52411Vacuumoven0.9_1.9_ver_1.0 as version

www.coleparmer.com

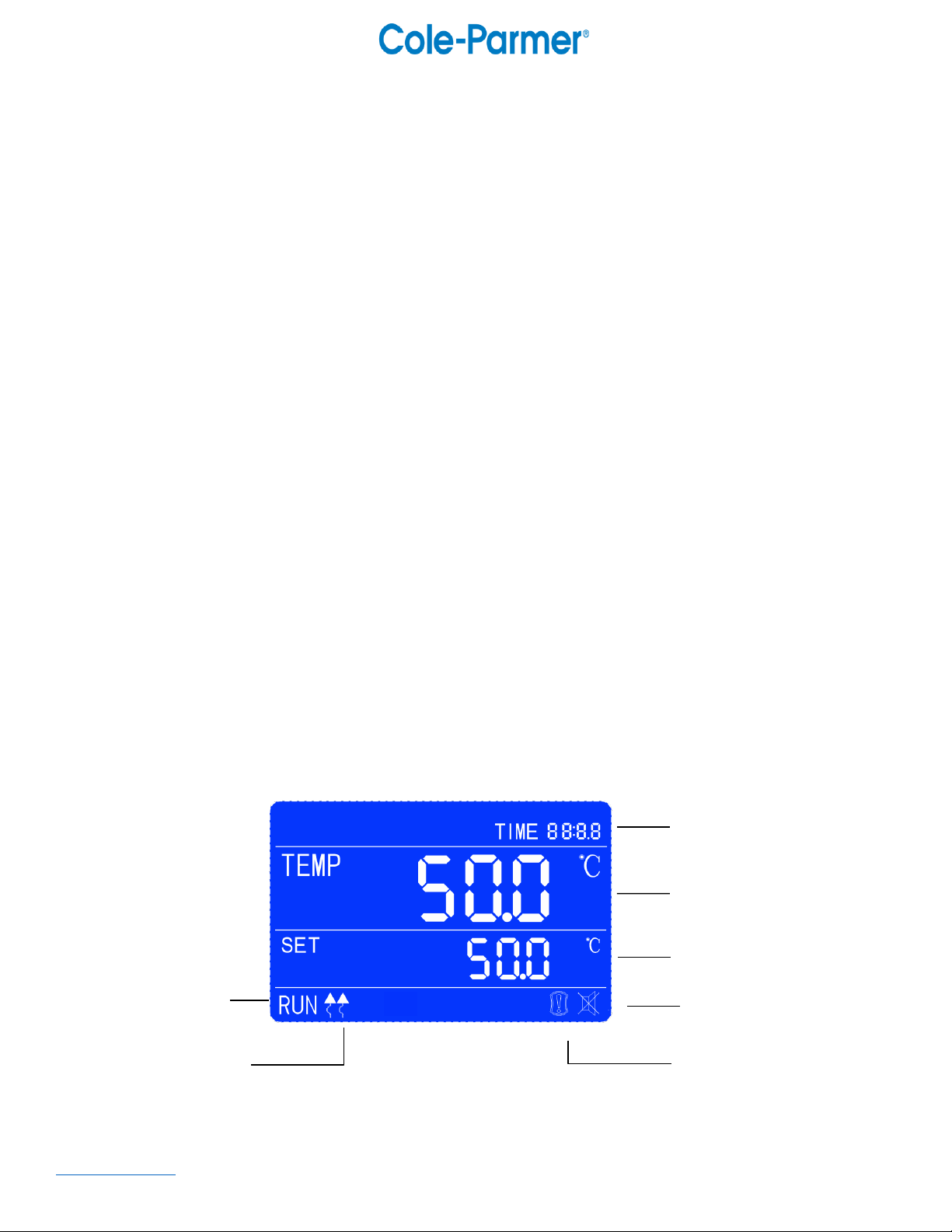

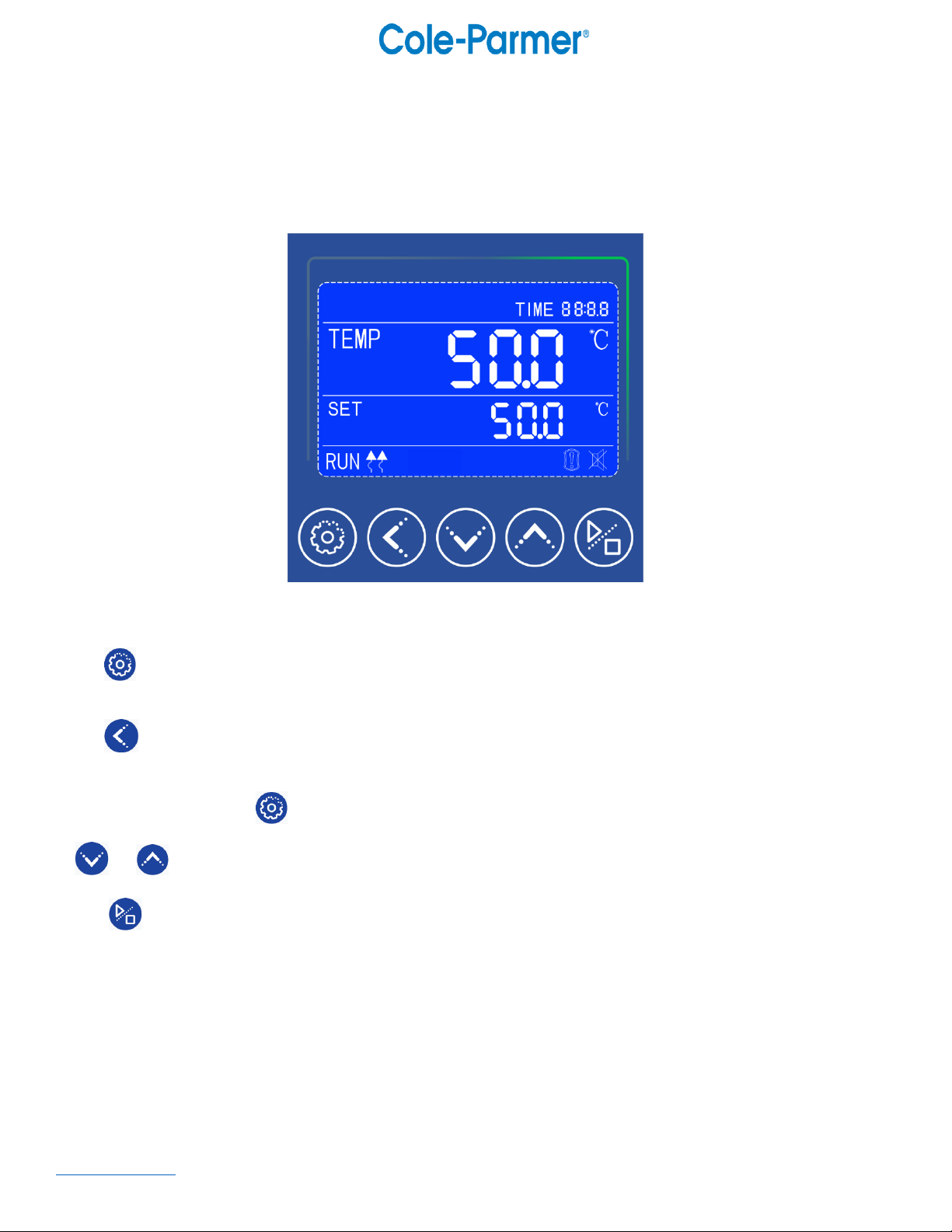

5. Temperature Controller Detailed Operation

5.1. Time Settings

1.When the instrument is switched on, pressing one time the button, the last value of the set time

(timer) starts flashing. Set the desired value (hh:mm) by pressing or keys. It’s possible a quick

movement between the digits using the button.

2.Confirm the set value with another press of button.

NOTE: the value “00:00” indicates the operating mode "continuous", that means once you start the

operating cycle by the START / STOP button, it continues maintaining the set temperature until it is stopped

manually (START/STOP)

3.If you set a value of time, such as 1 hour, the instrument will reach the set temperature and maintain it

for an hour.

5.2. Temperature Setting

1.When the instrument is switched on, pressing one time the button, the set temperature value starts

to blink. Set the desired temperature value (in Celsius degrees) pressing keys.

2.It’s possible a quick movement between the digits using the button.

3.Confirm the set value with another press of button

5.3. Start / Stop Operation

1.After setting the operating parameters, pressing button with long pressure (4-5 seconds), the

heating cycle starts for the defined time in hh:mm or continuous (00:00). The word “end” at the top right

corner of display disappears, the message RUN appears in the bottom left corner and display shows

contemporary: timer, temperature measured inside the chamber, set temperature a if present

2.At any time, you can always manually stop the cycle by pressing the button with long pressure (4-

5 seconds).

3.Once the set time or after manual stop, the instrument beeps intermittently, the icon of visual alarm

and the word "end" appear on the display. Pressing any button, it’s possible to silence the audible signal

and the icon appears.