Clover Systems DR340 User manual

D

DR

R3

34

40

0

Electronic Dynamo Control Box

INSTRUCTION MANUAL

COPYRIGHT 2014 ©CLOVER SYSTEMS All Rights Reserved

TM

INTRODUCTION

DR340 Instruction Manual Pg. 1

The Clover Systems DR340 is an all-electronic voltage and

current regulator for dynamos used in vintage cars, trucks,

tractors and boats.

HISTORY

Previous to the 1970’s, vehicles used DC generators rather than

the AC alternators used today. This was due to the lack of high-

power semiconductor rectifiers at the time.

In order to provide adequate power without destroying the

battery, some means of controlling the generator’s output voltage

and current are required. This was accomplished using

mechanical relays. When the output voltage reaches a pre-

determined value, a relay opens to cut off the current to the field

coils. As the voltage now drops below the threshold, the relay

closes, restoring current to the field coils. The rapid opening and closing of the relay regulates the output to a preset limit.

Figure

1

-

Wi

th Lucas Cover

Current can be controlled in the same way, but now determined by the current draw from the generator. Regulators previous

to the ‘60s typically did not have any current regulation.

Furthermore, power is supplied only when the output of the generator is greater than a preset value (the “cut-in Furthermore,

power is supplied only when the output of the generator is greater than a preset value (the “cut-in voltage”). This prevents

the battery from discharging through the armature of the generator when the output of the generator is less than the battery

voltage.

Although this scheme can do the job, there are some drawbacks:

1) The contacts of the relays become dirty, corroded, and burned, causing unreliable operation and failure. The contacts

must periodically be cleaned, and adjusted.

2) The cut-in voltage is fixed, so that the generator must reach a fairly high voltage before it can supply any power to the

battery or electrical systems.

The Clover Systems DR340 works in the same way, but substitutes transistor switches for the mechanical relays. As a result,

switching is cleaner and more reliable, and no cleaning or adjustment is ever required.

With the DR340, power is output whenever the generator voltage is higher than the battery voltage. This typically means

that useful power can be supplied at a lower RPM. DR340 also includes current limiting, which is not included in most

mechanical regulators.

INSTALLATION

1) First, be sure that you have the correct model DR340 for your vehicle

(Positive or Negative Earth, 6 or 12 volts, and correct current limit to match

your dynamo). Although DR340 is protected against most every possible

problem, it is possible to damage the unit and/or your generator if for instance,

the battery is hooked up backward.

2) Disconnect the battery ground cable to prevent any mishaps.

3) Next, label all wires connected to your existing regulator. With RB340, the

wires are (left to right, viewed from the front) E (Earth), D (Dynamo

Armature), WL (Warning Light), F (Field Coil), B (Battery1), and B

(Battery2). The two B terminals are connected together. One goes to the

battery, and the other goes to the vehicle’s ignition switch and lights, often

through a fuse box. Since they are connected together, it doesn’t matter which

goes on which terminal The WL terminal is connected directly to the D

terminal. If your vehicle doesn’t have a warning light connection, it can be left

