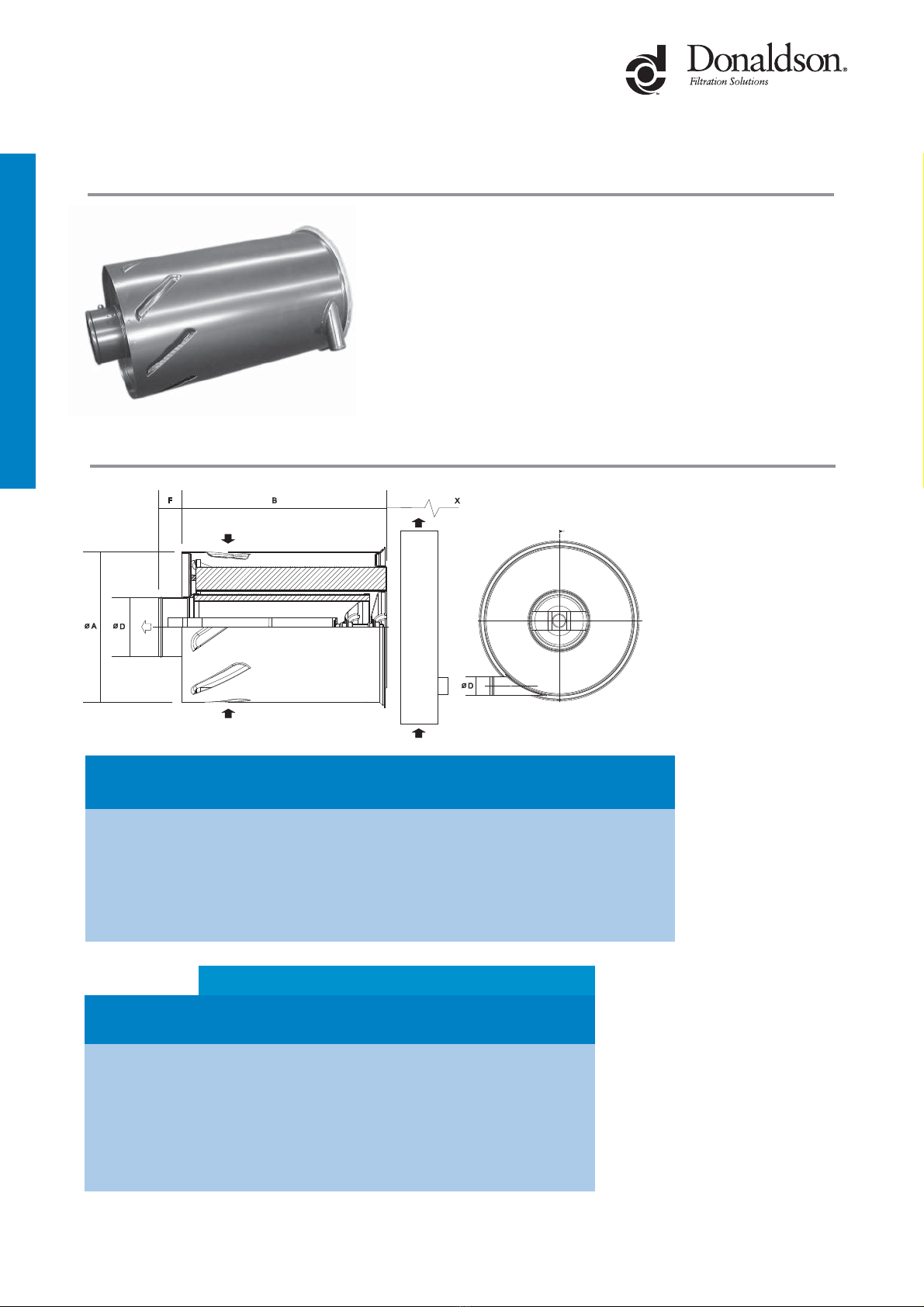

FLB Air Cleaner

90

Q

Engine Air Cleaners, Accessories & Service Parts

Heavy Dust Conditions

Two-Stage Louvered Body Air Cleaner

The FLB - Louvered Body Air Cleaner is a two-stage air cleaner with

scavenge exhaust system and Axial Seal Sealing Technology. Body

diameters in 6", 8", 10" and 12". Handles airflows of 3-17 m³/min.

Sustained temperature tolerance: to 82°C.

Designed especially for combines and other heavy-duty construc-

tion and agricultural equipment operating in severe dust, fibers, lint

and shaft environments. To be used with an exhaust ejector.

For all available Donaldson Exhaust Ejectors, see page 124-125.

