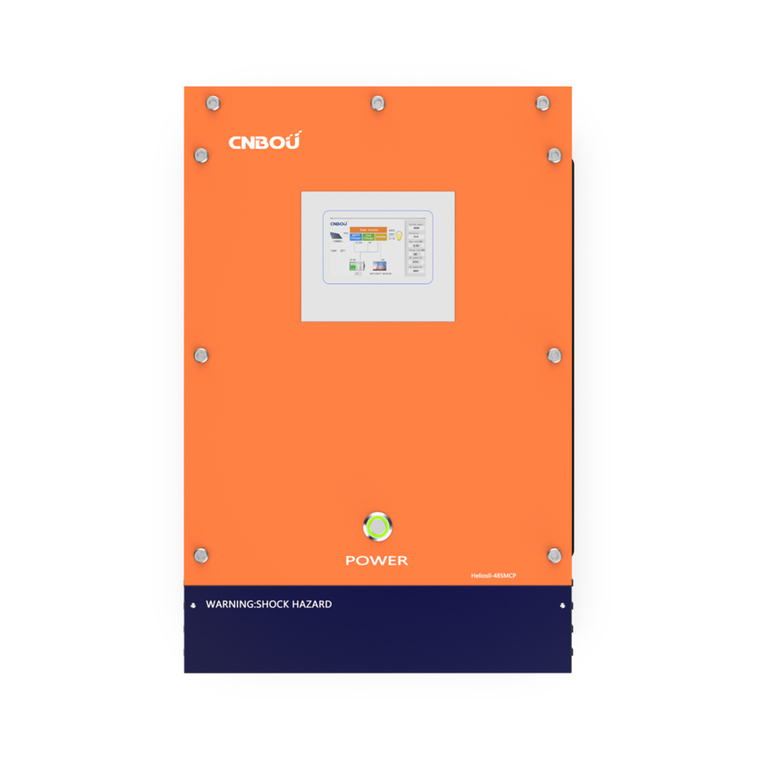

CNBOU Helios III Series User manual

Helios III-243MCP、Helios III-485MCP

Table Of Contents

1. About This Manual...............................................................................1

1.1 Purpose............................................................................................... 1

1.2 Scope.................................................................................................. 1

1.3 Safety Instructions ............................................................................. 1

2. Introduce..............................................................................................1

2.1 Features.............................................................................................. 2

2.2 Basic System Architecture .................................................................. 2

2.3 Product Overview................................................................................ 3

3. WIFI Connection

(

Optional

)

.................................................................3

4. INSTALLATION....................................................................................4

4.1 Unpacking and Inspection................................................................... 4

4.2 Preparation ......................................................................................... 4

4.3 Mounting The Unit............................................................................... 4

4.4 Battery Connection ............................................................................. 4

4.5 AC Input/Output Connection ............................................................... 5

4.6 PV Connection .................................................................................... 5

4.7 Final Assembly.................................................................................... 6

4.8 RS232/USB Communication Connection ........................................... 6

4.9 Dry Contact Signal

(

Optional

)

............................................................. 7

4.10 Bluetooth Communication

(

Optional

)

............................................... 7

5. OPERATION........................................................................................8

5.1 Power ON/OFF ................................................................................... 8

5.2 Operation and Display Panel .............................................................. 8

5.3 LCD Display Icons .............................................................................. 9

5.4 LCD Setting........................................................................................11

5.5 Fault Reference Code....................................................................... 17

5.6 Warning Indicator.............................................................................. 18

6.TROUBLE SHOOTING.......................................................................19

7. SPECIFICATIONS.............................................................................21

Table 1 Solar Mode Specifications .......................................................... 21

Table 2 Line Mode Specifications............................................................ 22

Table 3 Charge Mode Specifications....................................................... 23

Table 4 Inverter Mode Specifications ...................................................... 24

8.Installation Dimension Drawing ..........................................................25

1

1. About This Manual

1.1 Purpose

This manual describes how to assemble, install and operate the units and how to troubleshoot of this

unit. Please read this manual carefully before installation and operation. Keep this manual for future

reference.

1.2 Scope

This manual provides guidelines of safety installation as well as the information on tools and wiring.

1.3 Safety Instructions

WARNING: This chapter contains important safety and operating instructions. Read and keep this

manual for future reference.

1.Read and follow all installation, operation, and maintenance information carefully before using the

product.

2.CAUTION:To reduce risk of injury, charge only deep-cycle lead acid type rechargeable

batteries .Other types of batteries may burst, causing personal injury and damage.

3.Do not disassemble the unit personally. Take it to a qualified service center to repair.

4.To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or

cleaning, turning off the unit will not reduce this risk.

5. WARNING : Disconnecting all power supply before any maintaining or cleaning ,please noted that

if you only turn off the unit are not safe enough.

6. WARNING: Only qualified service persons are allowed to operate this product. If fault not solved

after following troubleshooting table, please send this inverter back to local dealer or service center

for maintenance.

7. WARNING: Because this inverter is non-isolated, only three types of PV modules are adaptable:

single crystalline, poly crystalline with class A-rated and CIGS modules. To avoid any malfunction,

do not connect any PV modules which likely with current leakage flow to the inverter. For example,

grounded PV modules may cause current leakage flow to the inverter. When using CIGS modules,

please be sure of NO grounding.

8. CAUTION: It’s requested to use PV junction box with surge protection. Otherwise, it may cause

damage on inverter.

2. Introduce

This is a multi-function inverter/charger; combining varies of functions of inverter, solar charger and

battery charger .Supply uninterruptible electric energy to loads. It’s comprehensive LCD display

allowed user setting the varies date according to user’s requirements, such as battery charging

current, AC/solar charger priority, and setting different input voltage based on different applications.

2

2.1 Features

1. Off grid inverter

2. Output power factor COSφ=1.0

3. Configurable AC/Solar Charger priority via LCD setting

4. Smart battery charger design for optimized battery performance

5. Compatible to mains voltage or generator power

6. Overload ,Over temperature ,Short circuit protection , battery low voltage

7. External WIFI devices

8.Can connect Bluetooth device

2.2 Basic System Architecture

The following illustration shows basic application for this inverter/charger. It also includes following

devices to have a complete running system:

Generator or Utility. PV modules

Consult with integrators who provide you the system about the architectures as you request. this

inverter can supply power to all kinds of appliances in home or office ,including motor-type appliances,

such as tube light, fan, refrigerator and air-conditioner.

NOTE: The following picture is only a schematic diagram of the equipment .If the actual chassis does

not conform to the schematic due to a structural upgrade, it is subject to prior notice.

Figure 1 Hybrid Power System

Solar power input

Discharging

Charging

Utility power input To load

3

2.3 Product Overview

NOTE:The following picture is only a schematic diagram of the equipment .If the actual chassis does

not conform to the schematic due to a structural upgrade, it is subject to prior notice.

1:RS232(RS485/CAN port is optional) 6:WIFI port

2:USB port(optional) 7:Battery input

3:Generator dry contact(optional) 8: PV input

4:AC input 9:AC output

5:Breaker 10:Power on/off switch

Communication port definition:

RS232 1:RXD , 2:TXD,8:GND

RS485 6:485-B ,7.485-A

CAN 3:CAN-H,5:CAN-L

3. WIFI Connection

(

Optional

)

1.Users can download ”SmartEss” WIFI monitoring software from the app store on their phone.