F

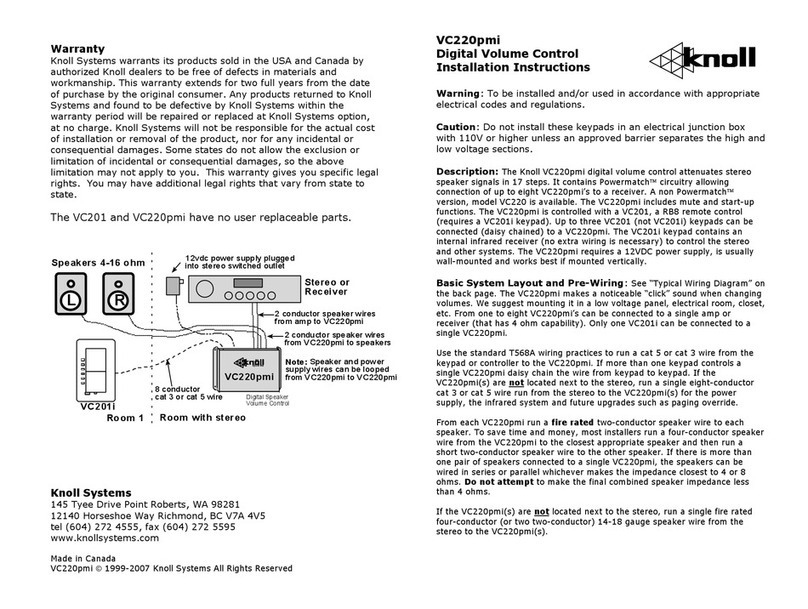

i

g

ure 2 - Connections

open.

4) If you do not already have a regulator connected, you may need to trace the wires to see exactly where they go.

5) If you are installing a new generator, or your existing one is in unknown condition, you should perform some simple

tests to verify that it is workable:

a) With an ohm-meter, you should measure resistance of ~ 2 ohms from terminal D to ground. If the resistance is

infinite, then either the wire from D to the generator is not connected, or the generator’s armature is open.

b) Similarly, you should measure resistance of ~ 5-6 ohms from terminal F to ground. Infinite resistance indicates the

wire from terminal F to the generator’s field coil is not connected, or the field coils are open. A low resistance (3

ohms or less) indicates partial shorting of the field coils to ground.

6) Attach the wires to the DR340, and mount the DR340 using the three stainless steel machine screws provided.

7) Reconnect the battery ground. If there is excessive sparking, there may be a wiring mistake.

8) If everything seems to be in order, start the engine and observe the ammeter and ignition warning light. If everything is

working correctly, the warning light should go out at around 900 RPM (depending on generator model). You should

also be able to see charging of the battery on the ammeter.

9) If there is no output from the generator, and it passed the above tests, see the troubleshooting section in the appendix.

10) Installing the cover. DR340 does not include the Lucas plastic cover. You can however, use your existing cover, or

find a used one. The base plate is laid out to accommodate a genuine Lucas cover. Two #8 machine screws are

provided to install it. Some aftermarket covers have different dimensions from the original Lucas covers.

Caution

Although the DR340 is protected against most everything that can go wrong, there are some things that can damage the

DR340 and/or your dynamo:

1) Connecting the battery backward. Be sure that you have the correct polarity regulator. If there is any doubt, check the

battery connections to see which battery terminal is connected to the vehicle’s chassis.

2) Reversing the D and B wires will create a direct path from the battery to the dynamo’s armature, which could damage

your dynamo.

3) B-circuit regulators: If the F wire is shorted to the D wire (dynamo armature), the dynamo will run at full output

without any voltage or current limiting. Lucas regulators and wiring are made so that you cannot connect the F wire to

the WL terminal (which is connected to the D terminal). We have copied this scheme, but if your wiring is not original,

it may be possible to accidentally connect the F wire to the WL terminal.

A-circuit regulators: If the F wire is shorted to ground, the dynamo will run at full output without any voltage or current

limiting. As a result, your dynamo and wiring could be damaged.

4) If the ground wire is not connected to the regulator, there will be no output from the dynamo. The regulator ground is

connected to the back plate, but in the normal installation, the back plate is insulated from the chassis ground by the

rubber mounting bushings. Therefore, the ground wire must be connected to the E terminal.

TESTING & CALIBRATION

The DR340 voltage and current limits are set at the factory, and normally, no adjustment or calibration is required. You may

however, wish to confirm that everything is working properly, or change the settings to accommodate your needs.

Both voltage and current limit are user adjustable, but within limits. For instance, changing from 12V to 6V will require

component changes. In the standard configuration, voltage limit is adjustable from 13 to 17V. and the current limit is

adjustable from 17A to 30A. Higher or lower settings will require component changes.

Adjustment to the voltage or current limit must be carried out on the car. For these adjustments, you will need an analog

moving-coil voltmeter (0-20V) and/or analog moving-coil ammeter (0-40A) plus a very small flat-blade screwdriver.

