Chapter 1: Introduction

Overview

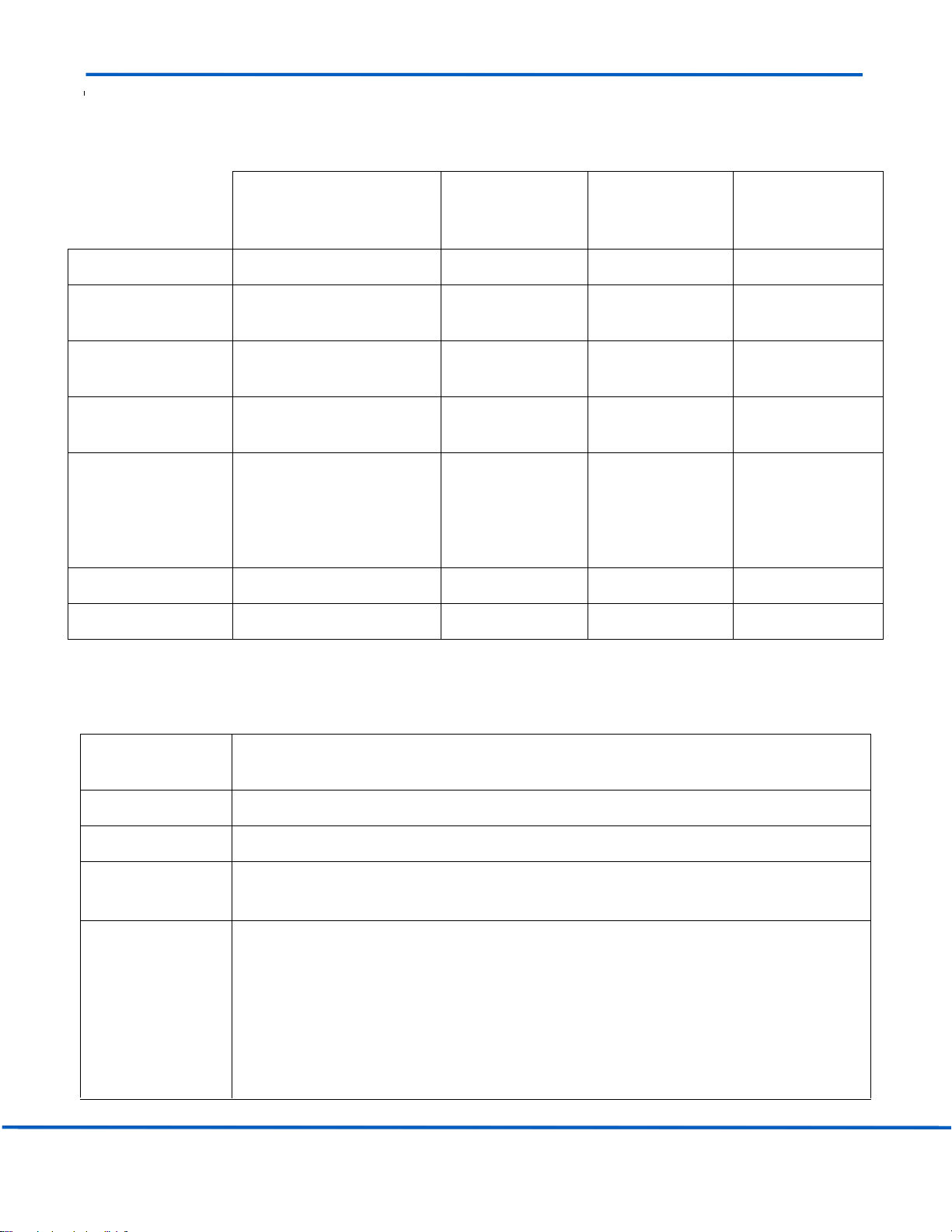

This chapter briefly describes the GX-Force portable gas monitor. This chapter also describes the GX-

Force Operator’s Manual (this document). Table 1 at the end of this chapter lists the specifications for

the GX-Force.

