C (G)-310 Main Frame Connector

comtestnetworks.com

5. Grounding

5.1 Three methods may be used to connect the C–

310 connector to electrical ground. The connector

ground wiring is terminated at a no. 10 ground

screw terminal on the rear of the connector base

(Figure 4). This ground screw is jumpered to the

lower portion of the connector mounting bracket

through a short (3-1/2-inch) ground strap. The

grounding methods are described in the following

paragraphs.

5.2 Basic grounding method: Use the 7 3/4-

inch interconnector ground strap supplied with the

unit to connect the 1/4-20 mounting screws on

adjacent connectors (see I Basic, Figure 5).

Repeat this procedure for each pair of connectors

on the same vertical. Connect the bottom 1/4-20

mounting screw on the lowest connector to a 1/4-

20 terminal on the main frame copper ground bar

using the long (26 1/2- inch) ground strap.

5.3 Independent ground method: Use the

interconnector ground strap (17 1/2 inches long) to

connect the no. 10 ground screw terminals of each

pair of adjacent connector bases on the same

vertical (see II Independent, Figure 5 ). Connect

the no. 10 ground screw ground terminal on the

lowest connector to the 1/4-20 terminal on the

main frame copper ground bar using the long (28-

inch) ground strap.

5.4 Isolated ground method: Remove the short

(3 1/2-inch) ground strap from the no. 10 screw

ground terminal and the connector mounting

bracket. Use the interconnector ground strap (17

1/2-inch) to connect the no. 10 screw ground

terminals of each pair of adjacent connector bases

on the same vertical (see III Isolated, Figure 5).

Connect the no. 10 screw ground terminal on the

lowest connector to the 1/4 -20 terminal on the

main frame copper ground bar using the long

(28-inch) ground strap.

Note: The long ground straps, 26 1/2-inch and 28-

inch, and the interconnector ground strap, 17 1/2-

inch, are accessory items and must be ordered

separately.

5.5 Tighten all mounting screws after all of the

connectors and ground straps are placed in

position on the vertical mounting bar.

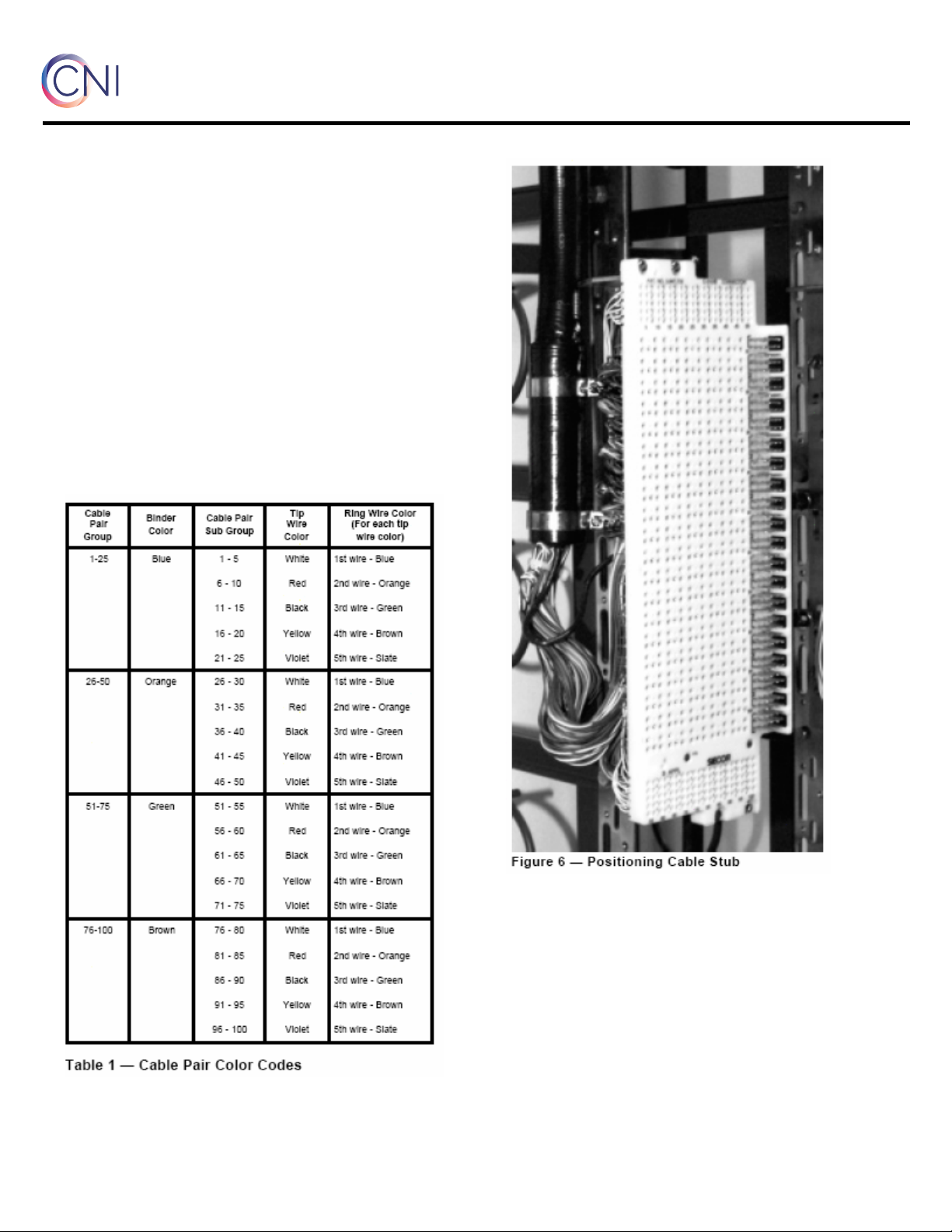

5.6 The clamps on the pressure plug of the

connector stub should be carefully bent to the

vertical mounting bar, so the stub cable will be out

of the way for future work at the frame (Figure 6).

5.7 The stub cables of all connectors on a

vertical mounting bar should be neatly arranged

against the transverse arms of the frame. Lash the

stub to these transverse arms in a neat manner.

5.8 Close the cable entrance slots, or ferrules, in

the floor, in accordance with local instructions.