6 Calibration with gas

A calibration is due after installation, sensor replacement or in time intervals as required by local

regulations. Allow 30 min warm up time.

Calibration to liquid substances in the field is labor intensive and prone to error. Use Isobutene as

reference gas and apply the response factors provided by Compur Monitors.

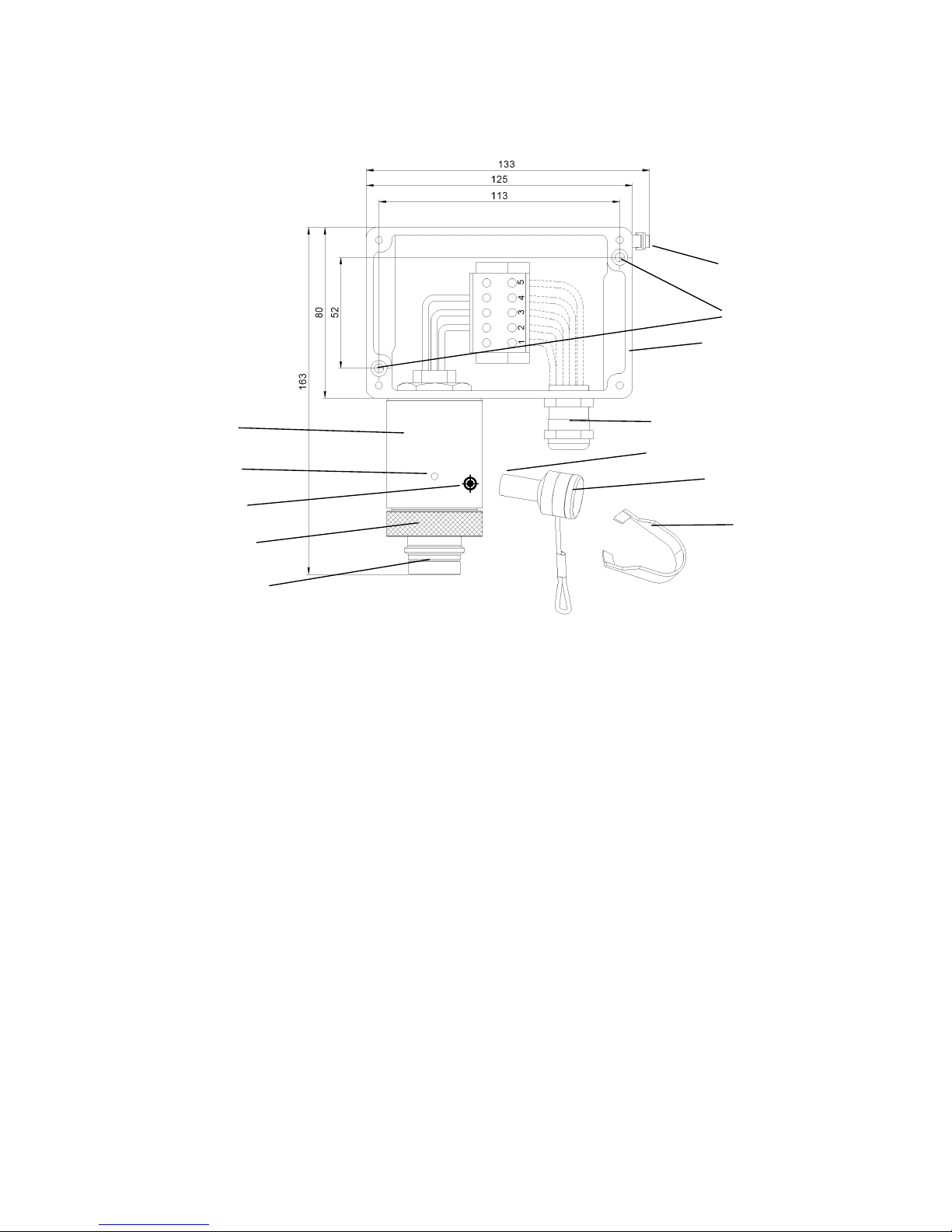

The tools required for calibration are: Span gas in appropriate concentration, a regulator and a gas

adapter.

The interface will accept set points between 10 and 100 % of the end of scale value.

