3 ComCo Systems Inc. | 800.533.3794 | www.comcosystems.com 500648 Rev. A

Series

System Features

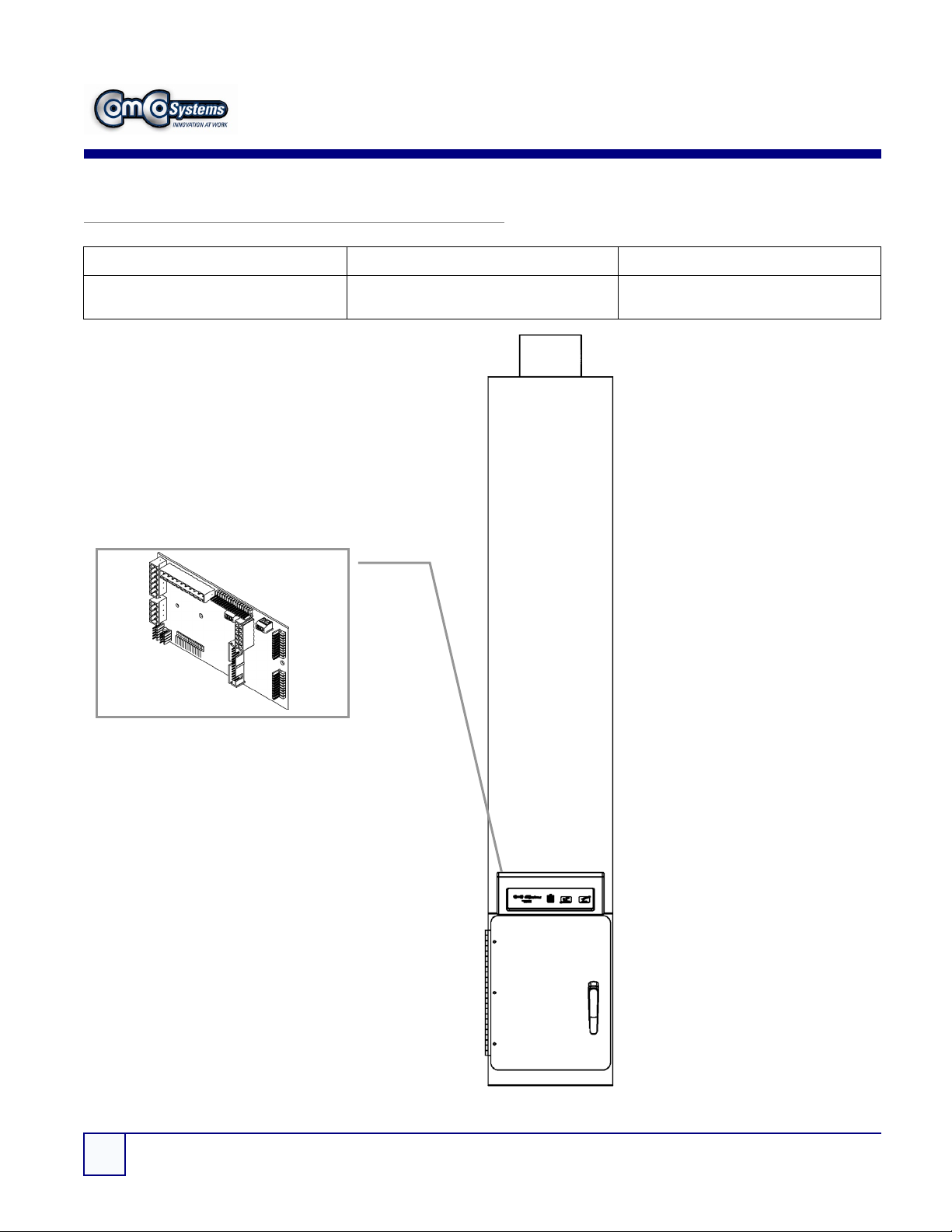

The Model 621 is an overhead pressure/vacuum system that utilizes 6” tubes and

carriers. The carrier travels from the teller unit to the customer unit under pressure and

returns under vacuum. The blower unit is located near the teller unit.

•The Model 621 is configured with three major subsystems:

1. 621 Operator Unit P/N: 201314

2. Dual Blower Unit P/N: 200281-3

3. 621 Customer Unit P/N: 201315

TU-621-201314

Manual operated door unit,

which is suspended from the

ceiling, typically over

countertop.

CU-621-201315

Open carrier access design

with optional 2-way video

Blowers

200217-2(x2)

Features:

2 Power Cords

2 115Vac/15A

2 Blowers for pressure

2 Blowers for vacuum