Clockaudio CCRM 4000-Retracta Guide

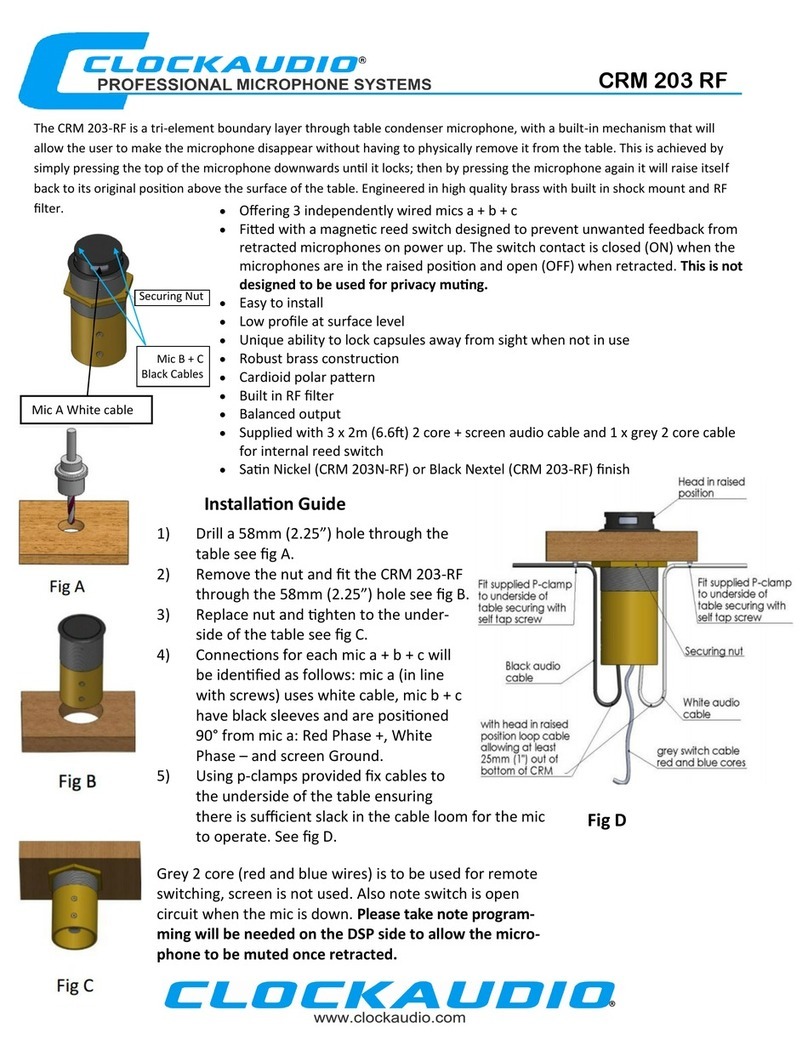

CCRM 4000-Retracta Motorized Ceiling

Microphone

Installation Manual and user Guide

1

Contents Page

Contents 1

Features 2

Parts supplied 3

Connections 4

Installation 5-8

Controls 9

DSP Connections 10

Mute Control 11

Master to DSP Connections 12

Slave Connections 13

IR Remote Control 14

Remote Control Information 15

Programming Master Cable Height 16

Programming Slave Cable Height 17

Microphone Angle Adjustment 18

Horizontal / Vertical Mounting 19

Slave Communication Link 20

Cautions / Troubleshooting 21

Specification 22

Warranty 23

IMPORTANT SAFETY INSTRUCTIONS

Read these instructions carefully as they contain important information

concerning safety and safe operation of this equipment..

Heed all warnings in this manual they are there for the safety of you and others.

Keep these instructions in a safe place in case they need to be referred to later.

Do not install near sources of heat or water. Clean with dry cloth only.

Use only with the bracket supplied.

Do not burn or incinerate the remote control battery. Danger of explosion.