2.Inverters come equipped with factory-integrated Wi-Fi capability which makes it very easy to

integrate into a home network (Wi-Fi Dongle is Optional)This makes it ideal for local monitoring via the

inverter's own wireless home network or for online monitoring platforms

.

1

4

4. INSTALLATION

4.1 Unpacking and Inspection

Before installation, please inspect the unit. Be sure that everything in the package is not damaged.

The following items inside of package would be received.

The inverter x1

User manual x 1

Communication cable x1

4.2 Preparation

Please remove the two screws on the bottom cover of the inverter as shown below before connecting

all wirings.

4.3 Mounting The Unit

Consider the below points before selecting where to install:

1. Do not mount the inverter on the surface of flammable construction materials.

2. Mount on the surface of a solid material.

3. Install the inverter at a visible place in order to the LCD display can be read easily.

4. For proper air circulation and dissipate heat ,make sure there is 20 cm distance from the two side,

50 cm distance from bottom of the unit.

5.The ambient temperature should be between -10°C and 50°C to ensure optimal operation.

6.The recommended installation position is to be adhered to the wall vertically.

7.Be sure to keep other objects and surfaces as shown in the diagram to guarantee sufficient heat

dissipation and to have enough space forcollecting wires.

Suitable for mounting on concrete or other non-combustible surface only

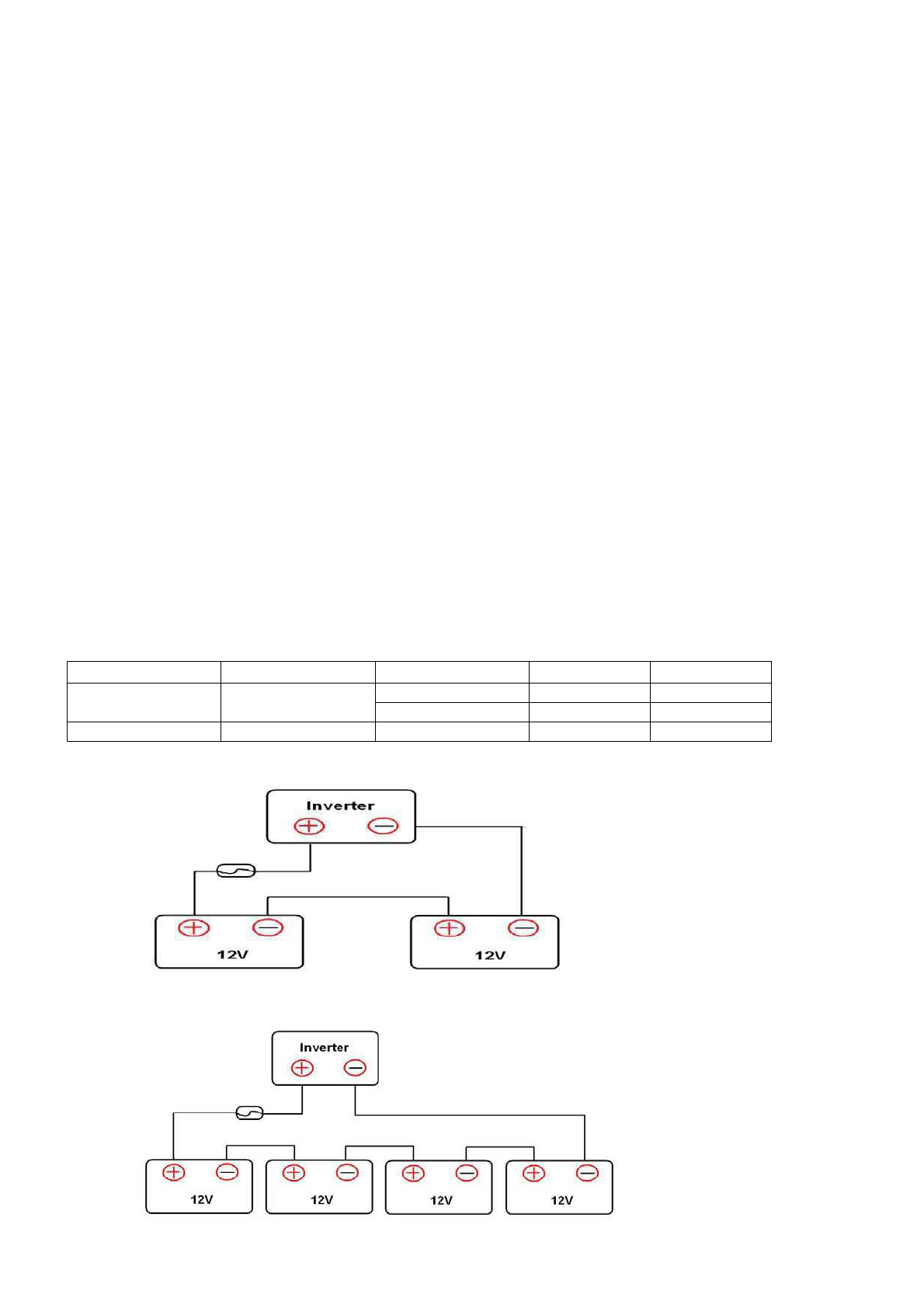

4.4 Battery Connection

CAUTION: For safety operation and regulation compliance, it’s requested to adopt a separate DC

over-current protector or disconnect device between battery and inverter. It may not be necessary to

have a disconnect device in some applications, however, it’s still need to adopt over-current

protection device. Please refer to typical amperage in below table as required fuse or breaker size.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It's very important for system safety and efficient operation to use appropriate cable for

battery connection. To reduce risk of injury, please use the proper cable as below.

Model Typical amperage Battery capacity Gauge Cable(mm²)

3.5KW24Vdc 167 100AH 1*2AWG 1*35

200AH 2*2AWG 2*35

5.5KW48Vdc 131A 100AH 1*2AWG 1*35

24VDC battery connection diagram

48VDC battery connection diagram

5

CAUTION! Before connection the DC breaker, be sure positive (+) must be connected to positive (+)

and negative (-) must be connected to negative (-).

4.5 AC Input/output Connection

CAUTION! Before connecting to AC input power source, please install a separate AC breaker and

lightning arrester between inverter and AC input power source. This will ensure the inverter can be

securely disconnected during maintenance and fully protected from over current of AC input. The

recommended spec of AC breaker is 32A for 3.5KVA and 50A for 5.5KVA. There are two terminal

blocks with “IN” and “OUT” markings. Please do NOT connect input and output connectors wrong.

WARNING! All wiring must be performed by a qualified personnel. It's very important for system safety

and efficient operation to use appropriate cable for AC input connection. To reduce risk of injury, please

use the proper recommended cable size as below.

