6

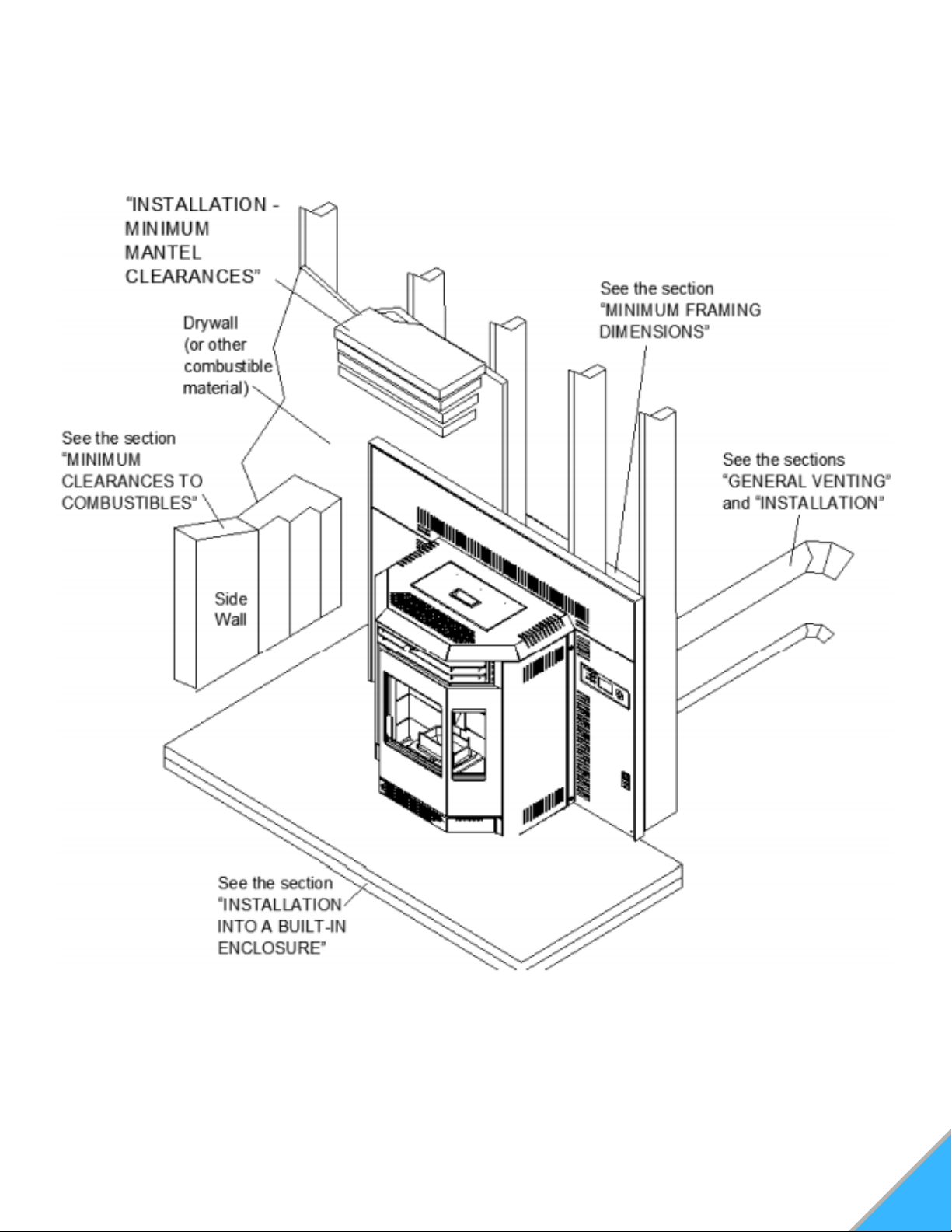

All applicable building codes for your location

must be followed. In areas where building codes

require additional steps to the installation of this

product that are not included in this manual, the

building codes will take precedence and must be

followed. Contact your local building inspector to

obtain any necessary permits or inspection

guidelines before installing the product.

Contact local building or fire officials about

restrictions and installation inspection

requirements in your area

Contact your local authority (such as municipal

building department, fire department, fire

prevention bureau, etc.) to determine the need

for a permit

This pellet stove is designed to burn pellet fuel

only

A working smoke detector is required and must

be installed in the same room as the stove.

This stove is not intended for use in

commercial applications

Door and ash pan must be closed and latched

during operation

Notify your insurance company of pellet stove

installation

This installation must conform with local codes.

In the absence of local codes you must comply

with EN 14785.

The structural integrity of the manufactured

home floor, wall, and ceiling/roof must be

maintained.

Keep combustible materials (such as grass,

leaves, etc.) at least three feet away from the

flue outlet on the outside of the building.

This stove should not be used as the only

source of heat in the house. Power outages

and periodic maintenance will result in a total

loss of heat.

Do not leave hopper door open while

unattended.

CAUTION CAUTION

Installation and repair of this pellet stove

should be done by a qualified service person.

The appliance should be inspected before

use and at least once per year by a qualified

service person. It is imperative that the control

compartments, fire box, and circulating air

passageways of the stove are kept clean.

The operation of exhaust fans such as

bathroom fans, attic fans, etc... might starve

the pellet stove of combustible air, creating a

negative pressure in the room. Provide

adequate ventilation of the room the stove is

installed in, otherwise the pressure switch may

shut off operation of the pellet stove.

The moving parts of this stove are propelled

by high torque electric motors. These parts

can cause severe damage to body parts that

get near them. Keep all body parts away from

auger and fans while the stove is plugged into

an electrical outlet. Moving parts are subject

to begin moving while power is supplied.

The venting surfaces can become hot enough

to cause burns if touched. Non combustible

shielding or guards may be required.

Install all venting at the clearances specified

by the vent manufacturer. All venting joints,

whether vertical or horizontal, should be made

gas-tight with recommended sealants

specified by vent manufacturer.

According to HUD (Housing & Urban

Development) requirements, when installing

within a mobile home, this stove must be

grounded directly to the steel chassis of the

mobile home, and bolted to the floor. Direct air

access must be provided by way of a fresh air

intake kit.

For use in the United States and Canada.

Approved for installation in mobile homes.

Producer of this appliance reserves the right to

alter its products, specifications, and/or price

without notice.