WARNING: Do not connect a supply Voltage until the CCRM 4000 is fixed securely in

place, IR sensor connected (if fitted / Master only), Ceiling bezel is mounted in the

ceiling tile, microphone and magnet has been passed through the Ceiling Bezel and

all other connections have been made.

Do not power the system off when the cable is fully extended. Always retract the cable back

to the ceiling bezel after use.

Do not angle the microphone more than 40 degrees or it will become jammed In the

bezel

2

Features

Control ports allow DSP connection and Link / daisy chain expansion to other

CCRM 4000 Retracta units.

A positive (+2.5V to +12V) signal applied to the MASTER DSP control port will

simultaneously operate all slave units connected to the master.

Logic Hi / Lo for DSP mute detection port.

Master & Slave units are Identical in construction. Two rotary 0-9 digital

decimal encoders are used to set Master (00) and 01 –99 determines slave

designation. The factory default is set to Master (00).

XLR socket allows easy and fast connection of the audio to mixer or DSP. A

9-48 Volt phantom power is required.

IR remote control is supplied with the master unit. Remote control can be

used to activate the units in the absence of a DSP.

IR receiver sensor with integral green programme mode led and red range led

(supplied with master unit).

Audio cable length 2.5 Metres.

Supplied with 350 degree rotation, 40 degree knuckle joint angle microphone

with cardioid polar pattern.

Up to 99 slave units can be daisy chained to the master.

Ceiling bezel fitted with detection switch.

Universal mains switched mode power supply available as separate item.

Operates up to 4 units.

Automatic safety detection for cable hang-ups.

3

Parts supplied with CCRM- 4000 Master

1. CCRM-4000 Retracta unit complete with microphone

2. IR receiver sensor (CCRM-4000-IR)

3. IR remote control (CCRM-4000-R)

4. 2 x wall fixing brackets

5. Safety hook and wire harness

6. Installation manual

7. Ceiling tile fixing bracket (CCRM-4000-Rack)

8. White ceiling Bezel with pulley (CCRM-4000-BW)

9. 18 VDC universal power supply (PS-018)

Parts supplied with CCRM-4000 Slave

1. CCRM-4000 Retracta unit complete with microphone

2. White ceiling Bezel with pulley (CCRM-4000-BW)

3. 2 x wall fixing brackets

4. Safety hooks and wire harness

5. Installation manual

6. Ceiling tile fixing bracket (CCRM-4000-Rack)

4

CONNECTIONS BLOCK DIAGRAM

Important: When using a DSP to control the system make

sure that the DSP control signal is already outputting to

SK3 on the CCRM 4000 master (+2.5 to 12 Volts) before

powering the system up otherwise the DSP command will

not be recognised by the system and will fail to operate.

5

Installation

The CCRM 4000 is supplied partially disassembled and simply requires reassembly /

push to fit. Below is picture of the fully assembled unit.

To prevent unnecessary damage to the system it’s vitally important to follow

the instructions below:

1. Remove the CCRM 4000 system from its transportation box and remove the 2

foam end caps.

2. Cut the tape securing the large cardboard box to the large black ceiling frame.

3. Carefully move the box out of the ceiling frame and set to one side being

careful not to snag or cause the microphone cable to kink. Do not remove

the microphone and pulley assembly at this stage.

4. Remove the small cardboard box located under the CCRM 4000. This

contains the PSU (master only).

5. Now open the large cardboard box and remove from the packaging the large

lower bezel with bezel clamp.

Wall mount

IR sensor

Remote

Top bezel with

pulley

Microphone

6

To install this system a (65 mm) (2.5") hole must be cut into the ceiling tile to allow

the large lower bezel just removed from the packaging to be fixed to the tile. The

hole should ideally be cut in the centre of the tile and must not be closer than

(76mm) (3") from the edge of the tile or it will not be possible to align the CCRM

4000 support bracket over the hole.

