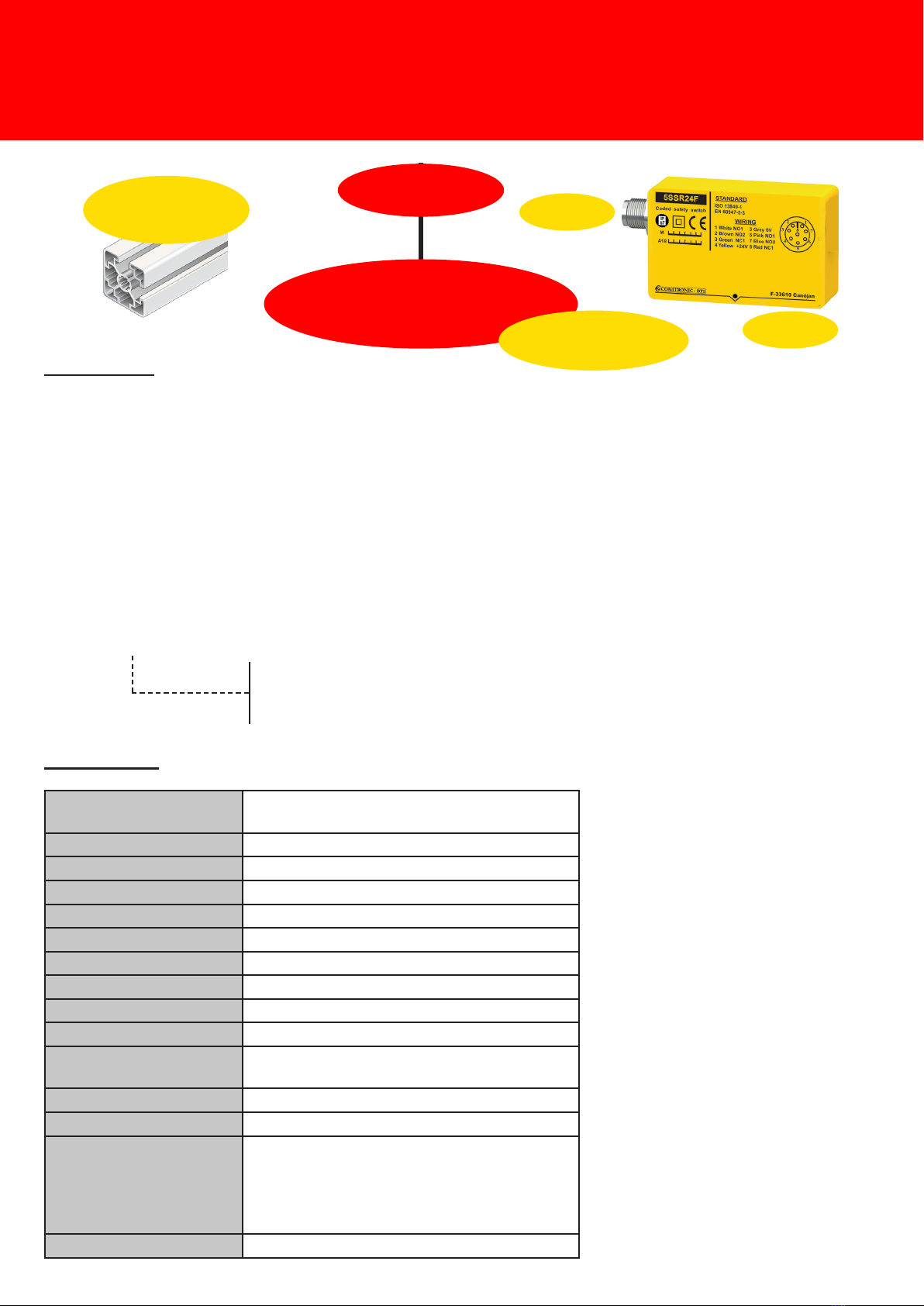

Contactless safety switch,

without polarity, stand alone,

with direct control of dangerous movement

CONTENTS

B10d: Beware of being trapped __________________________________________________________

1. Informations__________________________________________________________________

1.1. "Reed contact" technology_________________________________________________

1.2. ACOTOMtechnolgy_________________________________________________

1.3. MTTFd comparison_____________________________________________________

Locking devices for guards : ISO 14119___________________________________________________