DR340 Instruction Manual Pg. 2

Note: Use only analog moving-coil voltage and current meters for these tests. Digital meters will not read correctly because

of rapid variations and noise in the dynamo output.

Voltage Limit Test (open circuit):

1) Remove the die-cast cover by removing the three screws from the back of the unit:

Figure 3 - Cover Mounting Screws

2) Remove both wires from the B terminals, and connect them together with a clip lead. This will provide power from the

battery to the vehicles electrical system so the engine can run.

3) Connect an analog voltmeter capable of measuring 0-20 volts between the B terminal and ground.

4) Now start the engine. As you increase the engine speed, you should see an increase in the voltage on the meter. Run up

the engine speed, and you should see the voltage rise with engine RPM, until it reaches it’s preset limit (See the Final

Test Sheet at the end of this manual for the proper voltage).

5) If necessary, adjust the voltage limit control to get the desired output voltage limit. Turn the pot clockwise to increase

the limit, and counter-clockwise to lower the voltage limit. You should be able to reach the voltage limit at no more

than 3000 or 4000 RPM.

6) When finished, remove the voltmeter and re-attach the wires to the B terminals.

Current Adjust

Voltage Adjust

Figure 4 – Location of Pots

DR340 Instruction Manual Pg. 3

The correct voltage limit also depends on they type of battery. The requirements for “flooded” type batteries, where you can

add water are different than for sealed, “Maintenance Free” batteries, also known as VRLA, AGM, or Gel batteries, which

require a lower charging voltage. The chart below shows optimal settings for the two types of batteries. Tolerance is ±0.3

Volts.

We normally set the voltage at 14.3V at 25°C for 12v dynamos, and 7.2v for 6v dynamos, which is safe for all batteries.

Since there are many types and models of batteries, you may wish to consult the battery specs for the optimum charging

voltage.

Voltage vs. Temperature

12.5

13

13.5

14

14.5

15

15.5

16

10 15 20 25 30 35 40

°C

Volts

Flooded

VRLA

Figure 5 - Voltage vs. Temperature

If the car has been running with substantial electrical load, the regulator may be hotter than ambient temperature. Therefore,

it is best to perform the test with the regulator at ambient temperature.

Figure 6 - Ammeter Hookup

Current Limit Test:

1) With the two B wires disconnected from the DR340, and

connected together, connect a 0-40A ammeter between the B

terminal of the regulator and the two B wires connected

together. If your vehicle is negative ground, then connect the

+ terminal of the ammeter to the B terminal of the regulator,

and the – terminal of the ammeter to the two wires. For

positive ground, reverse these connections.

2) Start the engine and turn on all loads such as headlights, fans,

etc. As you increase the engine RPM, you should see the

current flow increase until it reaches the preset limit. You

may need to add additional loads to reach the desired limit.

3) You can turn the potentiometer to adjust the current limit.

Turning clockwise increases the limit, and counter-clockwise

decreases the limit.

4) When finished, remove the ammeter and re-attach the wires

to the B terminals.

Warning: Do not adjust the current limit higher than the rated output of your dynamo, as this may overload the generator

and reduce it’s life.

DR340 Instruction Manual Pg. 4

Note: Typically, the ammeter in your vehicle only measures current to and from the battery. It does not measure the total

output of the generator, which could be more. To measure total generator output, you need to connect an ammeter as

described above.

Appendix

How the regulator works

All generators work by rotating a loop of wire in a magnetic field. In a dynamo, the magnetic field is created by

electromagnets (field coils). Voltage and current are controlled by controlling the current to the field coils. The current

through the field coils determines the strength of the magnetic field that the armature rotates in, and thus the output of the

generator.

In the DR340, the output voltage of the generator is compared to a precision voltage reference. When the generator output

exceeds this reference, the current to the field coils is cut off. This causes the generator output to fall. When the output falls

below the reference voltage, the field current is turned back on. In this way, the field current is modulated at a rate of 50 –

125 Hz. These rapid changes are smoothed out by the inductance of the field coils, thus maintaining a constant output

voltage.

