Ta b le o f Co n t e n t s l i

Ta b l e o f Conte n t s

1-1 I n t r o d u c t i o n

Purpose of the User uide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

How the uide Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using the Carousel Plus W Series as a Central Dryer. . . . . . . . . . . . . . . . . . . 1-2

Your Responsibility as a User. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ATTENTION: Read this so no one gets hurt . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

How to Use the Lockout Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1 D e s c r i p t i o n

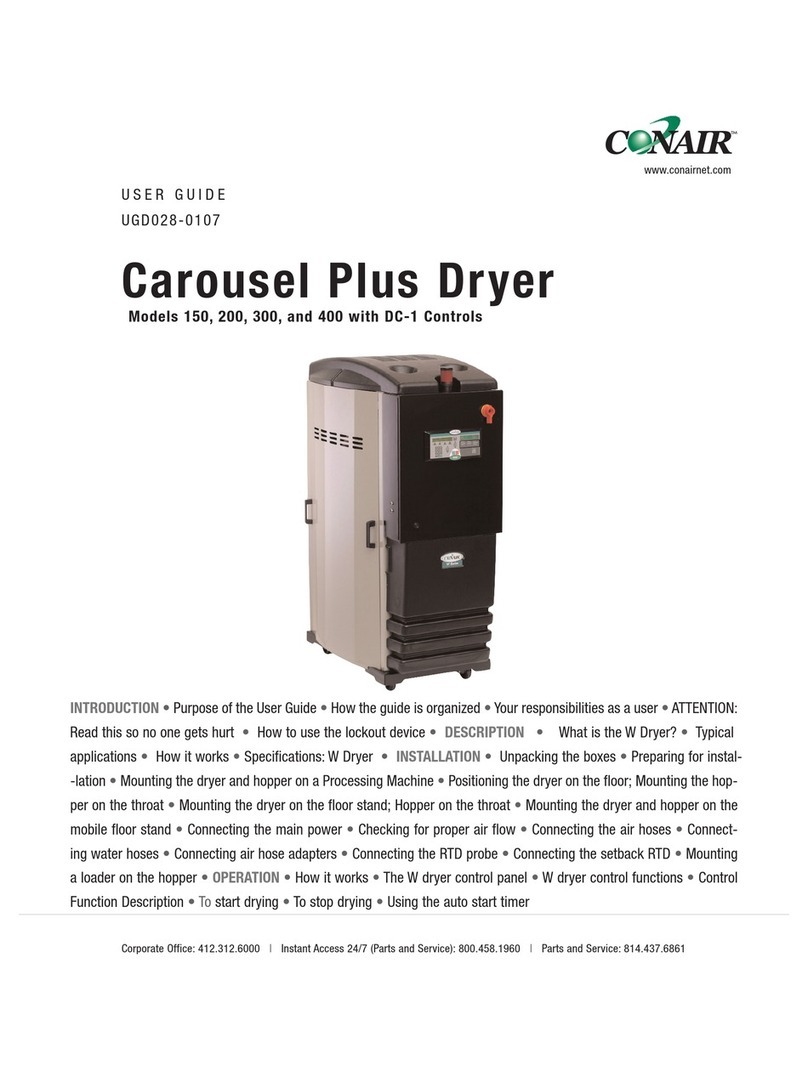

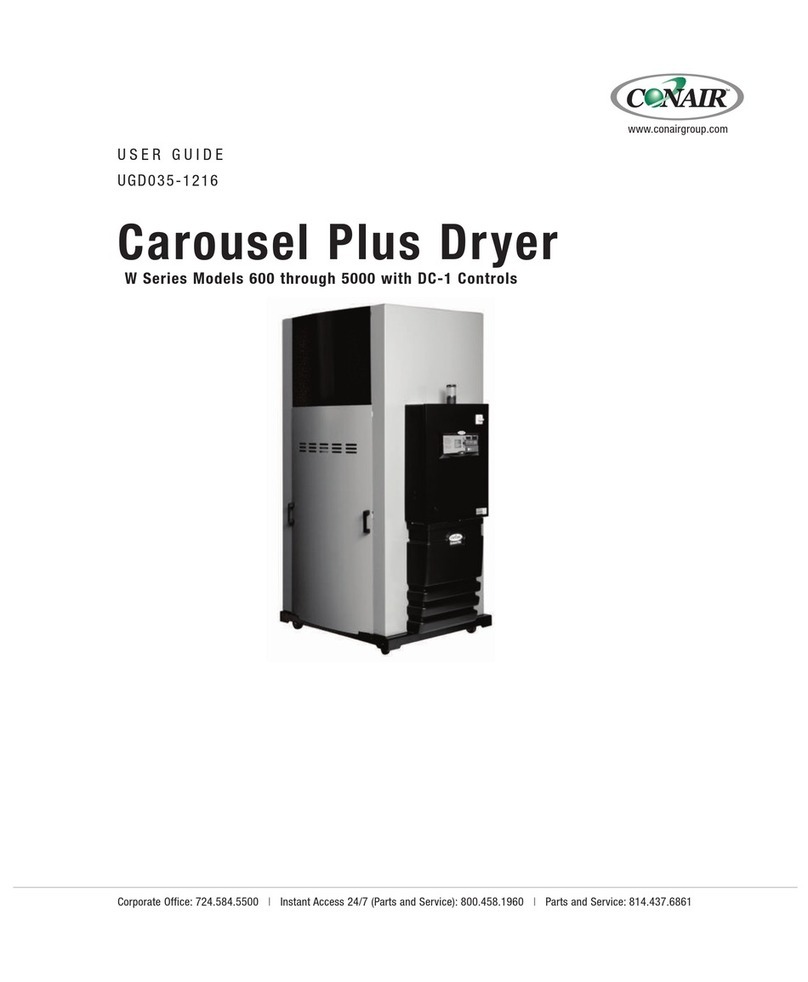

What is the Carousel Plus W Series Dryer?. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

How the Carousel Plus W Series Dryer Works. . . . . . . . . . . . . . . . . . . . . . . . 2-4

Specifications: Carousel Plus W Series Dryer . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Carousel Plus W Series Dryer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3-1 I n s t a l l a t i o n

Unpacking the Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Positioning the Dryer on the Floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing the Cable Tie from the Desiccant Wheel . . . . . . . . . . . . . . . . . . . . 3-3

Connecting the Main Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Connecting the RTD probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Connecting the Setback RTD Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Checking for Proper Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Connecting the Air Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting the Dryer to the Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting Air Hose Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Connecting the Aftercooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Mounting a Loader on the Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Using Communications (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4-1 O p e r a t i o n

The Dryer System control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

How to navigate the control screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

DC-T Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6