Take the entire CCRM 4000 kit up to the final location site. Carefully align the

CCRM 4000 complete with ceiling tile bracket so that the large slot is directly

over the hole that has previously been cut in the ceiling for the bezel. Make

sure that the front and back of the bracket fits snugly over the ceiling tile “T-

Bar rails”. Secure the ceiling bracket to the T Bar rails using the four eye bolts

finger tight.

(65mm) 2.5" Hole

Insert the bottom part of the bezel up through the ceiling tile through the hole

and slot in the tile bracket. Secure the bezel in place with the securing ring.

7

Now carefully remove from the foam packing the IR sensor, pair of metal

fixing brackets with screws, remote control and 4 cable fixing kits and set

aside. Next remove the top bezel containing the pulley along with the

microphone and magnet assembly.

1. Remove the protective covering on the microphone and insert the

microphone through the lower ceiling bezel and then push fit the top part

of the bezel to the lower bezel making sure the magnet is inside the top

part of the bezel.

2. Carefully twist the bezel around until the pulley / cable is in alignment with

the cable exiting the CCRM 4000. Lift the cable over the top of the pulley.

Any kinks or bends in the cable can be straightened by gripping the

cable with your hands and passing it through a clean dry cloth a few

times.

8

IMPORTANT: For safety reasons the frame to ceiling tile fixing eye bolt (2 at

each end of the bracket) are used to secure the frame in place and also used to

suspend the CCRM 4000 and bracket. It is suggested that the cable hook is

attached to the eye bolts leaving the bare wire end to a secure fixing such as a

ceiling truss or any structure capable of taking 7Kgs of weight. The cable

length is 2 Metres (78").

Thread the other end of the cable through one of the holes on the quick release

locking device tube observing the direction arrows on the locking device. The tube is

spring loaded and when pressed will allow the cable to be pulled back out Pass the

cable over a beam or through a hanger of your choice then pass the cable through

the other tube on the locking device observing the direct arrows and pull the cable

until the slack is taken up on the cable. Repeat for the remaining 3 safety cables.

Quick release cable locking device allows for fast connection and

disconnection of the safety cable to the CCRM 4000 eye bolt. The cable

once threaded cannot be removed / pulled back out unless the loading

tubes are first pressed inwards.

9

Controls and Connections

Decimal rotary (Units)

Decimal rotary (Tens)

Termination impedance switch

18Vdc power In/Out socket

- Negative

+Positive

Sk4 Coms link to next slave

Sk3 DSP/Mute connection

Sk2 Ceiling Bezel connection

Sk1 IR connection

10

DSP Connections

The table below lists the pin functions for DSP control signals to the master unit.

Slave units require just a daisy cable link ( standard straight RJ45 male to male

cable required) between master and slave units. Check that the DSP control signal is

present logic +2.5 to 12 Volts is required. It is important that the DSP + command signal is

already present before powering the system up.

The logic control signal (pin 1) is an optically isolated input with a dedicated return

connection (pin 2). Voltages as low as 2.5V DC are recognised as a ‘logic high’ input

which will command the master unit (and any connected slaves) to deploy their

microphones to a preset height. A ‘logic low’ (0V DC) will command all units to raise

their microphones to the ceiling.

SK3 Pin No.

Function:

DSP MUTE

FEEDBACK

1

Logic Control Signal Input:

Between +2.5V DC and +12V DC: Microphones down to set-height.

0V: Microphones up to ceiling bezel switch.

2

GND Return for Logic Control Signal.

Note: This is not a common GND for the unit, it is the return leg of an

optically isolated input.

3

Mute Feedback Signal.

Open collector output that requires a pull-up resistor (10K Ohm) at the DSP

to function correctly.

0V: Microphones not deployed (Mute)

High Impedance (Pulled-Up to voltage): Microphone deployed (Un-Mute)

4

GND Return for Mute Feedback Signal.

Note: This is not a common GND for the unit, it is the return leg of an

optically isolated output.

