4

Use and storage of the

manual

This assembly manual makes the safe and

eicient installation and commissioning of

the RightViu Turn Assist system possible.

The itter must read through and

understand this manual before starting

work. A pre-requisite for safe work is

compliance with all safety information and

instructions provided in this manual. In

addition, the local occupational protection

regulations and general safety regulations

for the speciic work area apply.

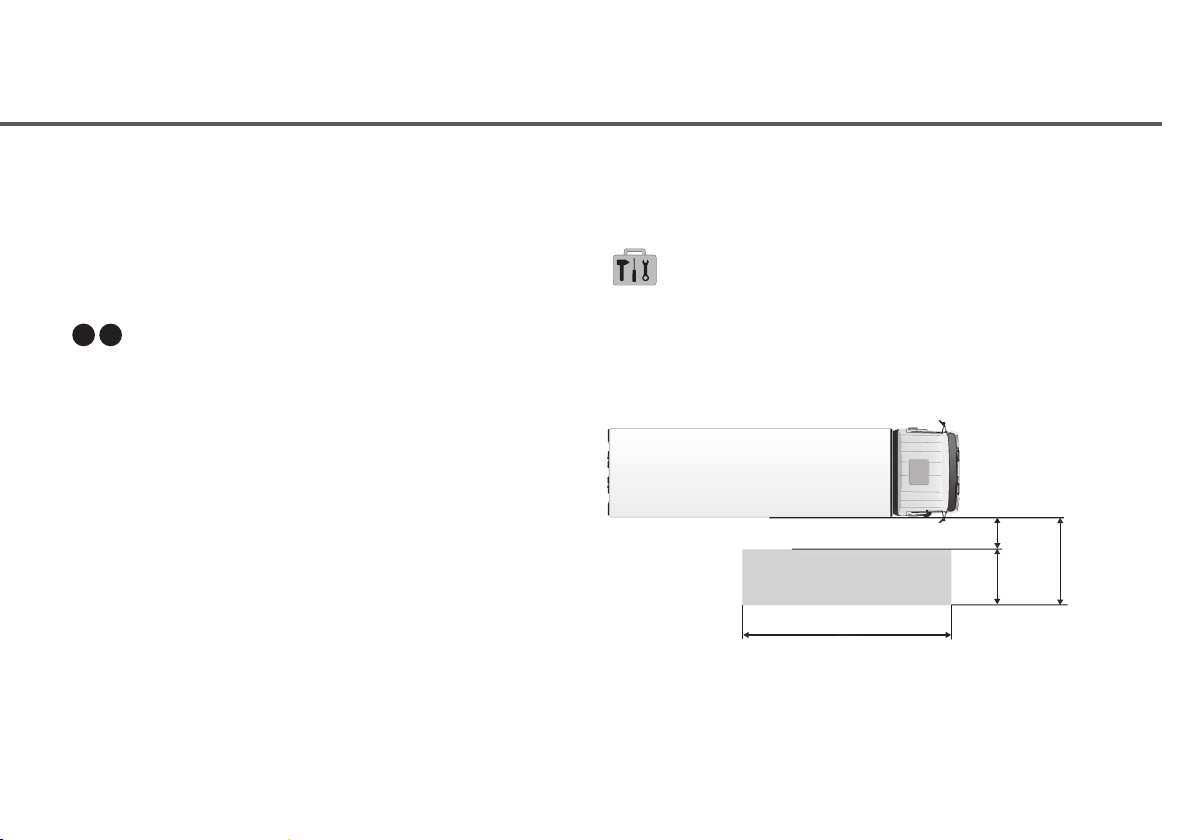

Images in this manual are for general

understanding and may deviate from the

actual version used. The operating manual

makes the safe and eicient use of the

RightViu Turn Assist system possible. The

operating manual is part of the product. The

driver must be provided with the operating

manual after commissioning. The operating

manual must be stored in the direct vicinity

of RightViu and must be accessible to the

driver at all times. The driver must read

through this manual and have familiarised

himself with the system.before driving with

it for the irst time. A pre-requisite for safe

application is compliance with all the safety

information and instructions provided in the

operating manual.

Limitation of liability

Continental shall not be liable for the

improper installation or use of the Turn

Assist system or for malfunctions caused by

the purchaser's other systems.

In particular, Continental shall not be liable

for assembly or connection errors and for

damage caused by mechanical inluences

or overvoltage. If not otherwise agreed,

in particular in individual contractual

agreements, the following applies to

Continental’s liability:

Continental shall be liable for claims for

damages – for any legal reason – under

fault-based liability for intentional actions

and gross negligence.

In case of simple negligence, Continental

INFORMATION ON THIS MANUAL