About the GX-Force

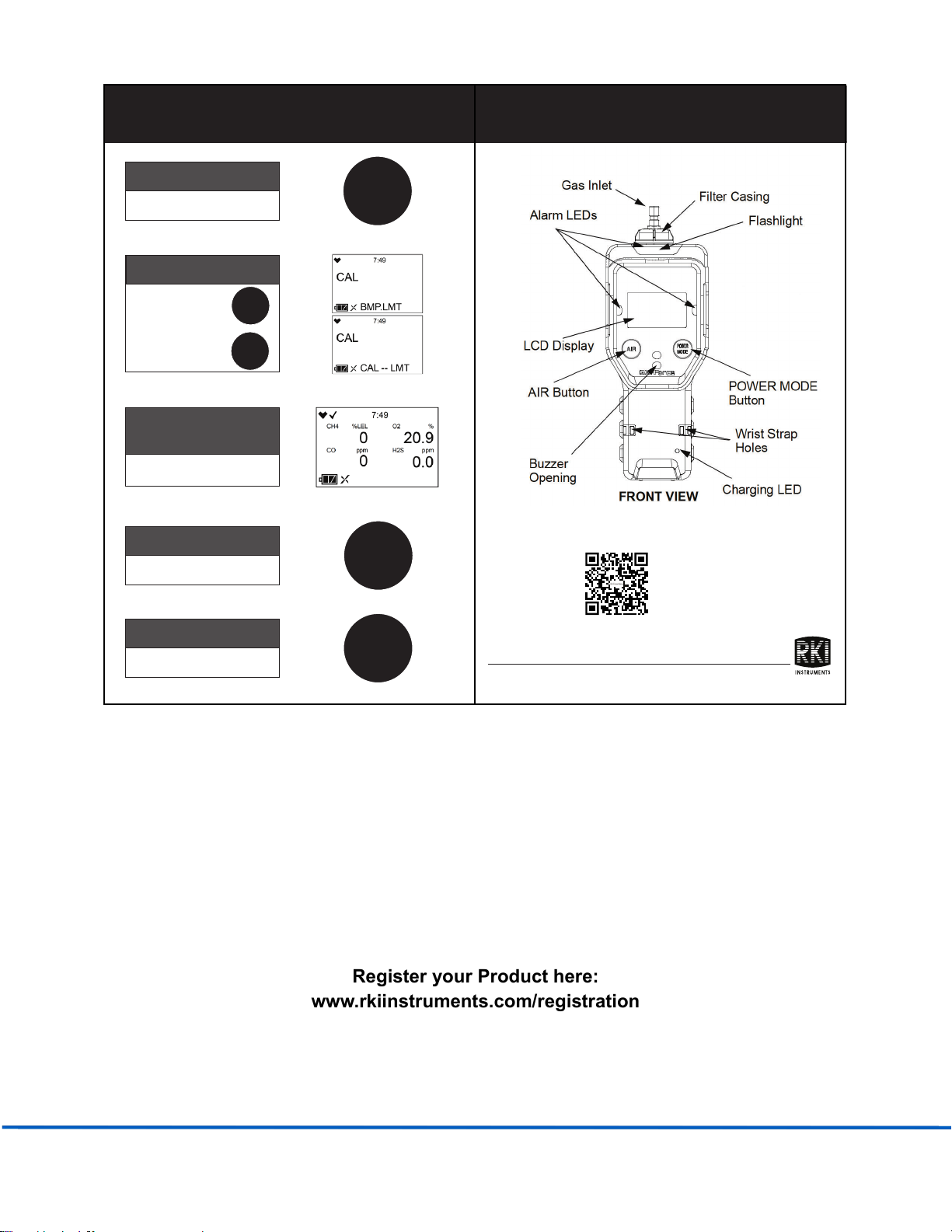

Using an advanced detection system consisting of up to three gas sensors, the GX-Force personal

four-gas monitor detects the presence of combustible gas, oxygen (O2), carbon monoxide (CO), and

hydrogen sulfide (H2S) simultaneously. The GX-Force’s compact size and easy-to-use design make it

ideally suited for a wide range of applications, including sewage treatment plants, utility manholes,

tunnels, hazardous waste sites, power stations, petrochemical refineries, mines, paper mills, drilling

rigs, and fire fighting stations. The GX-Force offers a full range of features, including:

•Simultaneous monitoring of one to four gases

•Liquid crystal display (LCD) for complete and understandable information at a glance

•Ultrabright alarm LEDs

•Distinctive audible/vibrating alarms for dangerous gas conditions and audible alarms for unit

malfunction

•Microprocessor control for reliability, ease of use, and advanced capabilities

•Data logging functions

•Alarm trend data

•STEL, TWA, and over range alarms

•Peak readings

•Built-in time function

•Lunch break feature

•CSA “C/US” classified as intrinsically safe (pending, see page 11)

WARNING: The Model GX-Force detects oxygen deficiency, elevated levels of oxygen,

combustible gases, carbon monoxide, and hydrogen sulfide, all of which can be

dangerous or life threatening. When using the GX-Force, you must follow the

instructions and warnings in this manual to assure proper and safe operation of the

unit and to minimize the risk of personal injury. Be sure to maintain and periodically

calibrate the GX-Force as described in this manual.

CONTROL EQUIPMENT Pty Ltd

www.controlequipment.com.au