5

RS485 (+) Communications (Not used on master unit)

6

RS485 (-) Communications (Not used on master unit)

7

RS485 0V (Not used on master unit)

8

Unused

11

DSP Mute Control

As detailed on the previous page, each unit is provided with an optically isolated

open-collector output for the mute signal which is accessed through the DSP socket

on the master. Muting of the microphones has to be performed by a DSP. If using IR

remote then it will not be possible to mute.

The drawing below represents an equivalent circuit for the mute signal which shows

how the open collector output on each Retacta is connected in parallel when the

units are connected together using the correct RJ45 connection cable.

Mute Signal Equivalent Circuit

SK3 Pin 3

SK3 Pin 4

SK3 Pin 3 or

SK4 Pin 3

Master

SK3 Pin 4 or

SK4 Pin 4

Slave 1

SK3 Pin 3 or

SK4 Pin 3

SK3 Pin 4 or

SK4 Pin 4

Slave 2

SK3 Pin 3 or

SK4 Pin 3

SK3 Pin 4 or

SK4 Pin 4

Slave ‘n’

DSP

Unit

Pull-Up Resistor

(10K Ohm)

V

DSP

I/P

Common Mute Signal

Common Mute Signal Return

To function correctly, the common mute signal from all units must be connected via

an external resistor (not supplied) pull-up resistor to an arbitrary voltage (V) at the

DSP as illustrated above. The arbitrary pull-up voltage (e.g. 5V DC or 12V DC) can

either be supplied by the DSP itself (preferred option), or by an external voltage

source, although if an external voltage source is used, the 0V return must be

common with the DSP 0V.

When the microphones are not deployed, the voltage on the common mute signal

will be pulled to the common signal return (logic low at the DSP input). The DSP

input will only switch to the logic high state when all microphones are deployed and

resting at the preset height.

Note that the common mute signal must be provided with an external voltage through

a 10K Ohm pull-up resistor, the mute signal will not function without this.

12

Master Unit Cable Wiring Connections using a DSP

1. Connect socket (3) to the DSP making sure that all parameters are met in

accordance to the instructions shown under “Mute Control” and Logic Hi /Lo

2.5V –12V required for activation.

2. Connect the XLR microphone audio output to DSP audio input. If connected

to a mixer then the mute will not be detected and the microphone will always

be live. The DSP is used to mute the microphone. Note Phantom power

must be supplied to the XLR microphone socket.

Termination Impedance (Z switch)

On each of the units is a slide switch “Z” In a multi system 10 or more units it is only

the final slave unit that needs to have this switch ON and all other units switches

must be OFF.

On Off

IR SENSOR INSTALLATION

Mount the IR sensor in a position (ceiling or wall) where it will be convenient to see

all the Retracta movements whilst maintaining good line of site with the IR sensor.

Do not place any obstruction in front of the sensor as this will prevent operation. Drill

a (16mm) (5/8") diameter hole. Pass the sensor through the hole and secure it using

the C clip. Connect the cable to the IR sensor input socket number 1 on the

Retracta unit. IR sensor has 2 coloured led’s: Green = In programme mode, Red =

will show each time a button is pressed on the remote.

13

Slave wiring connections

When adding a second Retracta unit (slave 01)

1. Connect a DC supply cable between the Master and slave DC input sockets.

Make sure that the correct polarity is applied to the Phoenix plug supplied

Positive (+) Negative (-)

2. Connect socket (4) on the master to socket (3) on the slave unit using an

RJ45 straight through cable. (if further slaves are connected then link between

socket (4) and socket (3) of the next slave and so on (daisy chain).

3. Bezel cable . Connect the cable to socket (2) on the slave.

4. Connect the DSP microphone audio input to the XLR audio out socket.

5. Make sure that the “Units” decimal rotary switch is set to “1” (01)

Further Slave wiring connections

1. Up to 99 Slaves can be linked together in the same / identical way as

described above under “adding a second cable Retracta”.

2 Repeat the same instructions shown under heading of Slave wiring

connections and link between / daisy chain between sockets 3 and 4 of each

slave unit.

