Service Manual Cooltech

Content

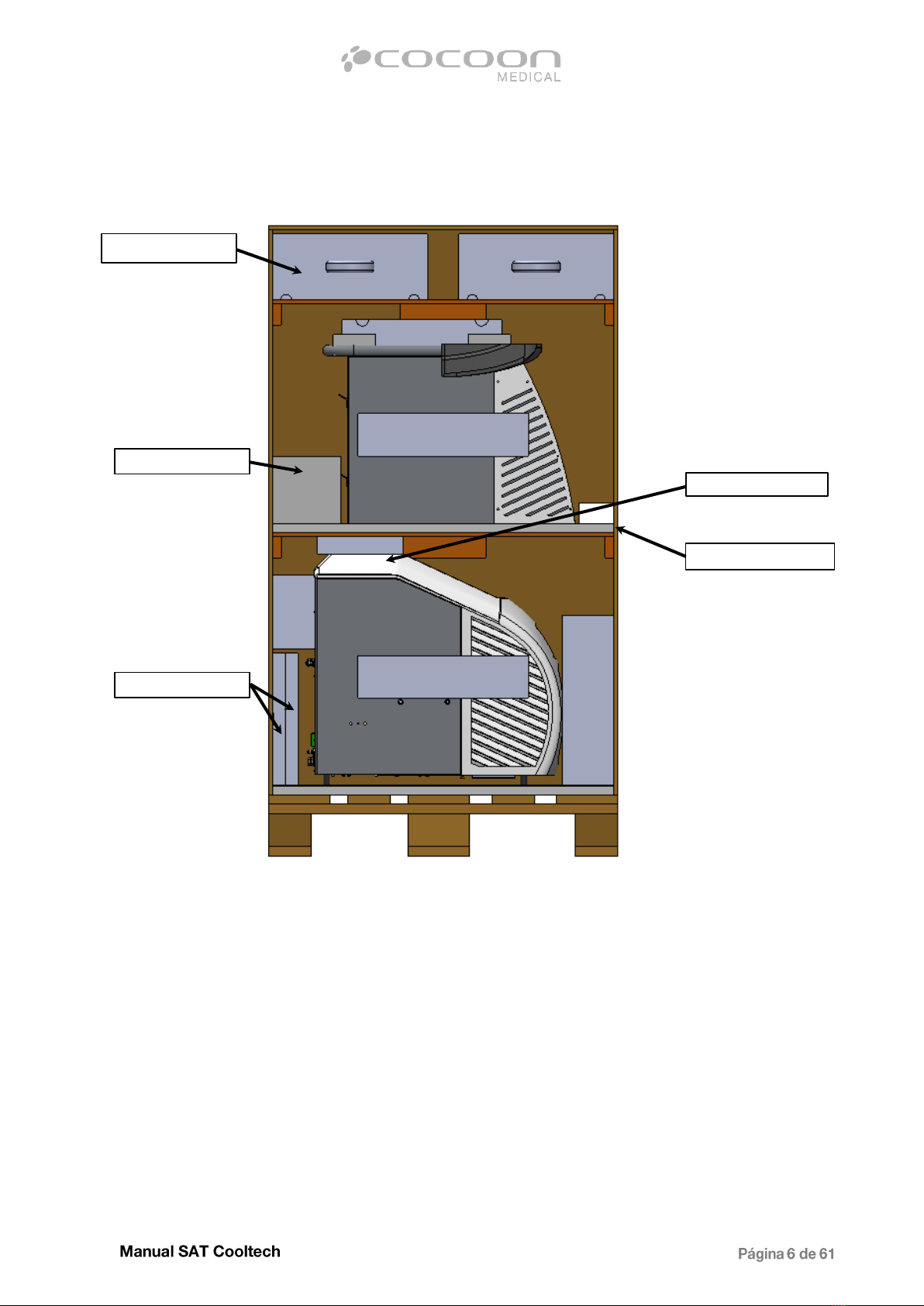

1. Equipment description ........................................................................................................................................ 3

1.1. Unpacking and installation ........................................................................... ¡Error! Marcador no definido.

1.2. Equipment components ............................................................................... ¡Error! Marcador no definido.

