®

23801 E. La Palma Ave., Yorba Linda, Ca 92887 Ph. 714.692.8180, Fax. 714.692.5016

www.fi2000r.com

11/10 2

Instruction Manual >

Page 2 of 3

10. Once all connections have been verified, lower the fuel tank into proper position and install bolt.

Reinstall seat and make sure all bolts are properly tightened.

11. Reinstall left side cover.

ADVANCED TUNING

The Fi2000 has the ability to efficiently tune the EFI system on your motorcycle for slip-on or full

exhaust systems. It comes pre-set from the factory for popular brand name full exhaust systems.

Both dyno testing and on-road exhaust gas analysis have been used to develop the best base

settings for drivability and power.

Not all slip-on mufflers flow exactly the same. Some eliminate power valves and others don’t. Some

are made with street baffles, others with race or competition baffles. Full exhaust systems offer even

greater variation in construction, features and performance. The Fi2000 has the ability to tune the EFI

system on your motorcycle to any of these exhausts by applying a logical and systematic approach to

altering the base settings supplied with your Fi2000. These suggestions should be followed step by

step and help you achieve success.

** Only attempt adjustments on a fully warmed motor **

1. Start with the base setting in Figure 4 if a full exhaust system is installed. If a full exhaust system

is installed in combination with a Cobra PowrFlo™ Air Intake System the same setting will be

adequate, please visit: www.cobrausa.com for system details. Refer to Step 2 if the stock

exhaust is installed or a slip-on muffler is being used to determine the proper pot settings. Adjust

and test only ONE adjustment pot at a time until you are happy with the result.

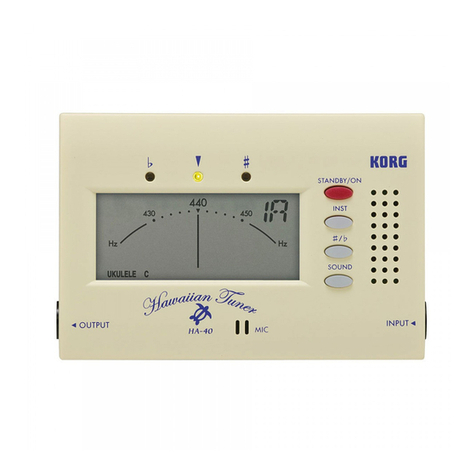

2. Start with the left hand or green light pot. This adjustment works either from idle or above idle

(varies with bike) to a R.P.M. of about 5000 (also varies with bike) while the bike is driven at a

steady throttle or slowly increasing throttle. This is the cruise range and is where the emissions

leanness creates issues like choppy on-off throttle application, surging, and backfiring on trailing

throttle.

3. Turn this pot back to zero, and make one position increases until you feel the best performance in

this range. Do this test a few times to make sure you have it right.

4. The middle or yellow pot is an engine load-triggered fuel adding adjustment. A rapid increase of

the throttle at any R.P.M. will add additional fuel and as long as that predetermined load is

present, fuel will continue. As engine loads increase in higher gears the acceleration fuel will stay

on longer and be more effective. Starting with the base setting, test ride the motorcycle in 4th or

5th gear and perform moderately fast roll-on throttle from a repeating standard R.P.M. or speed.

Increase the pot one position at a time and stop as soon as you don’t feel any improvement.

5. The right hand or red pot is for the fuel setting required when the engine is maximizing its R.P.M.

and power delivery. This pot is similar to the main jet in a carburetor. It will take a combination of

a minimum R.P.M. and a predetermined amount of engine load to initiate this fuel. The

straightaway on a racetrack or an inertia dyno are the best places to set this pot. Full exhaust

systems of high quality construction increase flow characteristics and may increase fuel demands

over our base settings. Also, air filters specifically designed for higher than stock airflow can

create need for higher fuel setting. Try an additional one-position pot setting at a time.

6. Camshaft changes or major air box modifications can alter an engine’s volumetric efficiency and

create a greater demand on the engine’s fuel system than the Fi2000 may have the ability to

adjust for.

TROUBLE SHOOTING

If you have any problems refer to note 9 in the main body of these instructions.