3 Make sure that the “Units” decimal rotary switch on each subsequent slave

units are set to “2”for the 2nd slave, “3” for the 3rd slave etc etc....

14

IR Remote control operation

The remote is primarily intended to allow the initial programming of the desired

height for each individual winch in the system. The preferred operation is then by

logic input from a DSP logic high of 2.5V to 12V is required to release microphone to

programmed height and a logic 0 low will raise the microphone. The IR remote

Up/Down buttons can be used if a DSP is not used. Open the battery compartment

pull and remove the battery insulator / protector.

IR Remote Layout

Aux: Used to programme the remote.

Up: Used to rewind cable upwards

Down: Used to deploy cable downwards.

Enter: Used to complete / store a programme.

Setup: Only used to programme the remote.

Numeric buttons: Used to input Master / slave

designation and programme remote.

The red LED indicator shows with each press of any button. If the LED fails to light

then replace the battery

Replacement battery type Lithium 3V CR2025

WARNING: DANGER OF EXPLOSION DO NOT BURN OR INCINERATE THE

BATTERY.

Warning: Do not use both the IR Remote control and DSP together it will not

work. The microphones must be at the ceiling bezel then use the remote or DSP

to operate the unit.

Remote code 0515

When the battery is replaced it

may be necessary to re code the

remote. Press Aux, Press and

hold Setup until red led lights,

enter 0515 on the key pad.

Remote coding is now set.

15

IR REMOTE CONTROL ADDITIONAL INFORMATION

When programming an incorrect address code for example 32 when there are

only 3 units connected it will just be ignored / nothing will happen if either the

up-arrow & down-arrow keys are then pressed. Wait 5 seconds and re enter

the correct address code.

During initial programming of the cable height the Up & Down buttons work on

a press and hold basis, where the microphone will continue to move either up

or down all the time the button is pressed. The cable will stop when either

button is released.

If there is a pause of longer than 5 seconds between button pressing before

the ENTER button is pressed the sequence will need to be started again from

the beginning. Once the green programme led is lit there is no time out limit.

A green led will light on the IR sensor to indicate that programme mode has

been entered. The led will extinguish when you exit the programme mode

(press Enter). Thereafter each time a remote button is pressed a red led will

flash indicating a command has been received and the transmitter is in range.

IR range is approx. 25 feet (7.5M). Do not use the IR remote control if a DSP

is being used to operate the Retracta. Only use the IR remote for setting the

height after installation.

Do not mix IR and DSP operation together. i.e. when microphones are at the

ceiling bezel if IR is used to deploy the microphones then the IR must be used

to retract the microphones. If the microphone is at the ceiling bezel and DSP

is used to deploy the microphones then the DSP must be used to retract the

microphones.

16

Programming cable height on master unit

The remote control is used to set up the cable height and also to deploy and retract

the microphone. For a single unit installation (Master) this has already been factory

defaulted to Master (Master unit decimal code setting is 00)

Point the remote at the IR receiver and press 00 followed by the ENTER

button (Green led will light on the IR sensor showing it’s in programme mode).

Press the Up / Down buttons on the remote set the correct height of the

microphone, press the ENTER button to store this height position into

the memory (green light will go out). Immediately afterwards the microphone

will retract to the ceiling bezel to confirm that the operation has been

successful.

Test by briefly pressing the Down button on the remote and the microphone

will move down and stop at the programmed height. Press the Up button and

the microphone will retract back up to the Bezel. If an incorrect height has

been programmed then repeat the above instructions.

Programming cable height on a second unit (slave designation 01)

Make sure 01 has been selected on the slave “unit.

17

Point the remote at the IR Sensor press 01 followed by the ENTER button (green

programme led on the IR sensor will light). Press the Up / Down buttons on the

remote set the correct height of the microphone, press the ENTER button to store

the desired height in the memory (green led will extinguish).

Immediately afterwards the microphone will retract to the ceiling bezel to confirm that

the operation has been successful.

