9

11 .FG10-011 Ф10 Flat washers 1

12 .FG10-012 M8X25 hex screw 4

13 .FG10-013 Dust shroud SHMDJ71504 1

14 .FG10-014 M12X25 socket hexagon screw 2

15 .FG10-015 Detachable shroud SHMDJ71505 1

16 .FG10-016 Shroud plastic wear strip set(long)1

17 .FG10-017 Shroud plastic wear strip set(short)1

18 .FG10-018 motor driving sleeve SHMDJ71503 1

19 .FG10-019 M10X30 hex screw 1

20 .FG10-020 M10 nuts 2

21 .FG10-021 Ф10 Flat washers 2

22 .FG10-022 flex coupling-Morse SHMDJ71509 1

23 .FG10-023 M10X55 hex screw 2

24 .FG10-024 M10X55 socket hexagon screw 2

25 .FG10-025 connection disc SHMDJ71511 1

.FG10-026 M8X12 socket hexagon screw 3

.FG10-026A 3/8”-24 x 3/4" socket hexagon screw For G-Head 4

27 .FG10-027 Dowel disc SHMDJ71514 1

28 .FG10-028 Flexible conduit SHMDJ71515 1

29 .FG10-029 ClipФ60 2

30 .FG10-030 M10X30 hex screw 2

31 .FG10-031 Ф10 Flat washers 2

32 .FG10-032 Wheel 2

33 .FG10-033 M8X12 hexagon screws 2

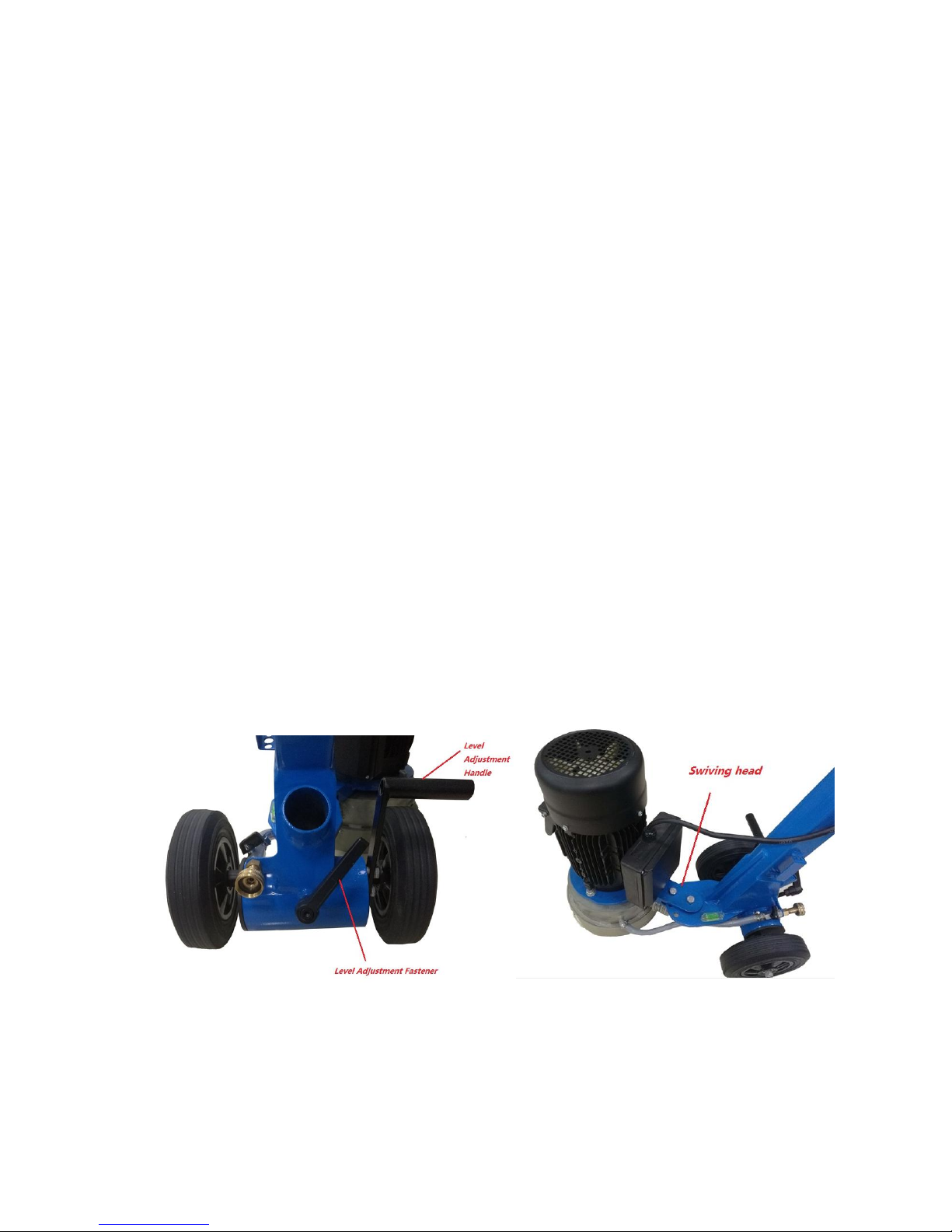

34 .FG10-034 Lift lever SHMDJ71507 1

35 .FG10-035 Eccentric shaft SHMDJ71506 1

36 .FG10-036 M12 locking screws 1

37 .FG10-037 cooling water pipe SHMDJ71516 1

38 .FG10-038 Frame body part SHMDJ71502 1

39 .FG10-039 M10 nuts 2

40 .FG10-040 Ф10 Flat washers 2

41 .FG10-041 Connection sets SHMDJ71512 2

42 .FG10-042 M12X25 Round socket hexagon screw 2

43 .FG10-043 adjust handle 1

44 .FG10-044 M8X20 hexagon screws 2

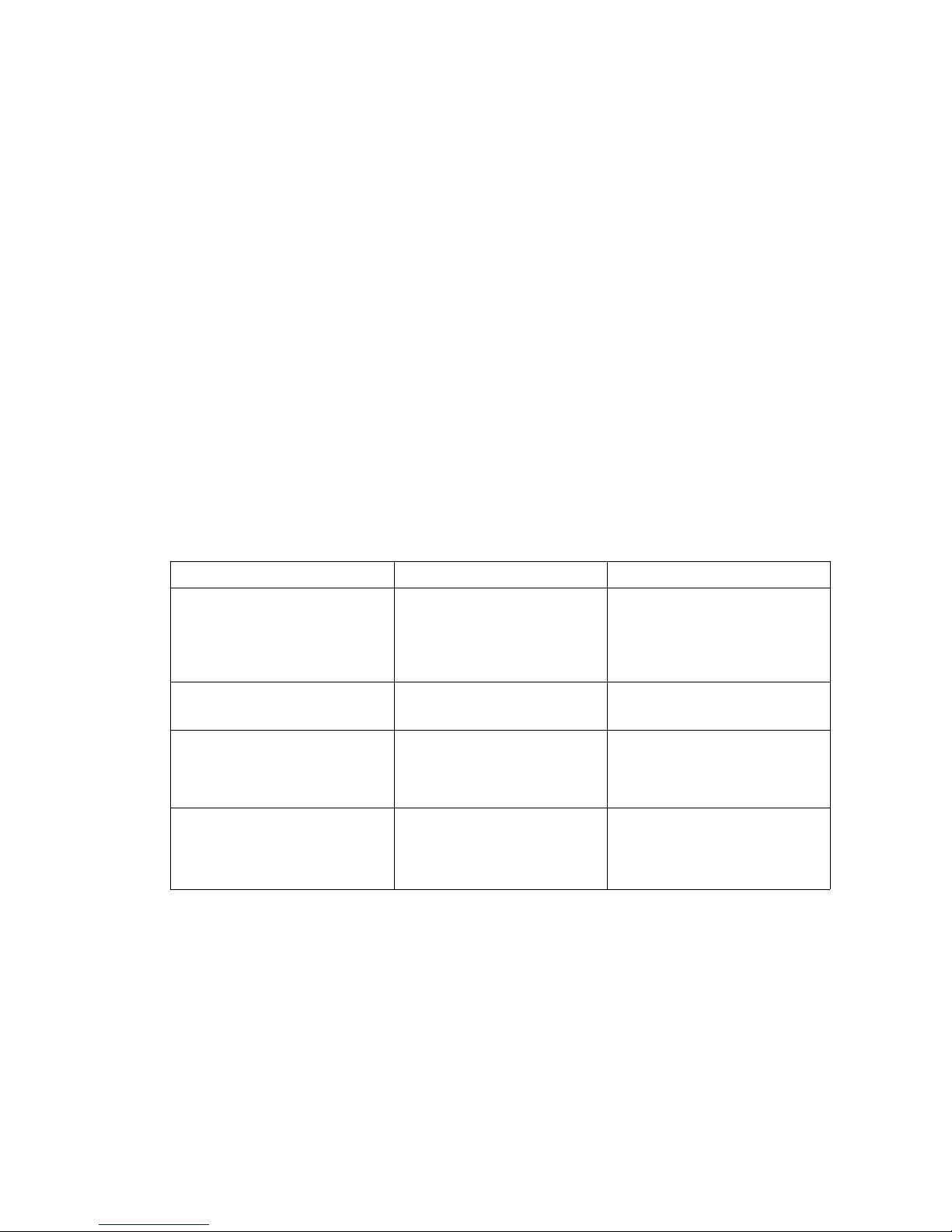

45 .FG10-045 Positioning clamping claw buckle SHMDJ71510 1

46 .FG10-046 Level bubble 1

26