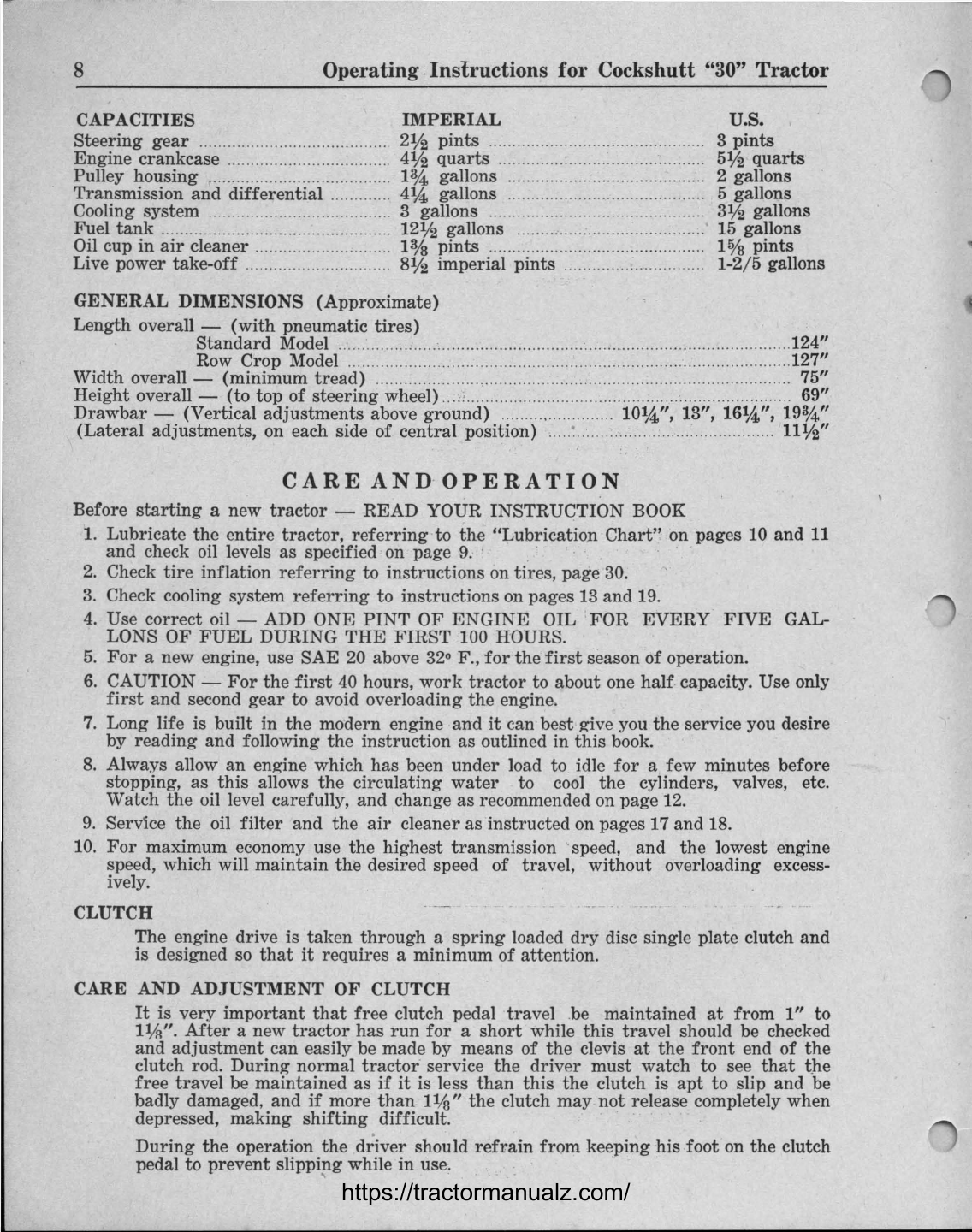

ENGINE Cylinder sleeves - Removeable, Alloy Type.

Engine lubrication -Pressure.

Ignition -

Battery

through

high

tension coil and distributor.

Engine speed - 1650 R.P.M. (maximum) under full load; 1810.R.P.M. no

load.

Power

take-off ·1%" diameter - 6 spline shaft. - Speed 530 R.P.M.

with

engine speed

at

1500 R.P.M.

TRACTOR

SERIAL

NUMBER -Stamped on

left

side of main

frame

or on left side of

cylinder block.

ENGINE

NUMBER -Stamped on

left

side of cylinder block.

Number of cylinders - 4; Bore and stroke -3-7/16" x

4th";

Displace-

ment

- 153 cubic inches.

Spark

plugs -Champion J5.

Main

and

connecting rod bearings -Steel backed, babbitt lined Precision

Type

.

7

SPECIFICATIONS

CLUTCH AND

BELT

PULLEY

Clutch -single plate,

dry

disc

(spring

loaded) 9"

Pulley speed (Engine speed

at

1500 R.P.M.) 1227

r.p.m,

Belt speed

(with

8%," pulley) (Engine speed

at

1500 R.P.M.) .. 2650 f.p.m,

Pulley diameter 8%,"

Pulley face

6%"

TRANSMISSION

(Standard)

4-speed

forward;

sliding

gear

type.

(Based on 10-38 pneumatic

tires;

Engine speed

-1500

r.p.m.)

1st

2.5

2nd 3.6

3rd

~

5.

Speed miles 4th

(At

maximum no load engine speed 1810 R.P.M.) 12.

per hour Reverse .................................................... 3.2

ADDITIONAL

SPEEDS

USING

CREEPER

UNIT:

1st

1.5

2nd 2.2

3rd

3.

Speed miles

4th

5.9

per

hour Reverse 1.9

DIFFERENTIAL

-Spiral bevel.

FINAL

DRIVE - One piece forged steel bull gears splined to alloy steel main axle.

WHEELS AND TREAD -

Front

Wheels (pneumatic

tires)

5.50 -16

Rear

Wheels (pneumatic

tires)

10.00 -38

.Tread -

front

Standard

Model

53%"

and

560/8"

Row Crop Model

73,4"

and 11"

Rear

Wheels ... (Both Models) 56", 60", 64", 68", 72", 76", 80" and 84"

Wheel Base -

Standard

Model 81%,"

Row Crop Model

84%.'~

Minimum

turning

radius (56"

rear

wheel

thread)

Standard

Model-

(without applying brakes 12'

.(applying brakes 11' 2"

Row Crop Model - (without applying brakes 8' 4"

(applying brakes 7' (\"

Operating Instructions for Cockshutt "30" Tractor

https://tractormanualz.com/