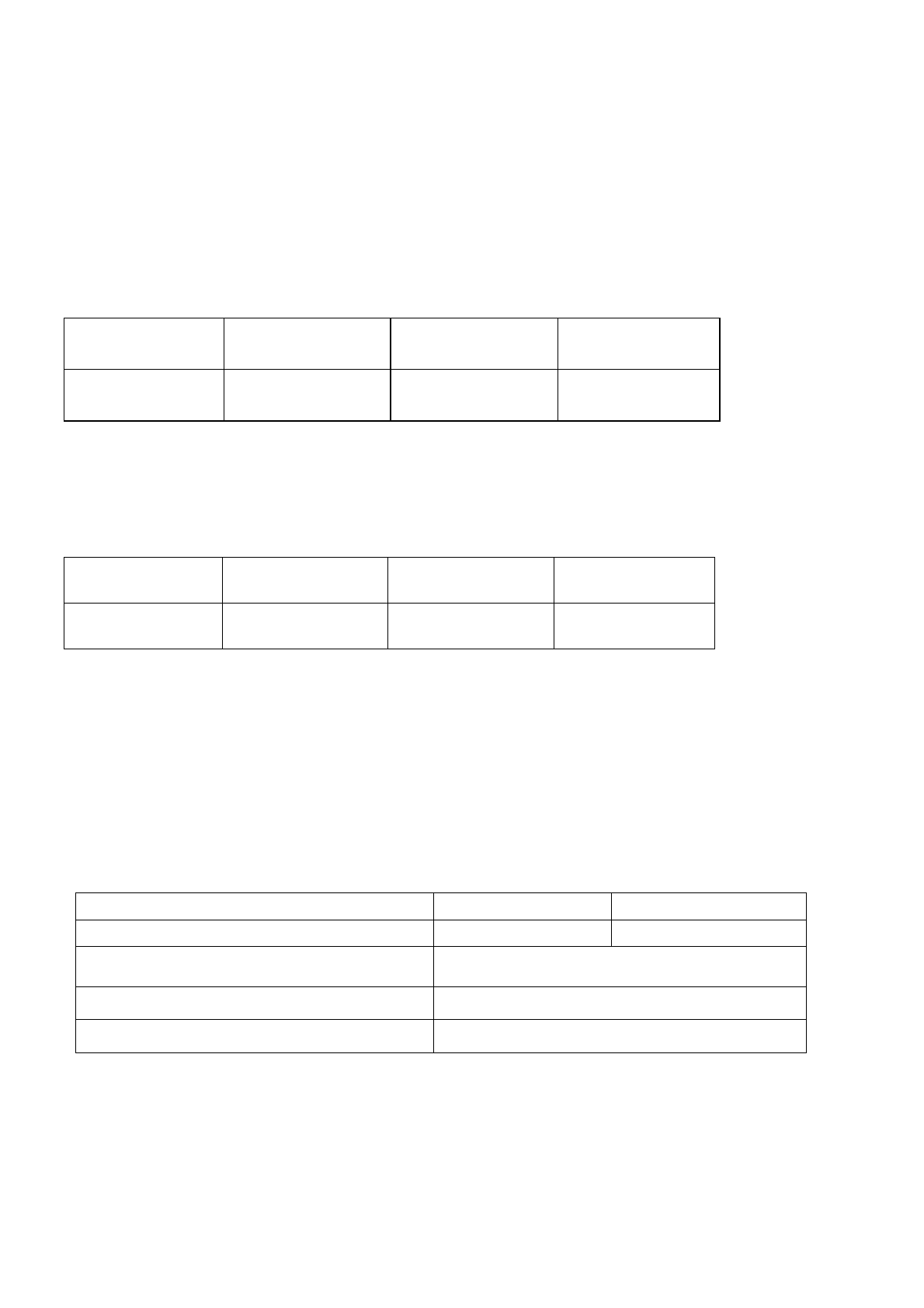

Model Gauge Cable (mm2)Torque Value(Max.)

3.5KVA/5.5KVA 10 AWG 61.4-1.6 Nm

4.6 PV Connection

CAUTION:It is forbidden for inverter to share the same solar panel group.

CAUTION: Before connecting to PV modules, please install separately a DC circuit breaker

and lightning arrester between inverter and PV modules.

WARNING: It's very important for system safety and efficient operation to use appropriate cable for

PV module connection .To reduce risk of injury ,please use the proper cable size as below.

Model

Wire Size Cable (mm2)Torque value(max.)

3.5KVA/5.5KVA

12AWG 41.2-1.4 Nm

WARNING: Because this inverter is non - isolated, only three types of PV modules are

acceptable : single-crystalline, poly crystalline with class A-rated and CIGS modules .To avoid

any malfunction, do not connect any PV modules with possible current leakage to the inverter.

For example, grounded PV modules will cause current leakage to the inverter. When using CIGS

modules, please be sure NO grounding.

CAUTION: It’s requested to use PV junction box with surge protection. Otherwise, it will cause

damage on inverter when lightning occurs on PV modules.

PV Module Selection:

When selecting proper PV modules, please be sure to consider below parameters:

Open circuit Voltage (Voc) of PV modules not exceeds max. PV array open circuit voltage

of inverter.

Inverter Model 3.5KW 5.5KW

Max. PV Array Power 4500W 5500W

Max. PV Array Open Circuit Voltage 500Vdc

PV Array MPPT Voltage Range 120Vdc~450Vdc

Start-up Voltage 150Vdc +/- 10Vdc

6

Application Example:

Solar Panel

Spec. 250Wp

Vmp: 30.1Vdc

Imp: 8.3A Voc:

37.7Vdc Isc:

8.4A

SOLAR INPUT

Q’ty of

panels

Total input

power

(Min. in serial: 5 pcs, max. in serial: 11 pcs)

5 pcs in serial 5 pcs

1250W

8 pcs in serial 8 pcs

2000W

10 pcs in serial 10 pcs

2500W

9 pieces in serial and 2 sets in parallel 18 pcs

4500W

10 pieces in serial and 2 sets in parallel

(only for 5.5KVA model) 20 pcs

5000W

11 pieces in serial and 2 sets in parallel

(only for 5.5KVA model) 22 pcs 5500W

PV Module Wire Connection

Please follow below steps to implement PV module connection:

1.Remove insulation sleeve 10 mm for positive and negative

conductors.

2.Suggest to put bootlace ferrules on the end of positive and

negative wires with a proper crimping tool.

3. Fix PV wire cover to the inverter with supplied screws

as shown in below chart.

4.7 Final Assembly

After connecting all wires, please put bottom cover back by screw

4.8 RS232/USB Communication Connection

Please download software“SolarPower” from the official website.when the inverter is connected to the

computer,the following interface will be displayed. Note:the following date are for reference only.

7

4.9 Dry Contact Signal

(

Optional

)

There is one dry contact (3A250VAC) available on the rear panel. It could be used to deliver signal to

external device when battery reaches warning level.

Unit Status State

NC & C C & NO

Power off Unit is off and no output is powered Open Close

Power on Battery voltage <Setting the voltage in program 12 Close Open

Battery voltage >Setting the voltage in program 13 Open Close

4.10 Bluetooth Communication

(

Optional

)

This unit is equipped with a Bluetooth transmitter. Download “RevoMonitor” APP from Google Play .

