V2.1 2021-01 Page iii of iv

Contents

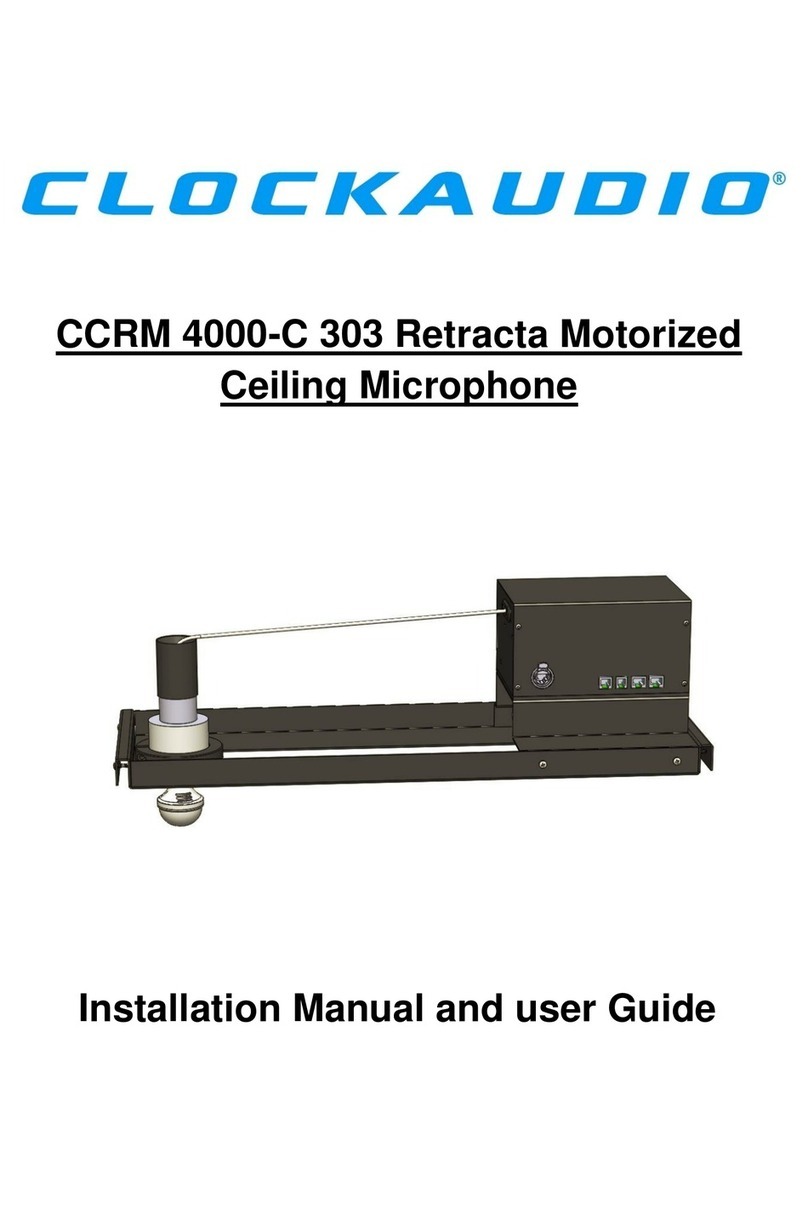

1 Overview ......................................................................................................................................... 1

