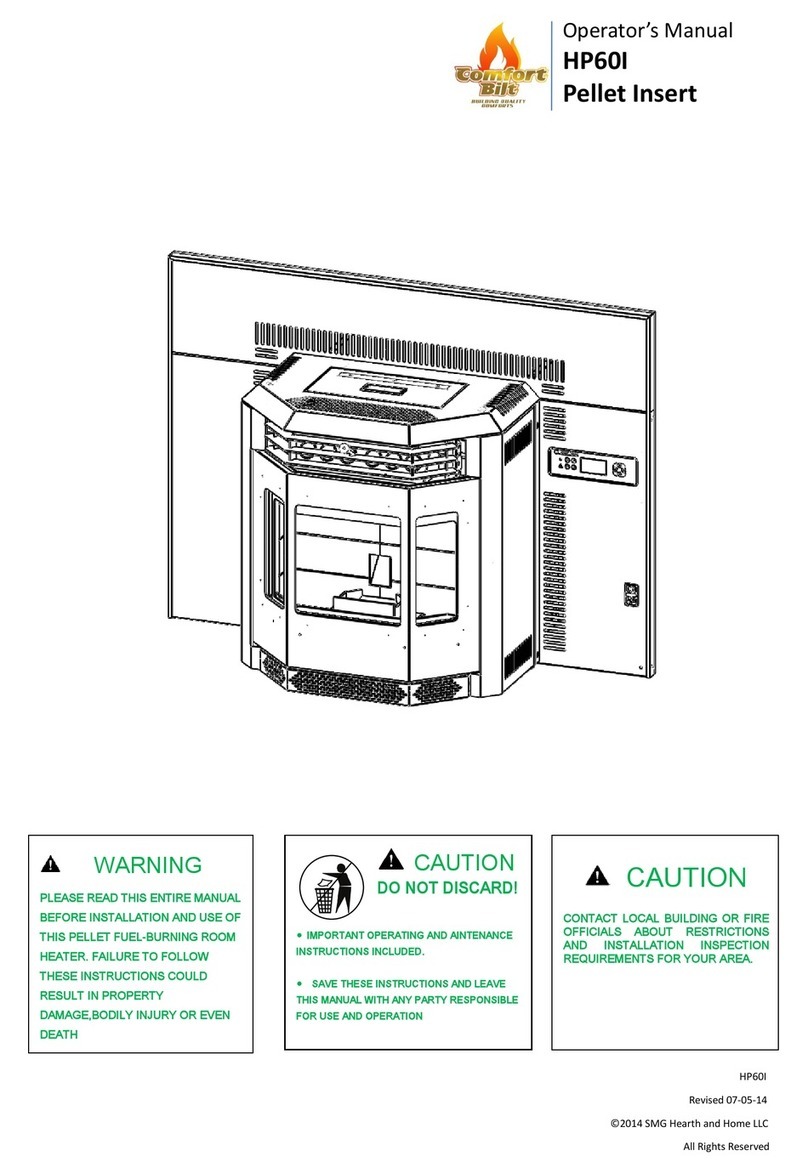

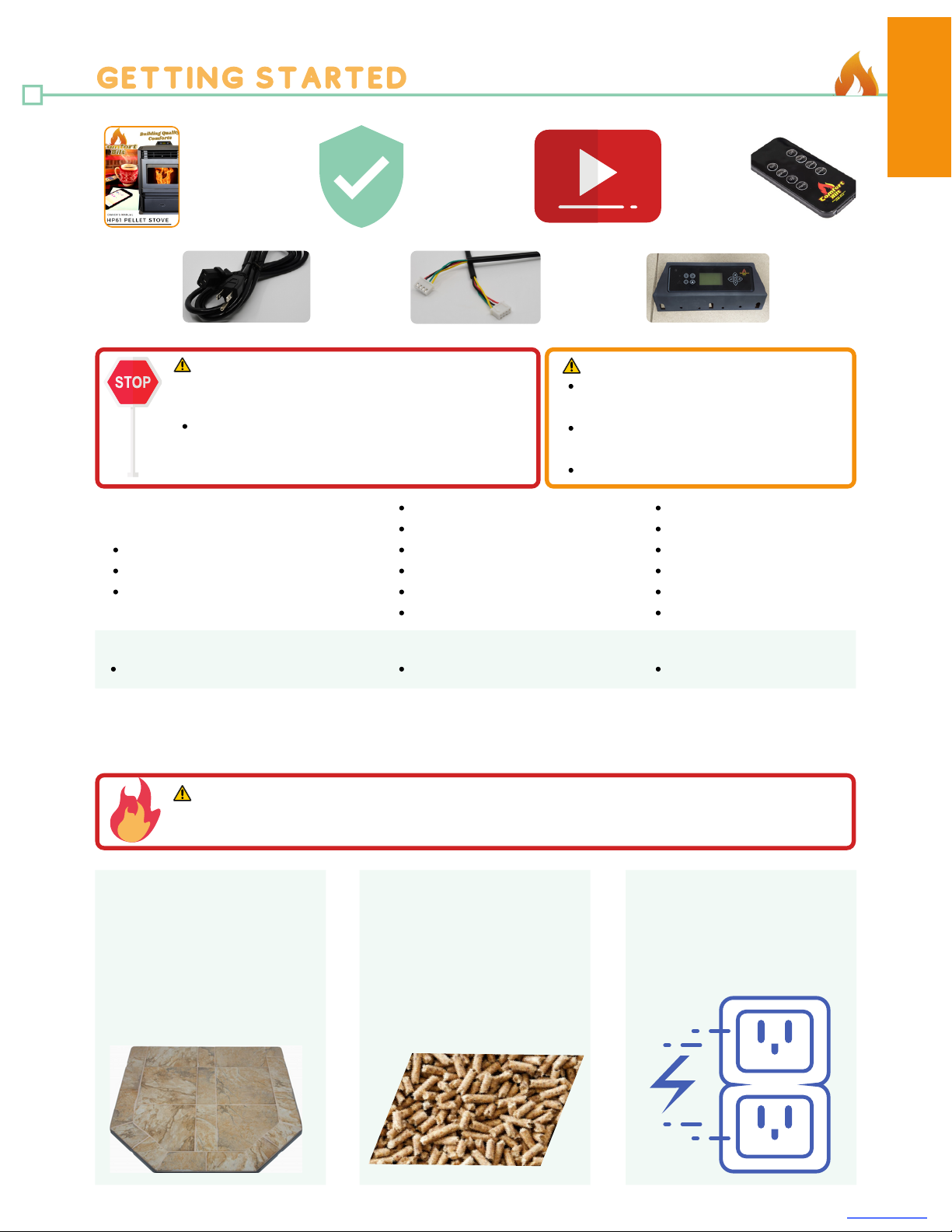

Remove cardboard lid, outer box sleeve, and packing foam.

Inspect for any shipping damage. (Preferably before delivery

team leaves)

Unscrew the mounting L brackets that secure the rear of the

stove to the pallet. (4mm Allen)

Open hopper lid and remove control panel, power cord, remote

control, and all literature and packing material from the hopper.

Open the front door via the latch on the right side behind the

magnetic side panel (see picture) and remove cardboard

packing material from the firebox chamber.

Remove any tape or adhesive on the outside of the glass.

Unpacking:

Remove all four Phillips mounting screws along the top rear of

the stove where you wish to mount the controller bracket.

Line up the holes in the back to the mounting bracket and

secure in place. (Note: Universal mounting brackets are used,

so only the far left and two right screws align. This is normal,

and will still secure the panel to the stove)

Find the data cable line at the rear of the stove, and plug it

snugly into the back of the control panel.

Mounting the Control Panel:

1.

2.

3.

8comfortbilt.net

Installation

Pre-Installation

The universal mounting bracket will also allow for the control

panel to be mounted to the side farthest from the exhaust port

for specific vertical venting scenarios. (The two left and the far

right screws are used in this case).

Installation MUST comply with local, regional, state and national codes and regulations.

Consult insurance carrier, local building inspector, fire officials, or authorities having jurisdiction over

restrictions, installation inspection and permits.

Pro Tip: It is recommended that your pellet vent pipe be installed and serviced by a professional installer.

Placement:

Where you place your stove can significantly affect its performance and safety.

Sketch out a plan for installing the stove, including dimensions, before permanent placement. When

determining the location for the stove, wall stud location is critical. You may need to adjust the location of the

stove to avoid encountering a wall stud. Before placing the pellet stove, connect the vent to allow for minimum

clearances to combustible walls.

WARNING!

Asphyxiation Risk:

DO NOT INSTALL IN A SLEEPING ROOM.

Stove consumes oxygen in the room.

Front Door Latch

Control Panel Mounting

Data Wire Connection

Side Mounting

Installation