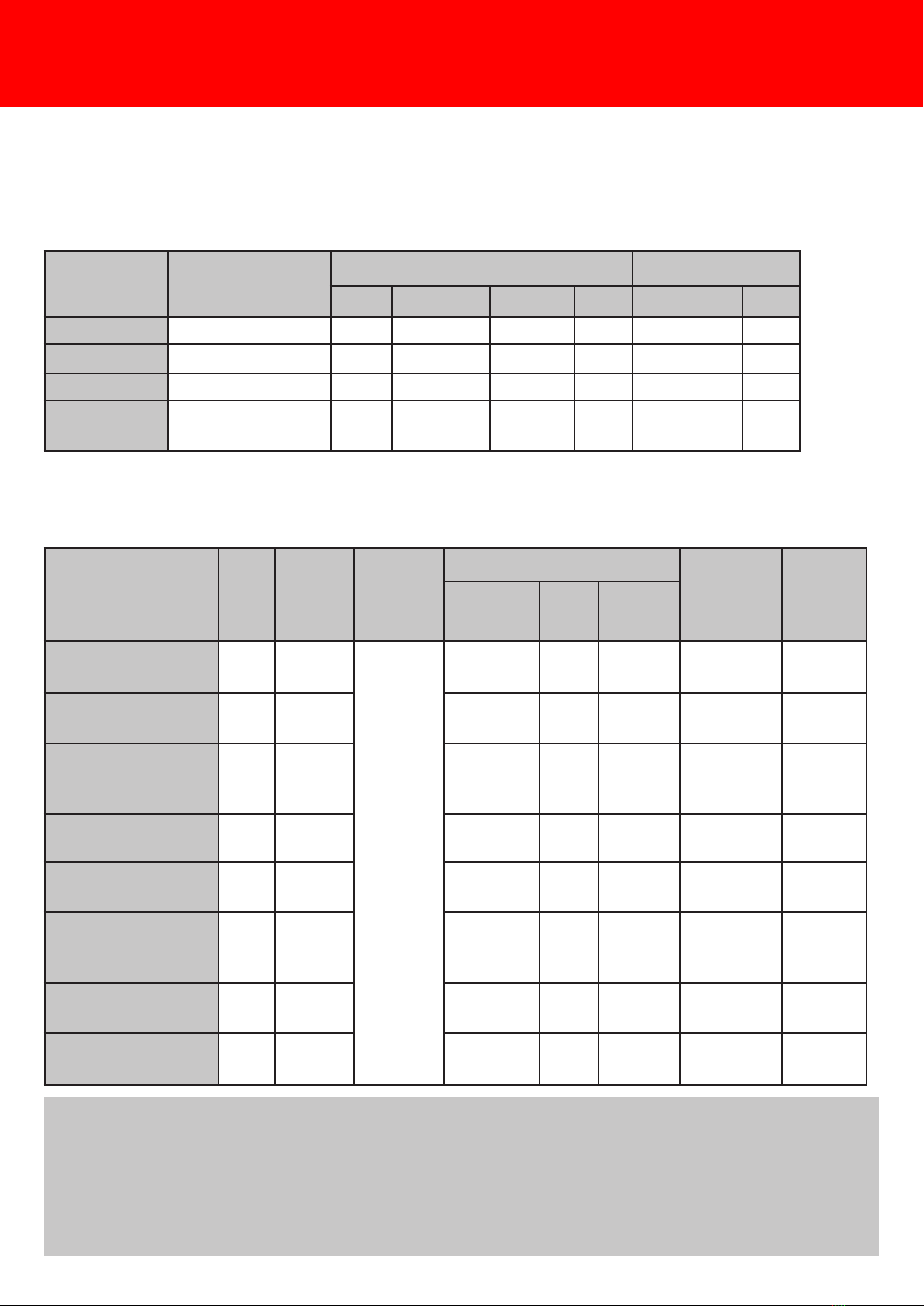

2. Comparative technologies______________________________________________________

ACOTOM process

1. ACOTOM process____________________________________________________________

1.1. The birth of a revolutionary technology ___________________________________

1.2. Principle of ACOTOM process__________________________________________

Safety switches and RFID technology_____________________________________________________