Once the APP is download, you may connect “RevoMonitor” APP to your inverter with the pairing

password “1234”. The communication distance is roughly 6 ~ 7 meters.

Note:1.the following date are for reference only.

2.Bluetooth APP only supports Android phone users.

8

5. OPERATION

5.1 Power ON/OFF

Once the unit has been properly installed and the batteries are connected well, simply press On/Off

switch(located on the button of the case) to turn on the unit.

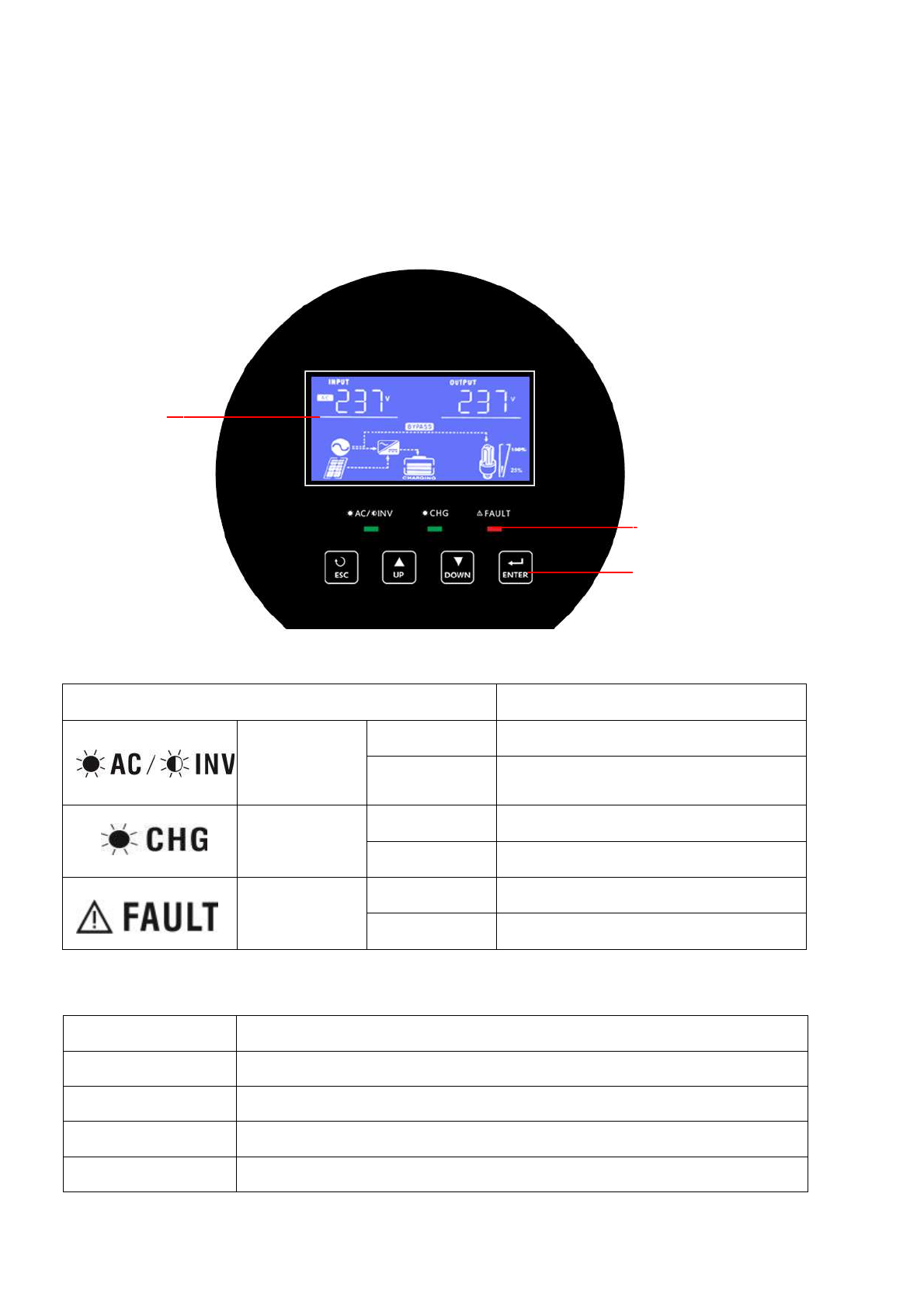

5.2 Operation and Display Panel

The operation and display panel, shown in below chart, is on the front panel of the inverter. It includes

three indicators, four function keys and a LCD display, indicating the operating status and input/output

power information.

LED Indicator

LED Indicator Messages

Green

Solid On Output is powered by utility in Line mode.

Flashing Output is powered by battery mode

Green

Solid On Battery is fully charged.

Flashing Battery is charging.