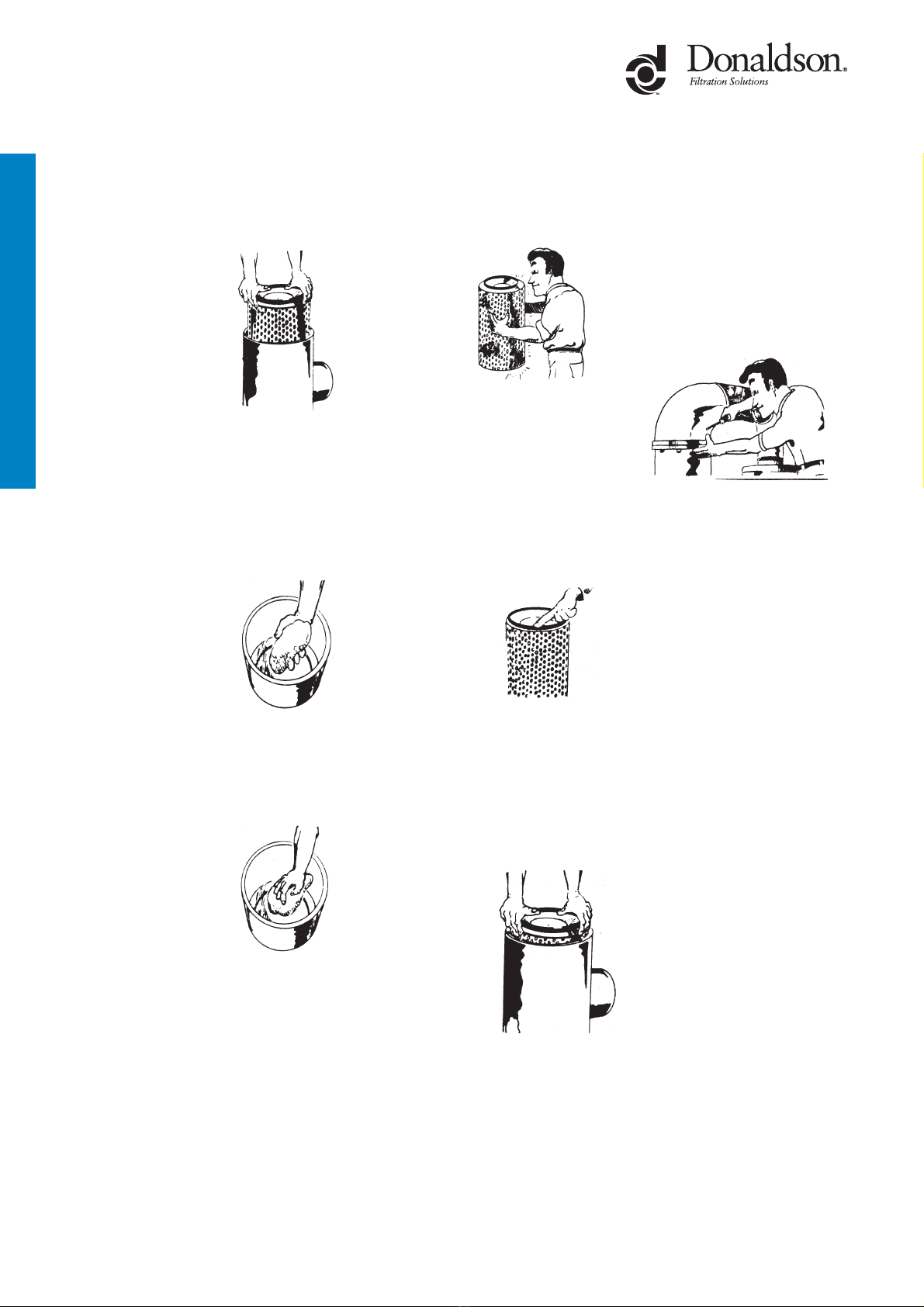

Air Cleaner Airflow Range Dimensions (mm)

Model No m³/min. A B D F G X°

B065018 3 - 5 167 360 76 28 32 345

B080022 4,5 - 7 203 423 89 54 32 415

B100067 7 - 12 259 430 101 50 32 425

B120260 12 - 17 300 424 127 80 32 415

X° Free space needed to remove main element

Air Cleaner Main Safety Mounting Filter

Model No. Element Element Band* Wing Nut

B065018 P772565 P770207 P007191 P138403

B080022 P772556 P119410 P004307 P138403

B100067 P772530 P133138 P004076 P138403

B120260 P772520 P770678 H000349 P134803

* Two mounting bands needed per Air Cleaner

FLB Specifications - Service Parts

Service Parts