ATE-ANPL-ANPA

Fan Installation, Operation &

Maintenance

This document contains information on proper storage, installation, operation and general maintenance of Comefri

USA fans ATE, ANPL, ANPA. Failure to comply with proper installation procedures may void the warranty. The

technical data and the permissible limits of the fan are clearly listed on the fan plate. All fans are balanced and

tested before leaving the factory.

All Comefri USA Fans are manufactured according to our Quality Management System, in conformity with ISO

9001:2000. Comefri USA Quality System is certified by BSI.

Receiving and Handling

Each fan is carefully checked before shipment. When receiving a fan it is necessary to verify that it has not been

damaged during transit, especially the rotating parts and any electric part (Motor). In case of damage, immediately

document the damage on the delivery notes and contact the delivery company. Comefri will not take any

responsibility for the transport and the handling of the fan at the customer's premises. The handling of the fan

requires adequate care. Lifting tools according to the weight and packaging of the fan should be used. When

moving the fan with crane, four lifting points have to be provided.

Special care must be taken to ensure that the fan will never be lifted by the shaft ends, motor lifting lug, bearing

supports and/or inlet or outlet flanges. Fixing points of the fans are the base frame, housing frames or lifting eyes if

available.

Note: Any improper handling, even though it may not visually damage the fan, often produces a need to re-balance

the impeller.

Storage

Adequate storage must be provided to protect the fan from dirt and moisture. Do not use plastic sheets, as they will

promote condensation and rust especially in hot and humid environments. Indoor storage is recommended. Store in

a dry, clean area. Storage temperature should range between -4 °F and +113 °F.

Vibration Isolation Base

High vibrations can cause mechanical and structural failure. Bases must have sufficient rigidity to prevent the

generation of vibrations and resonances while supporting the fan and motor. Isolators are used to reduce

and prevent vibrations and noises from being transferred to the surrounding structure. When properly selected the

isolators will attenuate the vibration forces transmitted to the surrounding structure by approximately 90%.

Fan Foundations

Many fan problems are caused by a poorly designed foundation. The foundation must be strong enough to hold the

weight of the fan, motor, isolation base plus the loads created by its running. The natural frequency of the

foundation should be at least twice the natural frequency of the base isolators.

Installation 0 INSTALLATIONS

Installation is only to be carried out by trained personnel in observance of these operating instructions. The fans

must be firmly fixed on isolation base frames. The fixing must be made avoiding any stress or deformation of the

supporting structure.

Duct Connections

It is important to design proper ducting. Poor ducting can affect the fan performances reducing the volume flow and

pressure and increasing the system noise.

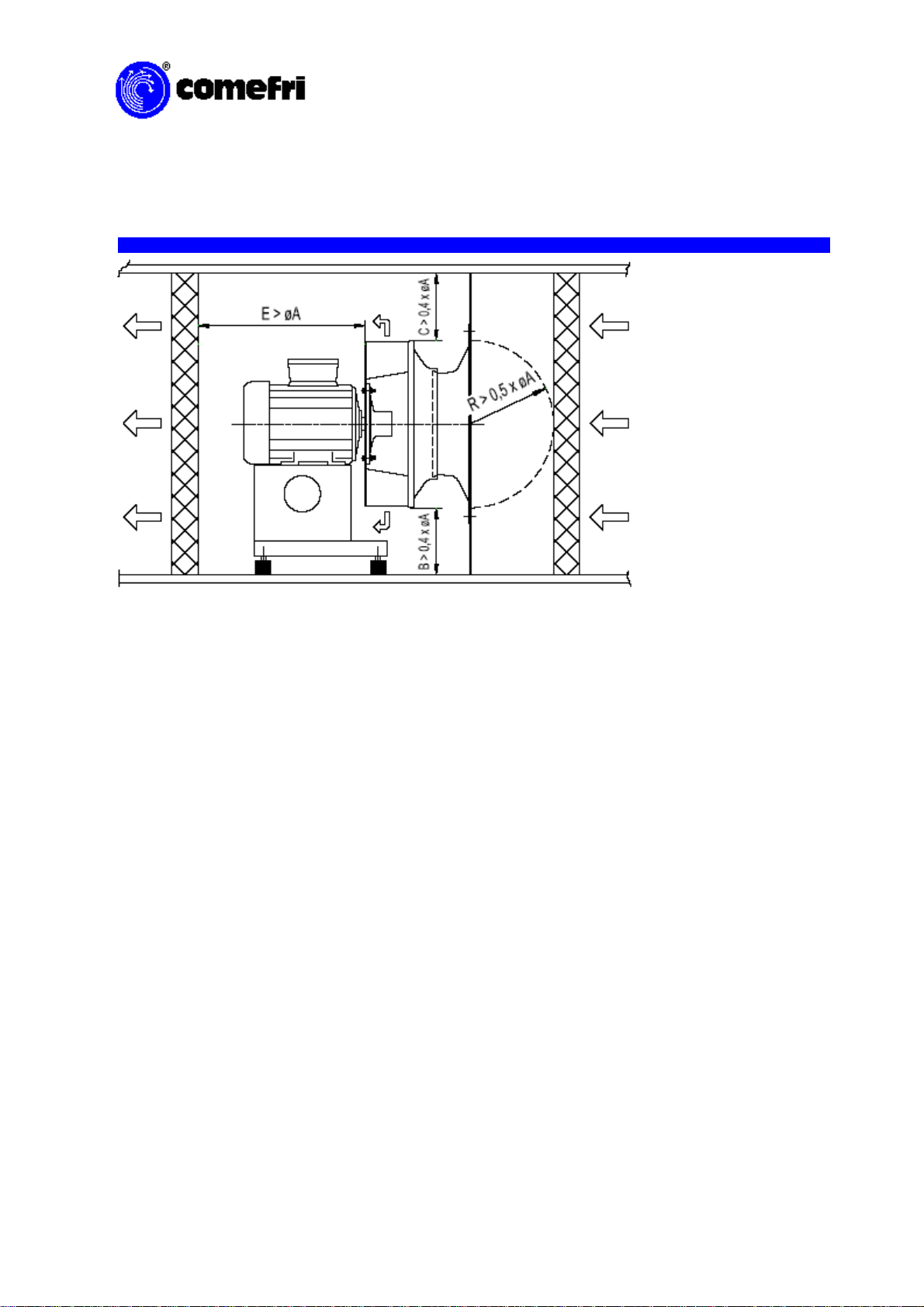

Inlet Connections

Inlet spin is caused by improper ducting on the inlet of the fan and will result in a reduction in fan

performance. The change in performance is directly related to the amount of the spin. Installing elbows or duct

turns too close to the fan inlet will also affect the fan performance. If the elbow is too close to the fan inlet, the air

will flow uneven into the fan. Allowing at least one wheel diameter from the elbow to the fan inlet will produce a

uniform inlet flow distribution. In installations where the inlet is un-ducted, there should be a least half wheel

diameter of free space on the inlet side, as shown in figure 1.