To achieve best accuracy Compur Monitors recommends to calibrate at the desired alarm threshold

value. Calculate the most suitable span gas concentration with this formula:

Alarm threshold

c Isobutene =

Response factor

Example: Measuring range 0 - 1000 ppm Methylmethacrylate, Response factor = 1,6

minimal Isobutene concentration: 100 ppm / 1,6 = 62,5 ppm Isobutene

maximum Isobutene concentration : 1000 ppm / 1,6 = 625 ppm Isobutene

Procedure:

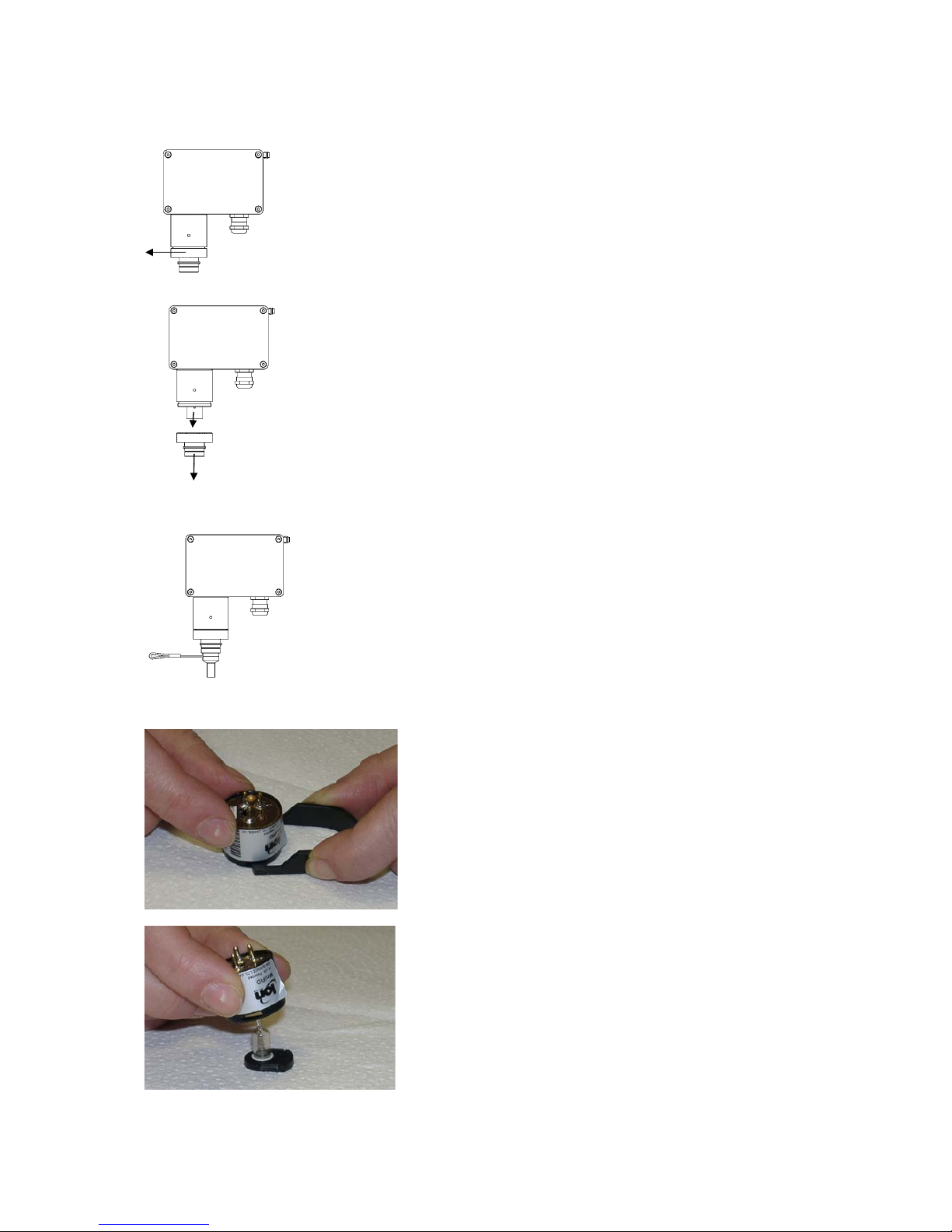

• Hold the magnetic pin on to the contact area to start the calibration routine. The green LED will start

flashing. If there is no further activity, the sensor head will automatically return to the measuring mode

after 30 minutes.

• Enter the calibration menu on the Control Module. Adjust zero.

• Connect the gas tube to one of the fittings of the gas adapter. If you want to avoid gas emissions, you

may connect an active carbon filter to the outlet. (Art.No. 806 488) Do not bend or twist the tube to

avoid overpressure in the gas adapter.

• As soon as the Control Module displays „GAS“, connect the gas adapter to the sensor and open the

valve. Press „Enter“ . The recommend flow is 20 l/h (300 ml/min). As soon as „CAL“ is flashing, press

„Enter“ again.

• Now enter the product of span gas concentration multiplied by the response factor.

Example: Calibration to methyl methacrylate with 100 ppm Isobutene.

You have to enter 100 ppm * 1,6 = 160 (The reponse factor of methyl metacrylate is 1,6)

In case the sensor signal is too low, you will get the message „SenS“ on the Control Module. Proceed

as described in the next chapter.

• Remove the gas adapter and switch the gas off.

• Push the „Reset“ button on the Control Module to leave the calibration menu.

• Touch the contact area on the PID with the magnetic pin to enter the measuring mode. The LED

should be green then.

8