Briefly press the Down button and the microphone will move down and stop at the

programmed height. Press the up button and the microphone will retract back up to

the Bezel. If an incorrect height has been programmed then repeat the above

instructions

Programming multiple units

As each additional slave units is added it will be necessary on each of the slaves to

change the “units” decimal rotary address switch to “2” for the 2nd slave / “3” on the

3rd slave etc… then as described above repeat the button sequences on the remote

to set each of the cable heights on each of the slaves in turn. Don’t forget to enter

the slaves assigned number on the remote (02 or 03, 04 etc) before completing the

programming sequence. If 10 or more Retractas are being used then it will be

necessary to change the Tens rotary address on the 10th slave to “1” and Units

rotary switch to “0” (10), for the 11th slave select “11” and so on. If you have now

completed the installation of several Retractas you can now check that all cables are

deployed simply by pressing the down button

18

Microphone adjustment

After installation has been completed it is important to operate the unit a few

times to allow the cable to settle and find its natural final rest position. The

microphone can then be aligned correctly and the knuckle joint angle

positioned for best audio reception.

NOTE: If the cable hits an obstruction such as a desk / floor or is held preventing the

upward motion (0.5lbs pull) of the cable motor will immediately stop. Remove the

obstruction and then press the up button on the remote, or up command if using a

DSP. The unit can now be operated normally. Should this fail to restore normal

operation disconnect and reconnect the supply Voltage to the CCRM 4000.

Important: The microphone angle must not be adjusted to more

than 40 degree angle from vertical as shown below. Failure to

observe this will cause the microphone to become stuck inside

the ceiling bezel.

19

Horizontal / Vertical mounting

Fig a shows a unit mounted horizontal using the supplied pair of metal brackets

(fixed using 6 x M4 x 12 countersunk screws) and is offset to the bezel using a

pulley. The Pulley is supplied and must be used if the unit is placed offset to the

bezel. The maximum distance that the unit can be mounted from the bezel / pulley is

(500mm). (19.68") which will allow approx 2 Metre (78.74") cable drop.

IMPORTANT: Make sure the microphone cable does not run up hill over the

pulley. The cable must be horizontal to the pulley. Failure to do so will cause

the slack detect safety device to operate.

Fig a

Fig b shows unit mounted vertical and inline with the bezel. The pulley is removed as its not

required.