Current limiting is accomplished in the same way. Output current is sensed with a Hall-Effect device that detects the

magnetic field created by the output current. When the output current exceeds a preset limit, the field current is turned off.

Just as with the voltage regulation, the field current is modulated to maintain a constant output current.

Instead of a cut-out relay, DR340 uses a MOSFET “ideal diode”, which is much more efficient than Schottky diodes. Power

is supplied whenever the dynamo output voltage is greater than the battery voltage, rather than a pre-set voltage as in the

mechanical regulator.

A-Circuit and B-Circuit

There are two types of 2-brush shunt-wound dynamos: A and B. The only

difference is in the way that the field coils are wired. In an A-circuit

dynamo, one end of the field coils is internally connected to the dynamo

output. In a B-circuit dynamo, one end of the field coils is internally

connected to ground. So in the B-circuit case, the regulator supplies

current to the field coils, and in the A-circuit, the regulator sinks current.

Lucas dynamos are always B-circuit. Delco and Autolite standard

generators used on autos are A-circuit.

How to Polarize a New Generator

A dynamo uses electromagnets to generate the magnetic field for the

armature to rotate in. But when starting up, there is no field current to

create this magnetic field. In order to get the process started, some

permanent magnetism is required to provide this field. This is provided by

iron pole pieces that can be permanently magnetized. A new generator

may not have the pole pieces magnetized, so there will be no output, and no field current. Also, a dynamo that has been used

with a different polarity (i.e., pos gnd instead of neg gnd) will be polarized backward, and will produce a voltage of the

wrong polarity.

Magnetizing the pole pieces is easy, but is different for A-circuit and B-circuit dynamos:

F

i

g

ure 7 - A and B circuits

B-Circuit: While the car is not running, connect a lead from the battery (or white wire) to the dynamo’s field coil terminal

(or the green wire) for one or two seconds. Connecting them for a long period could overheat and damage the field coils.

A-Circuit: Disconnect the output wire from the dynamo (usually labeled D or A). Then connect the field terminal of the

dynamo (usually labeled F) to ground with a jumper lead. Now using another jumper lead, briefly connect the battery output

to the dynamo output for a second. Connecting them for a long period could overheat and damage the dynamo.

DR340 Instruction Manual Pg. 5

DR340 Instruction Manual Pg. 6

The pole pieces will now be permanently magnetized, and the dynamo will start up. If the dynamo is properly polarized, it

will produce ~3 volts with the field coils disconnected.

Troubleshooting

In case there is no output from the dynamo, check the following:

1) D terminal is not connected to the dynamo output terminal

2) F terminal is not connected to the dynamo field terminal

3) E terminal is not connected to ground

4) Dynamo armature is shorted or open

5) Dynamo field coils are shorted or open

6) D, F, or WL are shorted to ground

7) Dynamo is not polarized

8) Regulator is not the correct A or B circuit model

S

If you ne

ervice

ed service or have questions, you can contact us at +1 949-598-0700 or support@cloversystems.com.

ll Clover Systems products are guaranteed against original defects for one year. Any products returned within the warranty

ou can also return the DR340 within 30 days for any reason for a full refund (less shipping cost) provided it is undamaged.

Warranty

A

period will be repaired or replaced at no charge except for return shipping.

