BASIC CALIBRATION INSTRUCTIONS

The calibration instructions below are given, based on the instrument being set

up prior to being shipped to you. The instrument will have been set up based

on the information supplied regarding the model, capacity and application the

forklift is being used.

This instrument can be used in a large variety of applications and changing the

parameters that are set will greatly affect the performance of this instrument in

the application you have indicated.

NOTE- To exit the calibration mode without saving, turn the power off to the

indicator.

Step 1. –Ensure you have an accurate test weight of approx 1/3 –½ of the

machine capacity. The more accurate the test weight, the more accurate the

scale

Step 2 –Start the forklift or loader, and the CL2000MKII should also turn on.

The indicator should power up and go through a short power up cycle. Once

the power up cycle finishes, the indicator will show a random reading in the

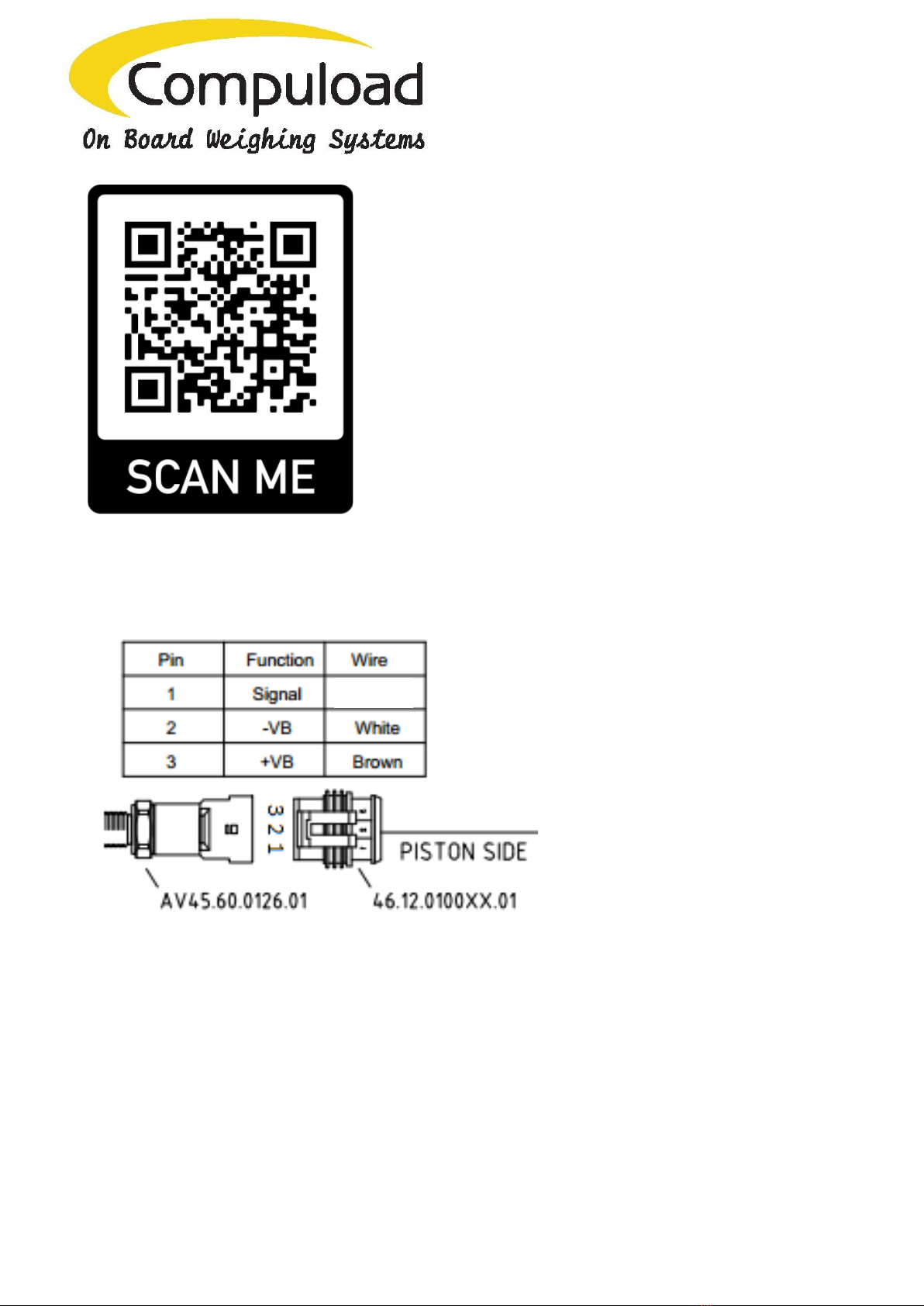

“Current Load” screen. To ensure you have the hydraulic pressure transducer

fitted correctly, raising of the forks or bucket should result in the figure on the

screen rising.

Step 3- Press the “Menu” button on the bottom right-hand corner of the screen

to enter the Menu screen.

Step 4 –Press the “Calibration” to enter the setup code. Enter the code 4482

using the up, down, left, right arrows. Then Press the “Exit” button. You will

now be in the Calibration Page. Press “Weighing Calibration” to enter the

Weighing Calibration page.

Step 5 –Raise the empty Forks or Bucket to your weighing height. (Raise to 1,

Lower to 2) Allow approx 2-3 seconds for the weight to settle, Press “Set

Empty Calibration”on the screen to set the Zero Calibration

Step6 –Place your test weight onto the forks or bucket. Don’t lift to weighing

height at this stage. Enter the test weight amount to “Known Load” using the

Up, Down keys.