6

3—TECHNICAL FEATURES

3.2- DESTINATION OF USE

The foreseen use for which this oven has been designed and produced is the following:

3.3- LIMITS OF USE

This oven has been designed and manufactured exclusively for the destination of use described in

Par. 3.2, therefore, any other type of use is strictly forbidden in order to assure, at any time, the

safety of the authorized operators, as well as the efficiency of the oven itself.

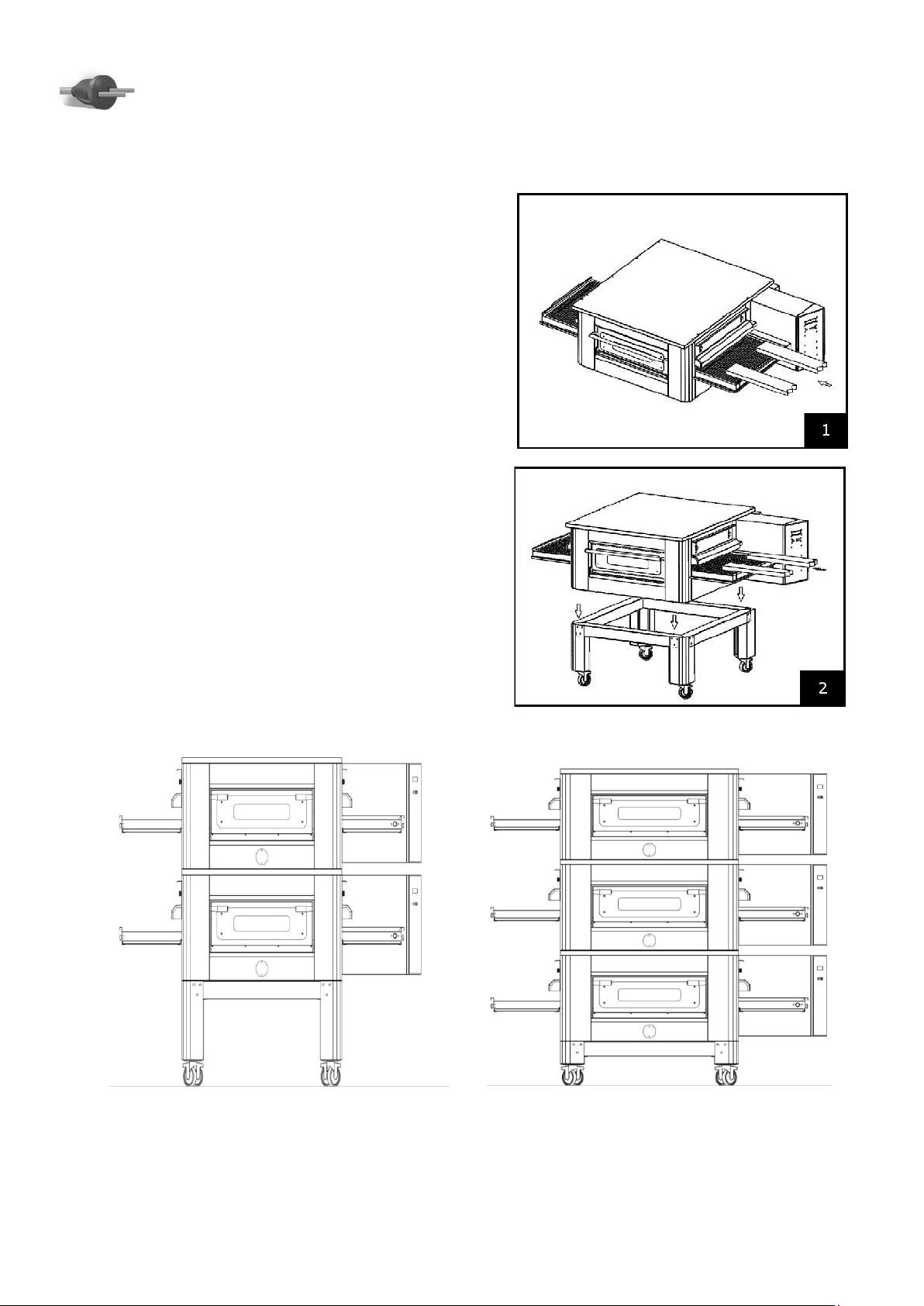

4—INSTALLATION

4.1–INSTRUCTIONS FOR THE USER

The place where the oven is installed must have the following environmental characteristics:

•To be dry, temperature and relative humidity of the room must not be over data stated in tab

3.1;

•Water sources at safe distance;

•Adequate ventilation and lighting corresponding to hygiene and security rules following the

existing laws.

Check that the electrical set-up corresponds with the numbers of the technical sheet Par. 3.1, and

on the small plate at the back of the oven. The characteristics of the electric socket must be

compatible with the plug installed on the cable.

FORESEEN USE: PIZZA BAKING, GRATINATING OF GASTRONOMY

PRODUCTS AND HEATING OF FOODSTUFF IN BAKING PANS.

THE OVEN CAN BE USED EXCLUSIVELY BY AN AUTHORIZED OPERATOR

(USER)

THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS (INCLUDING

CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL

CAPABILITIES, OR LACK OF EXPERIENCE AND KNOWLEDGE, UNLESS THEY

HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING USE OF

THE APPLIANCE BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT THEY DO NOT PLAY

WITH THE APPLIANCE.

THE OVEN MUST NOT BE INSTELLED IN PROXIMITY OF THE

INFLAMMABLE MATERIALS

(WOODS, PLASTIC, COMBUSTIBLE, GAS ETC.) AVOID THE CONTACT OF

INFLAMMABLE OBJECTS WITH THE HOT SURFACES OF THE OVEN.

ALWAYS ASSURE THE SAFETY FIREPROOF CONDITIONS. MAINTAIN A

FREE SPACE AROUND THE OVEN OF AT LEAST 30 CM