Red

Solid On Faultoccurs in the inverter

Flashing Warning condition occurs in the inverter

Function Keys

Function Keys Description

ESC To exit setting mode

UP To go to previous selection

DOWN To go to next selection

ENTER To confirm the selection in setting mode or enter setting mode

LCD display

Function buttons

LED in

d

i

ca

t

or

9

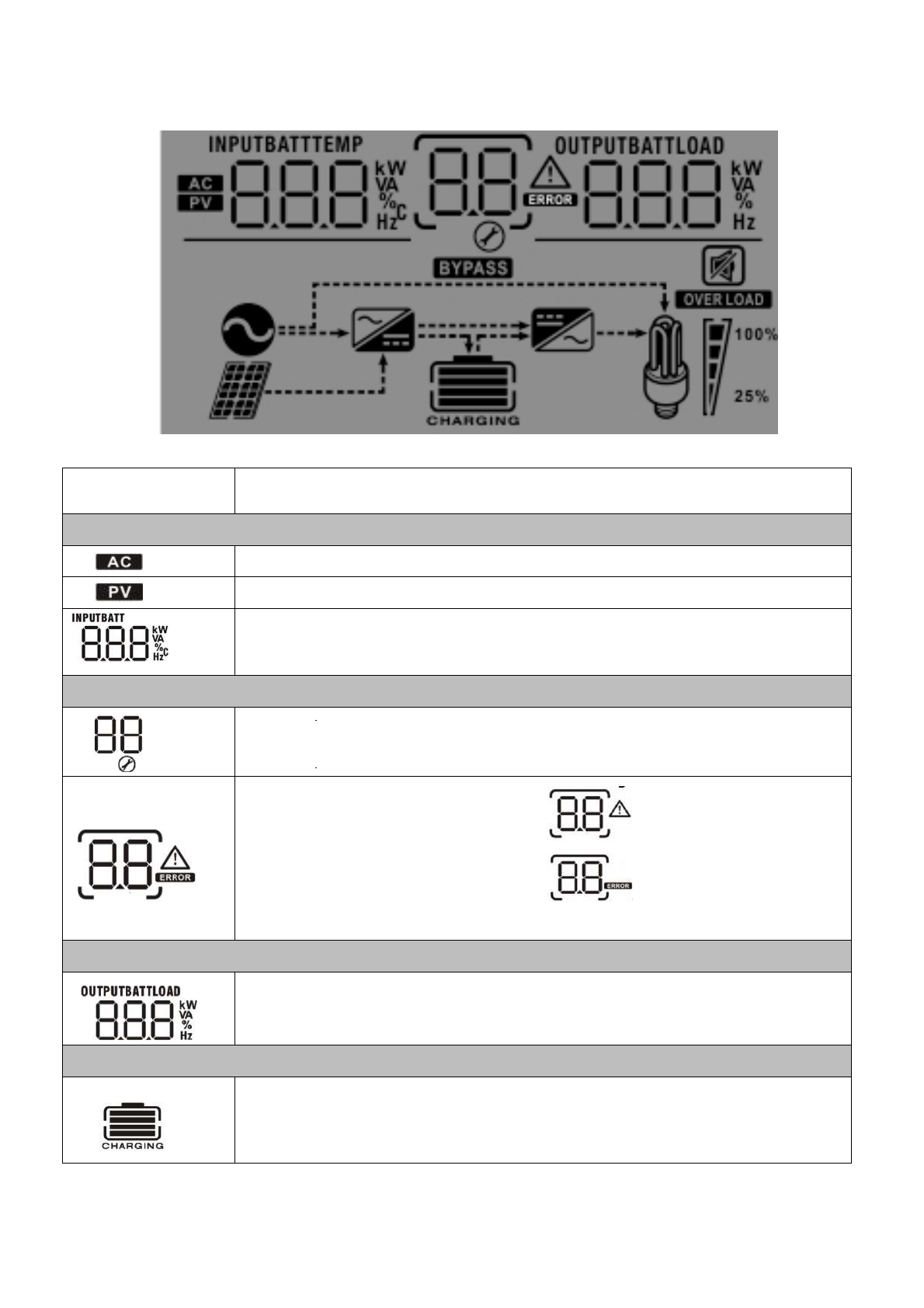

5.3 LCD Display Icons

Icon

Function

description

Input Source Information

Indicates the AC input.

Indicates the PV input

Indicate input voltage, input frequency, PV voltage, charger current, battery

voltage.

Configuration Program and Fault Information

Indicates the setting programs.

Indicates the warning and fault codes.

Warning: flashing with warning code.

Fault: lighting with fault code

Output Information

Indicate output voltage, output frequency, load percent, load in VA, load in

Watt and discharging current.

Battery Information

Indicates battery level by 0-24%, 25-49%, 50-74% and 75-100% in battery mode and

charging status in line mode.

10

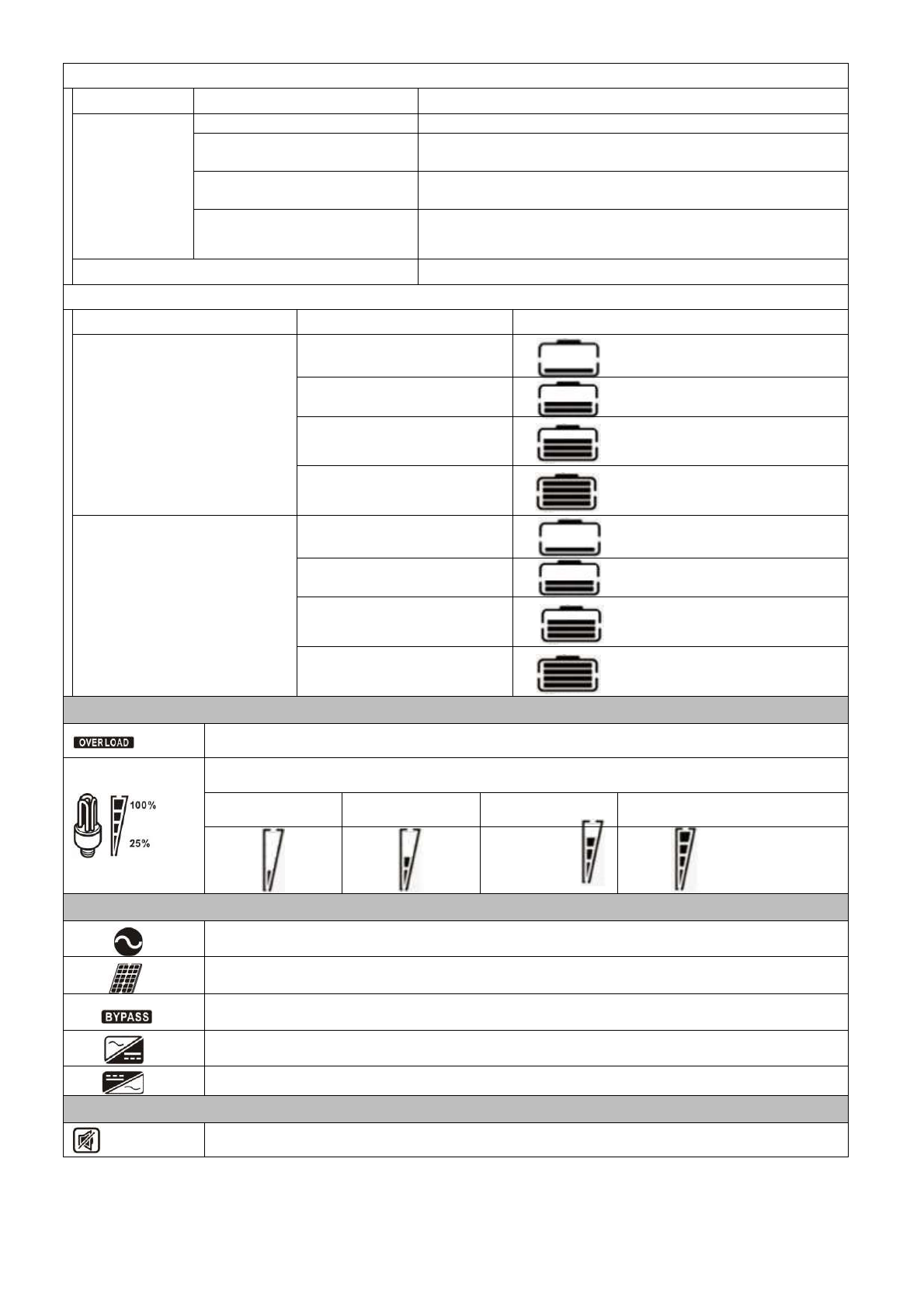

In AC mode, it will present battery charging status.

Status Battery voltage LCD Display

Constant

Current mode /

Constant

Voltage mode

<2V/cell 4 bars will

f

lash in tu

r

ns.

2 ~ 2.083V/cell Bottom bar will be on and the other three bars will flash in

turns.

2.083 ~ 2.167V/cell Bottom two bars will be on and the other two bars will flash

in tu

r

ns.

> 2.167 V/cell Bottom three bars will be on and the top bar will flash.

Floating mode. Batteries are fully charged. 4 bars will be on.

In battery mode, it will present battery capacity.

Load Percentage Battery Voltage LCD Display

Load >50%

< 1.85V/cell

1.85V/cell ~ 1.933V/cell

1.933V/cell ~ 2.017V/cell

> 2.017V/cell

Load < 50%

< 1.892V/cell

1.892V/cell ~ 1.975V/cell

1.975V/cell ~ 2.058V/cell

> 2.058V/cell

Load Information

Indicates overload.

