3

Table Of Contents

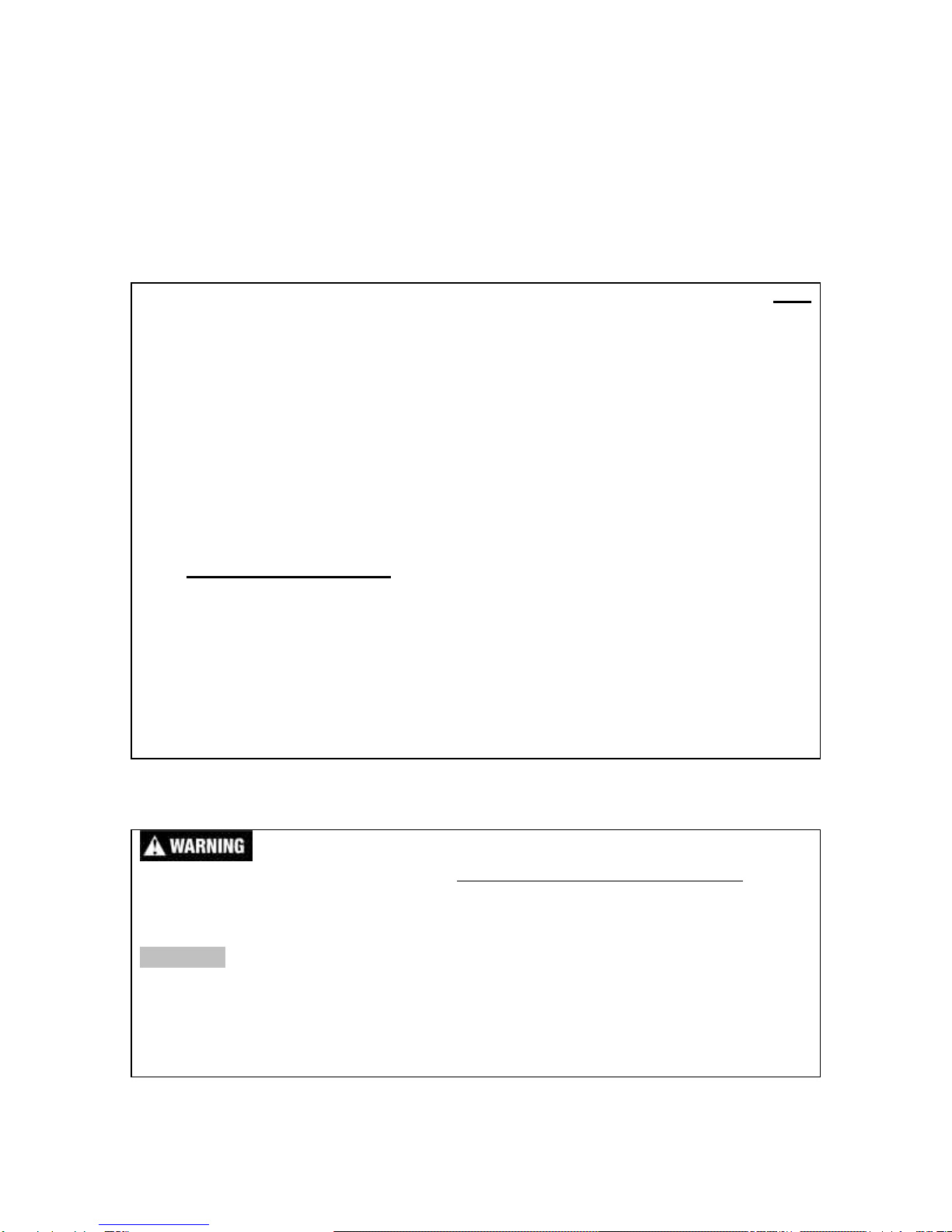

GENERAL INFORMATION............................................................................................5

SPECIFICATIONS -GENERAL...........................................................................................5

OPTIONAL COMPONENTS................................................................................................6

SPECIFICATIONS -TORQUE VALUES ..............................................................................7

BREAK-IN PROCEDURE...................................................................................................8

STARTING PROCEDURE ..................................................................................................9

GENERAL TIPS................................................................................................................9

MAINTENANCE .............................................................................................................10

SCHEDULE & TIPS.........................................................................................................10

REPLACING TRANSMISSION / CLUTCH LUBRICANT ......................................................11

CHAIN ADJUSTMENT......................................................................................................13

REAR BRAKE MAINTENANCE ........................................................................................13

AIR FILTER CLEANING...................................................................................................14

FORK OIL REPLACEMENT.............................................................................................15

PARTS .............................................................................................................................17

PARTS –BARS AND CONTROLS ...................................................................................17

PARTS -CARBURETOR .................................................................................................18

PARTS –COOLANT SYSTEM.........................................................................................19

PARTS –ELECTRICAL SYSTEM.....................................................................................20

PARTS –ENGINE –BOTTOM END AND TRANSMISSION...............................................21

Parts –Engine –Clutch and Kick Starter...........................................................22

Parts –Engine –Ignition and Water Pump........................................................23

Parts –Engine –Top End.....................................................................................24

PARTS –EXHAUST SYSTEM .........................................................................................25

PARTS –FORKS & TRIPLE CLAMPS.............................................................................26

Parts –Forks –Leg Assembly.............................................................................27

Parts –Forks –Damper Assembly......................................................................28

Parts –Forks –Damper –Base Valve Assembly.............................................29

Parts –Forks –Damper –Mid Valve Assembly................................................30

PARTS –FRAME –BRAKE MOUNTS, PLASTIC SHIELD & FOOTPEGS.........................31