1. Technical specifications

Copyright © 2015 by Endecotts Ltd. 23

1. Technical specifications

Specifications

Range 20μm to 125 mm

Drive / sieving motion electromagnetic 3D

Max. Batch / feed capacity 3 kg

Max. Number of fractions 8 full height / 16 half height (200 mm or 8”)

Amplitude 0 - 3 mm digital setting in 10 steps

Speed 3,000 min-1 at 50 Hz

Time display digital, 0:10-99:50 min

Interval operation yes (one mode)

Suitable for dry sieving yes

Suitable for wet sieving yes

Serial interface -

Sieve diameter 100 / 200 mm or 3”/ 8''

Max. Height of sieve stack up to 450 mm

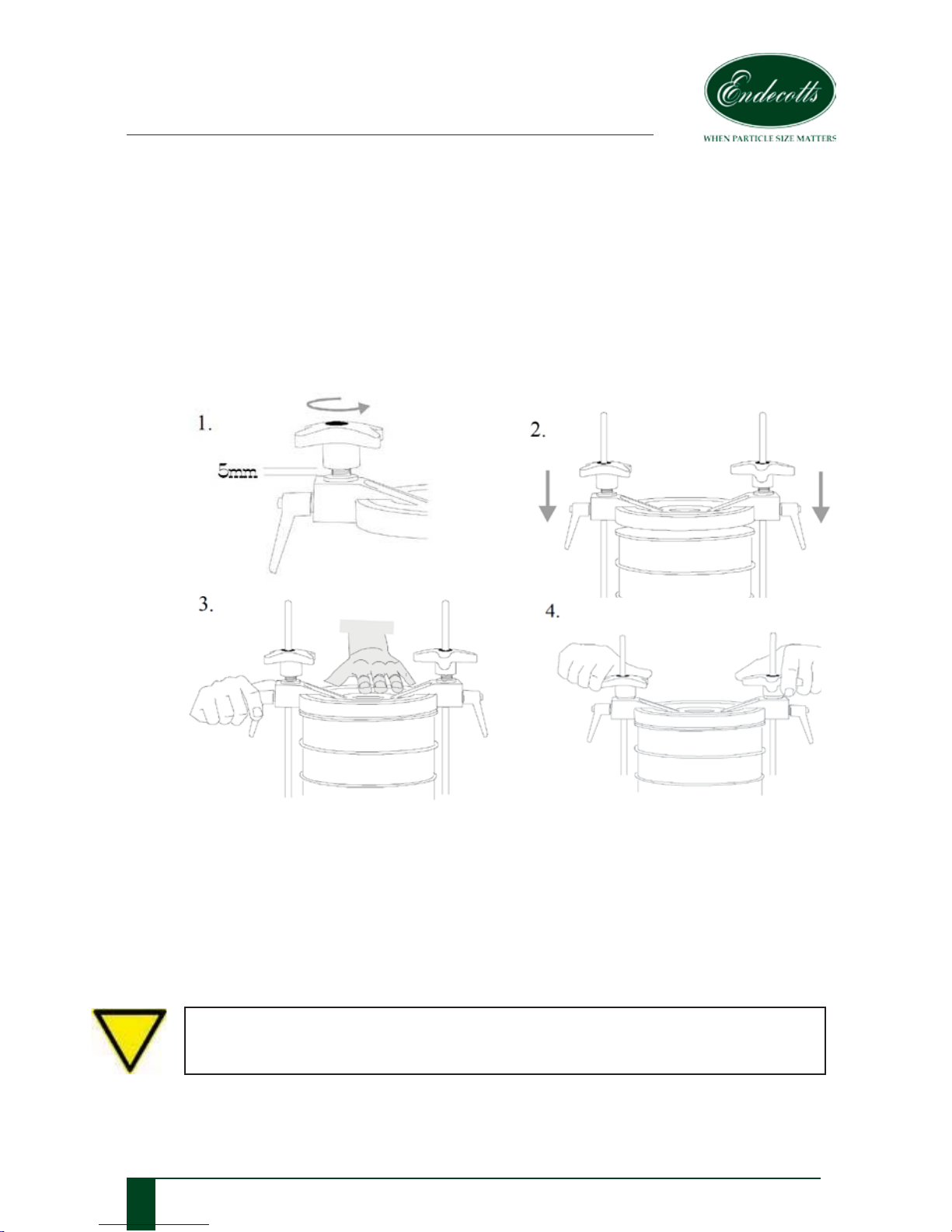

Clamping device quick-release clamping system (included)

Model bench top

Protection code IP 54

Electrical supply different voltages available

Power connection 1 – Phase

W x H x D 418 x 232 x 435 mm

Net weight 35 kg

Standards CE

Noise characteristic values:

Example 1:

Emission value related to workplace LpAeq = 63 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

1.5 mm)

Example 2:

Emission value related to workplace LpAeq = 67 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

3 mm)