1. RFID Technology______________________________________________________________

1.1. Why?________________________________________________________________

1.2 Disadvantages ________________________________________________________

1.3 Our RFID "AXKEF Process" Solution ______________________________________

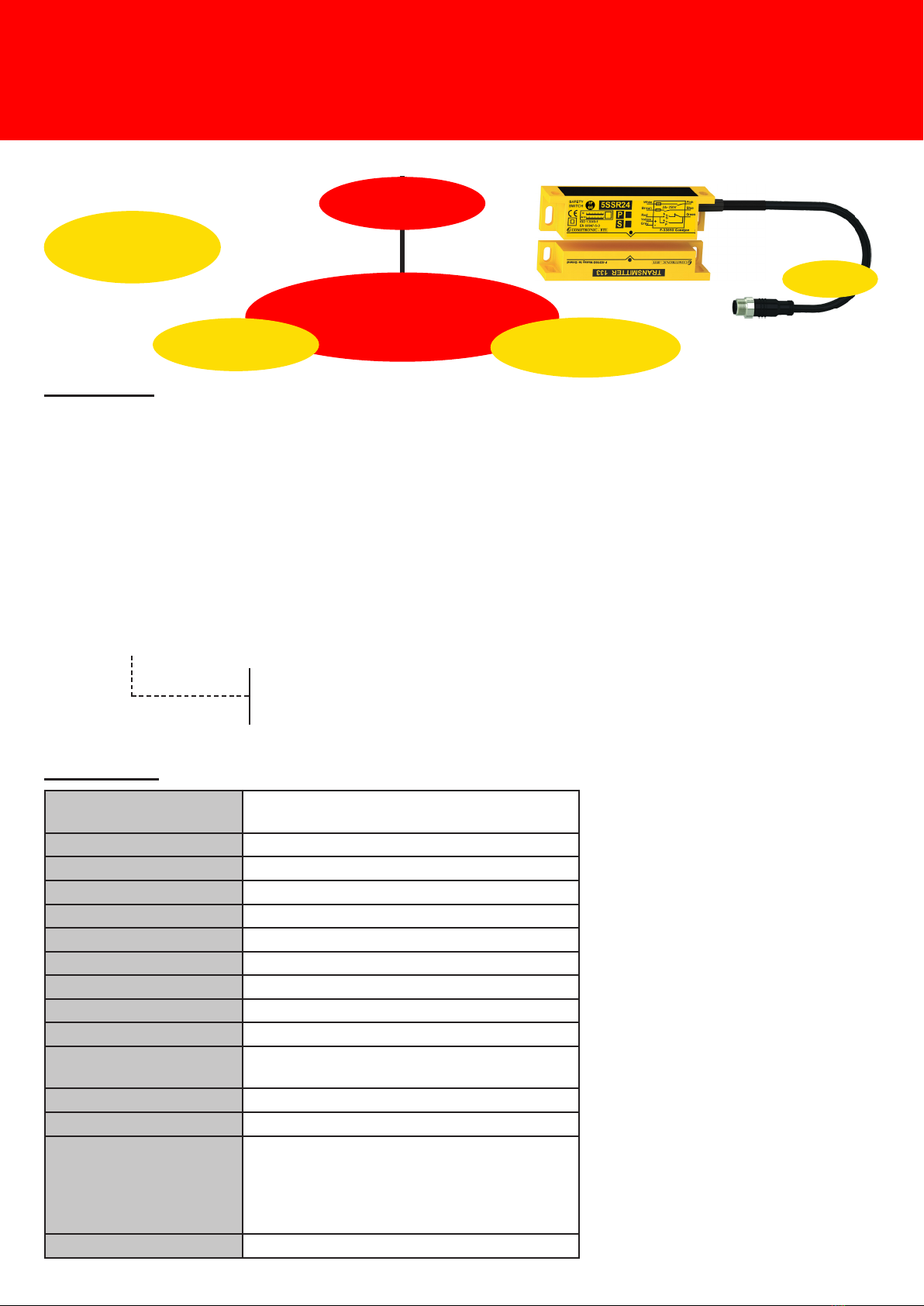

5SSR24-P et 5SSR24-S_________________________________________________________________