Indicates the load level by 0-24%, 25-49%, 50-74% and 75-100%.

0%~24% 25%~49% 50%~74% 75%~100%

Mode Operation Information

Indicates unit connects to the mains.

Indicates unit connects to the PV panel.

Indicates load is supplied by utility power.

Indicates the utility charger circuit is working.

Indicates the DC/AC inverter circuit is working.

Mute Operation

Indicates unit alarm is disabled.

11

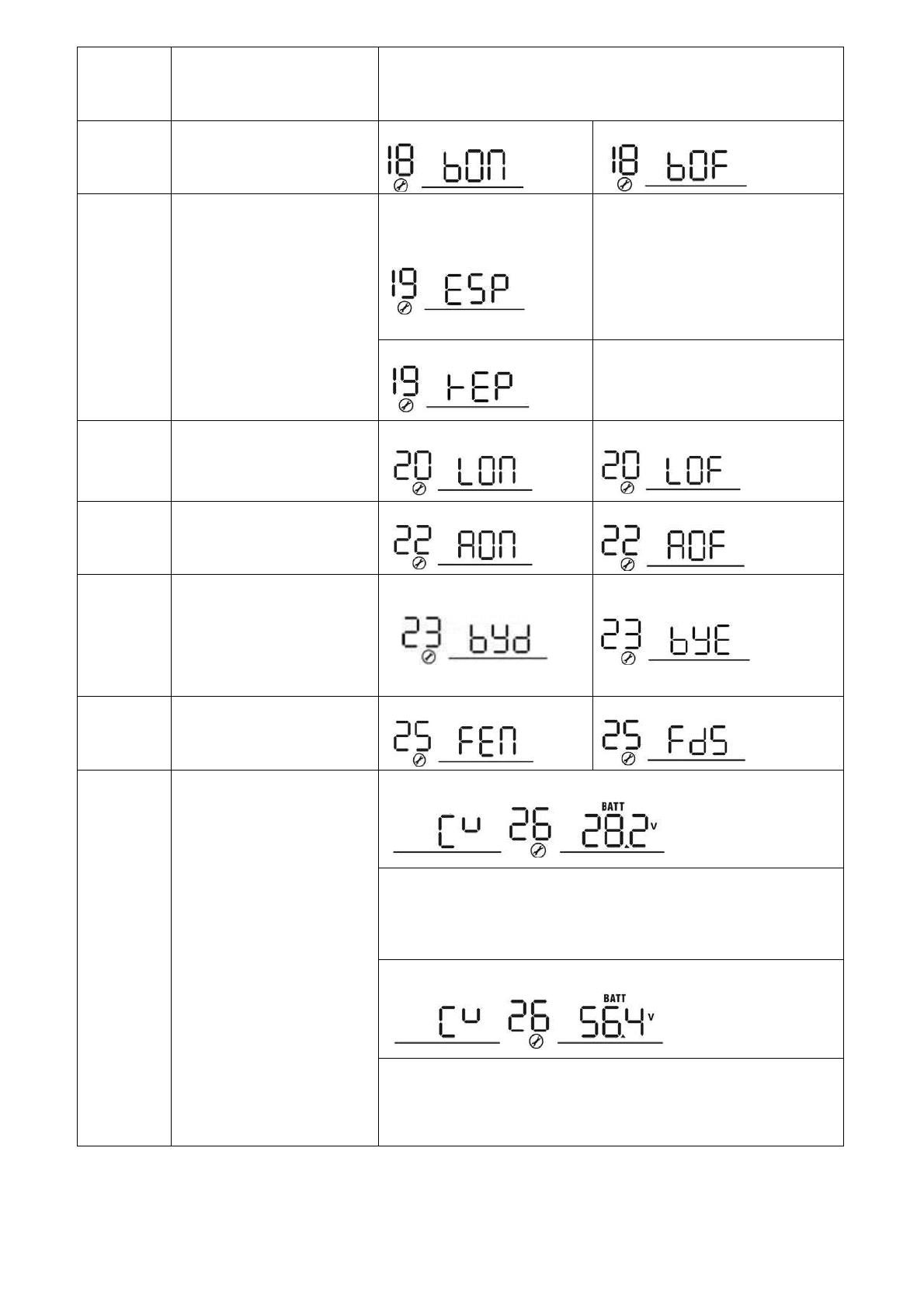

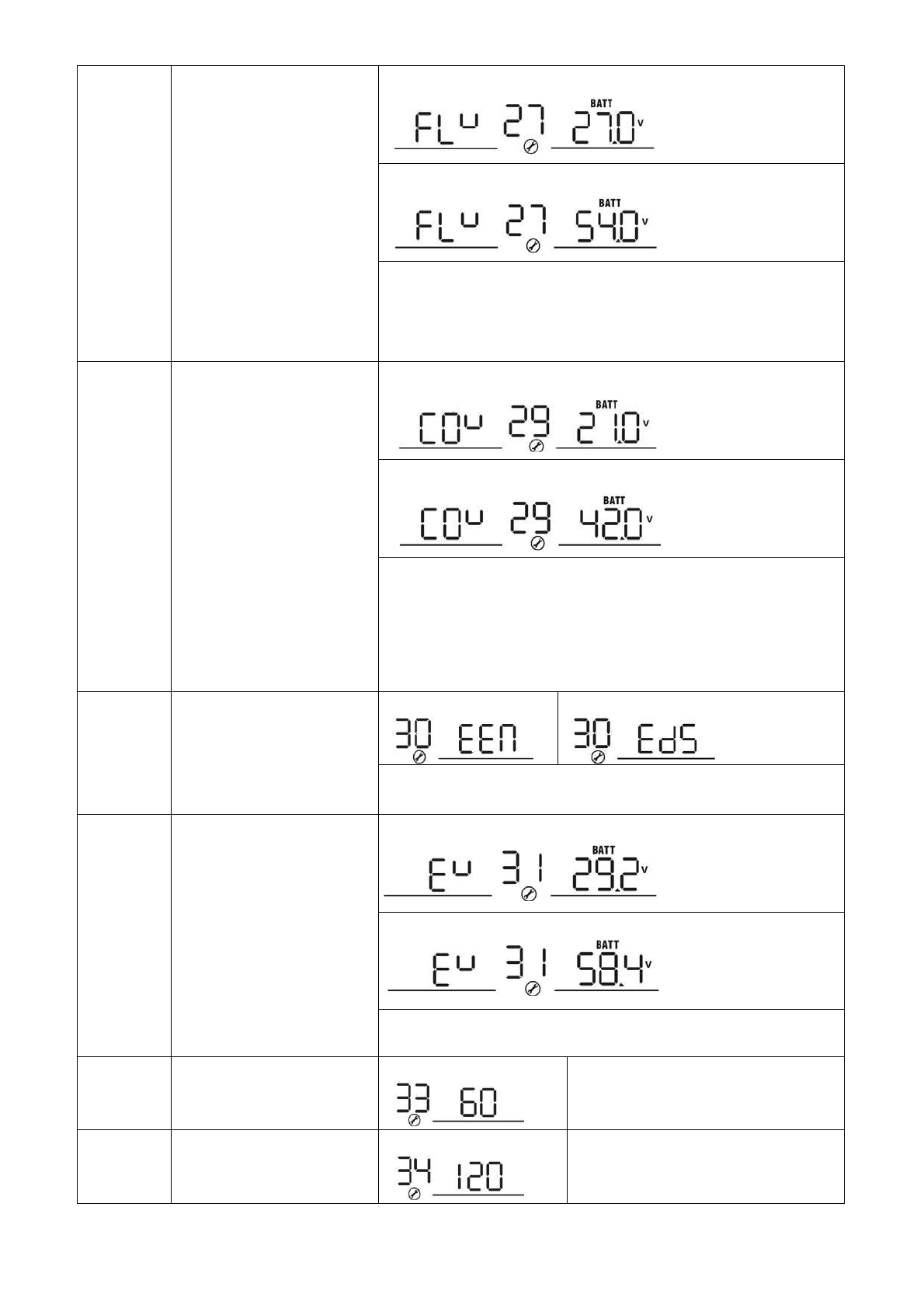

5.4 LCD Setting

After pressing and holding ENTER button for 3 seconds, the unit will enter setting mode. Press “UP” or

“DOWN” button to select setting programs. And then, press “ENTER” button to confirm the selection or

ESC button to exit.

Note:All settings must be modified in battery mode and must be rebooted to be valid.

Program Description Selectable option

00

Exit setting mode

Escape

01

Output source priority:

To configure load power

source priority

Utility first (default)

Utility will provide power to the

loads as first priority.

Solar and battery energy will

provide power to the loads only

when utility power is not available.

Solar first

Solar energy provides power to

the loads as first priority.

If solar energy is not sufficient to

power all connected loads, battery

energy will supply power the loads

at the same time.

Utility provides power to the loads

only when any one condition

happens:

- Solar energy is not available

- Battery voltage drops to

low-level warning voltage or the

setting point in program 12.

Battery first

Solar energy provides power to

the loads as first priority.