Fig b

Table of contents

Other Clockaudio Microphone manuals

Clockaudio

Clockaudio TIM-1000 User manual

Clockaudio

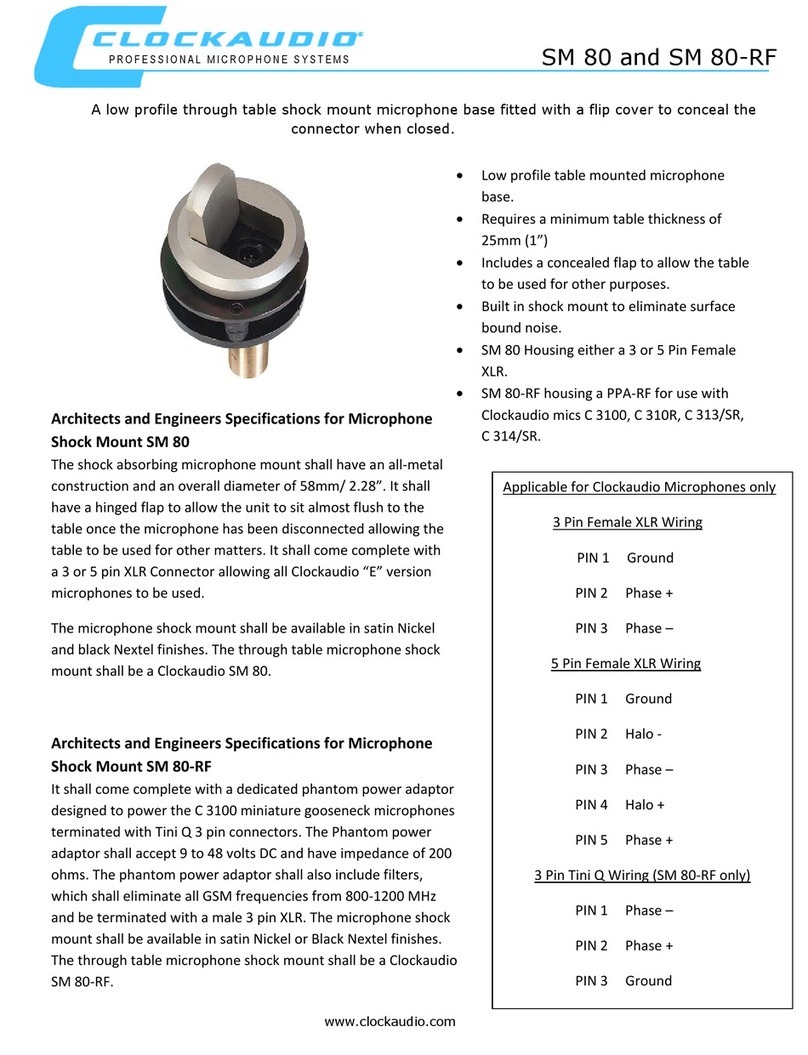

Clockaudio SM 80-RF User manual

Clockaudio

Clockaudio CCRM 4000 User manual

Clockaudio

Clockaudio C 303-RF User manual

Clockaudio

