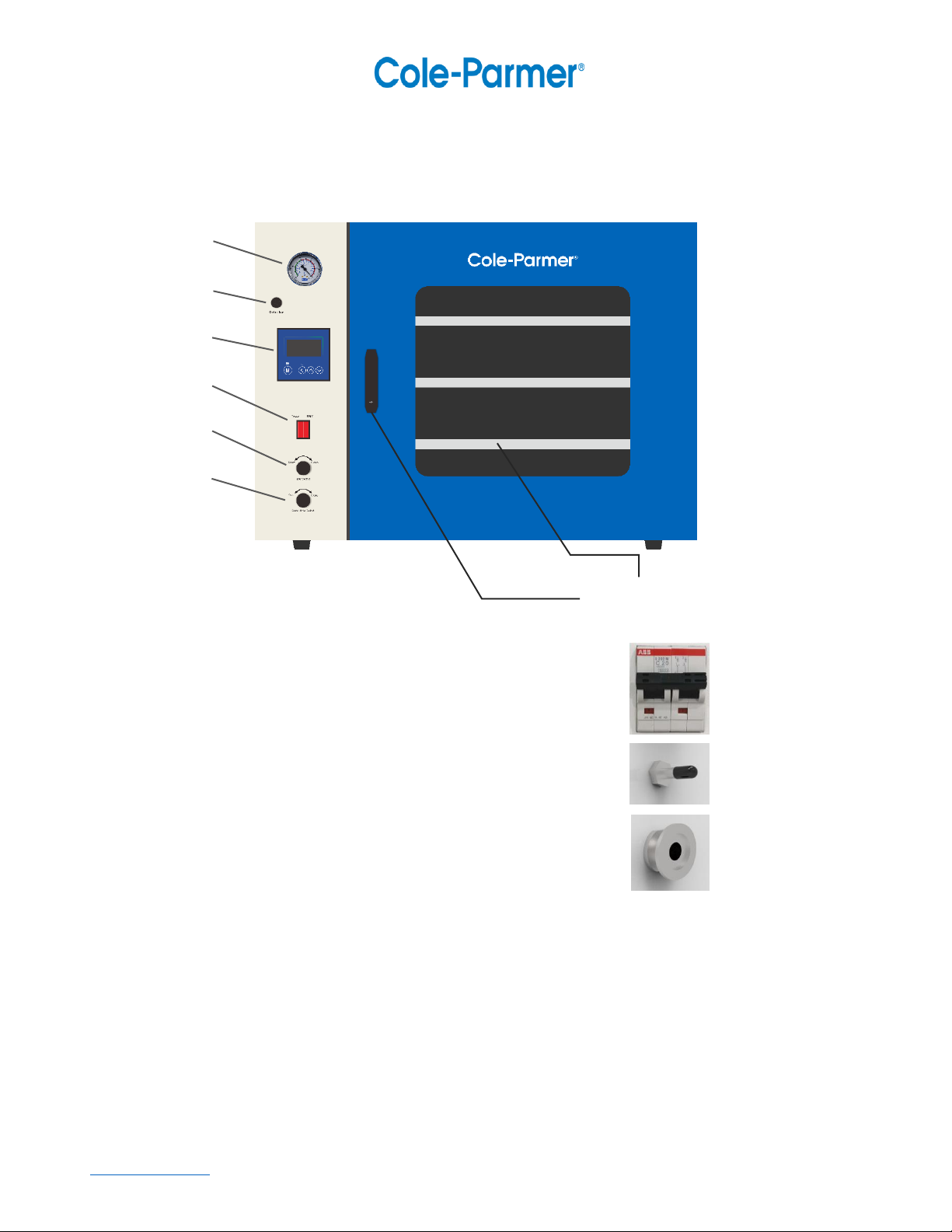

4. Operating Instructions

a. Place the sample in the oven and lock the door by rotating the handle downwards.

b. Close the Vacuum Valve and Inert Gas Purge Valve by rotating the dials clockwise.

a. Check the Vacuum Release Valve, and rotate closed if necessary.

c. Turn on your pump and open the Vacuum Valve by twisting counterclockwise.