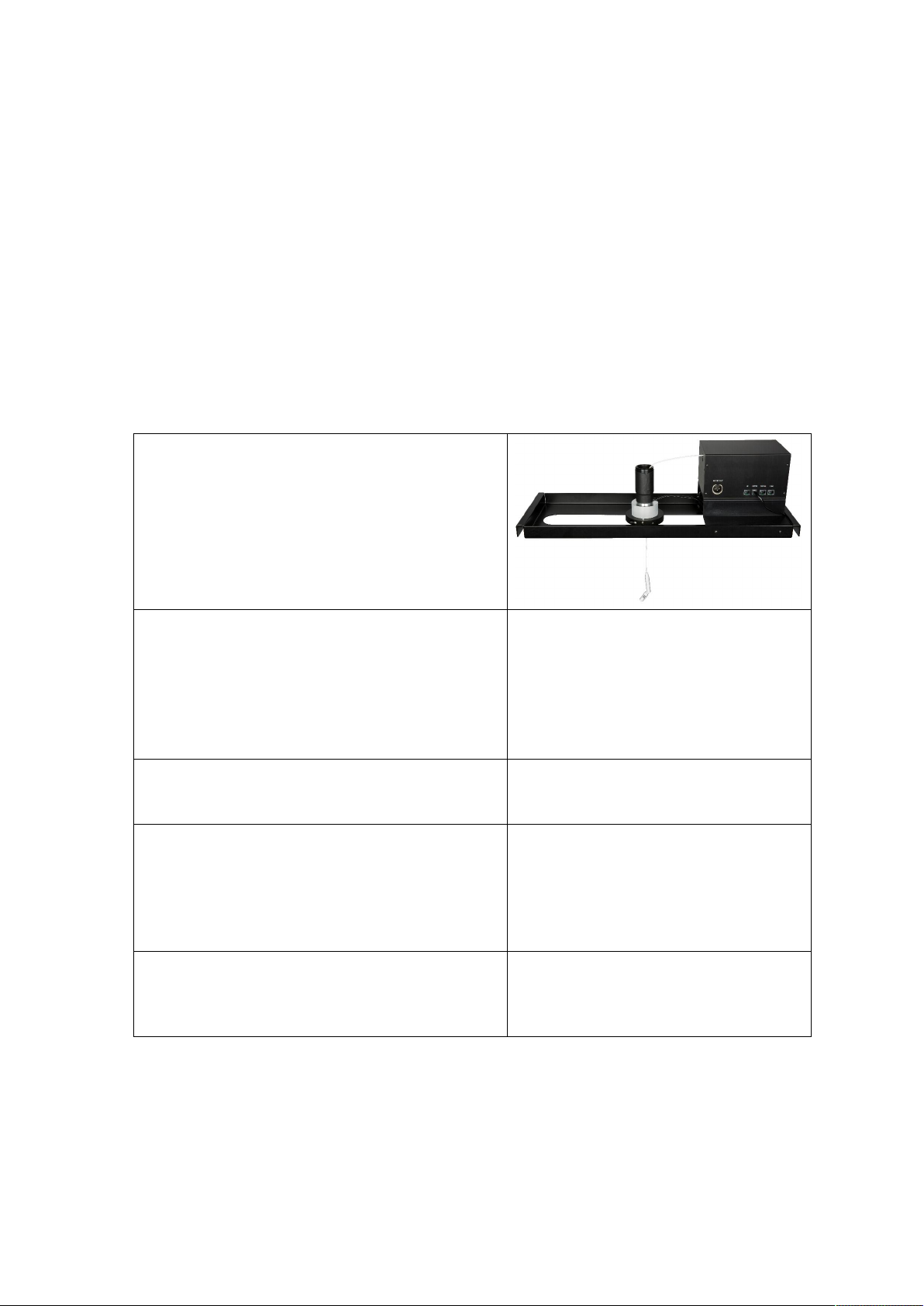

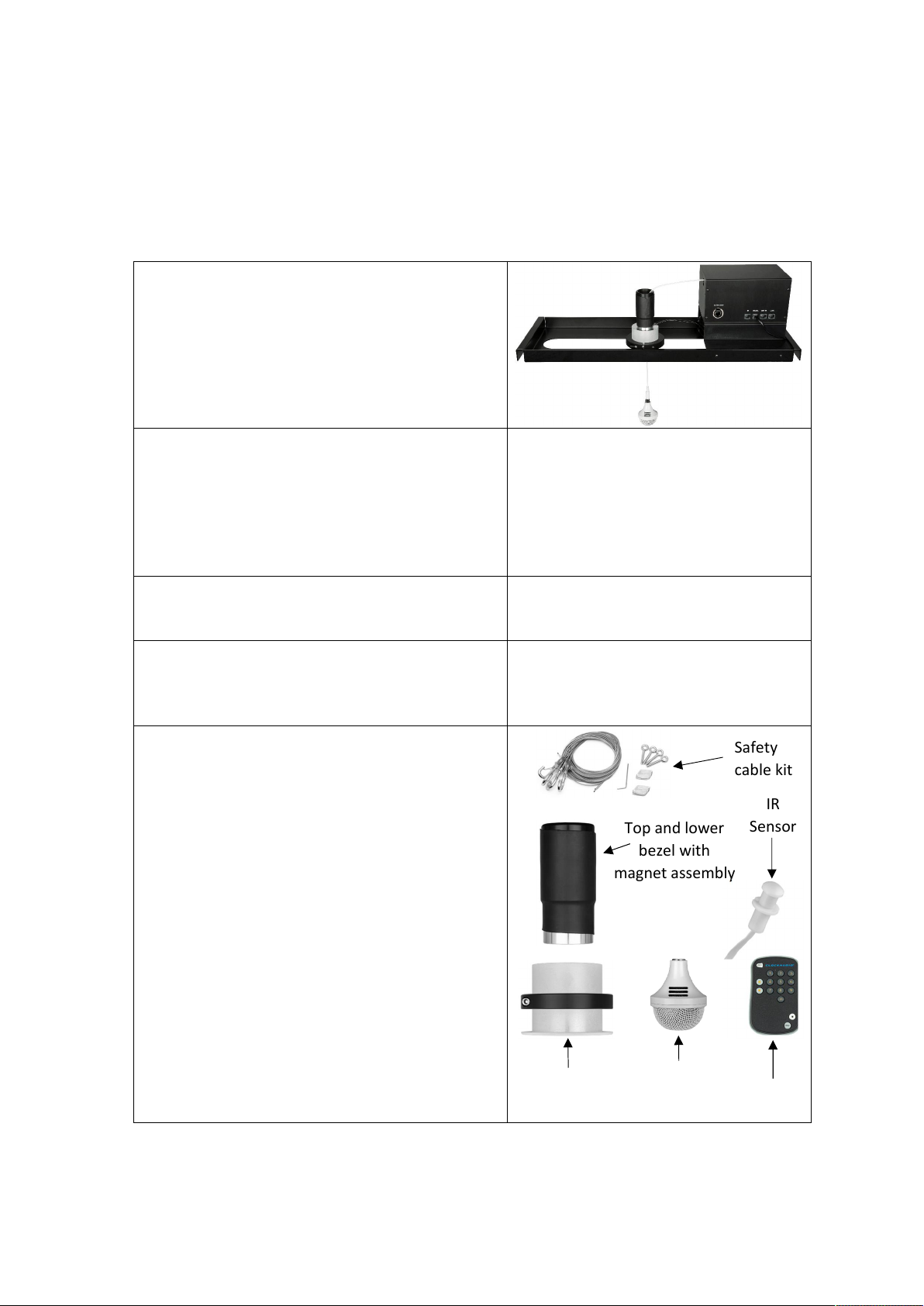

2 Package Contents ............................................................................................................................ 3

3 Installation ...................................................................................................................................... 4

3.1 Single Element version of CCRM 4000 .................................................................................... 4