If solar energy is not sufficient to

power all connected loads, battery

energy will supply power to the

loads at the same time.

Utility provides power to the loads

only when battery voltage drops

to either low-level warning voltage

or the setting point in program 12.

02

Maximum charging current:

To configure total charging

current for solar and utility

chargers.

(Max. charging current =

utility charging current +

solar charging current)

Default:60A

setting range is 10 A to100 A, the

increment or decrement is 10A pe

r

click.

12

03

AC input voltage range

Appliances (default) If selected, acceptable AC input

voltage range will be within

90-280VAC.

UPS If selected, acceptable AC input

voltage range will be within

170-280VAC.

05

Battery type

AGM (default) Flooded

User-Defined If “User-Defined” is selected,

battery charge voltage can be set

up in program 26, 27.

06

Auto restart when overload

occurs

Restart disable (default) Restart enable

07

Auto restart when over

temperature occurs

Restart disable (default) Restart enable

09

Output frequency

50Hz (default) 60Hz

10

Output voltage

220V 230V (default)

240V

11

Maximum utility charging

current

Note: If setting value in

program 02 is smaller than

that in program in 11, the

inverter will apply charging

current from program 02 for

utility charger.

Default:30A

setting range is 2 A,10A to 80 A,

the increment or decrement is 10A

per click.

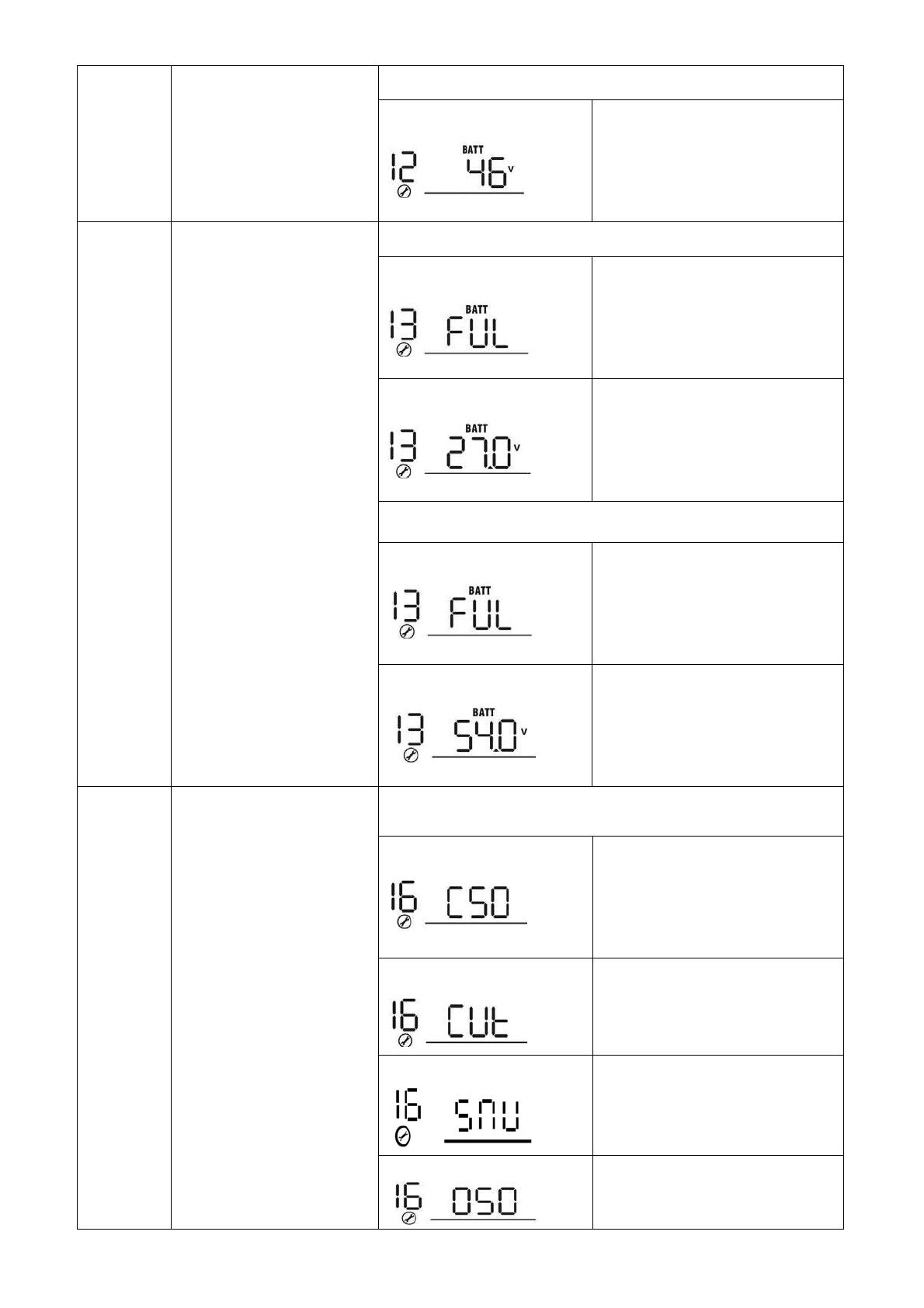

12

Setting voltage point back to

utility source when selecting

“SBU priority” or “Solar first”

in program 01.