2. Features_____________________________________________________________________

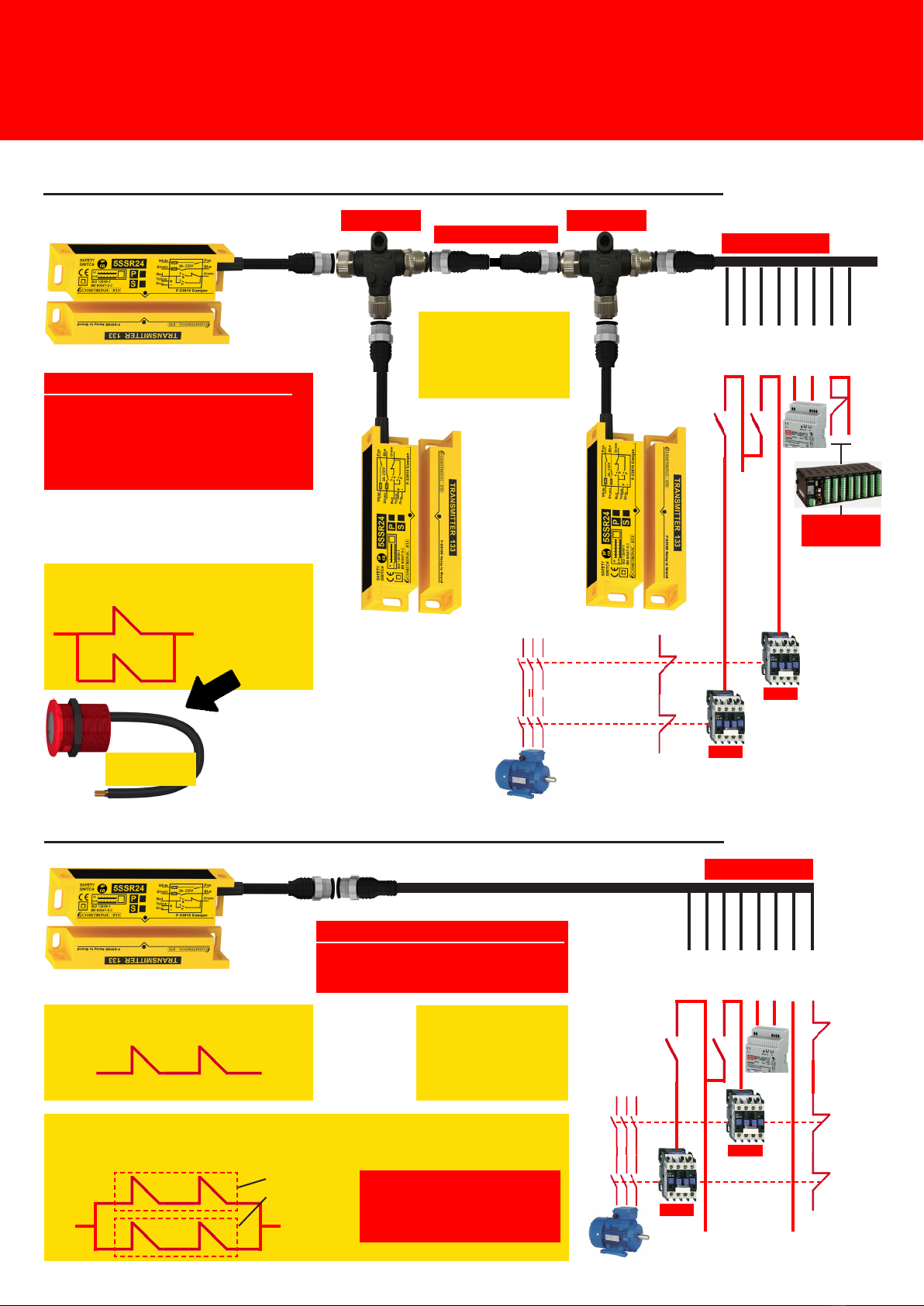

3. Installation Principle for 5SSR24-P_______________________________________________

4. Installation Principle for 5SSR24-S_______________________________________________

5. Assembly Instructions_________________________________________________________

6. Dimensions__________________________________________________________________

7. Recommendations____________________________________________________________

8. Periodic Inspection____________________________________________________________

5SSR24-F____________________________________________________________________________

2. Features_____________________________________________________________________

3. Installation Principle for 5SSR24-F for PL c________________________________________

4. Assembly Instructions_________________________________________________________

5. Dimensions__________________________________________________________________

7. Recommendations____________________________________________________________

8. Periodic Inspection____________________________________________________________

OPTO-2S_____________________________________________________________________________

2. Features_____________________________________________________________________

3. Installation Principle for PL c____________________________________________________

4. Assembly Instructions_________________________________________________________

5. Dimensions__________________________________________________________________

6. Recommendations____________________________________________________________

7. Periodic Inspection____________________________________________________________

DECLARATION OF CONFORMITY________________________________________________________

3

3

3

3

3

4

4

4

5

5

5

5

6

6

6

6

6

7

7

7

8

8

9

9

9

9

10

10

11

11

11

11

12

12

12

13

13

13

14

15

15

15

15

16