Y

Table of contents

Other Clover Systems Controllers manuals

Popular Controllers manuals by other brands

Seada

Seada G2000CTL user manual

Toshiba

Toshiba TMC7 Series Product guide

West Penn Wire

West Penn Wire AV-IP-NC811 Operation manual

Honeywell

Honeywell CentraLine LYNX BACnet CLLYUB1012S Product data

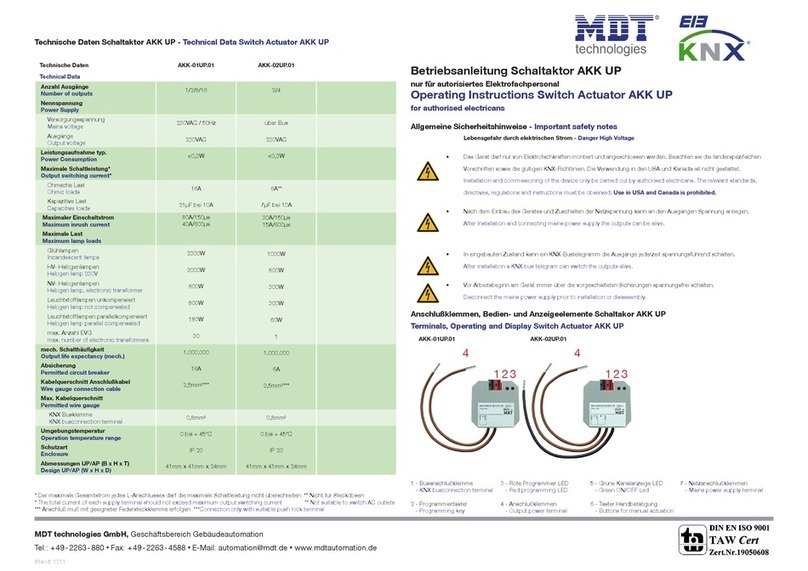

MDT Technologies

MDT Technologies AKK UP Series operating instructions

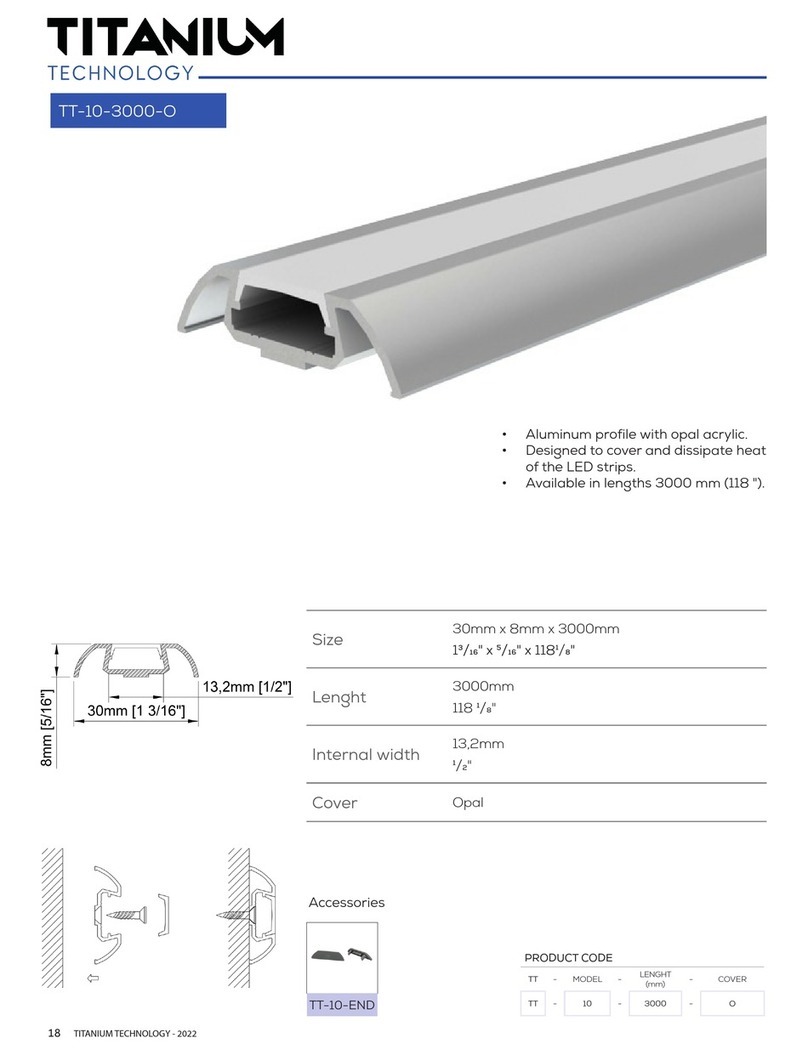

Titanium

Titanium TT-10-3000-O quick start guide