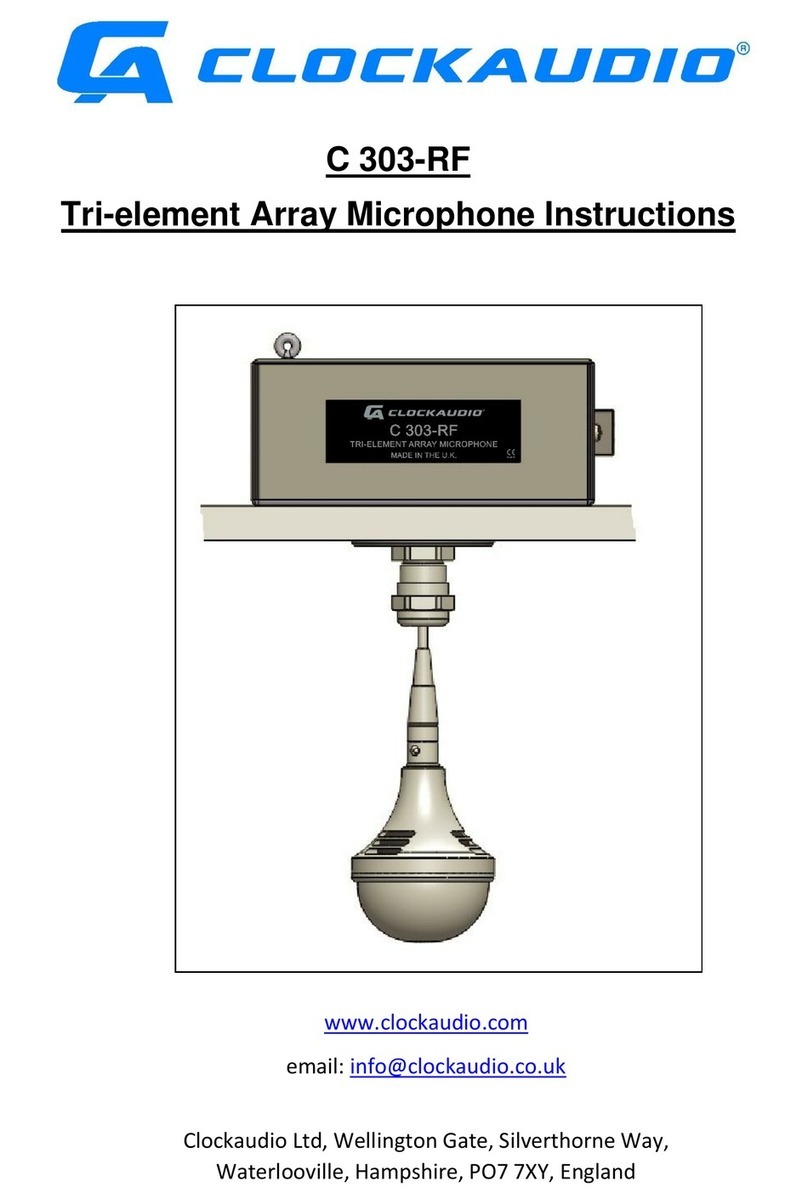

3.2 Tri Element version of CCRM 4000 ......................................................................................... 8

3.3 IR Sensor Installation ............................................................................................................ 11

3.4 Secondary unit wiring connections ....................................................................................... 11

3.5 Further Secondary wiring connection ................................................................................... 12