Available options in 3.5KW model:

23.0V(default)

Setting voltage point back

24V model:(default 23.0Vdc)

setting range :22.0V to 25.5V

setting increase or decrease of

0.5V.

13

12

Setting voltage point back to

utility source when selecting

“SBU priority” or “Solar first”

in program 01.

Available options in 5.5KW model:

46.0V(default)

Setting voltage point back

48V model:(default 46.0Vdc)

setting range :44.0V to 51V

setting increase or decrease of

1.0V.

13

Setting voltage point back to

battery mode when selecting

“

SBU priority” or “Solar first”

in program 01.

A

vailable options in 3.5KW model:

Battery fully charged

27.0V (default)

Setting voltage point back

24V model:(default 46.0Vdc)

setting range :24.0V to 29.0V

setting increase or decrease of

0.5V.

A

vailable options in 5.5KW model:

Battery fully charged

54.0V (default)

Setting voltage point back

48V model:(default 46.0Vdc)

setting range :48.0V to 58.0V

setting increase or decrease of

1.0V.

16

Charger source priority:

To configure charger

source priority

If this inverter/charger is working in Line, Standby or Fault mode,

charger source can be programmed as below:

Utility first Utility will charge battery as first

priority.

Solar energy will charge battery

only when utility power is not

available.

Solar first Solar energy will charge battery as

first priority.

Utility will charge battery only

when solar energy is not available.

Solar and Utility (default)

Solar energy and utility will char

g

e

battery at the same time.

Only Solar Solar energy will be the only

charger source no matter utility is

available or not.

14

16

Charger source priority:

To configure charger

source priority

If this inverter/charger is working in Battery mode, only solar

energy can charge battery. Solar energy will charge battery if it's

available and sufficient.

18

Alarm control

Alarm on (default) Alarm off

19

Auto return to default

display screen

Return to default display

screen (default)

If selected, no matter how users

switch display screen, it will

automatically return to default

display screen (Input voltage

/output voltage) after no button is

pressed for 1 minute.

Stay at latest screen If selected, the display screen will

stay at latest screen user finally

switches.

20

Backlight control

Backlight on (default) Backlight off

22

Beeps while primary source

is interrupted

Alarm on (default) Alarm off

23

Overload bypass:

When enabled, the unit will

transfer to line mode if

overload occurs in battery

mode.

Bypass disable (default) Bypass enable

25

Record Fault code

Record enable (default) Record disable

26

Bulk charging voltage

(C.V voltage)

3.5K default setting: 28.2V

If self-defined is selected in program 5, this program can be set

up. Setting range is from 25.0V to 31.5V Increment of each click

is 0.1V.

5.5K default setting: 56.4V

If self-defined is selected in program 5, this program can be set

up. Setting range is from 48.0V to 61.0V Increment of each click

is 0.1V.

15

27

Floating charging voltage

3.5K default setting: 27.0V

5.5K default setting: 54.0V

If self-defined is selected in program 5, this program can be set

up. Setting range is from 25.0V to 31.5V for 3.5KVA model and

48.0V to 61.0V for 5.5KVA model. Increment of each click is

0.1V.

29

Low DC cut-off voltage

3.5K default setting: 21.0V

5.5K default setting: 42.0V

If self-defined is selected in program 5, this program can be set

up. Setting range is from 21.0V to 24.0V for 3.5KVA model and

42.0V to 48.0V for 5.5KVA model. Increment of each click is 0.1V.

Low DC cut-off voltage will be fixed to setting value no matter

what percentage of load is connected.

30

Battery equalization

Battery equalization Battery equalization disable (default)

If “Flooded” or “User-Defined” is selected in program 05, this

program can be set up.

31

Battery equalization voltage

3.5KVA default setting: 29.2V

5.5KVA default setting: 58.4V

Setting range is from 25.0V to 31.5V for 3.5KVA model and 48.0V

to 61.0V for 5.5KVA model. Increment of each click is 0.1V.

33

Battery equalized time 60min (default) Setting range is from 5min to 900min.

Increment of each click is 5min.

34

Battery equalized timeout 120min (default) Setting range is from 5min to 900 min.

Increment of each click is 5 min.

16

35

Equalization interval 30days (default) Setting range is from 0 to 90 days.

Increment of each click is 1 day

36 Equalization activated

immediately

Enable Disable (default)

If equalization function is enabled in program 30, this program can

be set up. If “Enable” is selected in this program, it’s to activate

battery equalization immediately and LCD main page will

shows

“ ”.

If “Disable” is selected, it will cancel equalization function

until next activated equalization time arrives based on program 35

setting. At this time, “ ”will not be shown in LCD main page.

40 Discharge limited current

OFF: default ;

discharge current limited disable

setting range :10A to 200A

setting increase or decrease of 5A.

NOTE:1. if you work in “PV priority

mode” or “SBU priority mode”, when

the loads is greater than the current

limiting point, it will automatically

switch to utility mode.

2.if it only works in battery mode,when

the load is greater than the current

limiting point,the inverter will shut

down immediately.

41 Lithium battery discharge

stop

Default:6%

1.When the battery capacity of the

lithium battery is lower than the set

point, the inverter stops discharging

and output will be turned off.

setting range :1% to 60%

setting increase or decrease of 1%.

2.when the communication

connection between the lithium

battery and the inverter is

normal,”USER” will be displayed next

to the battery icon on ten display

screen

42 Lithium battery charge stop

Default:96%

1.When the battery capacity of the

lithium battery is higher than the set

point, the inverter stops charging

setting range :60% to 100%

setting increase or decrease of 1%.

2.when the communication

connection between the lithium

battery and the inverter is

normal,”USER” will be displayed next

to the battery icon on ten display

screen

17

5.5 Fault Reference Code

Fault Code Fault Event

01 Fan is locked when inverter is off.

02 Over temperature

03 Battery voltage is too high

04 Battery voltage is too low

05 Output short circuited or over temperature is detected by internal converter

components.

06 Output voltage is too high.

07 Overload time out

08 Bus voltage is too high

09 Bus soft start failed

51 Over current or surge

52 Bus voltage is too low

53 Inverter soft start failed

55 Over DC voltage in AC output

57 Current sensor failed

58 Output voltage is too low

59 PV voltage is over limitation

18

5.6 Warning Indicator

Warning Code Warning Event

01 Fan is locked when inverter is on.

02 Over temperature

03 Battery is over-charged

04 Low battery

07 Overload

10 Output power derating

15 PV energy is low

16 High AC input (>280VAC) during BUS soft start

Battery equalization

Battery is not connected

This manual suits for next models

2

Table of contents

Other CNBOU Inverter manuals

Popular Inverter manuals by other brands

Samlexpower

Samlexpower PST-120-12 owner's manual

Deye

Deye SUN-3.6K-G user manual

Lenze

Lenze i510 Series operating instructions

Endress

Endress ESE Series Use and maintenance manual

Solplanet

Solplanet ASW 3-6K S G2 Series Quick installation guide

Victron energy

Victron energy MultiPlus 12/5000/200-100 230V user manual