d. When your desired vacuum level has been reached, close the Vacuum Valve, then, power off

your vacuum pump.

e. Turn on the oven and set your desired temperature. The oven may take 30 –60 mins to reach

initial temperature, depending on settings.

f. We recommend letting your oven sit for 10 –20 minutes upon reaching temperature to allow

for optimal heat distribution. For detailed controller instructions, please see the next section.

g. To release vacuum upon completion, first power off the oven.

a. Rotate the Vacuum Release Valve to release your vacuum using atmospheric pressure. Or,

b. Connect an inert gas source to the Inert Gas Purge Port, and open the Inert Gas Purge

Valve to release your vacuum using an inert gas such as nitrogen.

h. When ambient pressure has been restored inside the oven, the door will open. You must wait

until pressure is completely restored, or a vacuum seal will hold the door closed.

a. Sometimes, it may be necessary to use your thumb or a flat screwdriver to separate a small

section of the Door Gasket from the glass window. A small “flick” will be enough to break

the seal- do not pierce the gasket! Please contact our support if you require assistance.

i. Take proper precaution when removing items from the oven as the contents will be hot!

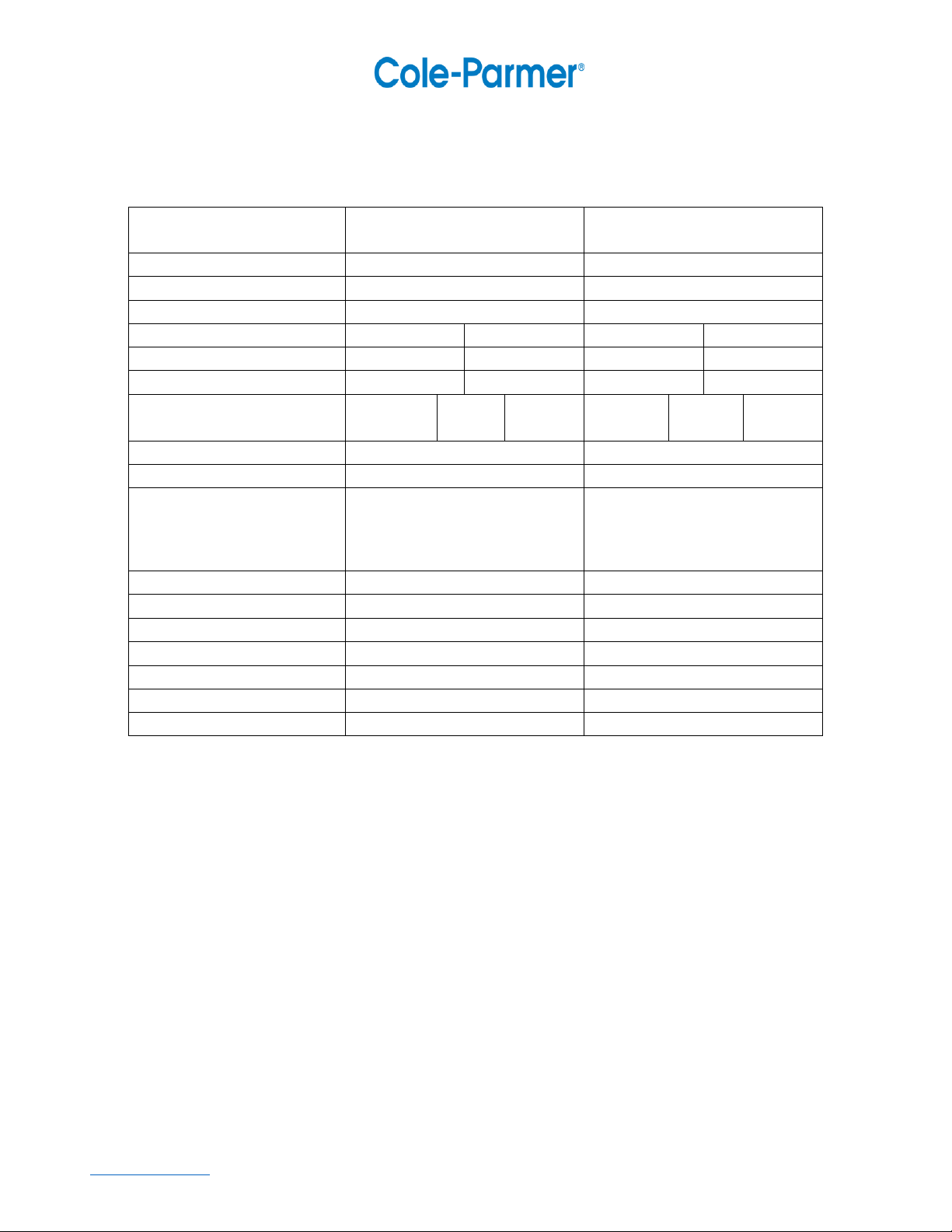

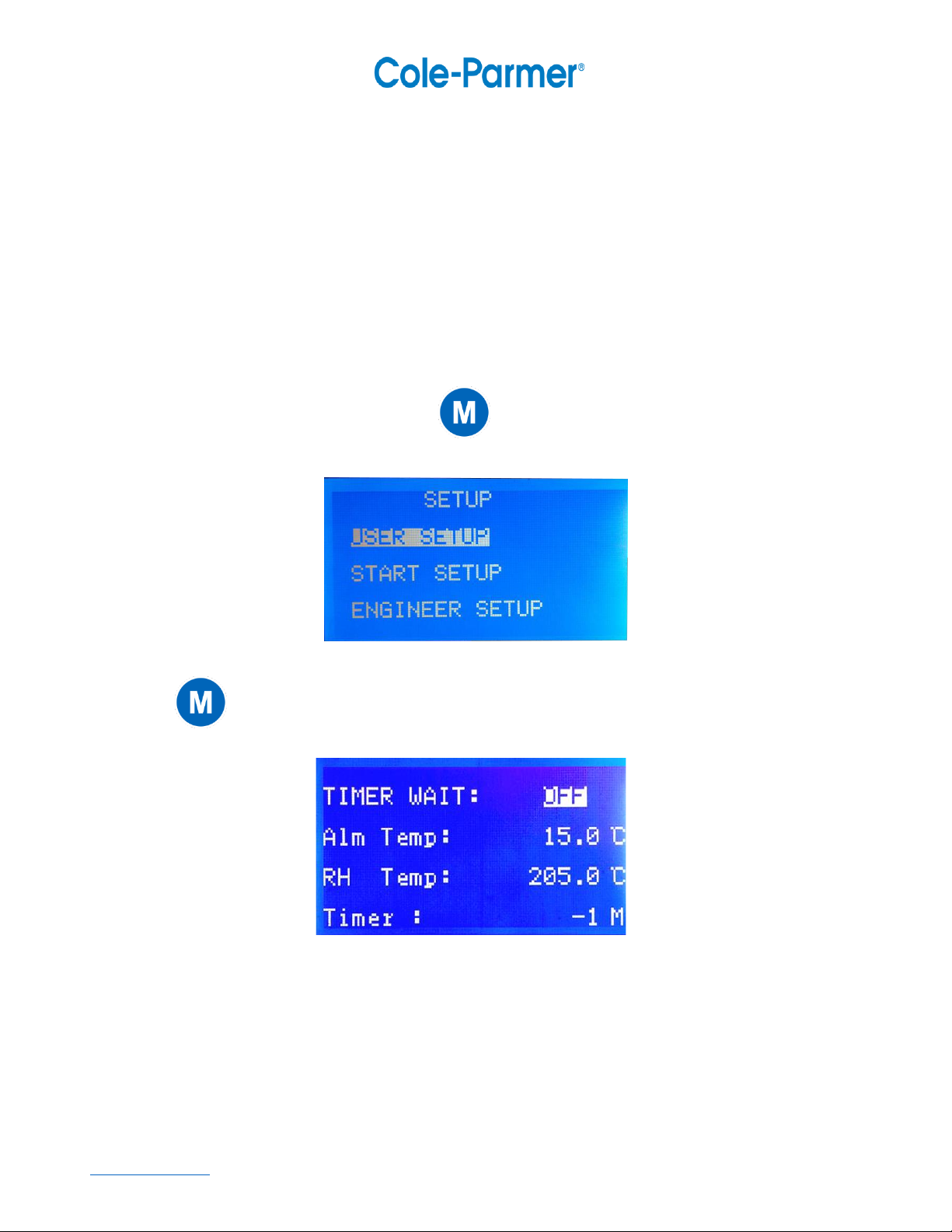

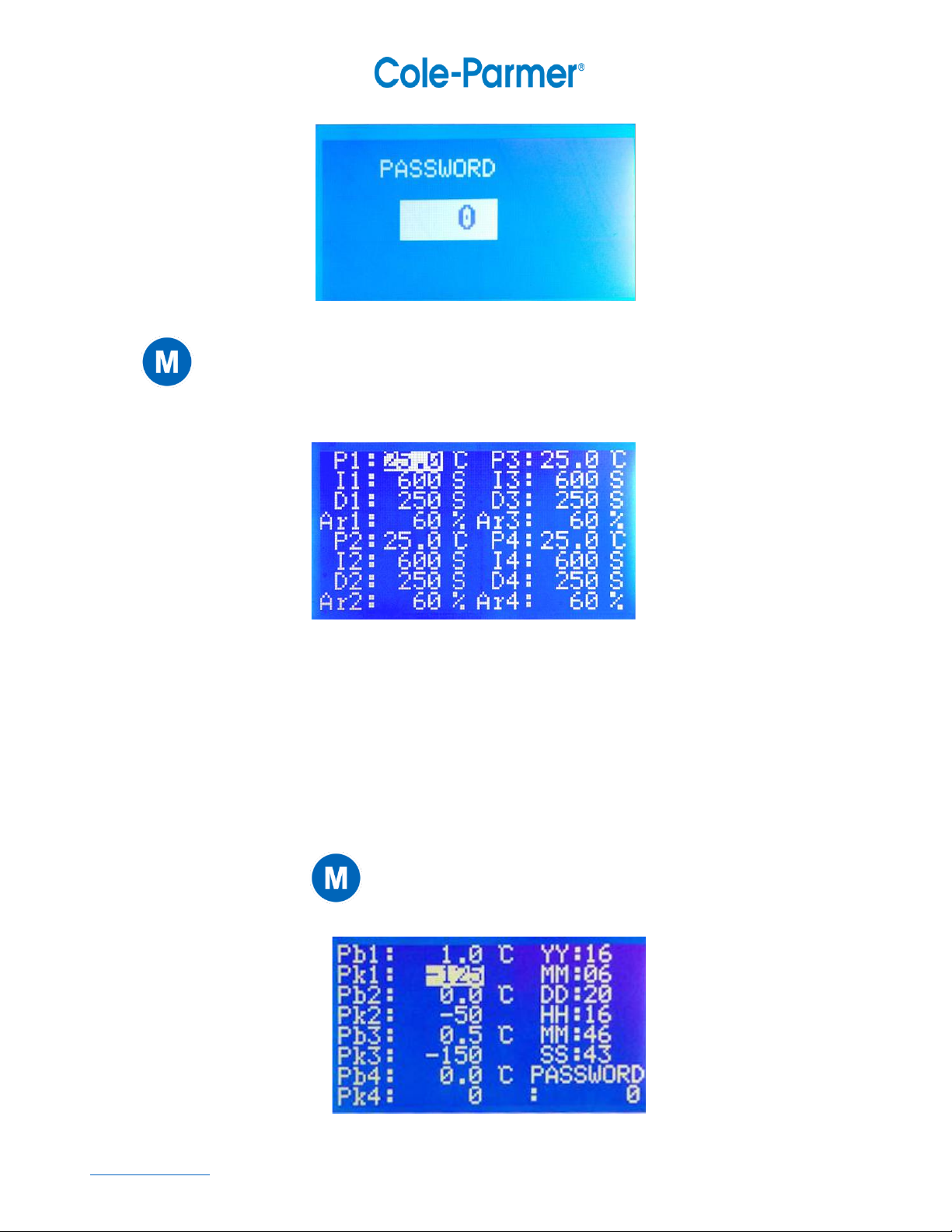

5. Temperature Controller Detailed Operation

5.1 controller panel layout