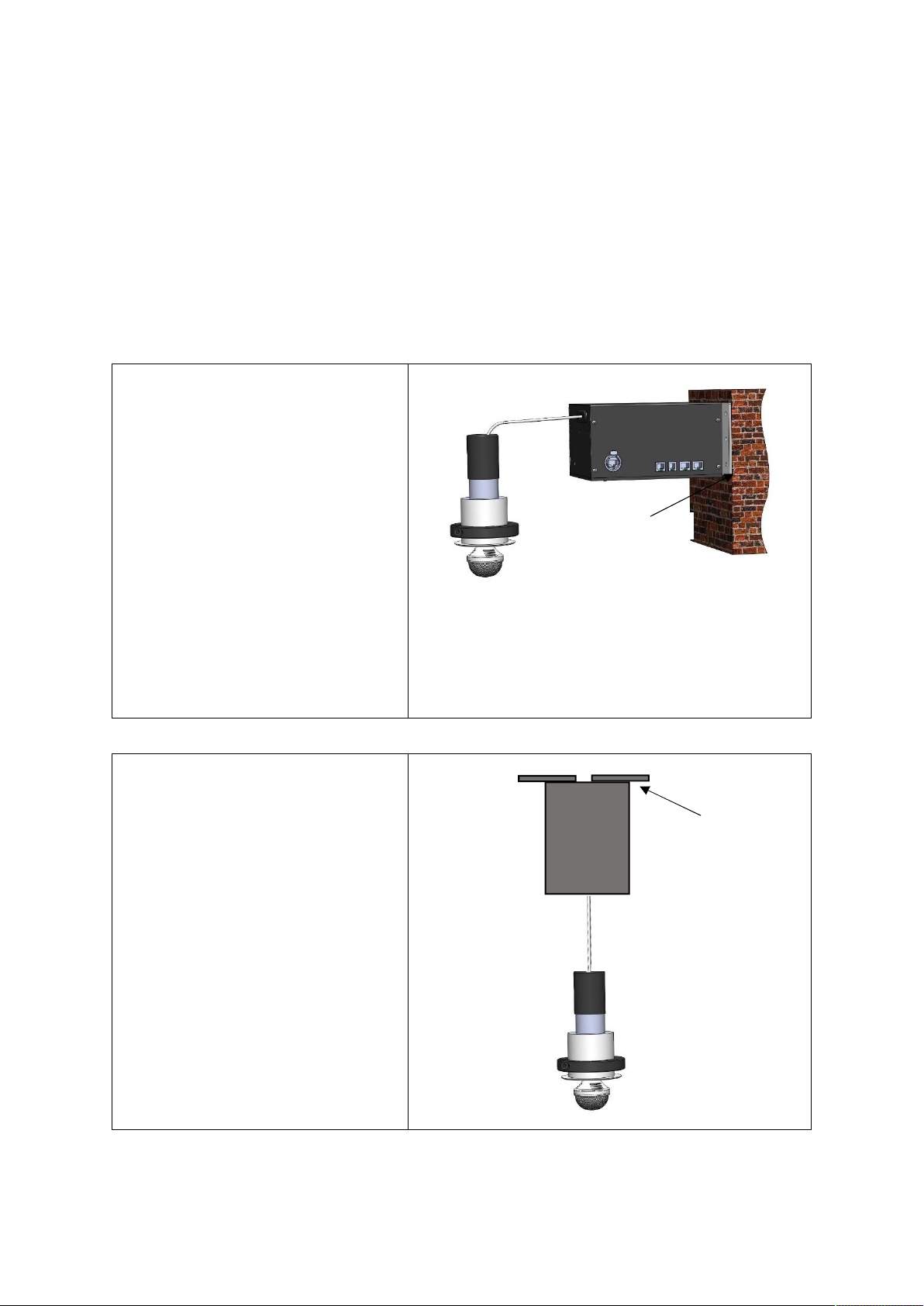

3.6 Horizontal / Vertical mounting ............................................................................................. 13