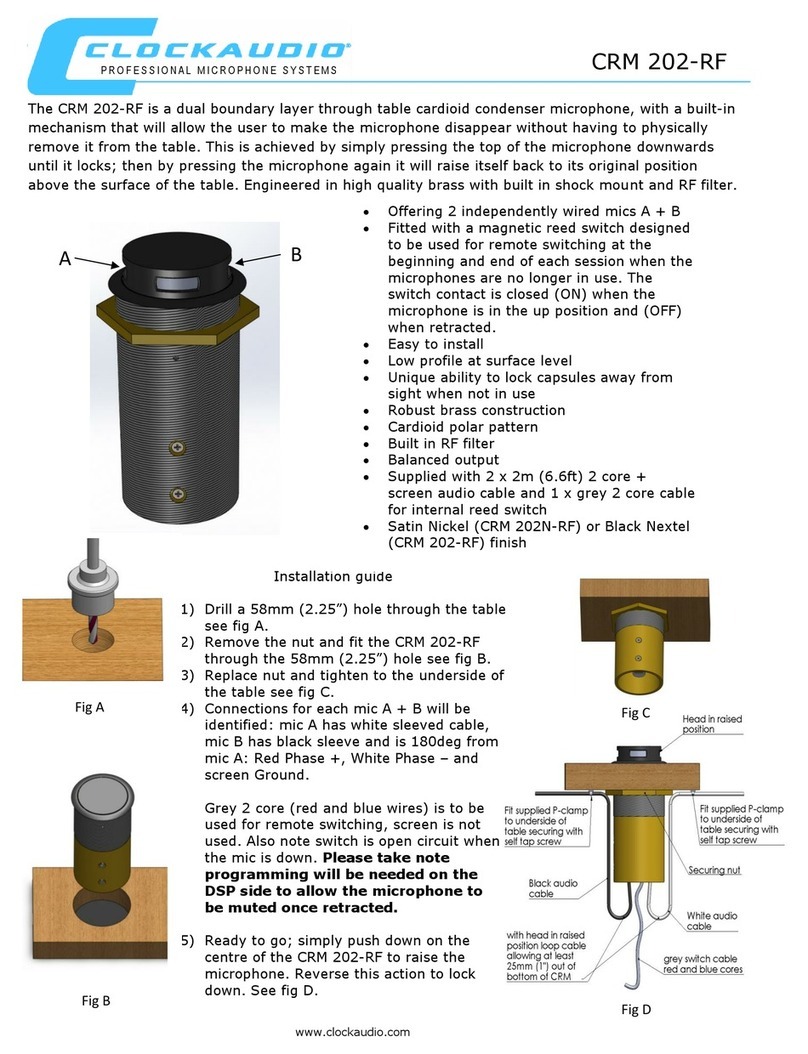

Clockaudio CRM 202-RF User manual

Clockaudio

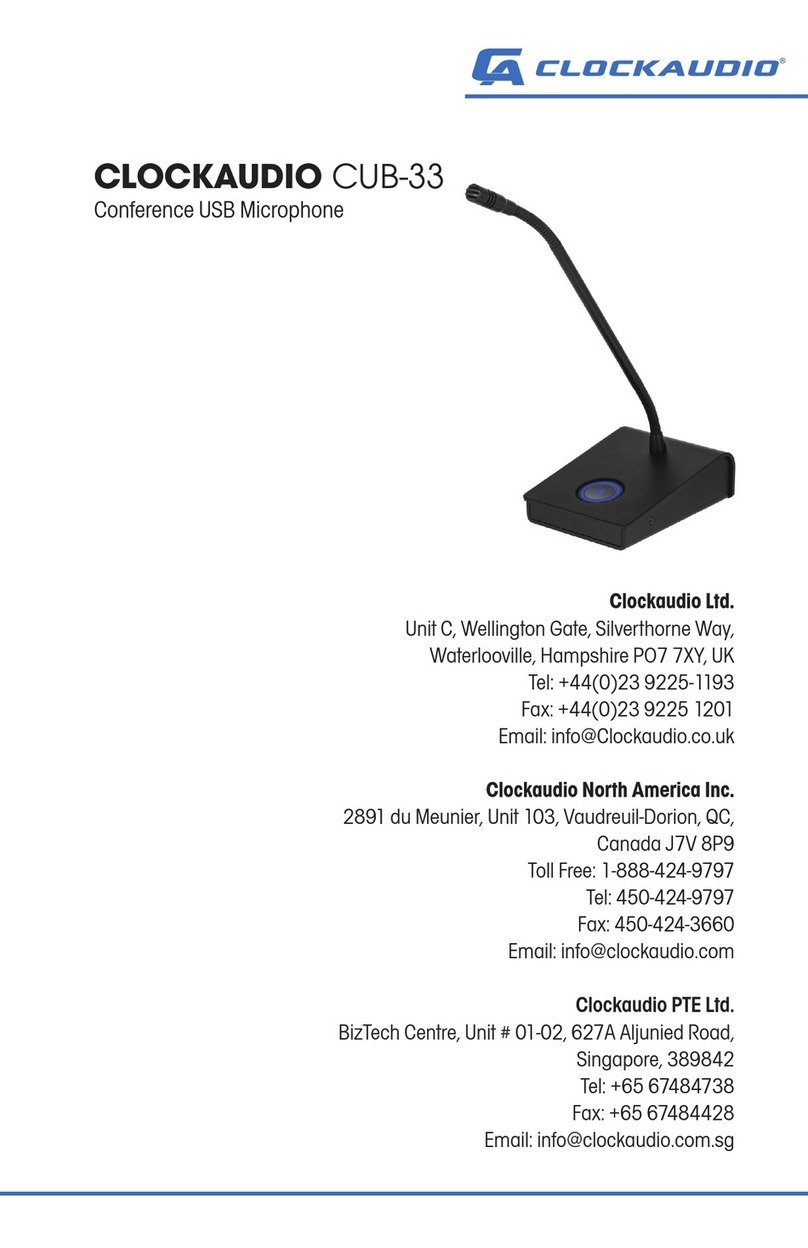

Clockaudio CRM 203 RF User manual

Clockaudio

Clockaudio CCRM4000-C303 Guide

Clockaudio

Clockaudio ARM 102-C MK2 User manual

Clockaudio

Clockaudio CUB-33 User manual