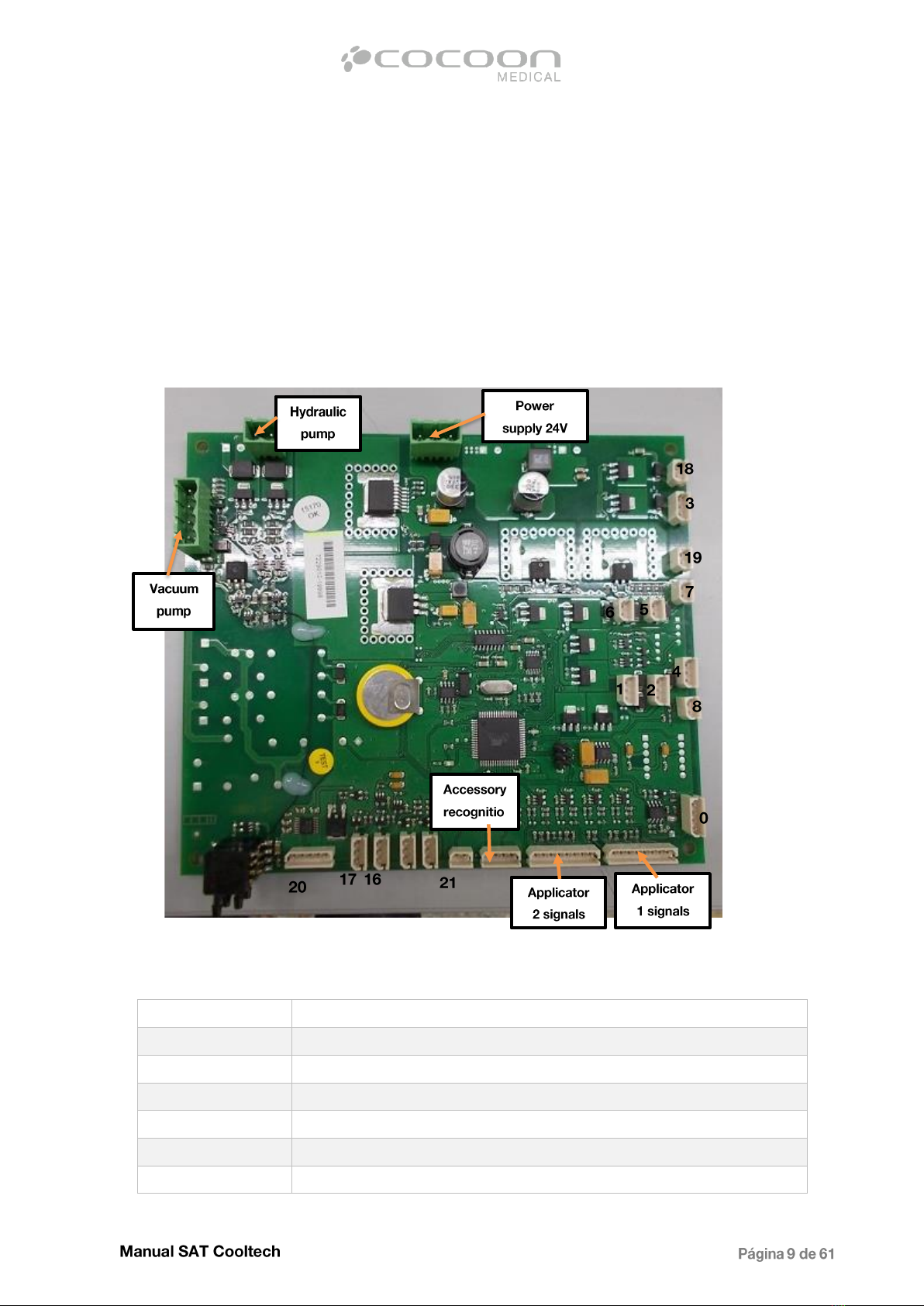

1.2.1. Electronics........................................................................................................................................... 8

1.1.1. Refrigeration system............................................................................ ¡Error! Marcador no definido.

1.1.2. Vacuum system.................................................................................... ¡Error! Marcador no definido.

1.2. Equipment maintenance and accessories .................................................... ¡Error! Marcador no definido.

1.2.1 - External tanks cleaning ........................................................................................................................... 13

1.2.2 - Air filter cleaning (ventilation) ................................................................................................................ 13

1.2.3 - Applicators internal cleaning................................................................................................................... 13

2. Sat tools ................................................................................................................ ¡Error! Marcador no definido.

2.1. SAT codes...................................................................................................... ¡Error! Marcador no definido.

2.2. Tools and special utilities.............................................................................. ¡Error! Marcador no definido.

2.3. Report incidents ........................................................................................... ¡Error! Marcador no definido.

2.4. Software update ........................................................................................... ¡Error! Marcador no definido.

3. Troubleshooting and alarms ................................................................................ ¡Error! Marcador no definido.

3.1. Screen alarms ............................................................................................... ¡Error! Marcador no definido.

3.1.1 - Low coolant level..................................................................................................................................... 22

3.1.2 - High or low pressure hydraulic circuit..................................................................................................... 22

3.1.3 - Emergency stop actived .......................................................................................................................... 25

3.1.4 - High or very low equipment temperature warning ................................................................................ 26

3.1.5 - Vacuum circuit cleaning reminder .......................................................................................................... 27

3.1.6 - Applicator disconnected.......................................................................................................................... 27

3.1.7 - Applicator temperature error ................................................................................................................ 29

3.1.8 -Applicator programmed vacuum not reached......................................................................................... 31

3.2. Equipment faults .......................................................................................... ¡Error! Marcador no definido.

3.2.1 - Equipment does not turn on .................................................................................................................. 35

3.2.2 - Accessories not recognized ..................................................................................................................... 38

3.2.3 - Screen does not respond ........................................................................................................................ 40

3.2.4 –Lined screen............................................................................................................................................ 41

3.2.5 - Treatment screen not allowed ................................................................................................................ 42

3.2.6 - Set temperature not reached.................................................................................................................. 44