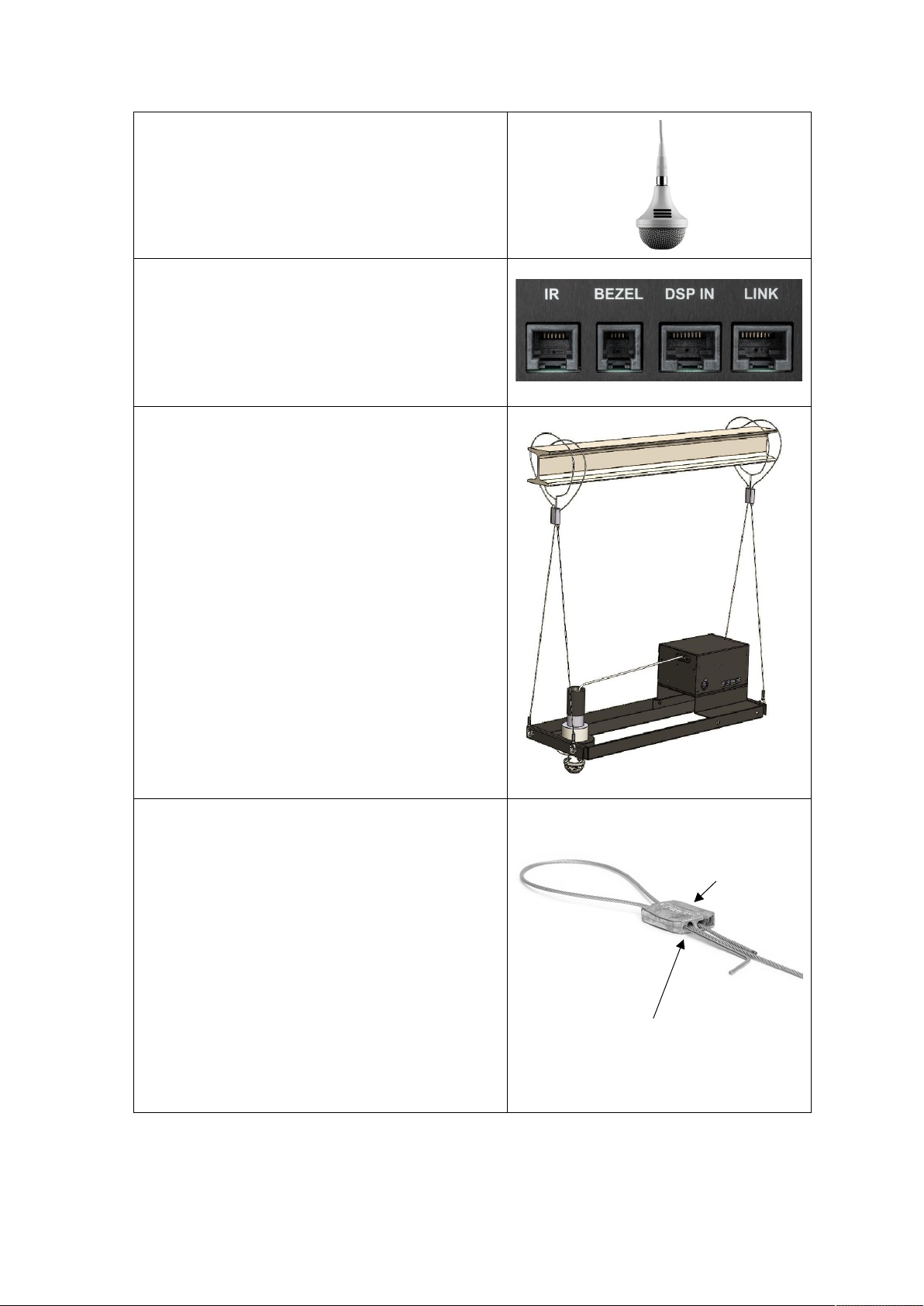

4 Controls and Connectors .............................................................................................................. 14

5 Connecting to DSP ......................................................................................................................... 16

5.1 CCRM 4000 DSP IN Connector .............................................................................................. 16

5.2 Main Unit Cable Wiring Connections using a DSP ................................................................ 16

5.3 DSP Mute Control ................................................................................................................. 17

5.4 Audio Out Socket .................................................................................................................. 18

5.4.1 Single Element version .................................................................................................. 18

5.4.2 Tri Element version ....................................................................................................... 18

6 Programming CCRM Cable Height ................................................................................................ 19

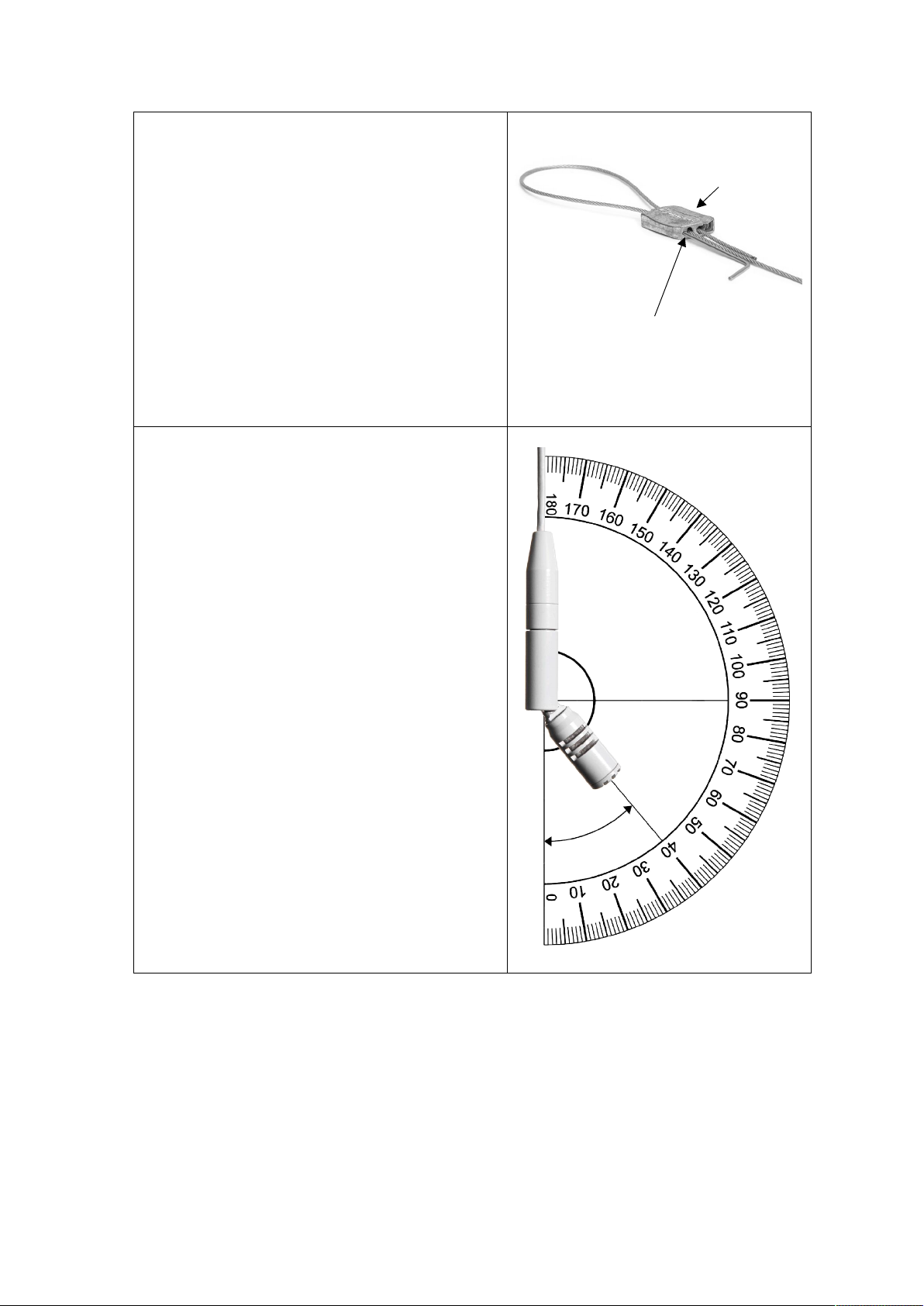

6.1 IR Remote Control Operation ............................................................................................... 19

6.2 IR Remote Layout .................................................................................................................. 19

6.3 IR Remote Control Additional Information ........................................................................... 20

6.4 Programming Cable Height on Main Unit ............................................................................. 20

6.5 Programming Cable Height on Secondary Unit .................................................................... 21

6.6 Programming Multiple Units ................................................................................................. 21

6.7 Microphone Deployment Safety Feature ............................................................................. 21

7 Troubleshooting ............................................................................................................................ 22

8 Specifications ................................................................................................................................ 23

9 Product Warranty ......................................................................................................................... 24

10 Product Disposal ........................................................................................................................... 25